Used ELS TECHNOLOGY ELS 106SA #9161431 for sale

URL successfully copied!

Tap to zoom

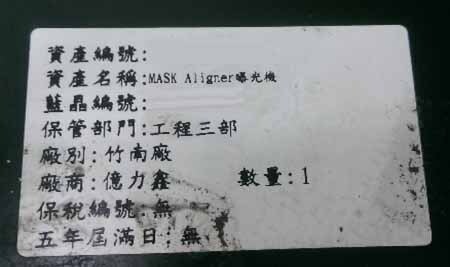

ID: 9161431

Wafer Size: 2"-4"

Mask aligner, 2"-4"

Sapphire wafers

Mask holder:

Mask size: 1.4 inch × 4 inch : 101.2mm × 101.2mm

Thickness: 1.6mm ± 0.2mm

Mask size: 2.5 inch × 5 inch : 126.6mm × 126.6mm

Thickness: 2.3mm ± 0.2mm

Method:

Pre-alignment: Stopper pin

Mask fixture: By vacuum

Substrate size: Φ2 inch sapphire wafer

Diameter: 50.8mm ± 0.2mm.

Thickness: 430um ± 25um

Substrate size: Φ2.5 inch sapphire wafer

Diameter: 61.75mm ± 0.2mm

Thickness: 430um ± 25um

Substrate size: Φ4 inch sapphire wafer

Diameter: 100mm ± 0.5mm

Thickness: 500um ~ 1000um ± 25um

Material: Aluminum

Method:

Loading / Unloading: By manual

Pre-alignment: Stopper pin

Substrate fixture: By vacuum

Stroke:

Item Driver Range Resolution

X axis Manual ±5mm 1um

Y axis Manual ±5mm 1um

Z axis AC Servo motor 0~1000um 1um

θ axis Manual ±5° 0.0001°

Parallelism compensation: Uniball mechanism

Contact pressure: 0~0.17N/ cm2

Alignment accuracy: ±1um

Lamp house:

Lamp: 500W Hg Arc lamp

Lamp is easy replace

Exposure area: 150mm × 150mm

Main wavelength:

Item Wavelength Light intensity Uniformity

i line 365nm >28mW/cm2 Within ±3%

h line 405nm >40mW/cm2 Within ±3%

g line 436nm >40mW/cm2 Within ±3%

Exposure function, 4"

Print resolution:

Item Wavelength Printing resolution Adjustment

Software contact 365nm 2um

Hard contact 365nm 1um

Vacuum contact 365nm 0.8um

Proximity 365nm >3um 0~1000um

Resist: AZ-5214E

Thickness: 1um

Utility:

Voltage: 3ψ4W 220VAC 50/60 Hz, 5KVA

Dry air: 6Kg/cm2 , 200L/min, Φ10mm

N2: 6Kg/cm2, 100L/min, Φ10mm

Vacuum: -1~0.8Kg/cm2, 200L/min, Φ10mm

Outline:

Substrate size: Φ2 inch sapphire wafer

Diameter: 50.8mm ± 0.2mm

Thickness: 430um ± 25um

Substrate size: Φ2.5 inch sapphire wafer

Diameter: 61.75mm ± 0.2mm

Thickness: 430um ± 25um

Substrate size: Φ4 inch sapphire wafer

Diameter: 100mm ± 0.5mm

Thickness: 500um ~ 1000um ± 25um

Mask size: 1. 4 inch × 4 inch : 101.2mm × 101.2mm

Thickness: 1.6mm ± 0.2mm

Mask size: 2.5 inch × 5 inch : 126.6mm × 126.6mm

Thickness: 2.3mm ± 0.2mm

Application:

ULD Stage

Leveling unit

Mask holder

Alignment unit

Exposure

Alignment accuracy and auto leveling: ±1um

AC Servo motor with pressure sensor for Z axis driving

Alignment with CCD modules

Easy to operate

2008-2010 vintages.

ELS TECHNOLOGY ELS 106SA is a state-of-the-art Mask Aligner designed with highly advanced and technology driven features for fabricating standard size semiconductor wafers. The equipment is powered by a custom designed, temperature controlled, programmable electronics source to ensure precise alignment of the mask onto the wafer. It also incorporates a multi-station pre-alignment feature to ensure fast, accurate and cost-effective alignment of mask and wafer. ELS 106SA mask aligner offers superior mask alignment accuracy with an accuracy rate of +/- 1.5 microns and a maximum positional resolution of 0.1 microns. Its high-resolution XY-stage offers smooth, stepper motor driven motion control with a separately adjustable speed and acceleration. This feature allows the user to accurately position and precisely align the wafer with the mask. Additionally, ELS TECHNOLOGY ELS 106SA is equipped with a precision optics system that guarantees a superior alignment of large or small masks. ELS 106SA mask aligner comes with a reliable, user-friendly and intuitive user interface to conveniently set up the unit and monitor the alignment results. The user can also access a real-time display of the machine parameters for efficient productivity and maximum control over the process. It includes a Windows based PC, monitor, and keyboard for easy access to the program's functions. ELS TECHNOLOGY ELS 106SA mask aligner is designed with a metrology tile for precise adjustment of the mask level position, and alignment operation verification. This serves to maintain the uniformity of mask alignment and helps in detecting any flaws in the alignment process. An integrated adjustment correction tool is also available to quickly adjust any positional errors in the asset's accuracy. ELS 106SA is equipped with an advanced Digital Image Correlation (DIC) alignment model, which uses a deformation-free imaging technique, to gives precise real-time feedback on the mask alignment process. This DIC equipment can be configured to measure the misalignment of aspherical features, while tracking the wafer warpage. The system also offers a powerful software platform that allows it to be remotely controlled and monitored. It also incorporates a wide range of external input/output interfaces and features a vacuum-plasma process-breaking robustness for highly stable operation. ELS TECHNOLOGY ELS 106SA mask aligner is a highly capable unit that is ideal for the fabrication of integrated semiconductor circuits. This machine is equipped with advanced features and technology that make it perfectly suited for the accurate alignment of large or small scale masks, and is also suitable for use in industrial environments.

There are no reviews yet