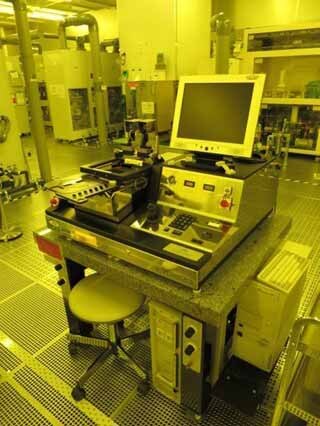

Used EVG / EV GROUP 620 #9402233 for sale

URL successfully copied!

Tap to zoom

ID: 9402233

Vintage: 2004

Mask aligner

Plug type:

US 5 Nema L 21-30 Plug, Wire length 1.8m

Europe: CEE7 European plug

Japan US 5 NEMA L‐ 21-30 plug, wire length 1.8m

Tube slzes:

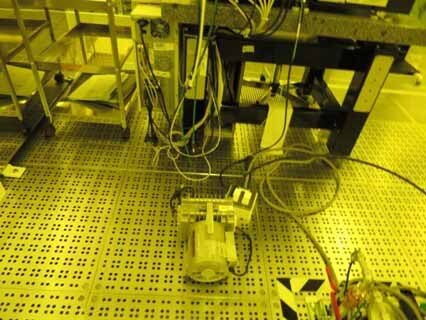

Compressed airi nitrogen and vacuum

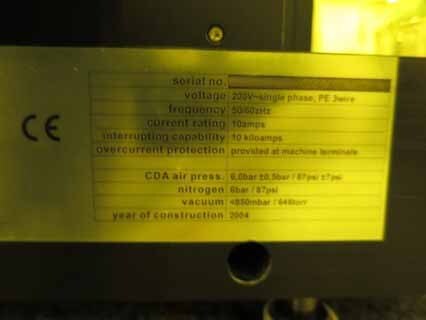

Compressed air: 6 Barr (87 Psi). dried and filtered

701/h FIow rate

Nitrogen / Compressed air (Dried, cleaned):

501/h Flow rate

Vacuum: 850 mbar (640 Torr)

Power recuirements 400W

Voitage:

Japan system: 200 V, 50/60 Hz, Single phases, 3 Wire system

US System: 208 V, 50/60 Hz, Single phase, 3 Wire svstem

European system 230 V, 50/60 Hz, Single phase, 3 Wire system

2004 vintage.

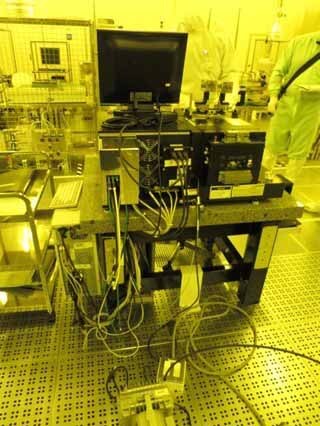

EVG / EV GROUP 620 is a fully automated mask aligner equipment designed to handle wafer fabrication of semiconductor devices. It utilizes a variety of industry standard substrates and exposure sources to provide responsive alignment results. The system is capable of achieving resolutions of 0.1 micron with a repeatability of within 1 micron. EVG 620's high-precision optics, motorized wafer stage, and integrated software make setting up and controlling the exposure process straightforward and efficient. The aligner's exposure sources are highly efficient, making the device capable of running a variety of jobs quickly and accurately. The aligner's user-friendly software facilitates a streamlined approach to job setup and allows users to monitor the progress of each job. The unit consists of several integrated components, including a computer-controlled mask exposure machine, a motorized wafer stage, an advance motor drive tool, and an exposure lamp. The exposure lamp is used to produce short wavelength exposure light, ensuring maximum resolution and repeatability. The motorized wafer stage is used to precisely control the wafer movement and exposure position. Finally, the integrated advance motor drive asset allows the user to control the speed and direction of the exposure process. EV GROUP 620 is designed to meet the demands of semiconductor manufacturers, providing them with a efficient and cost-effective tool for mask aligner/exposure tasks. The model's intuitive software also ensures ease-of-use and efficient job setup, allowing operators to monitor the process and maintain high levels of accuracy and precision. The aligner's robust construction and automated operation make it an ideal solution for those looking for a reliable, fast-paced exposure equipment.

There are no reviews yet