Used KARL SUSS / MICROTEC MA-150 #293600832 for sale

URL successfully copied!

Tap to zoom

ID: 293600832

Wafer Size: 6''

Mask aligner, 6"

Substrates, 6" x 6"

M206 / M236 Split field microscopes

Objectives: 5x, 10x, 20x

Eyepiece Magnification: 10x

Micrometer spindles

UV Ranges with optimized diffraction reducing systems

Splitfield topside microscope with turret

C-Mount for IR camera adaption

Alignment stage with loaded IR chuck

IR Illuminators and tube stage for target positioning

IR Tubes

Spare parts

Tool kit

X-Drive

IR Tool:

Chuck

Maskholder

Spacers for maskstage clamp

Stage:

X, Y Theta

Z Alignment

Wedge error compensation

Microscope manipulator with adapter

Movement synchronized with alignment

Lamp house LH 1000: 350 W / 1000 W lamp

With optical tube and mirror house / Eclipse mirror

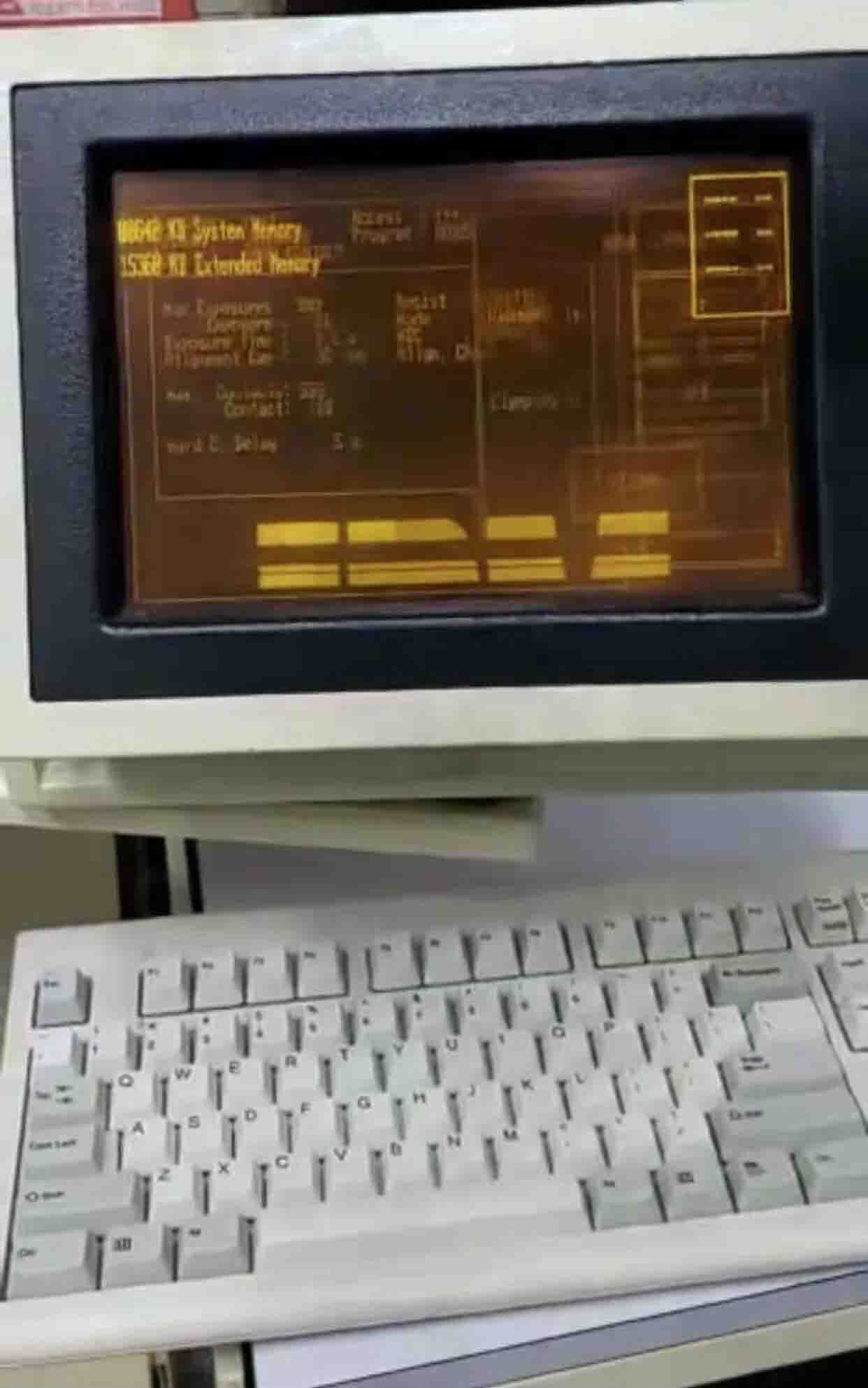

CRT Display

Serial dialog operator interface

Substrate size: 1" x 1" - 4" x 4", Pieces

Mask size: 7" x 7"

Exposure system:

Vacuum contact and proximity

Gas separation: 0-90 um

Gas adjustment resolution: 1 µm

Contact pressure: 0.02 - 1.0 N/cm²

Exposure optics:

Wavelength / Range / Source

UV400 / 350 mm - 450 mm / 1000 W Hg

UV300 / 208 mm - 350 nm / 1000 W Hg

Alignment:

Top Side Alignment (TSA)

Accuracy: TSA down to 0.5 µm

Back side alignment

Accuracy: BSA down to 1.5 µm

Alignment stage:

Alignment range X: ±5 mm

Alignment range Y: ±5 mm

Alignment range θ: ±3°

Mechanical resolution X, Yθ: 0.05 μm

UV400 With high peak intensity at 365 nm and 405 nm

Exposure area: 6"

CIC500 for 350 W HBO

Maximum intensity at 365 nm: 19 ±4% mW/cm²

Maximum intensity at 405 nm: 30 ±4% mW/cm²

Power supply: 110 V / 220V, 50/60 Hz, 1500 W.

KARL SUSS / MICROTEC MA-150 is a mask-aligner designed to perform the photolithography process required to construct microelectronic components, such as semiconductor chips. This type of machine is an important tool for the manufacture of circuitry used in industrial processes and consumer products. MICROTEC MA150 uses a process called "step-and-repeat" lithography in order to produce microelectronic parts. This equipment works by first exposing a glass photomask to a light source, causing a pattern of photolithography to be projected onto the substrate being treated. This photomask can be filled with a variety of different patterns which dictate the shape, size, and placement of the patterns which will be etched into the substrate. Next, the substrate is placed onto the stage of KARL SUSS MA 150; a series of stepper motors precisely adjust the substrate's position, or "step and repeat," causing the desired patterns to be aligned. Heated from underneath and exposed to light from the overhead optical system, the substrate is then bombarded with ions to etch the patterns onto the substrate. This process is repeated for as many "masks" as are necessary for the desired product. KARL SUSS / MICROTEC MA 150 is a highly automated unit, which requires very little operator input. Its software package provides comprehensive process recipes which minimize the risk of incorrect alignment and other errors. Additionally, KARL SUSS MA-150 has sophisticated diagnostics, reticles, and photomasks which allow the machine to be used with a wide range of substrates. MA 150 is a highly efficient, cost-effective solution for photolithography processes. It is user-friendly and enables manufacturers to produce microelectronic components quickly and accurately. MA150 is a valuable asset to any production line, providing increased efficiency and enhanced product quality.

There are no reviews yet