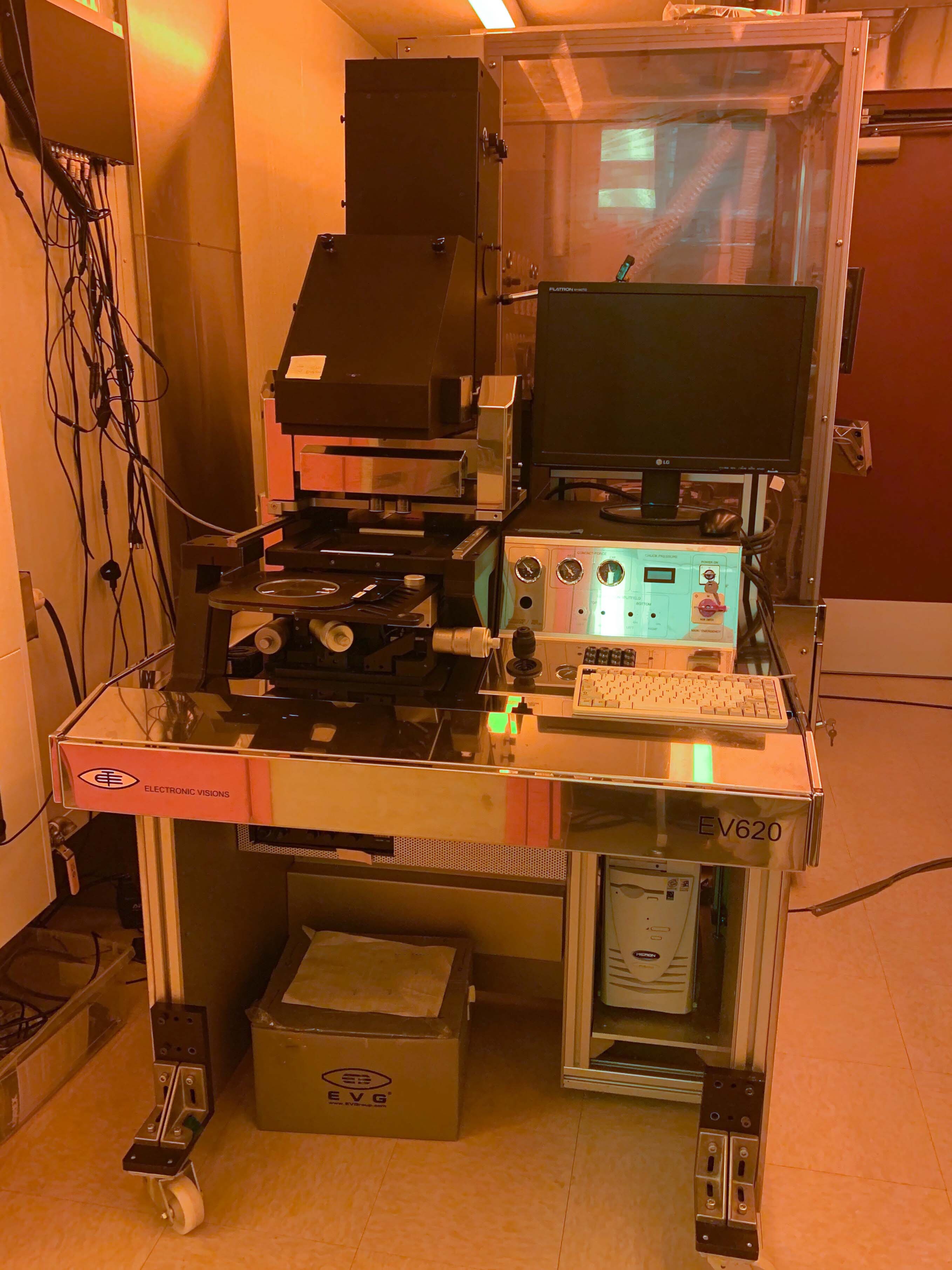

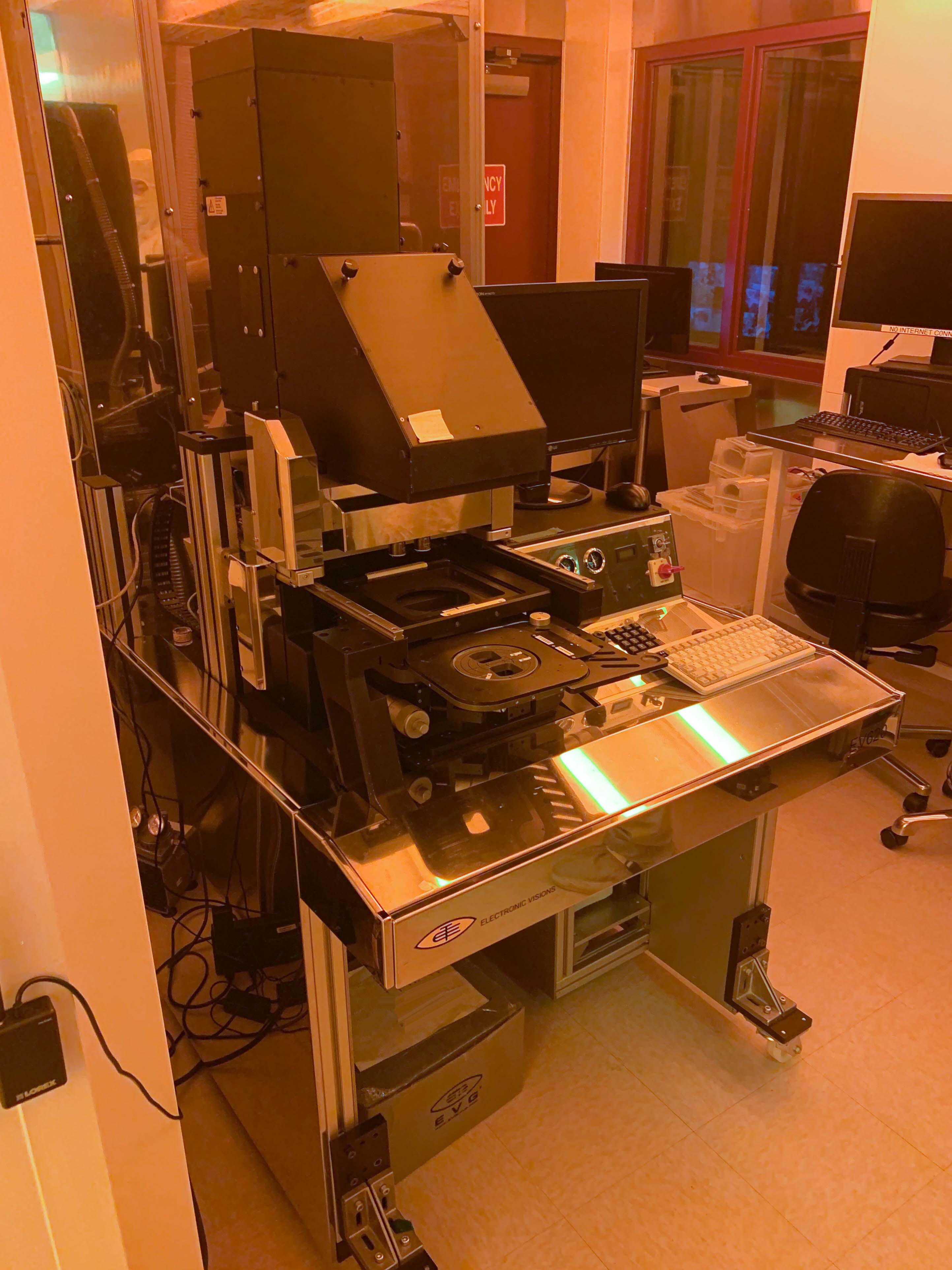

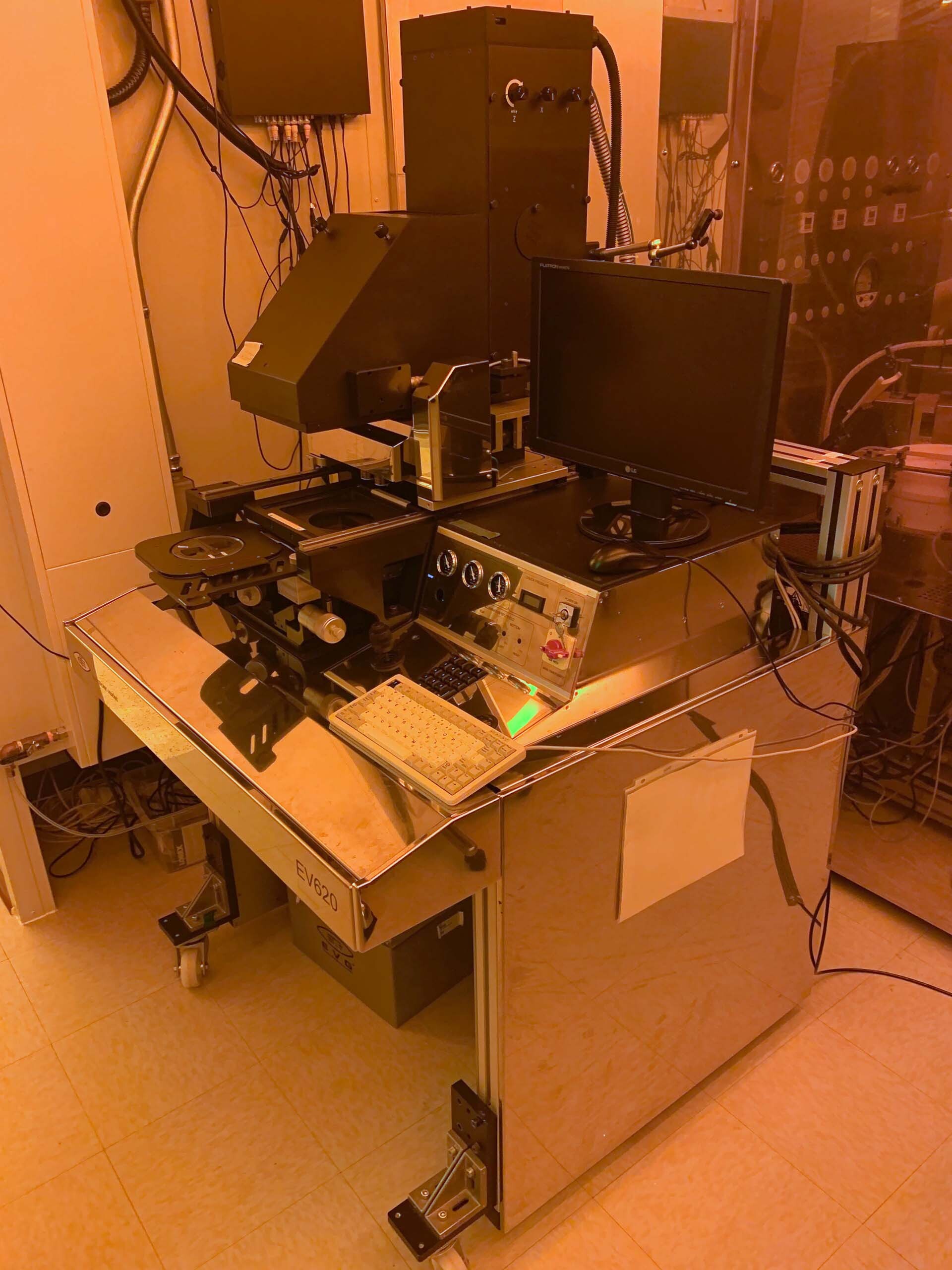

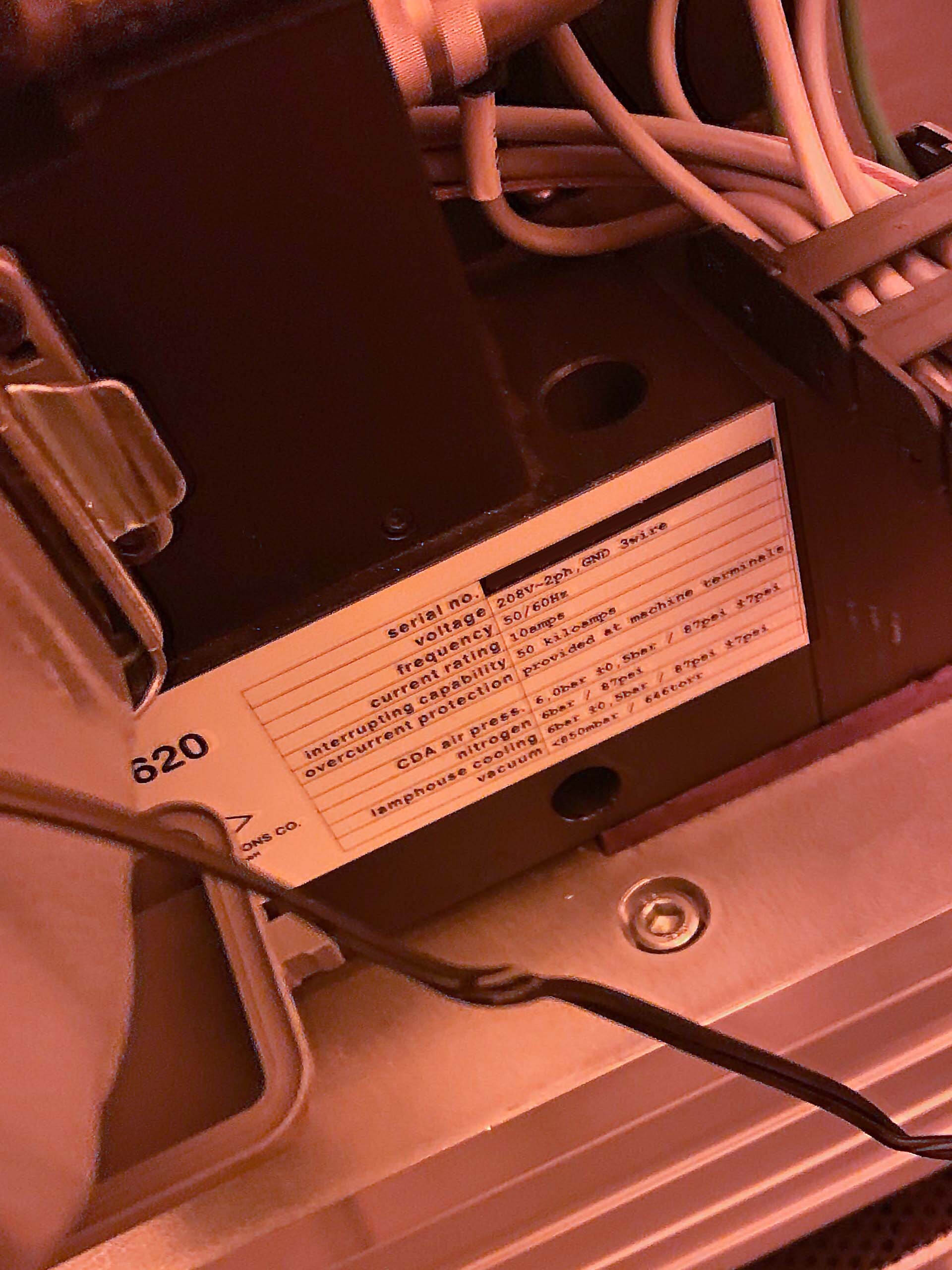

Used EVG / EV GROUP 620 #293591060 for sale

URL successfully copied!

Tap to zoom

ID: 293591060

Wafer Size: 2"-6"

Vintage: 2002

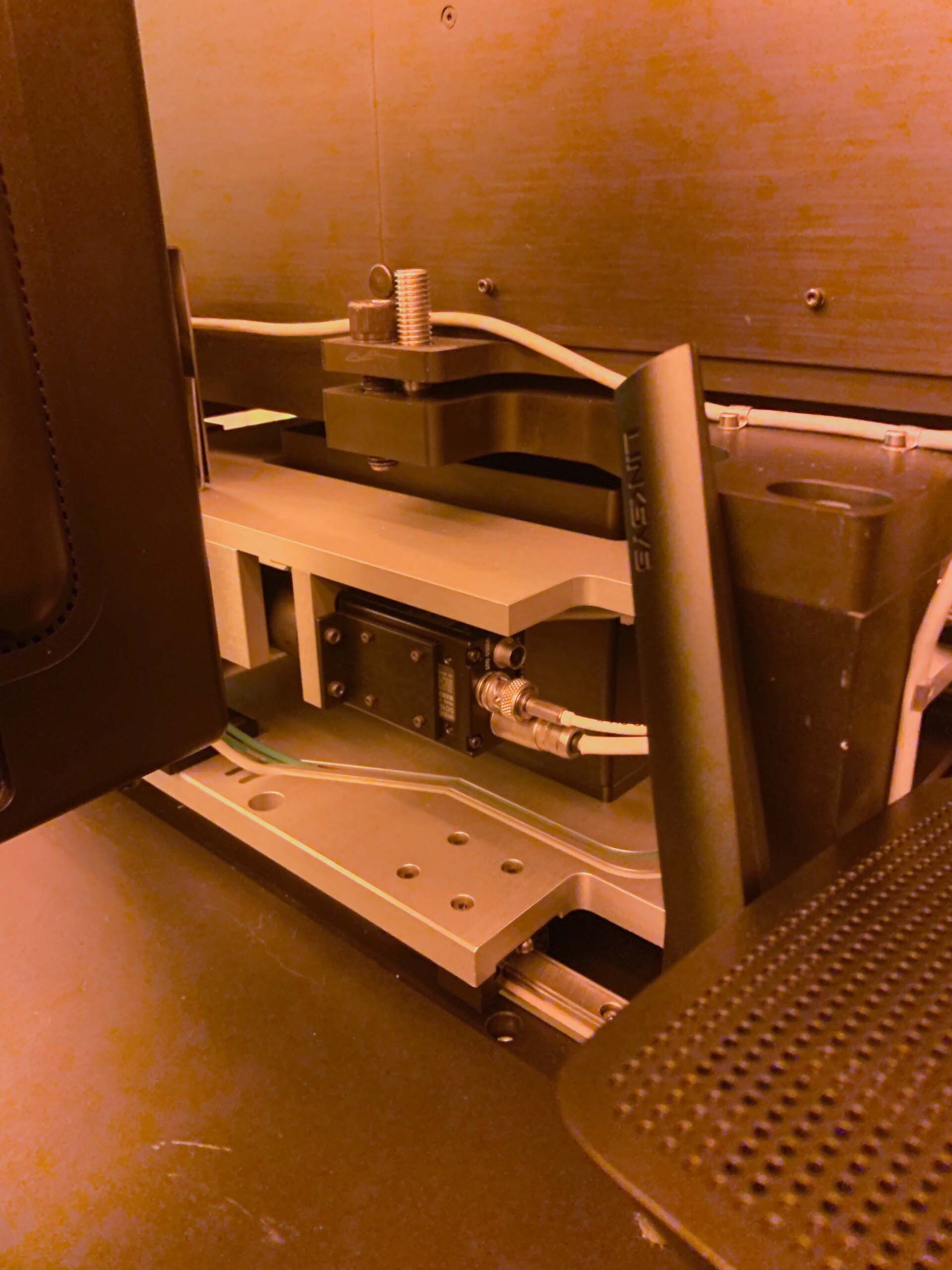

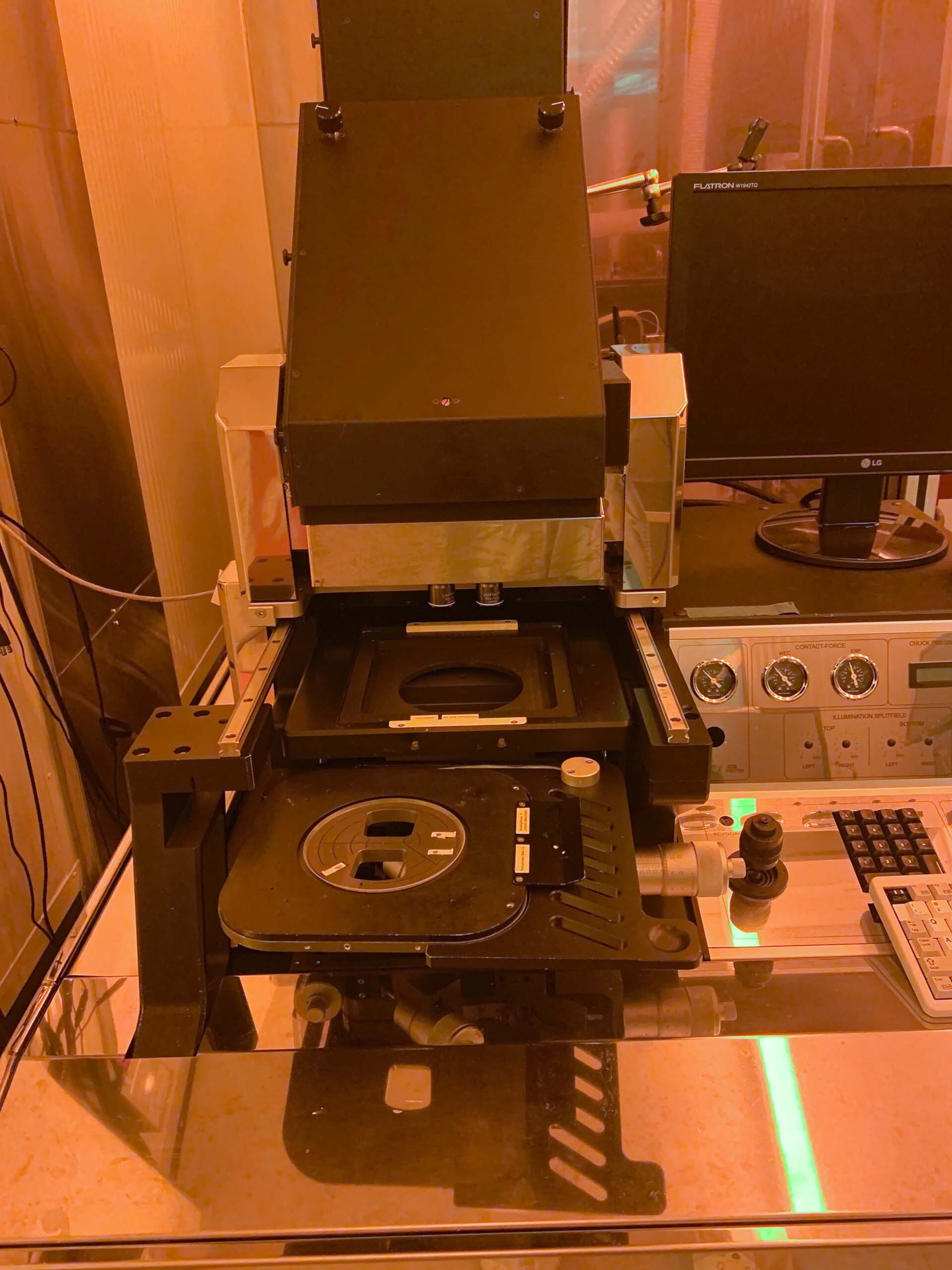

Mask aligner, 2"-6"

Wafer thickness: 4.6 mm

Masks: 3", 5" and 7"

Chuck, 2"

Resolution: 0.8 µm (Down)

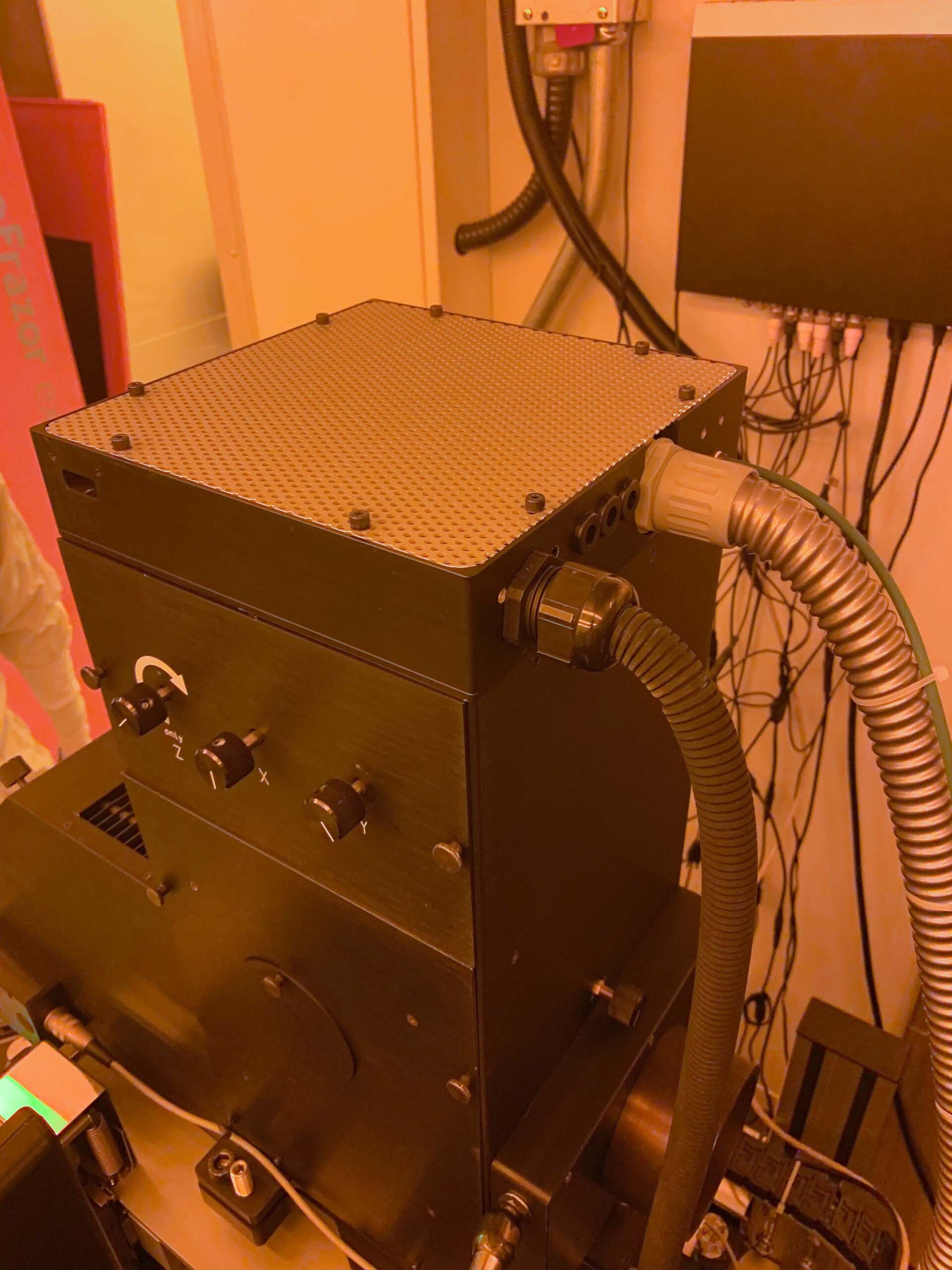

Topside alignment (TSA): 1 µm

Front and backside alignment

Objectives: 10x, 20x, 50x and flat objective (For pieces)

Bonding chucks for anodic bonding, thermal compression bonding and fusion bonding

Minimum resolution in dark field: 0.7 µm line and <1 µm contacts

Minimum resolution in clear field: 2 µm line and 2 µm contacts

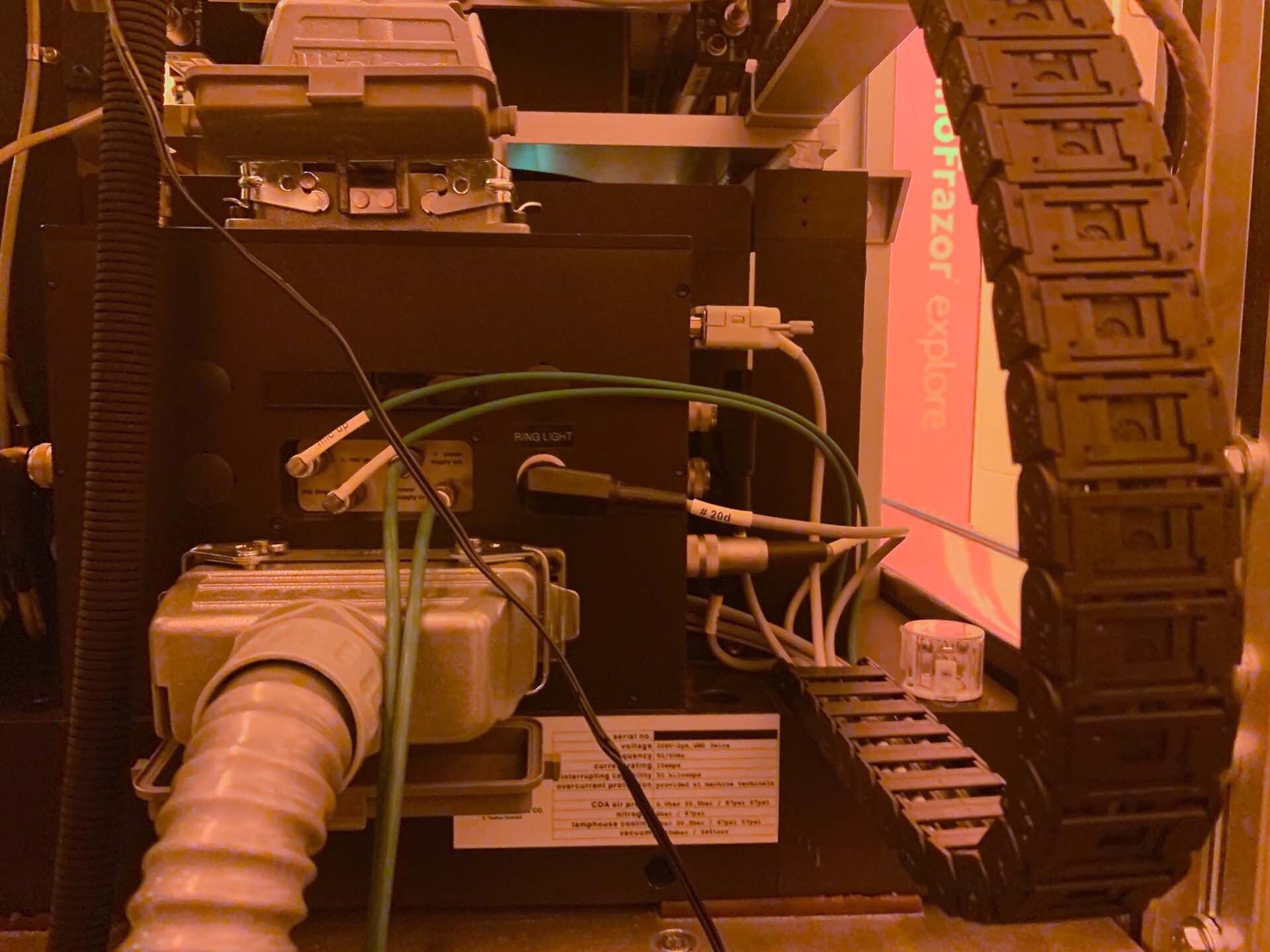

(5) Exposure modes:

Vacuum contact

Vacuum hard

Hard contact

Soft contact

Proximity

2002 vintage.

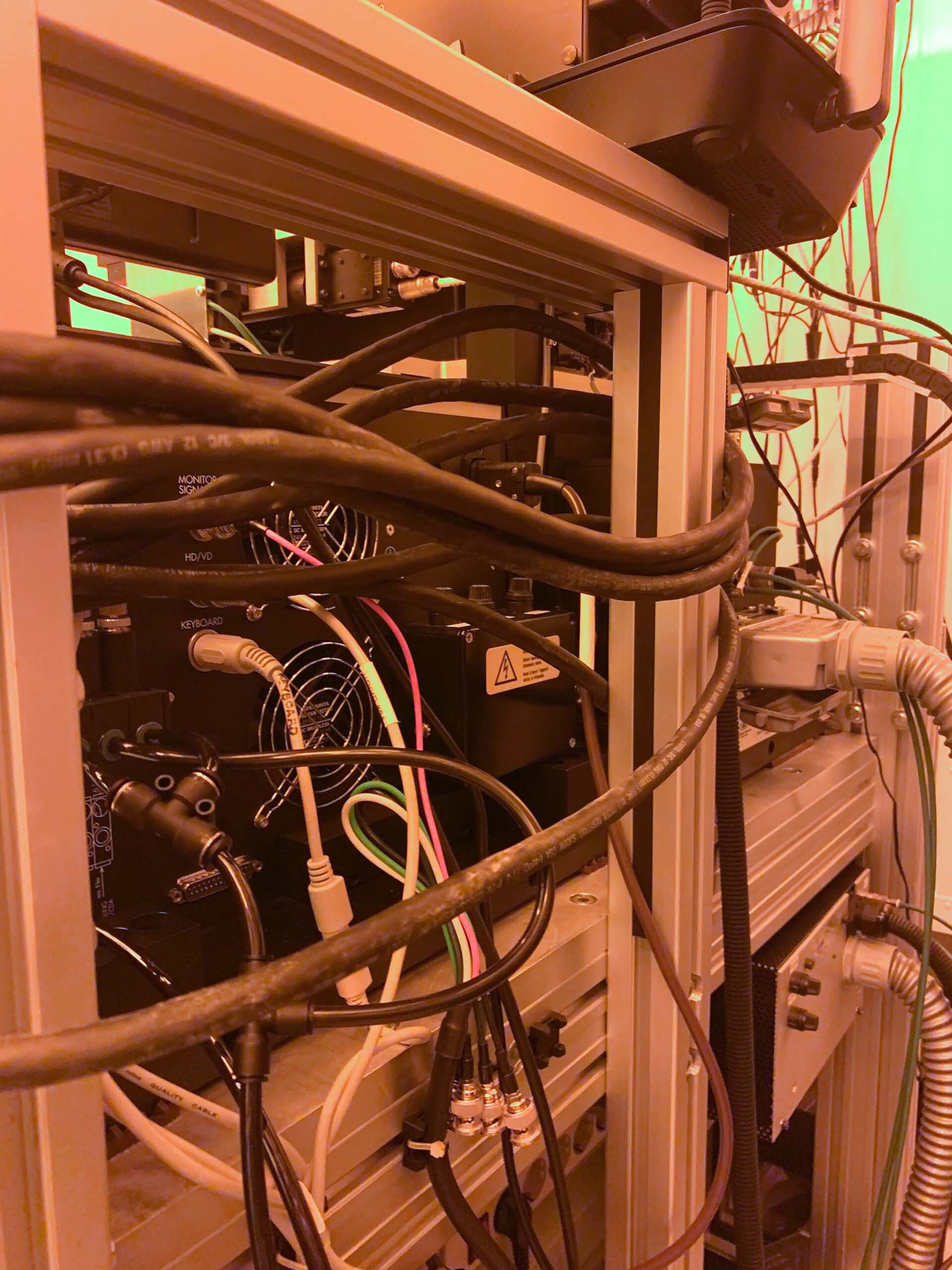

EVG / EV GROUP 620 is a state-of-the-art mask aligner designed to provide precision and accuracy in the area of photolithographic masking. It is suitable for a wide range of processing applications, such as wafer bonding, processing of MEMS and CMOS devices, and advanced integrated circuit fabrication. The aligner utilizes an advanced imaging system to provide accurate, repeatable alignment of the mask to the masking substrate. EVG 620 is designed with a positioning accuracy of <1 µm, an XY stage accuracy of 0.2 µm, and an XY stage repeatability of 0.1 µm. It utilizes a computer-controlled UV light source, which enables precise alignment of masks. The UV light source can be triggered manually or via a special scan program. In addition, it features a low vibration and isolated alignment platform to ensure optimal performance. EV GROUP 620 also features an integrated metrology system, which can be programmed to measure and track the substrate's tilt, twist, focus and height. This allows for the operator to adjust the masking parameters to optimize the process results. In addition, it has an integrated fourth generation lithographic module, which can process large-sized substrates with a maximum of 4000 x 4000 µm. 620 also offers a variety of processing options such as UV curable dry process (PDC) or spin coat for uniform processing results. It is also equipped with an advanced wafer heater, which can be calibrated for precise temperature control throughout the entire process. EVG / EV GROUP 620 also features a built-in gas box that can provide the controlled atmosphere necessary for special processing applications such as spin-on-glass (SOG). Lastly, EVG 620 offers a variety of control and compatibility options. It is compatible with a wide range of standard software windows, as well as host PC, and LabVIEW software. Additionally, EV GROUP 620 can be controlled remotely via a computer or host PC, as well as remotely with a virtual remote control. All of these features make 620 an ideal solution for advanced photolithographic masking applications.

There are no reviews yet