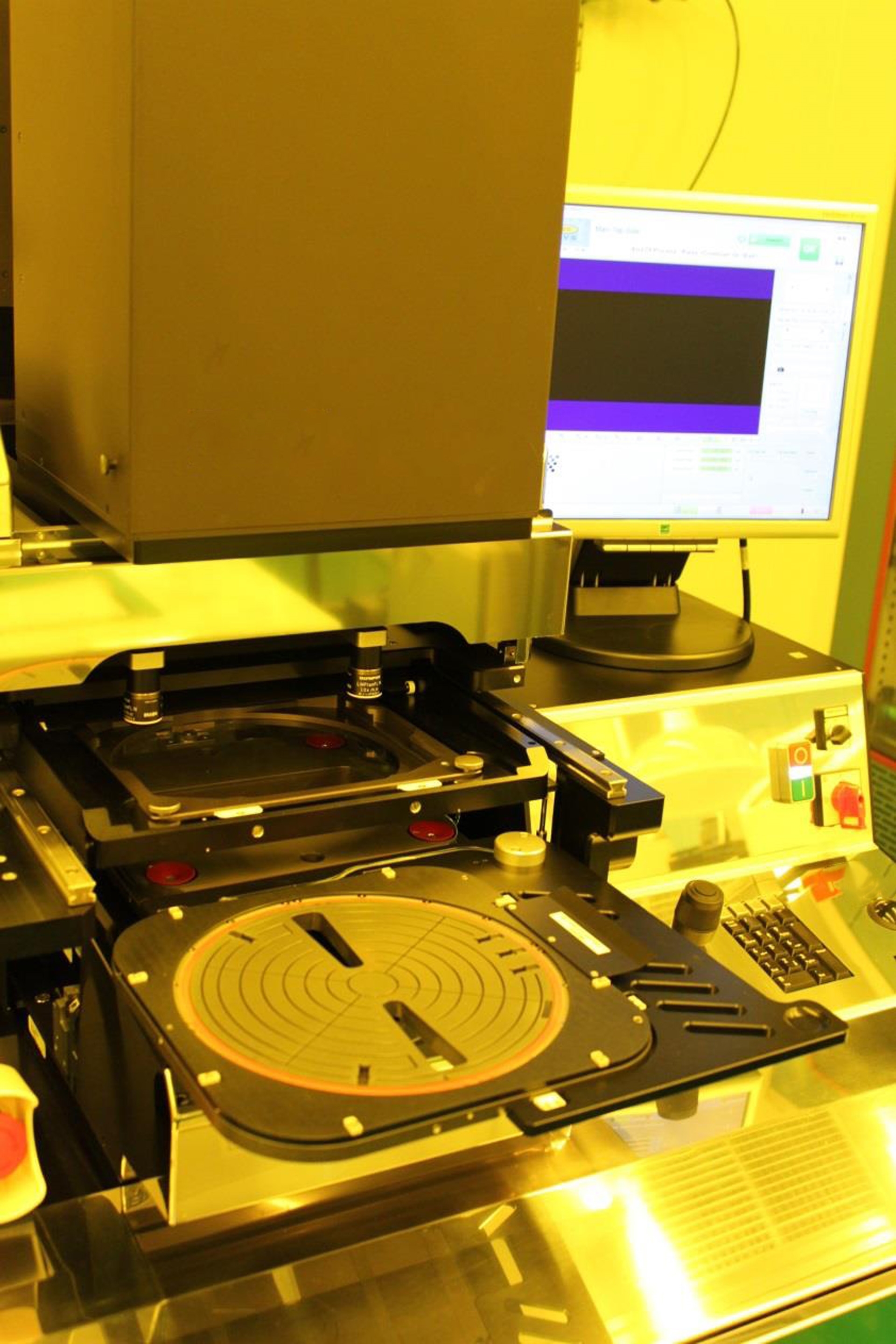

Used EVG / EV GROUP 6200 #9238655 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9238655

Wafer Size: 4"-8"

Vintage: 2017

Semi automated double side mask aligner, 4"-8"

Manual handling

High resolution top and bottom side split field microscopes

Constant power and intensity dose mode

Wafer thickness: 0.1 - 10 mm (For top side configuration only)

Semi automatic loading with mechanical pre-alignment on chuck

Quick change of mask and chuck

Storage rack for up to (5) aligner tools

PC Controlled operating environment

Graphical User Interface (GUI) for visualization

User interface including keyboard and monitor

Lamp: 1000 W Hg

Objective: 10x

Standard exposure modes:

Vacuum contact

Proximity

Hard

Soft

500 W-1000 W Light source:

Lamp house for 500 W / 1000 W Hg or HgXe lamps

Supports various optical sets

Including light integrator for accurate lamp control

Light uniformity better than ±3% for 6" wafer and ±4% for 8"wafer

Adjustment plate for UV probes with diameter 44.5 mm and maximum height 16 mm

Optical set for wave length range: 350 - 450 nm

Field lens, 8"

Dielectric mirror

Fly's eye lens

Alignment stage:

Fully motorized X, Y theta and Z alignment stage via three axis joystick

With DC motor controllers for cursor key fine alignment

Automatic wedge compensation system designed for optimized print gap control

Adjustable WEC and exposure contact force

Automatic alignment for top and / or bottom side includes COGNEX patmax:

Vector based image recognition

Storage of trained mask and substrate patterns on hard disk

Comply with user definable alignment marks for top and bottom side alignment

Key identification feature for multi layer alignment key design

For scaled (Over / under etched) alignment keys

Easy operation with menu assisted training of mask and wafer alignment marks

Alignment results are dependent upon process conditions and material properties

Nano align technology package:

Increases EVG aligner microscope resolution by factor ~2 (for improvement of alignment results or extended depth of focus)

Improved image quality due to 100 % digital signal processing

Enhanced digital zoom capabilities

Supports cross hair and overlay mode for standard backside alignment processes

Mask holder for 9 x 9" masks with loading frame:

According to EVG standard design:

Round opening for exposure of wafers

Hard coated and lapped surface finish for mask contact area

Bottom loading system with automated vacuum transfer

Vacuum contact wafer chuck 8":

According to EVG standard design:

For manual wafer loading with pre-alignment aid

Hard coated and lapped surface finish for wafer contact area

With Windows for bottom side alignment

Supports proximity soft hard and vacuum contact exposure

Seal for vacuum contact

Supports vacuum contact with substrates up to 1.5 mm thickness

Mask holder for 7 x 7" masks with loading frame:

According to EVG standard design

Round opening for exposure of wafers

Hard coated and lapped surface finish for mask contact area

Bottom loading system with automated vacuum transfer

Mask holder for 5 x 5" masks with loading frame:

According to EVG standard design

Round opening for exposure of wafers

Hard coated and lapped surface finish for mask contact area

Bottom loading system with automated vacuum transfer

Vacuum contact wafer chuck 4"-6":

For manual wafer loading with pre-alignment aid

Hard coated and lapped surface finish for wafer contact area

With Windows for bottom side alignment

Supports proximity soft hard and vacuum contact exposure

Seal for vacuum contact

Supports vacuum contact with substrates up to 1.5 mm thickness

Exposure uniformity:

Wafer:

Up to < ±3% across, 6"

Up to < ±4% across, 8"

Top side microscope:

Motorized split field microscopes for alignment in visible light

With high resolution CCD cameras for top and bottom side

Travel range of top side microscope:

X: 30 (optional 8) - 200 mm

Y: ± 75 mm

Bottom side microscope:

Motorized split field microscopes for alignment in visible light

With high resolution CCD cameras

Travel range of bottom side microscope:

X: 30 (8) mm - 154 mm

Y: ± 12 mm

Spare parts:

Qty Description

(3) Tension springs

(4) Tension springs d1, 4/De15, 4/Lo49/R0,6

(5) O-Rings 3x2

(5) O-Rings 2x1

(1) Lip seal, 6"

(2) Lip seals, 8"

(1) Lip seal, 4"

(2) Micro switches SPDT 1p

(1) Temperature switch

(2) Rotary switches CA4 A722-600-FS4

(5) G-fuse 7000135 T4A 250V 5x20

(5) G-fuse 7000135 T2.5A 250V 5x20

(1) Pneumatic cylinder

(2) Micro switches SPDT 1p

(1) Ellipsoid mirror 8'' EOF 390-4-AF

(1) Motor MGK 1616E012S /900:1 16/5 M16/5 09

(1) Cutting insert

(1) Power supply

(3) Pneumatic cylinders

(2) Pneumatic cylinders DSNU-16-40-P-A

(1) Power supply 100W, 12 VDC TXL-12S

(1) MGK 1524E012SR +15/8-485: 1 +IE2-512

(2) Light barriers

(1) Trackball 816TC712 11 0 USB

(2) Couplings WAC 10-3-3

(1) MGK 2342S024CR+23/1-14:1+IE2-16

(1) Linear measurement system DIT30.73 0.5 um

(4) Pressure sensors

(2) Light barriers

(1) Power supply 24 VDC, 230 W

(2) Light barriers

(2) Proximity switches

(2) Proximity switches

(1) Adjustment unit 9POI Sub-D mate l=15 cm

(1) Suction cup unit WEC

(2) Thermo couple units TKI 05/25 Type K

(1) Timing belt 6 T2, 5-200

(4) Operation manuals

2017 vintage.

EVG / EV GROUP 6200 is a mask aligner, a an advanced equipment designed for the alignment, exposure, and development of reticles or masks used in the photolithography industry. This machine is generic in nature and is configured to meet the specific needs of the user. It is an ideal tool for microfabrication processes such as the fabrication of circuits, components, and parts for advanced semiconductor applications. EVG 6200 features a high resolution pattern projector which accurately projects the pattern onto the steepest sides of the mask. This projection is achieved thanks to an electronic mask aligner which lets users accurately align the mask to the substrate, ensuring that it will fit precisely and exactly. The high resolution projection also guarantees a high-quality image. EV GROUP 6200 offers a number of other features to ensure quality manufacturing and safe performance. For example, this system utilizes a unique 'integrated imaging technology,' which combines a number of optical, mechanical, electrical, and software components. It also includes an autocollimator which constantly calibrates the projection and optical components, ensuring maximum accuracy. 6200 is outfitted with an advanced manipulation module which allows users to control the position, orientation, and tilt of the masks. It is also equipped with a robotic arm for precise and continuous alignment of the mask and substrate. This allows for an exact exposure of the masks and makes certain that the results align perfectly with the printed circuit board. Furthermore, EVG / EV GROUP 6200 comes with a number of safety features such as a cleanroom air unit, automated jam detection, automatic protection against over-exposure, and other protection mechanisms that enhance the accuracy and safety of the machine. To support its cutting-edge performance, the mask aligner features a Windows-based human-machine interface, a flexible range of polarity inversions, and a comprehensive fault reporting tool. In summary, EVG 6200 is an advanced and sophisticated mask aligner that enables users to align masks with the highest degree of accuracy and precision. This asset offers exceptional accuracy and precision, precision control, safety features, and an easy-to-use user interface. It is a great tool for those in need of precision microfabrication.

There are no reviews yet