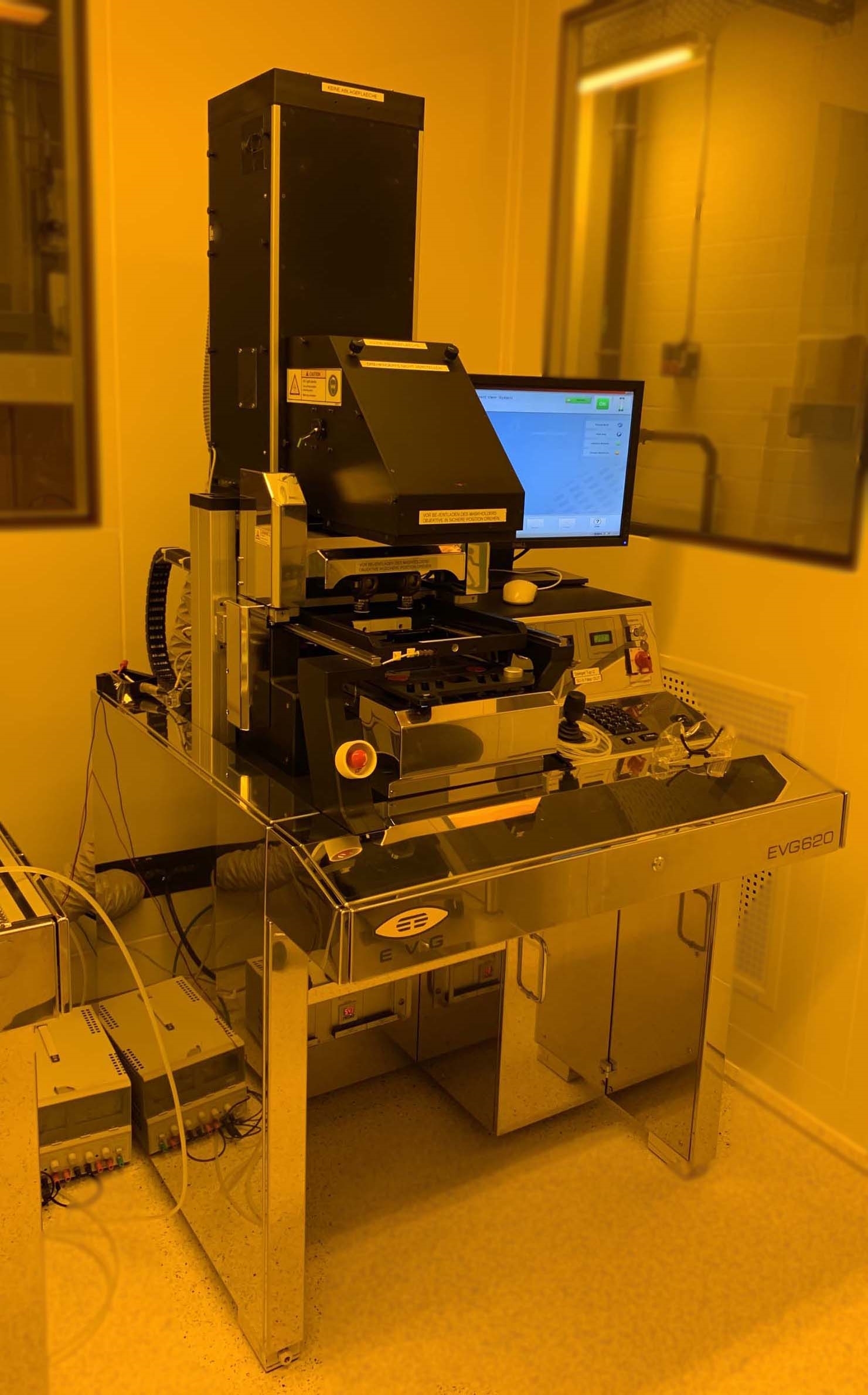

Used EVG / EV GROUP 620 #9232815 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9232815

Vintage: 2005

Mask aligner

Top and bottom side

Large cap option

Nano imprint tool

No robotics

Does not include IR Option

Power supply: 1000 W (Lamp)

2005 vintage.

EVG / EV GROUP 620 is a semi-automated mask aligner suitable for a variety of different applications. It has a process repeatability accuracy of 2.0 microns, and a substrate stage accuracy of 3.0 microns. The machine has a modular design which allows it to be operated in both embedding and nonembedding configurations. The embedding mode is more suited to general semiconductor wafer processing, while the nonembedding mode is more suitable for advanced masking applications. It features a patented direct imaging patterning technique, called 'Singleexposure', which results in superior imaging accuracy and high production throughput. This enables the machine to carry out a wide range of processes, from sputtering and ion-implantation to photoresist reflow and multilevel-metalization. EVG 620 also has a comprehensive range of built-in safety features. These include built-in sensors that detect any inconsistencies in the alignment accuracy of the mask and wafer, automatic beam shut-off when the alignment is off-by more than 2 microns, manual mask removal but automatic focus detection to reduce the possibility of operator errors, and optical fiber beam-dressing technology to maintain feature size with minimal loss of resolution. EV GROUP 620 has a software user-interface which allows users to easily configure various aspects of the machine. This includes setting up process recipes for particular mask and substrate types, creating tracing templates for multi-level patterning, aligning masks to wafers with precise pixel accuracy, creating a stackable trace list for batch process numbering, and adjusting the exposure parameters for each application. The software also has preconfigured profiles, enabling users to quickly set up batch process quickly and efficiently. The machine provides a cleanroom compatible environment with a tight temperature range of 10-38°C and a relative humidity level of 60%, ensuring no unnecessary disruptions to the process. 620 also features an advanced precision alignment system (APS) that ensures a highly accurate and repeatable alignment process. This ensures that the desired pattern is registered exactly according to the user's specification. Overall, EVG / EV GROUP 620 is a reliable and flexible mask aligner that will deliver high-quality results with consistent reproducibility. Its modular design and wide range of integrated safety features make it a powerful and desirable choice for any production environment that requires high precision masking.

There are no reviews yet