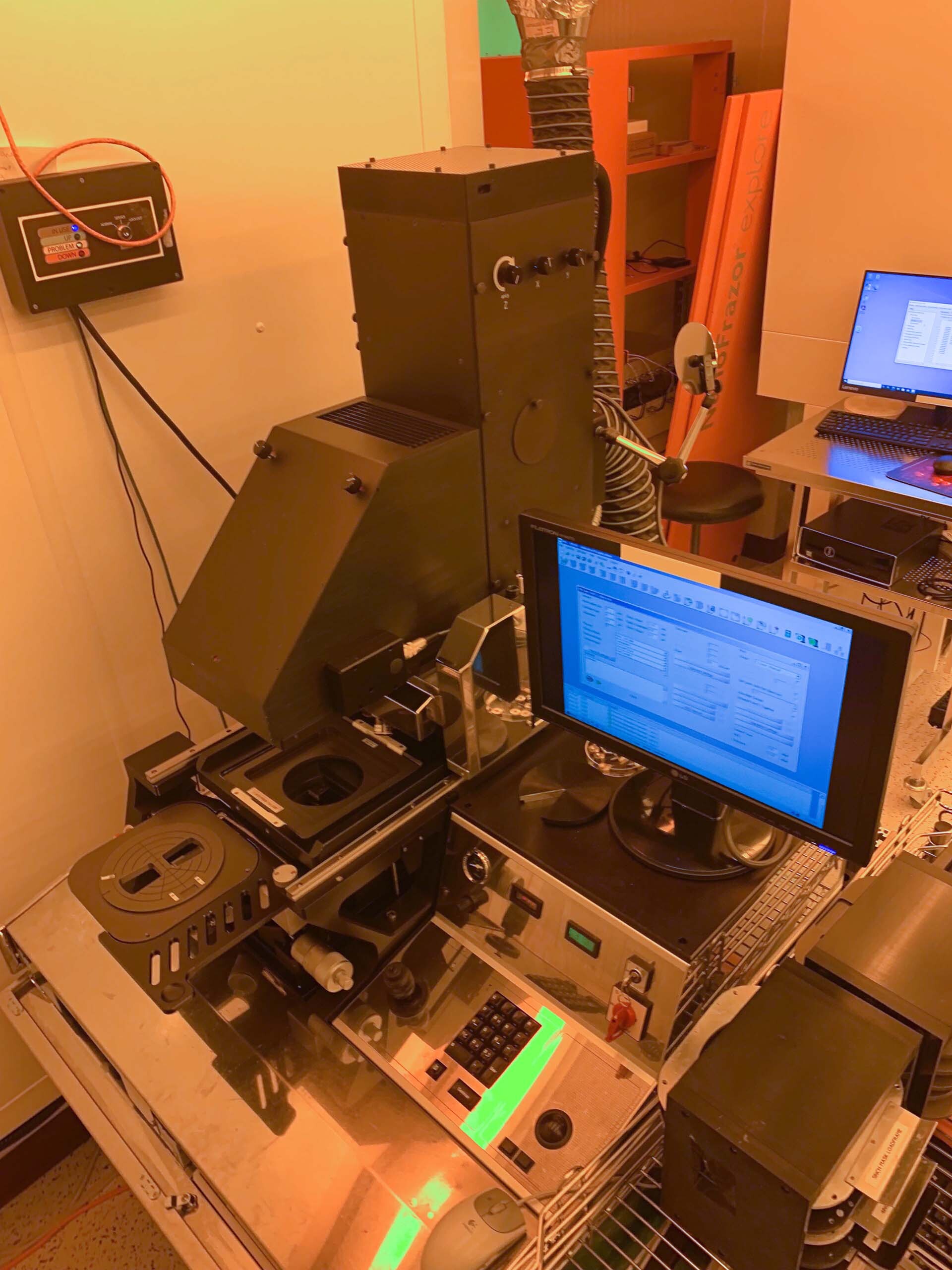

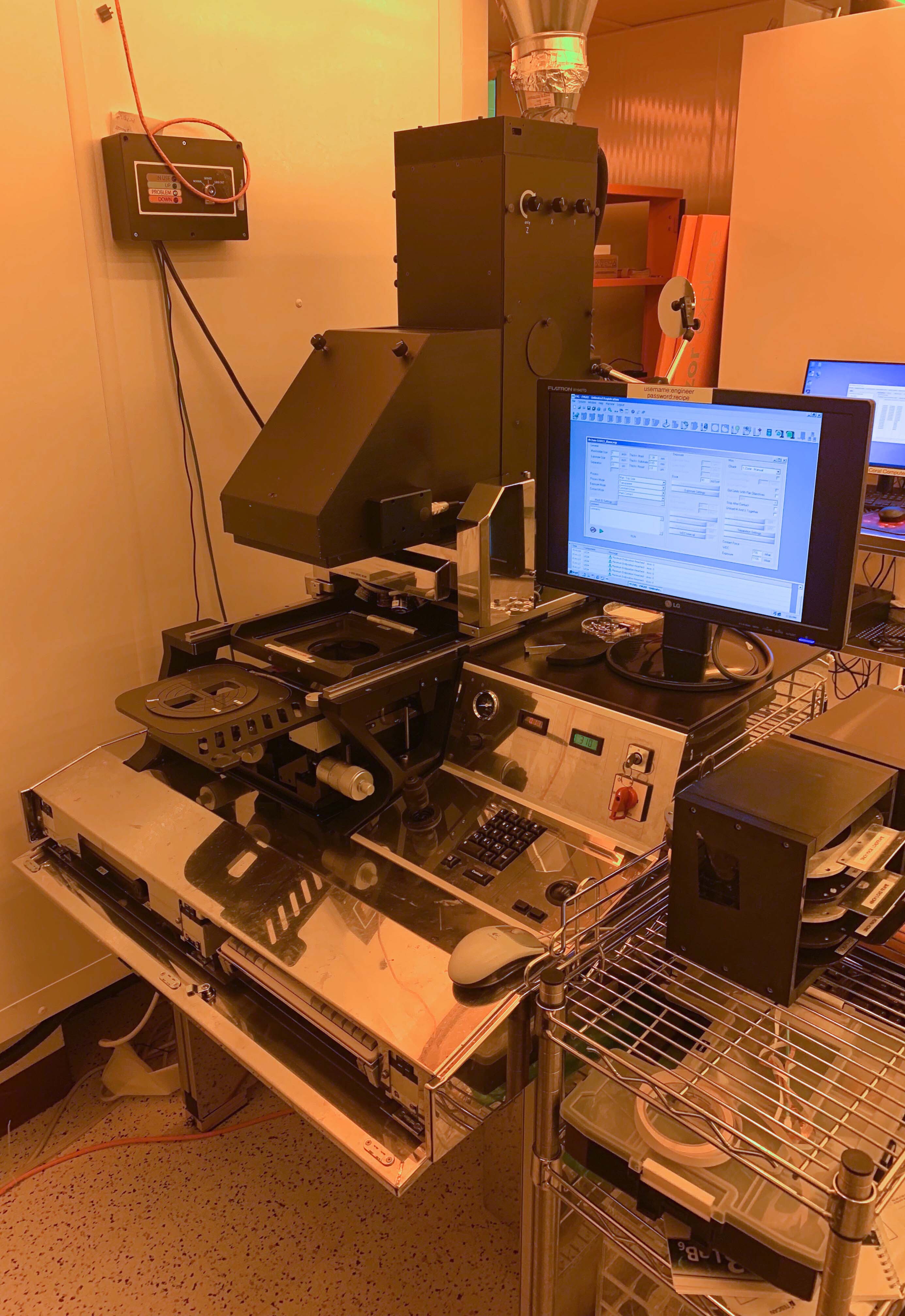

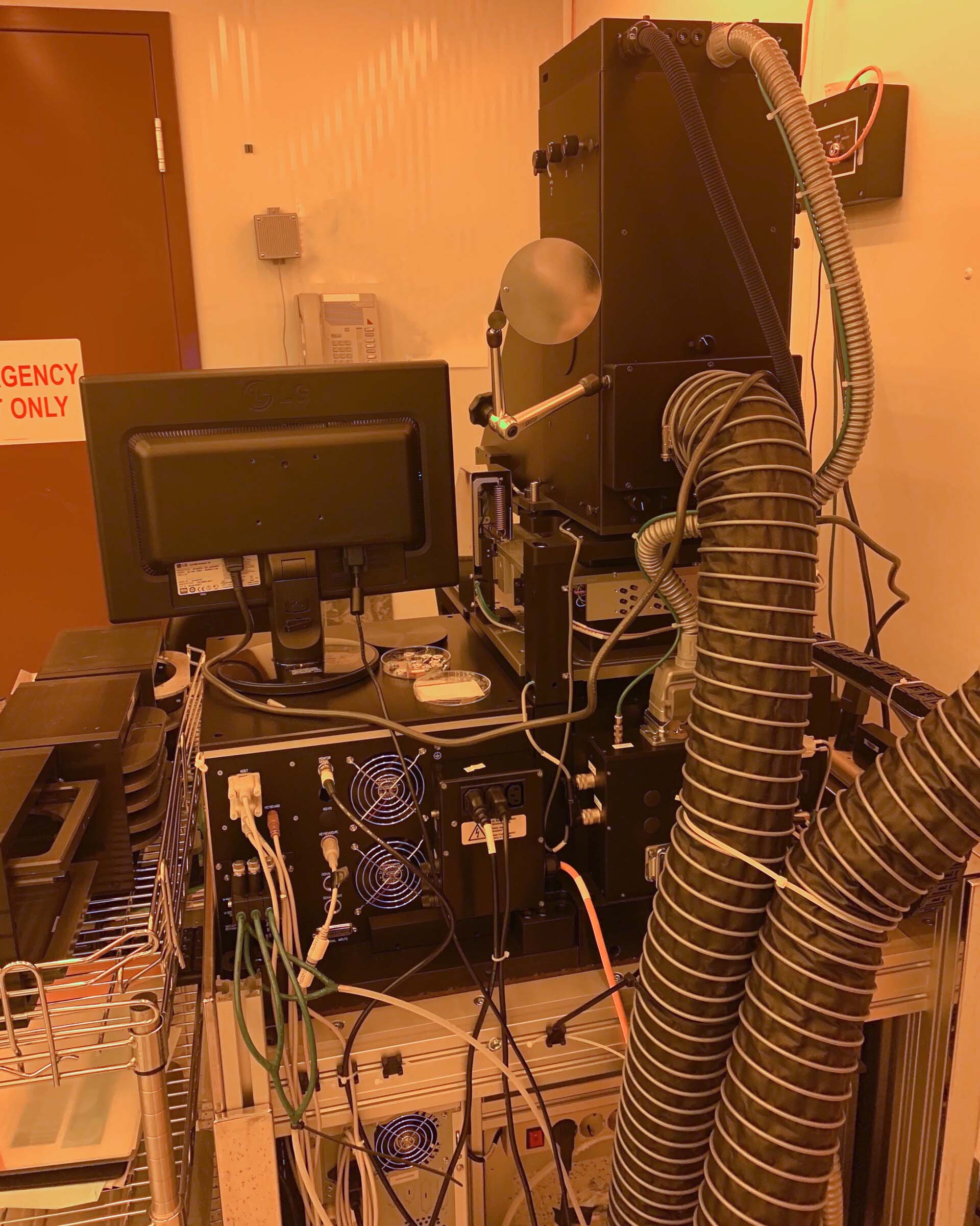

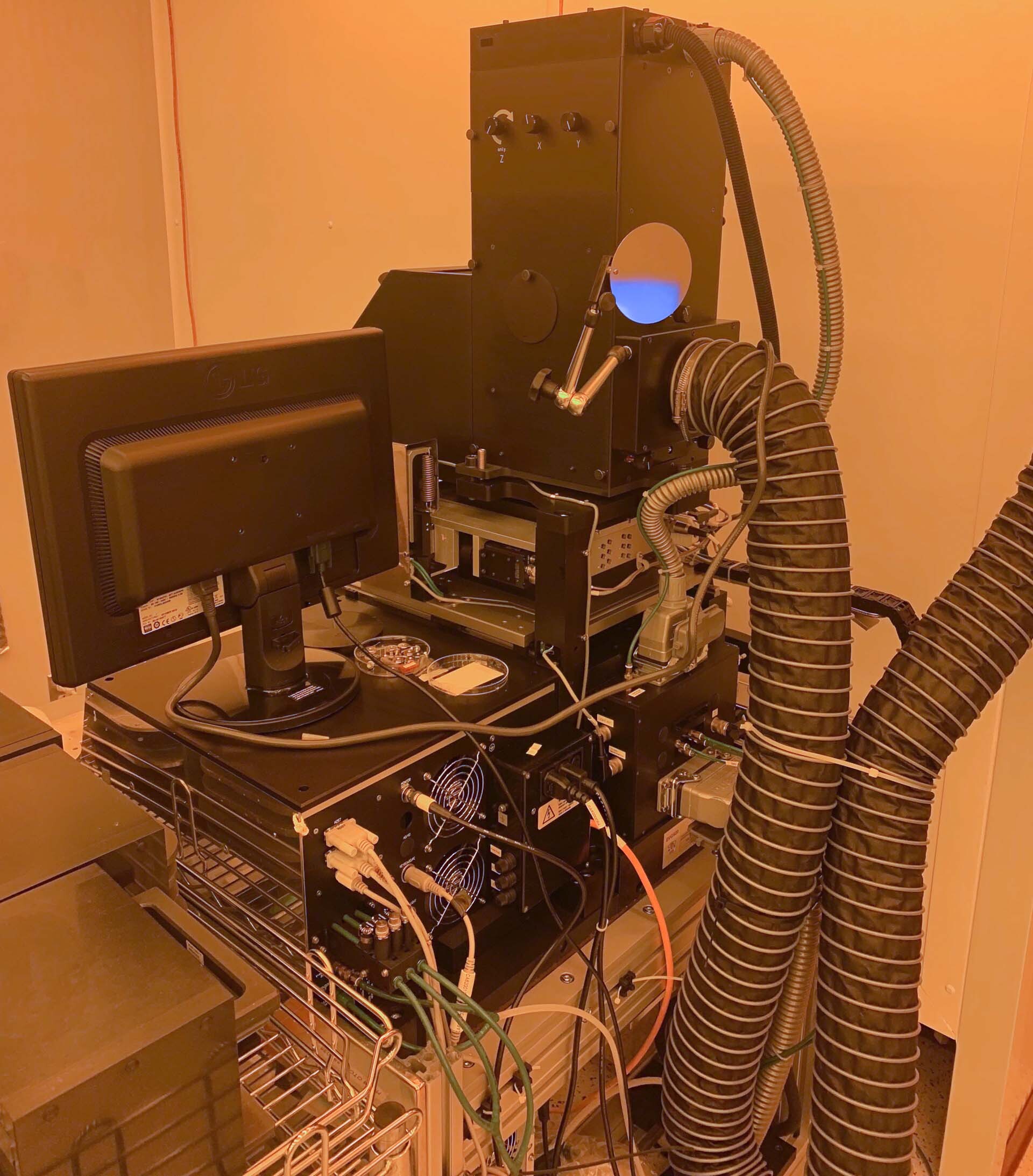

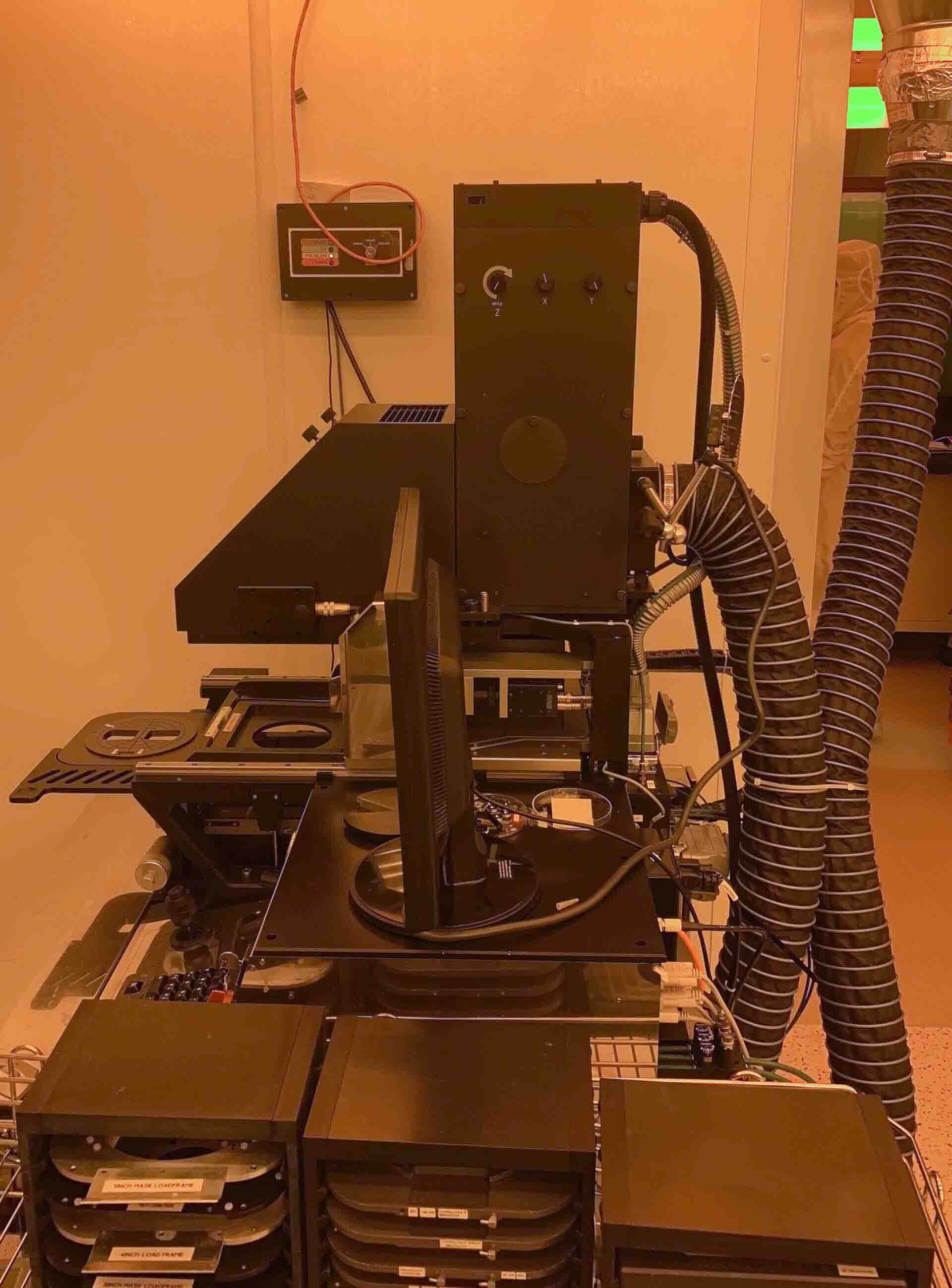

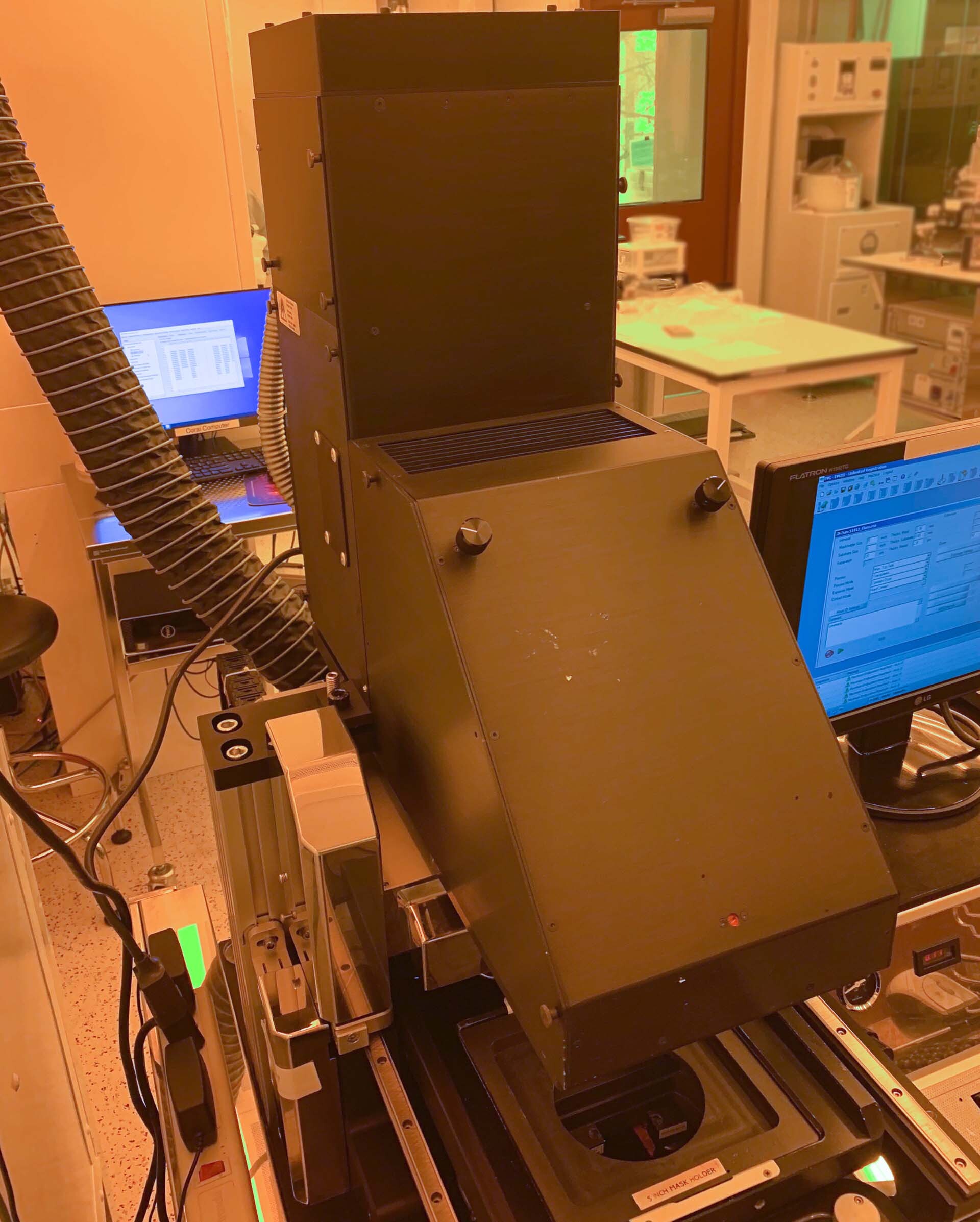

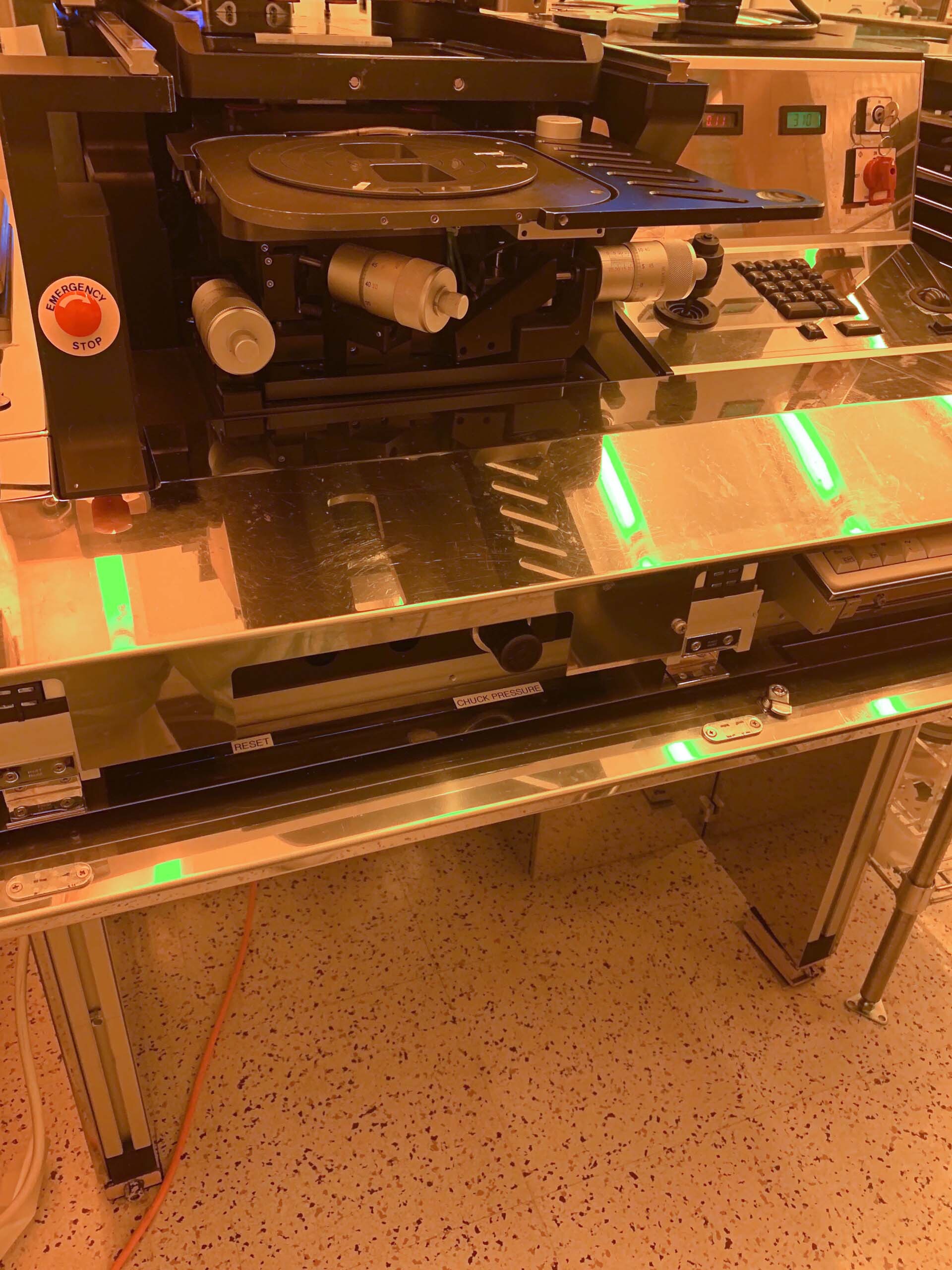

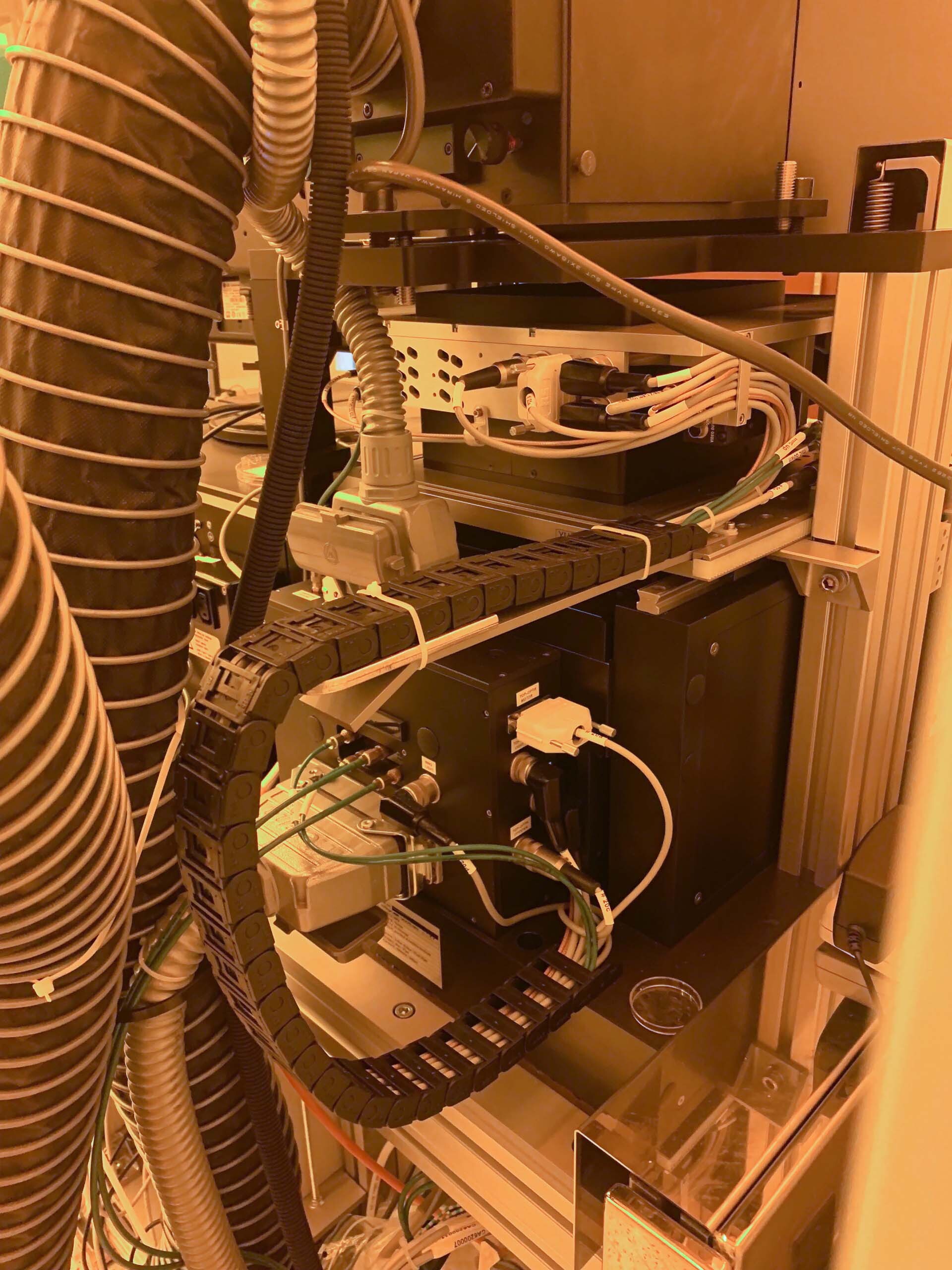

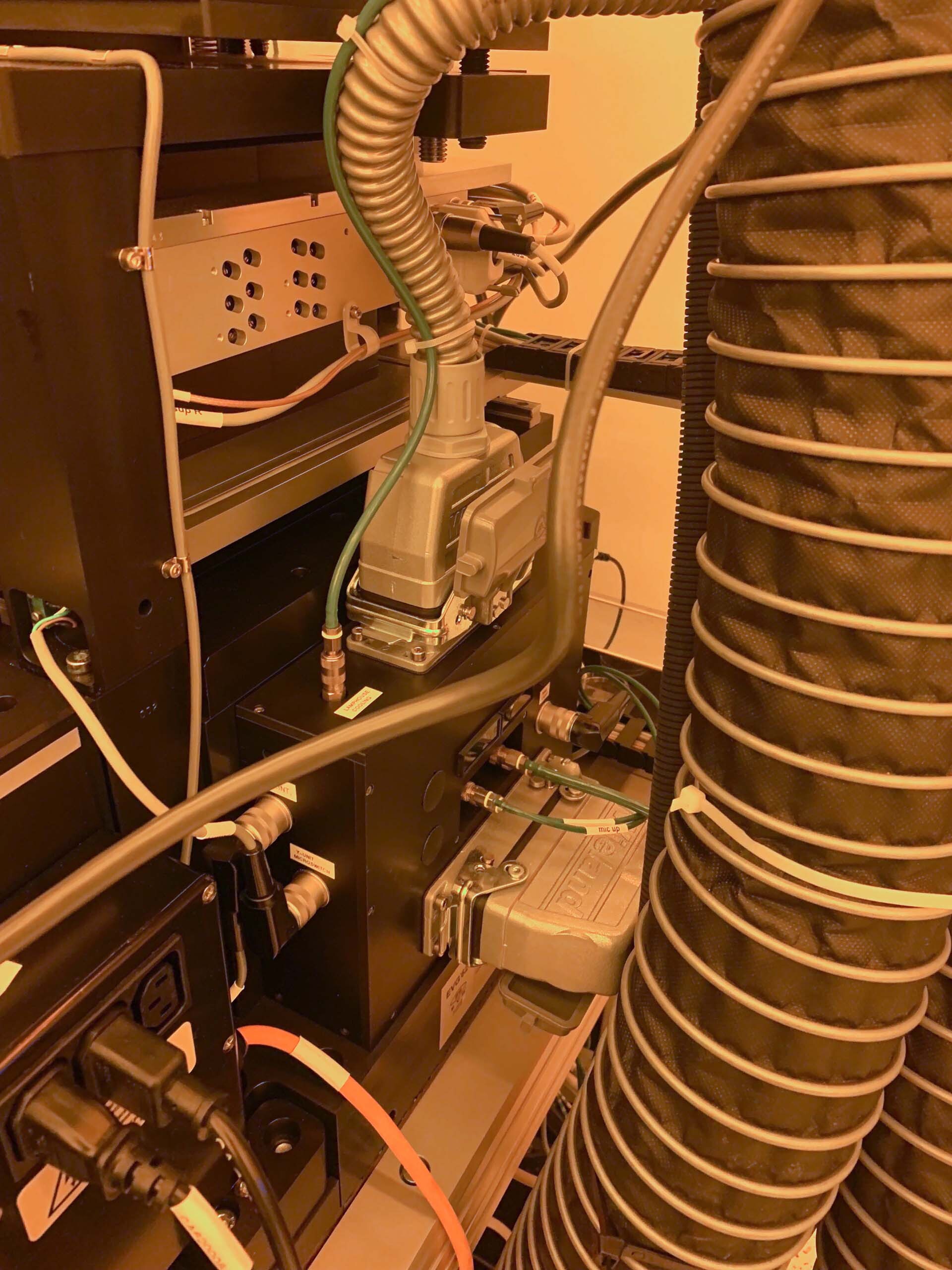

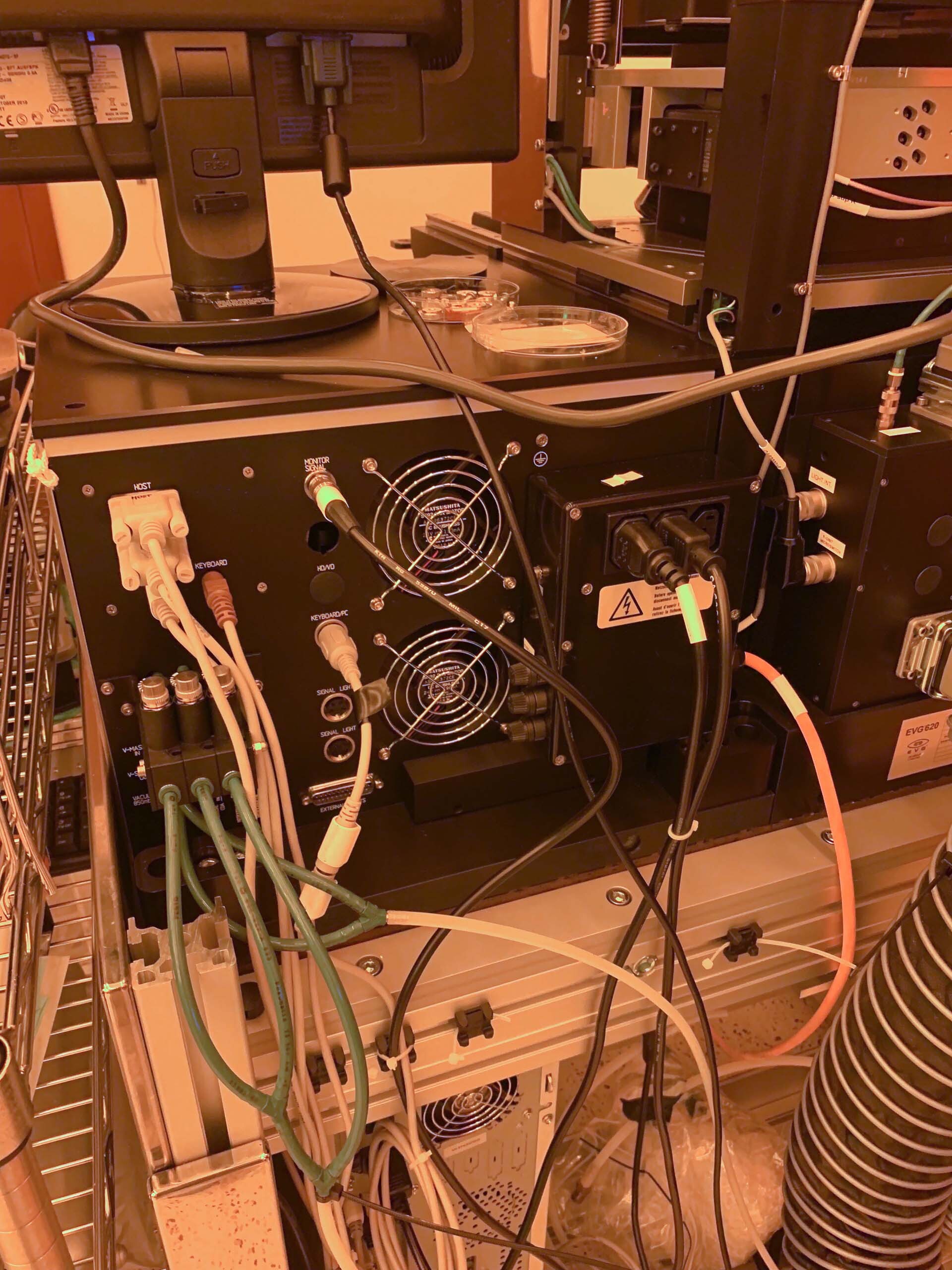

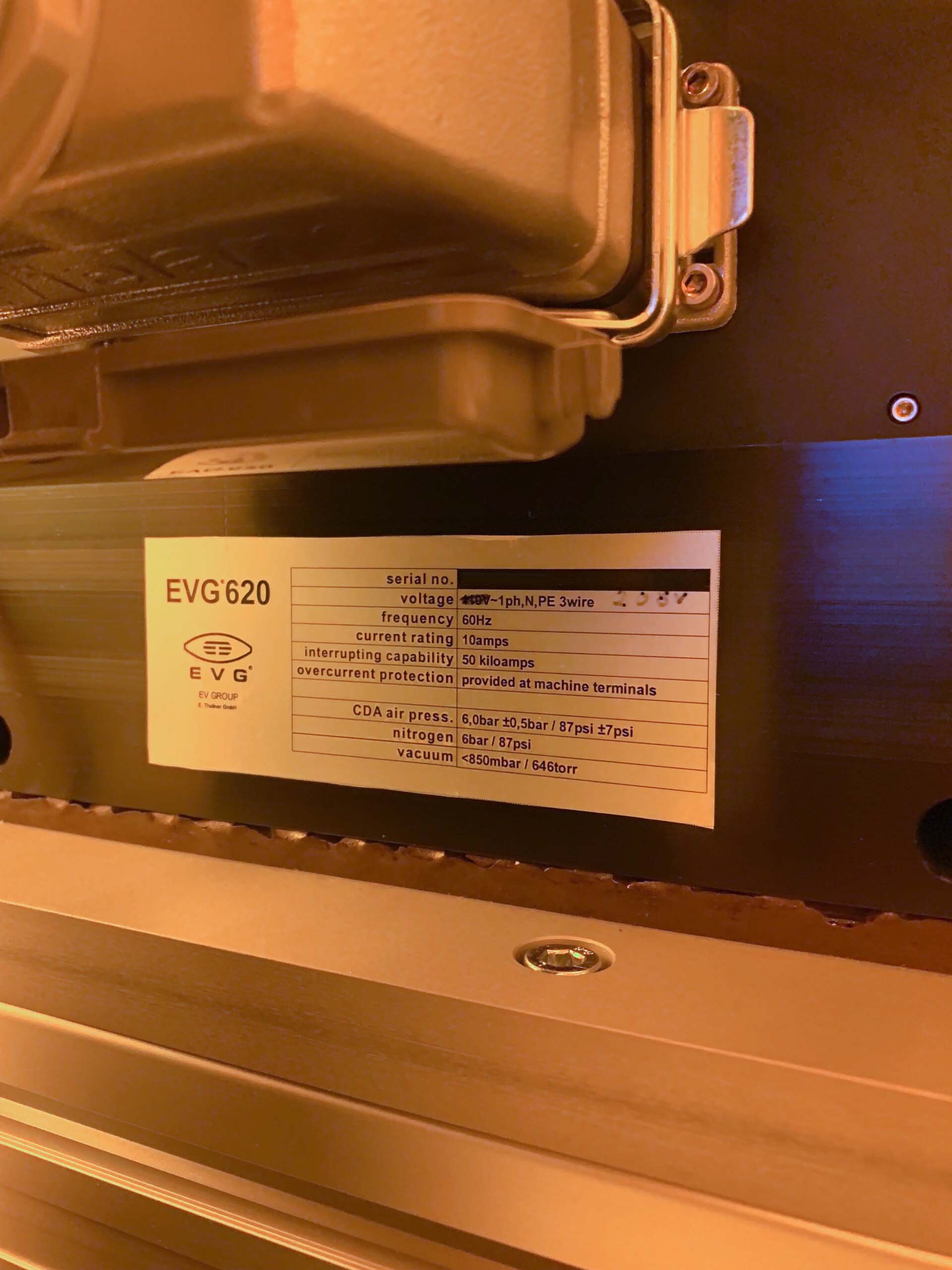

Used EVG / EV GROUP 620 #293591061 for sale

URL successfully copied!

Tap to zoom

ID: 293591061

Mask aligner

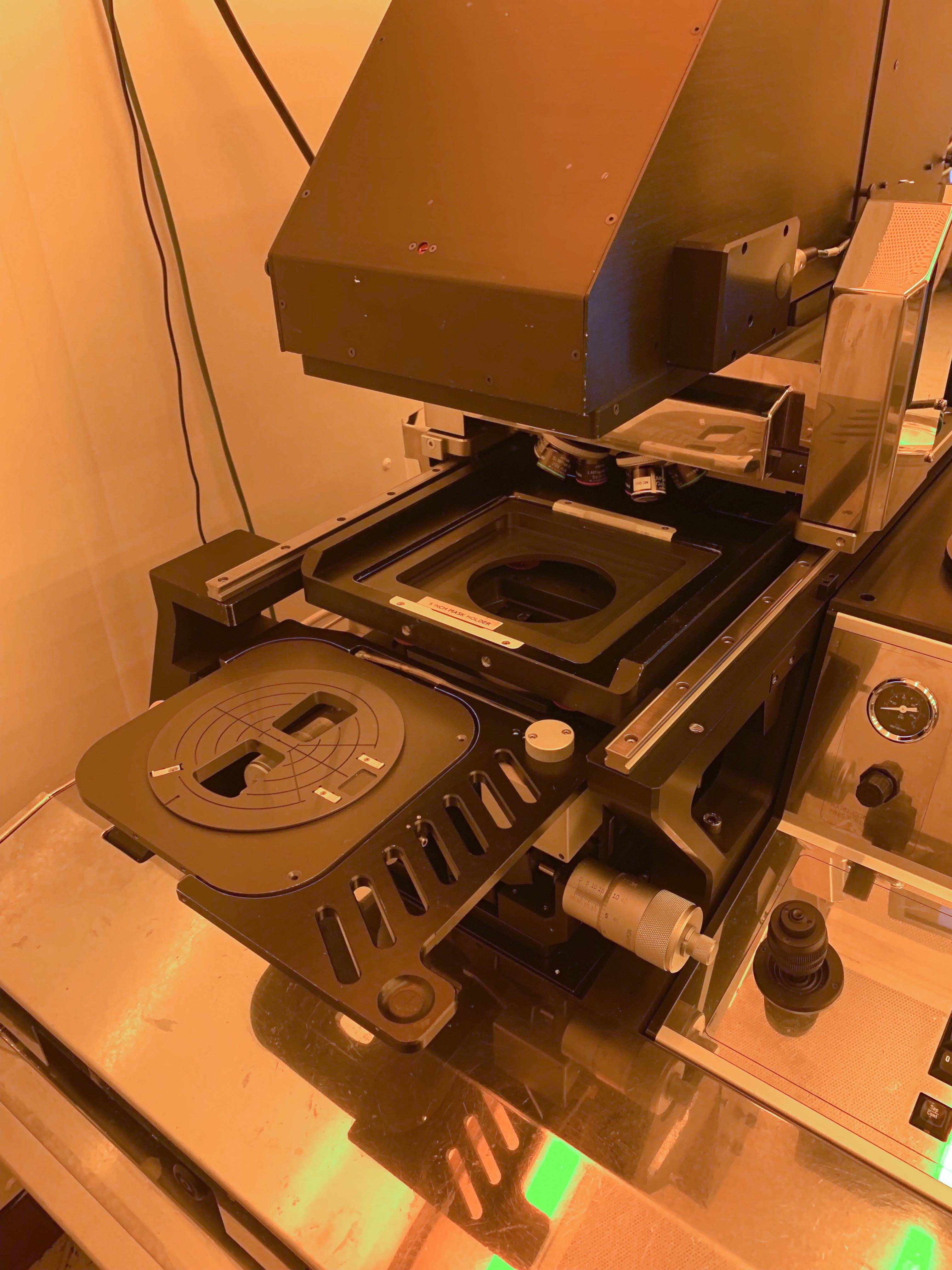

Interchangeable mask frame and bond tools

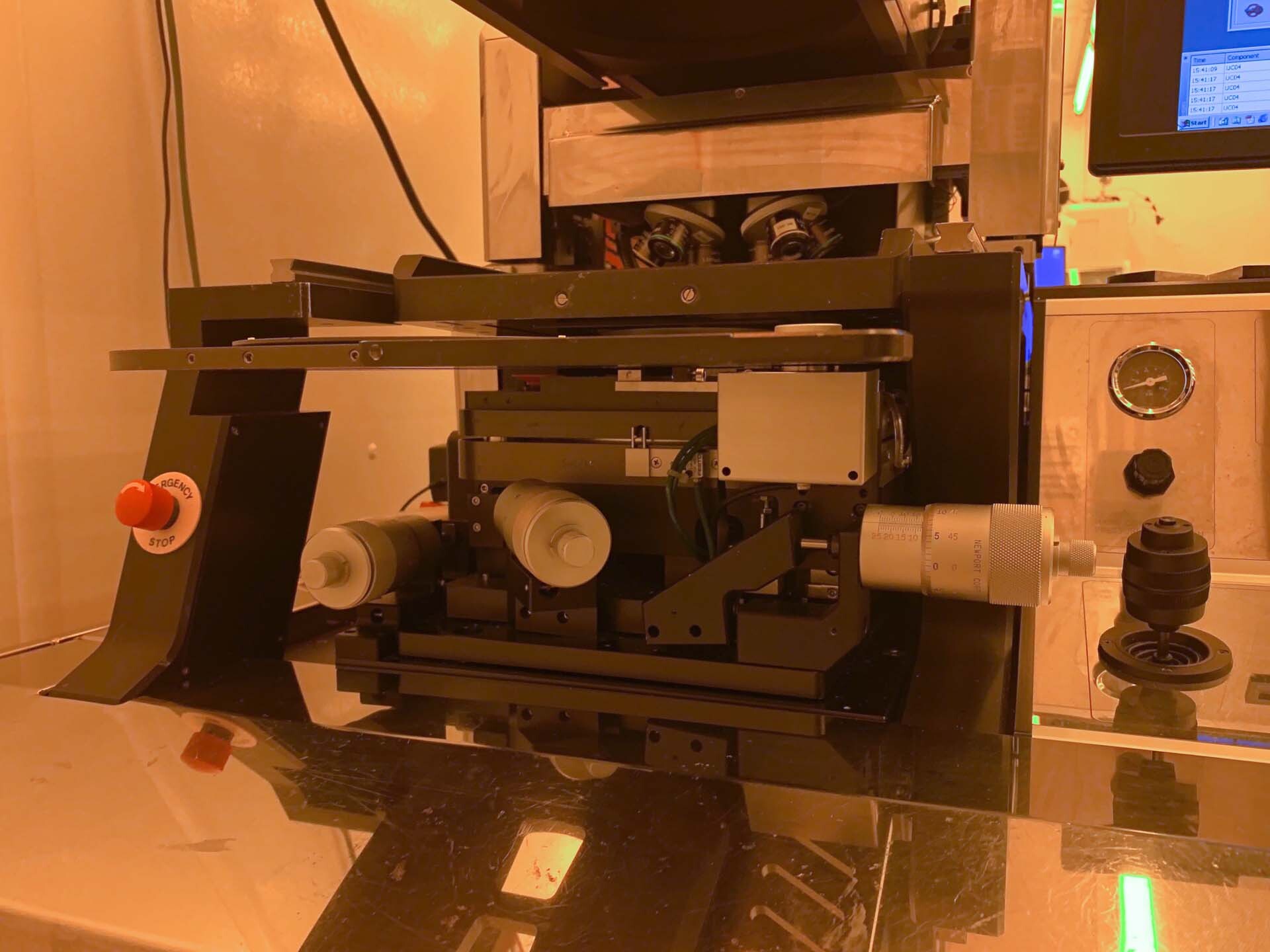

Alignment: Mask to wafer / Wafer to wafer

Front-side mask to wafer alignment accuracy: <0.6 microns

Precision front to backside alignment: <1 micron

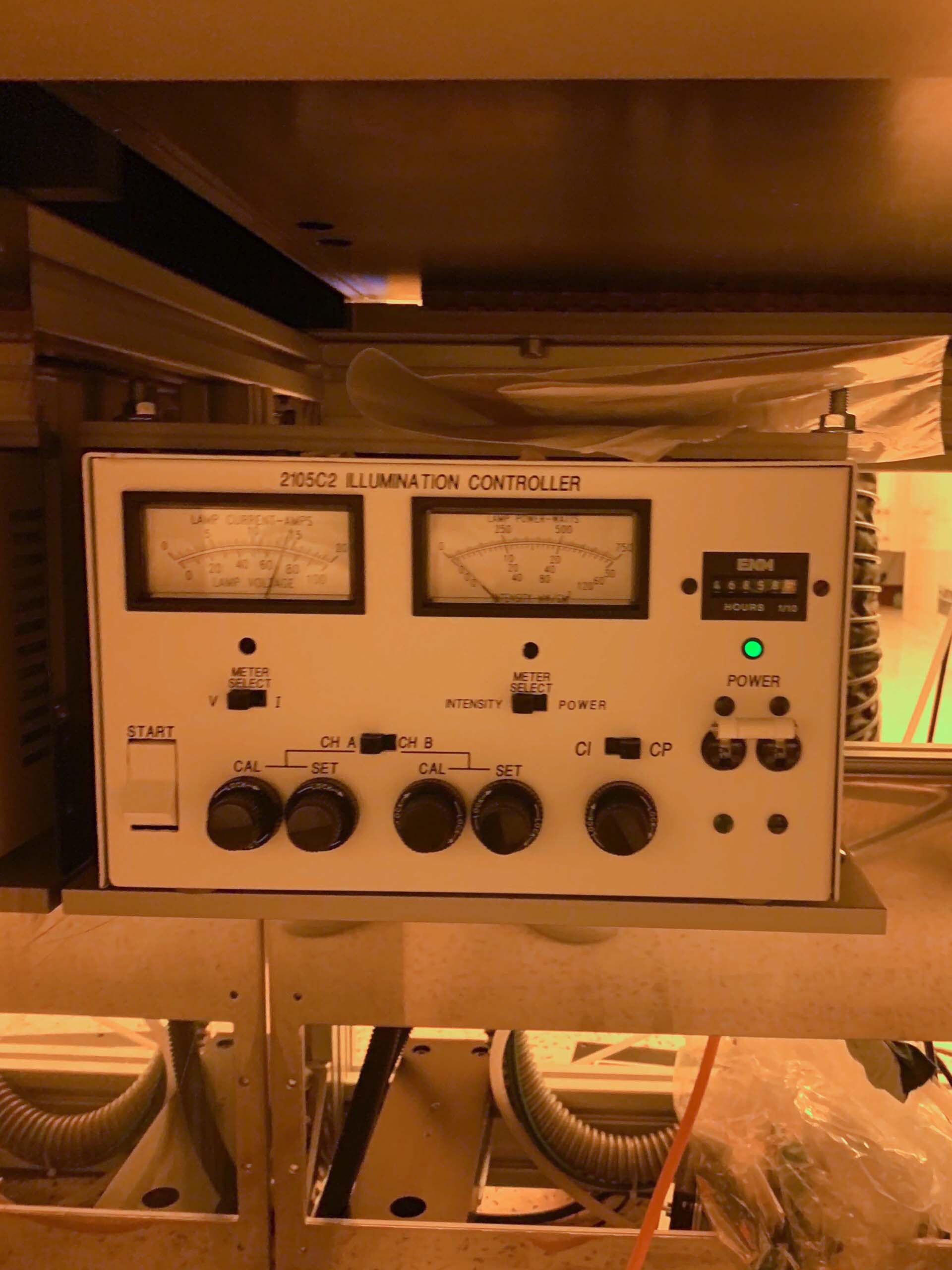

UV lamp source: 350 - 450 nm

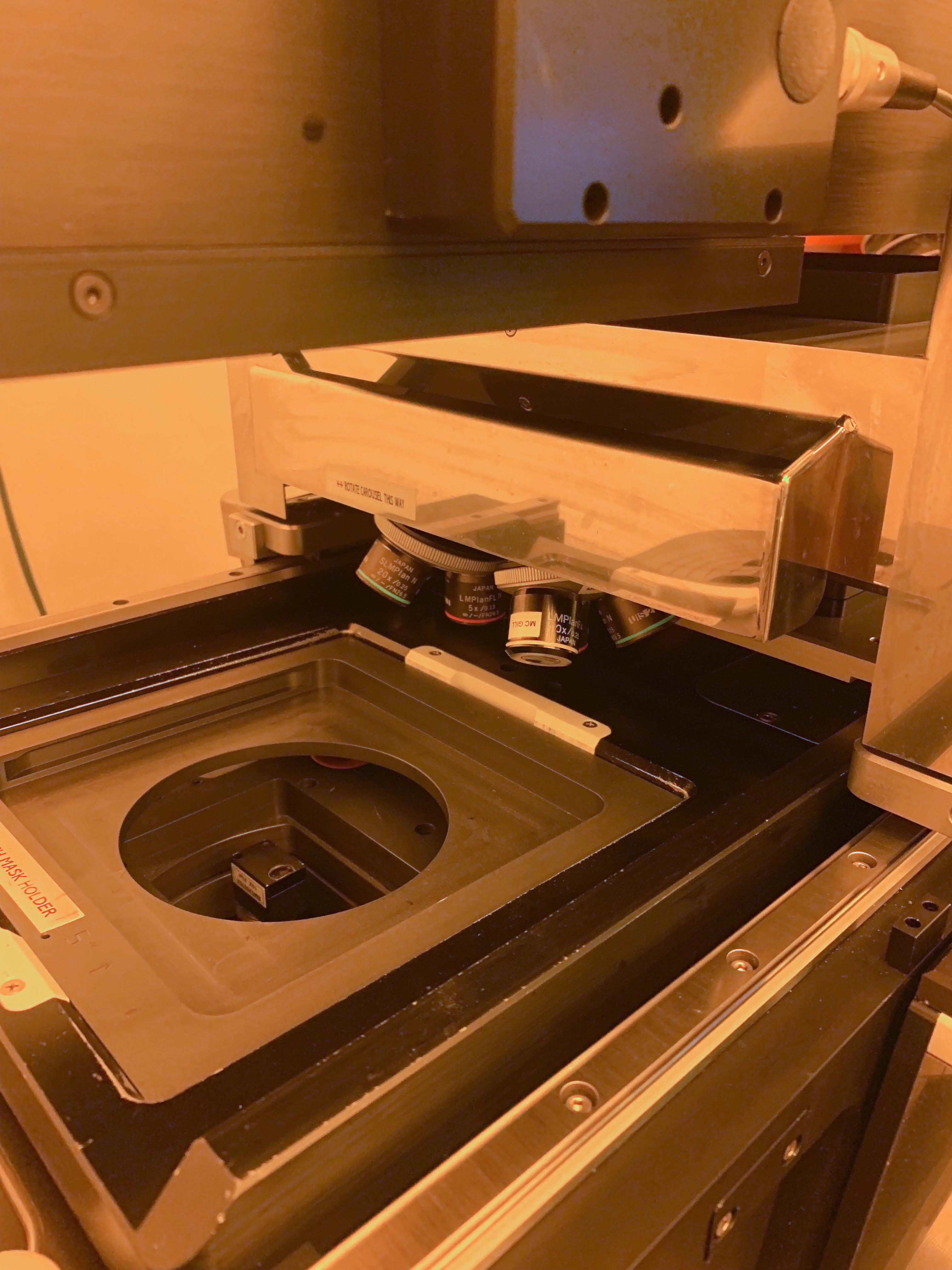

Fully motorized, split field microscopes with multiple objectives

(4) Exposure modes:

Proximity

Soft contact

Hard contact

Vacuum contact

Backside alignment modes:

Optical image capture

User-specified cross-hairs / Customized alignment keys.

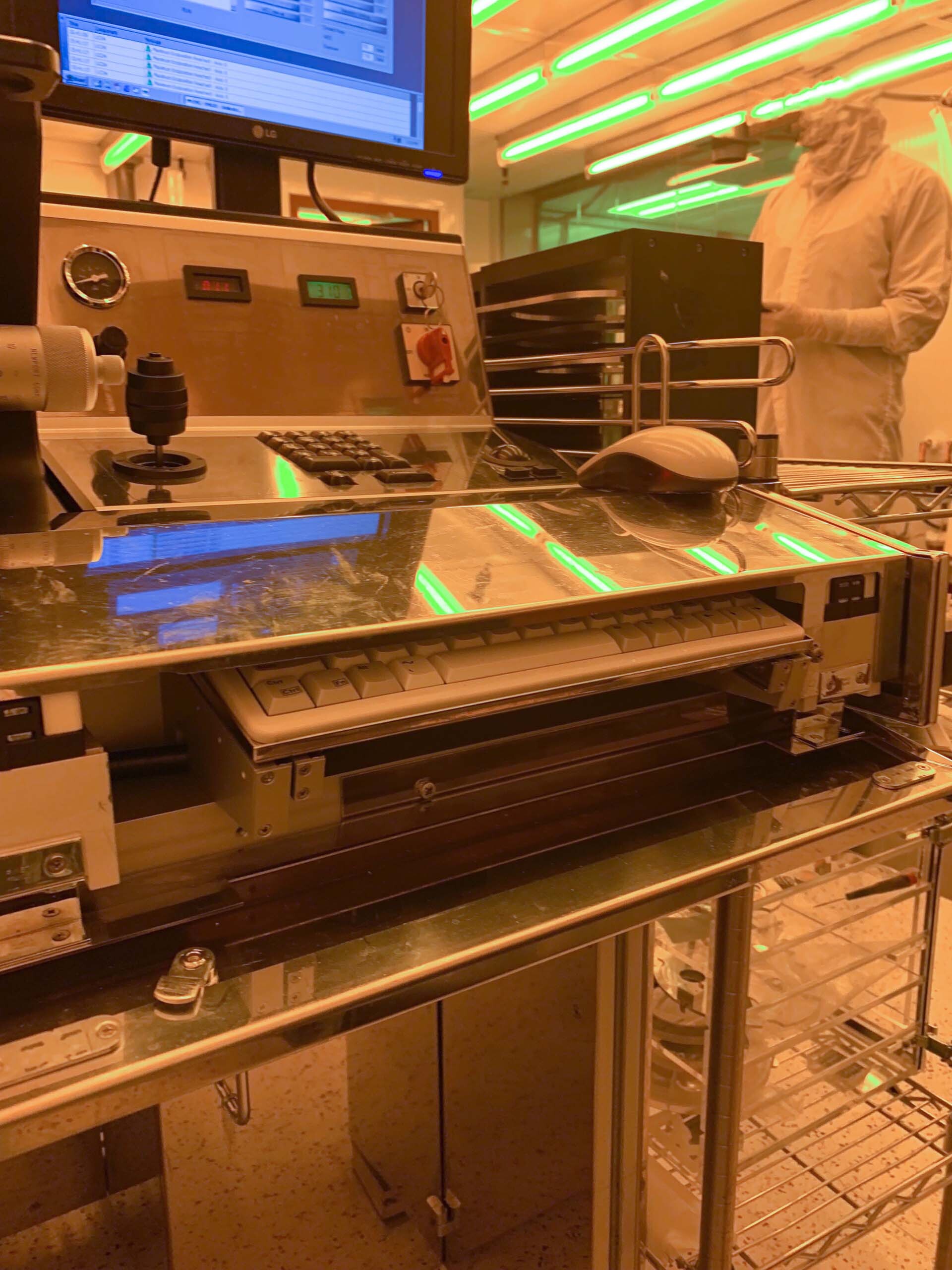

EVG / EV GROUP 620 is a mask aligner that is designed for cost-effective and efficient fabrication of photomasks and substrates in the photolithography process. It is an advanced, self-contained photolithography equipment with a precision accuracy of three micrometers. The mask aligner is ideal for processing a wide range of substrates, such as quartz, glass, silicon, and others, in sizes up to 8" x 10" (200mm x 250mm). EVG 620 mask aligner features an all-in-one processing cluster that simplifies the workflow and reduces turnaround time. The software, fixed-load processing station, and dual exposure stations are all integrated into one single unit. It has a built-in image processor and on-board exposure processing that can quickly process exposures, mitigating downtime between exposures. The software allows for process control, real-time monitoring, and data analysis to ensure that the quality and accuracy of photomasks and substrates are consistent. EV GROUP 620 mask aligner features an automated, six-axis, XYZBCC stage that is integrated with a high-resolution digital imaging system. The six-axis combination allows alignment of the mask to the exposed areas with sub-micron precision, thus giving a superior imaging quality. The motion is commanded by a closed-loop motion unit, thus increasing accuracy and repeatability. 620 mask aligner also has an on-board reflection source that enables imaging of the mask and the substrate. The source is equipped with 10x to 40x zoom optics to allow for precise imaging in a variety of situations. The mask alignment is further enhanced by the use of an advanced beam spot profiling machine. This tool enables the beam spot size to be adjusted, thus increasing exposure precision and accuracy. In addition to the top-of-the-line features, EVG / EV GROUP 620 mask aligner also has a built-in vacuum asset. This model allows for reliable and consistent positioning of the substrates in the wafer chuck, thus eliminating the need for manual tape application. Overall, EVG 620 is an advanced, self-contained equipment that is ideal for the efficient fabrication of photomasks and substrates in the photolithography process. It has a superior precision accuracy, on-board exposure processing, automated XYZBCC stage motion, and a built-in reflection source with 10x-40x zoom optics. Its advanced beam spot profiling system and built-in vacuum unit also allow for enhanced precision and accuracy.

There are no reviews yet