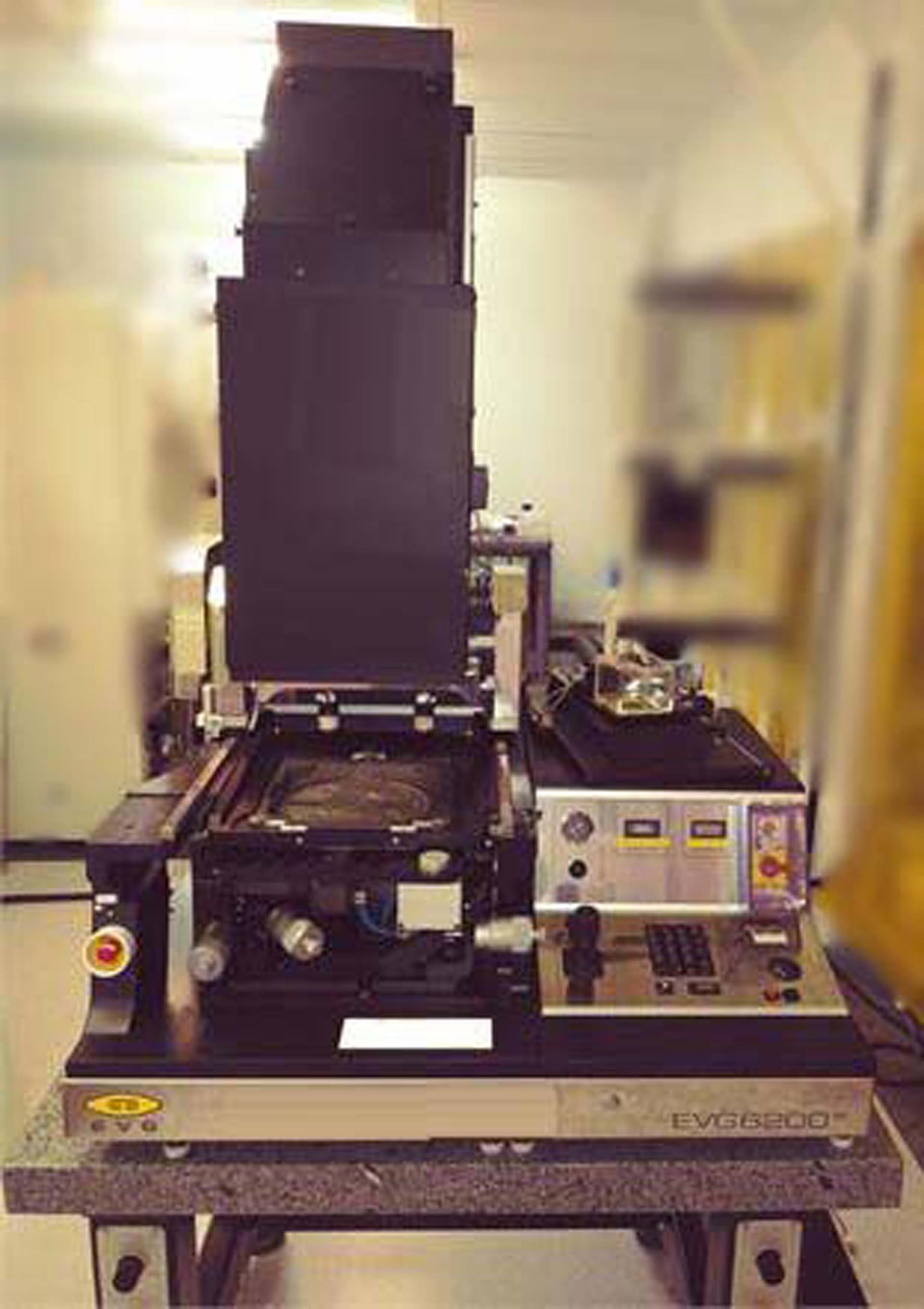

Used EVG / EV GROUP 6200 #9239987 for sale

URL successfully copied!

Tap to zoom

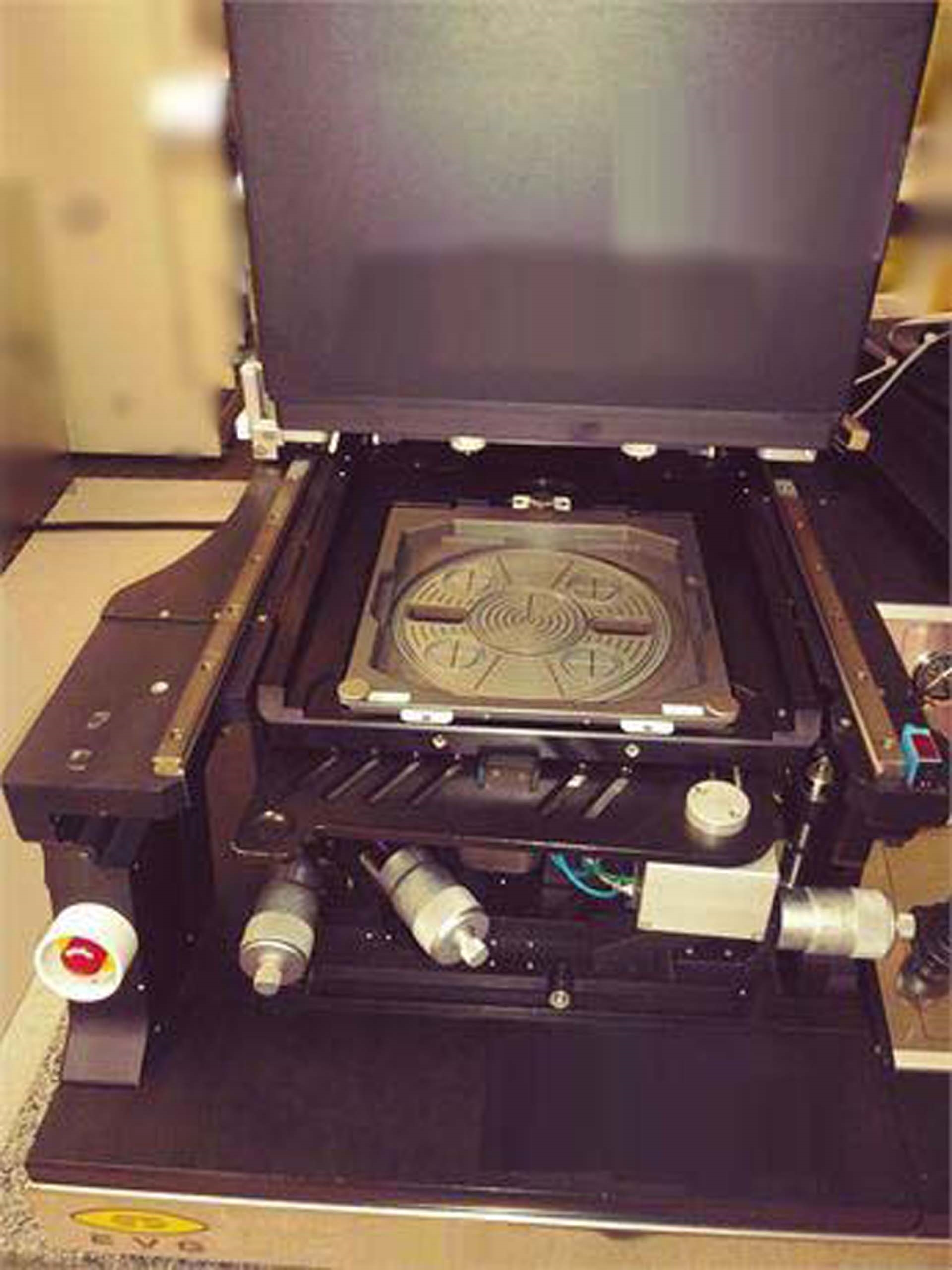

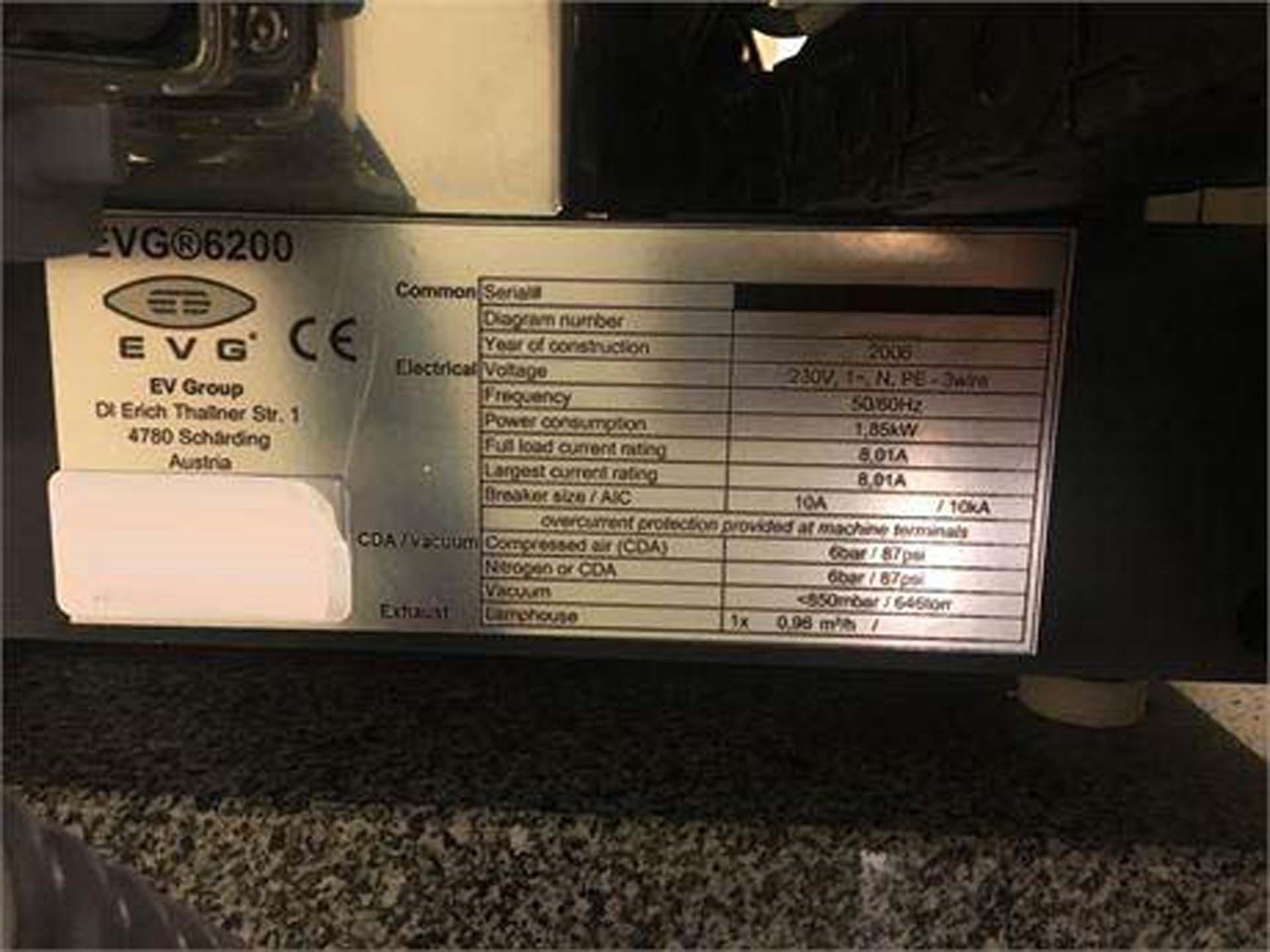

EVG / EV GROUP 6200 is a mask aligner designed for substrates up to 200mm diameter. This state-of-the-art machine consists of two separate stages. The first stage, known as direct imaging (DI), allows for patterned alignment marks to be created on substrates. These alignment marks are generated using a primary imaging equipment, which includes a screen plane camera and a digital micromirror device (DMD). The secondary imaging system consists of a charged-coupled device (CCD) camera and actinic light source, which allows the machine to detect patterned alignment marks on the substrate and align them to a predetermined overlay accuracy. The second stage of EVG 6200 is used for photolithography processing. This stage allows for the creation of patterns on substrates using photolithography techniques. It consists of two components; a large, fully-automated exposure unit, which is used for exposing patterned alignment marks onto the substrate and a high-pressure spray machine, which enables coating of photoresists onto the substrate. The exposure tool is equipped with a dedicated user interface for easy control of exposures and processing parameters, while the spray asset has user-defined controls which allow for optimal coating of photoresist layers. EV GROUP 6200 has built-in features which provide users with exceptional precision and accuracy. It includes a state-of-the-art image recognition algorithm which is used to identify patterned alignment marks at microscopic levels. The machine additionally features precise temperature control, enabling accurate and consistent processing. It is also equipped with a highly efficient and uniform light source for exposure purposes. In conclusion, EVG/EVGroup 6200 is a mask aligner designed for substrates up to 200mm diameter. It is equipped with two stages, the first allowing for patterned alignment marks to be created on the substrate, while the second is used for photolithography processing. The machine is equipped with a number of features which provide users with precision and accuracy, such as a user-friendly interface, an image recognition algorithm, precise temperature control, and a highly efficient light source.

There are no reviews yet