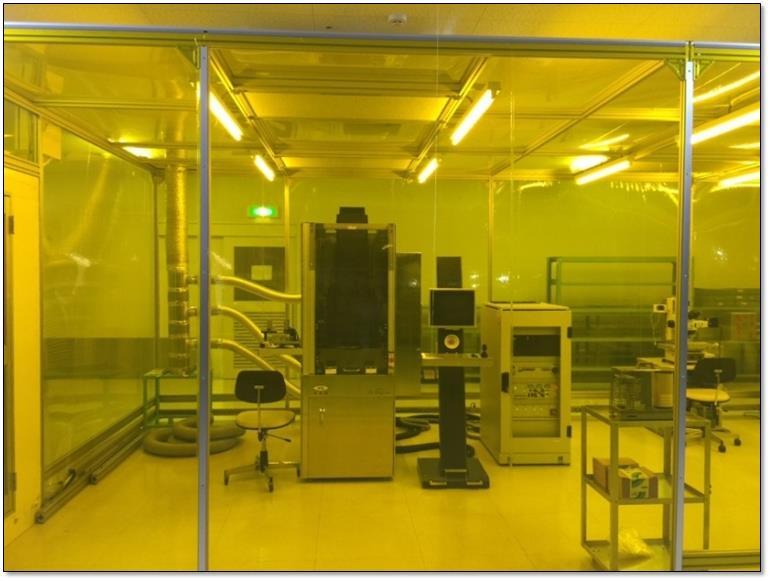

Used EVG / EV GROUP IQ #9138247 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9138247

Nano imprint lithography system, 8"

Top-side alignment only

Manual load

Wiring removal

Basic unit 200mm:

Flat screen:17"

Self Diagnostics during machine startup

Automatic initialization:All motors,encoders,limit switches,sensors and pneumatic

Remote diagnostics

Quick change:Stamp holders and imprint chucks

EC declaration of conformity

PC controlled operating environment

Solid state drive and hard drive

Earthquake protection device

Software:

MS-windows

Process software ,processing and diagnostics

Automated recording

Storage of files in hard disk or network

Password protected

Internal wedge compensation unit:

Automatic wedge compensation

Motorized alignment stage:

X,Y,T alignment

High resolution alignment

(3) axis joystick

Reinforced stage drives

Top side microscope:

Fully motorized split field microscope

Travel range X: 90-200mm*

Travel range Y: -10-100mm*

(3) axis joystick control

Display and storage of microscope position

(2) Objective 5x

Automatic alignment for top and / or bottom side:

Vision system

Storage of stamp and patterns on hard disk

Top and bottom side alignment

Stamp and wafer alignment marks

Large gap alignment capability:

Alignment at substrate separations >50um

Alignment during UV molding

Alignment during UV bonding

Manual wafer loading capability:

Motorized swivel arm

software integrated

(2kg) Manual substrate loading/unloading

Wafer loading trays

Wafer loading frame for 200mm wafers/stamps:

Manual wafer loading on chuck

process integrated substrate vacuum fixing

Notch or flat with pins

External wafer thickness measurement station:

(3) Point wafer thickness detection

Contact less imprinting

(3) Sensors adjustable range :150-200mm

Designed Warped substrate :1mm

Manual Operation

Sensors range: up to 10mm

manual system only

500W-1000W Light source NUV:

Lamp house :500w or 1000w

NUV range:280-450nm

Optimized parallel Light:+/-3% on 150mm and +/-4% on 200mm

Adjustable plate: diameter 44.5mm and max.height 16mm

Optical set for wave length range 350-450nm:

NUV and DUV light sources

Field lens:200mm

Dielectric mirror

Fly's eye lens

Stamp holder for 200mm UV hybrid lens molding:

UV molding automated de-embossing function

Hard coat surface finish

Quartz backplane

Imprint chuck for 200mm wafers/stamps:

Bottom chuck: 200mm wafer

Top side alignment

Hard coat surface finish

Manual and automated loading

Software for UV hybrid lens molding:

UV molding process flow

Designed for puddle dispense

Recipe parameters and user guidance

Software to compensate with specified tolerance

Force control capability up to 400N:

Load cells implemented

Maximum controllable imprint: 400N

Force control during imprint

Force control during UV exposure

UV molding software

Tooling for 200mm UV bonding,stamp fabrication and MLM:

Top substrate holder

Special quartz backplane with edge vacuum groove

Mechanical clamping

Vacuum supply to backplane via tube

Software for master and sub-master replication:

UV molding process flow

Tooling for polymer stamp fabrication

Software to compensate product within specified tolerance

Software for UV monolithic lens molding:

UV molding process flow

UV molding tools for puddle dispense

Recipe parameters and user guidance

Software to compensate with specified tolerance

Diffuser plate for tooling for stamp fabrication + MLM:

Tooling for stamp fabrication + MLM

Diffuser plate onto backplane prior to UV exposure step

Diffuser plate for hybrid lens molding tooling:

Hybrid lens molding tooling

Diffuser plate onto backplane prior to UV exposure step

Recipe controlled microscope illumination spectrum:

Contrast improving illumination system

Increased pattern visibility

Improved alignment reliability

(3) Adjustable LED light sources per microscope

Autom.Arm for puddle dispense and de-ionization:

Motorized swivel arm

Software integrated

Programmable dispense arm/nozzle

Puddle dispense of imprint material: up to 4 lines

Right-hand side alignment

Host ionization system

Ionization system:

Ionization nozzle with power supply

De-ionizing of stamp and substrate

Syringe dispense system:

Syringes :up to 3

(2) Dispense lines

Universal resists applications

Resist with short shelf life time

Programmable dispense rate

Adjustable suck back

Different resist and polymer viscosity

Chemistry cabinet:

Housing with front door access

Encapsulating of syringe dispense systems / arm

Exhaust port

Prepared for later pump upgrade

Pre-installed weight cell

2011 vintage.

EVG / EV GROUP IQ Mask Aligner is a high-precision, high-throughput wafer-level lithography equipment used in the semiconductor industry to pattern small devices such as chips, transistors, and other circuit elements. This advanced tool offers ultra-high resolution at high line edge roughness (LER) and overlay precision to improve device performance and yields. It utilizes an advanced wafer stage, laser interferometer for precise wafer alignment and motion control and utilizes a synchronized step-and-repeat method to project the desired image onto the wafer in a fast and repeatable way. EVG IQ Mask Aligner uses a beam-splitting lens to direct a laser light onto a rectangular mirror that reflects it onto the mask and photoresist-coated wafer, exposing them simultaneously, allowing for advanced multi-layer patterns to be created. The beam splitting lens also provides a source of illumination to the mask and wafer, so that each is exposed to the full intensity of the lithography system's source beam. EV GROUP IQ Mask Aligner is capable of printing sub-50nm features on standard aligners, or features on the sub-30nm scale with specialized equipment, making it ideal for fabricating advanced ICs and MEMs devices. To achieve such small features, the unit utilizes, powerful, high-fidelity digital stepper motors that drive the lens and cranker mechanisms to accurately move the wafer, aligh it, and patter. This enables a highly accurate and repeatable printing process. The wafer is held in place by a vacuum chuck, while an alignment laser is used to adjust the wafer's position, and ensure that it is aligned accurately with the mask. This allows for true overlay measurements from printing to printing. Finally, an additional ultraviolet-visible laser is used to scan for a wide range of mask and wafer features, reducing time between prints so that wafers can be processed quickly and efficiently. IQ Mask Aligner offers remarkable pattern precision, including line width control on the order of ±5nm and LER of less than 1nm. The machine is also highly reliable, with a service life of more than 20 years. With rapid throughput capabilities and advanced lithographic control, the tool is able to product accurate, complex patterns rapidly. As such, it is an invaluable tool for those in the semiconductor sector looking for high-precision, high-throughput wafer-level lithography solutions.

There are no reviews yet