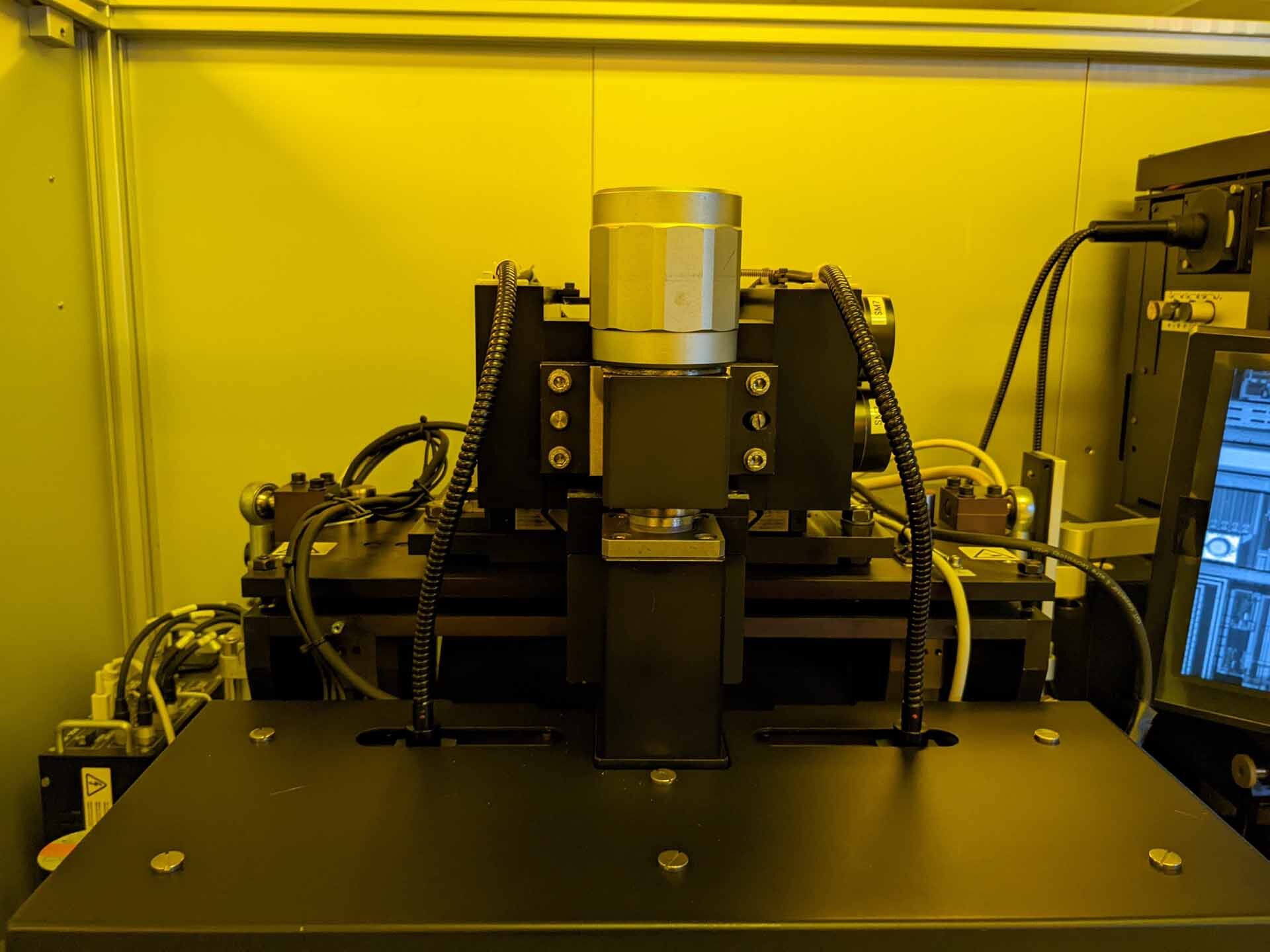

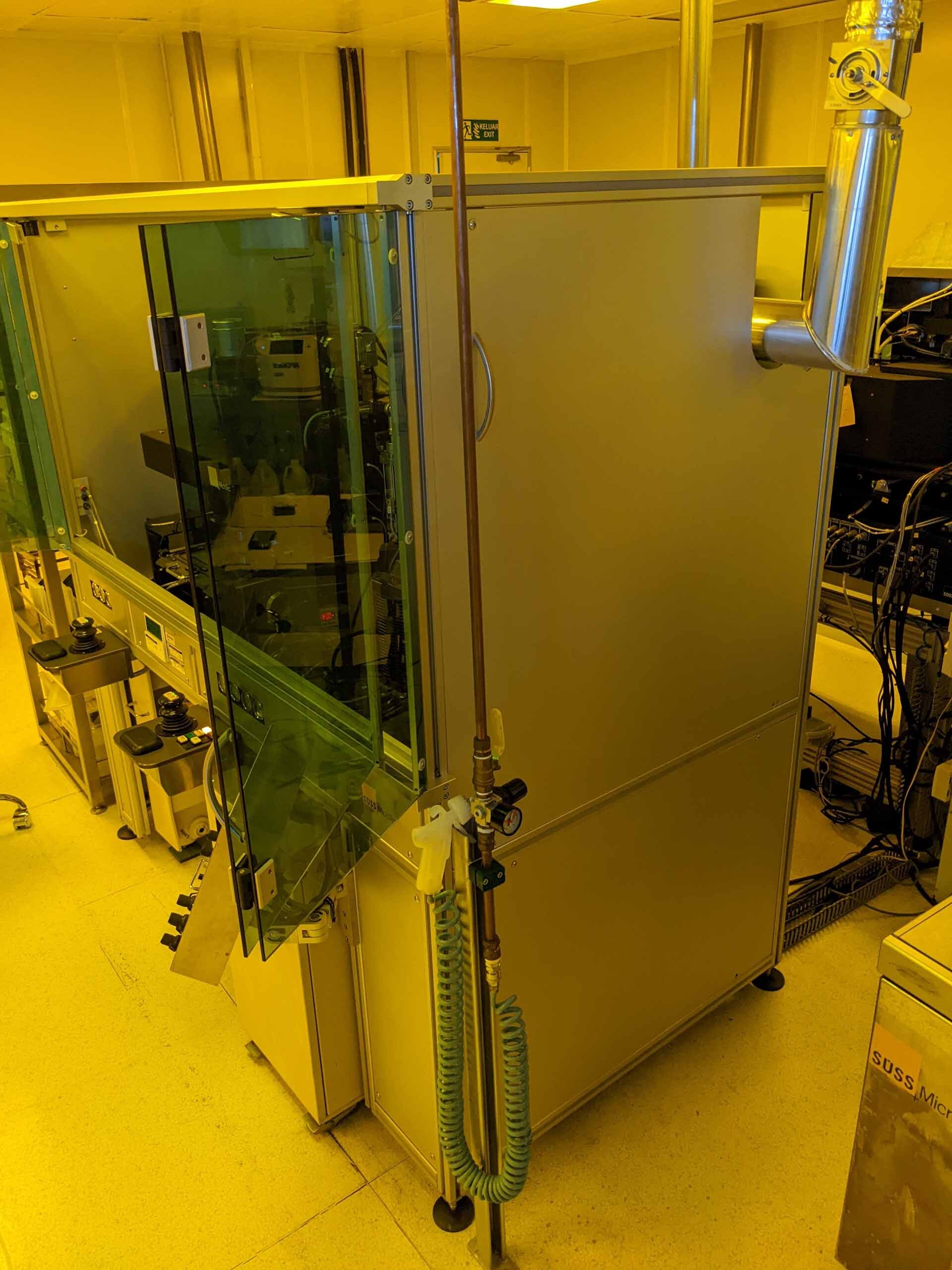

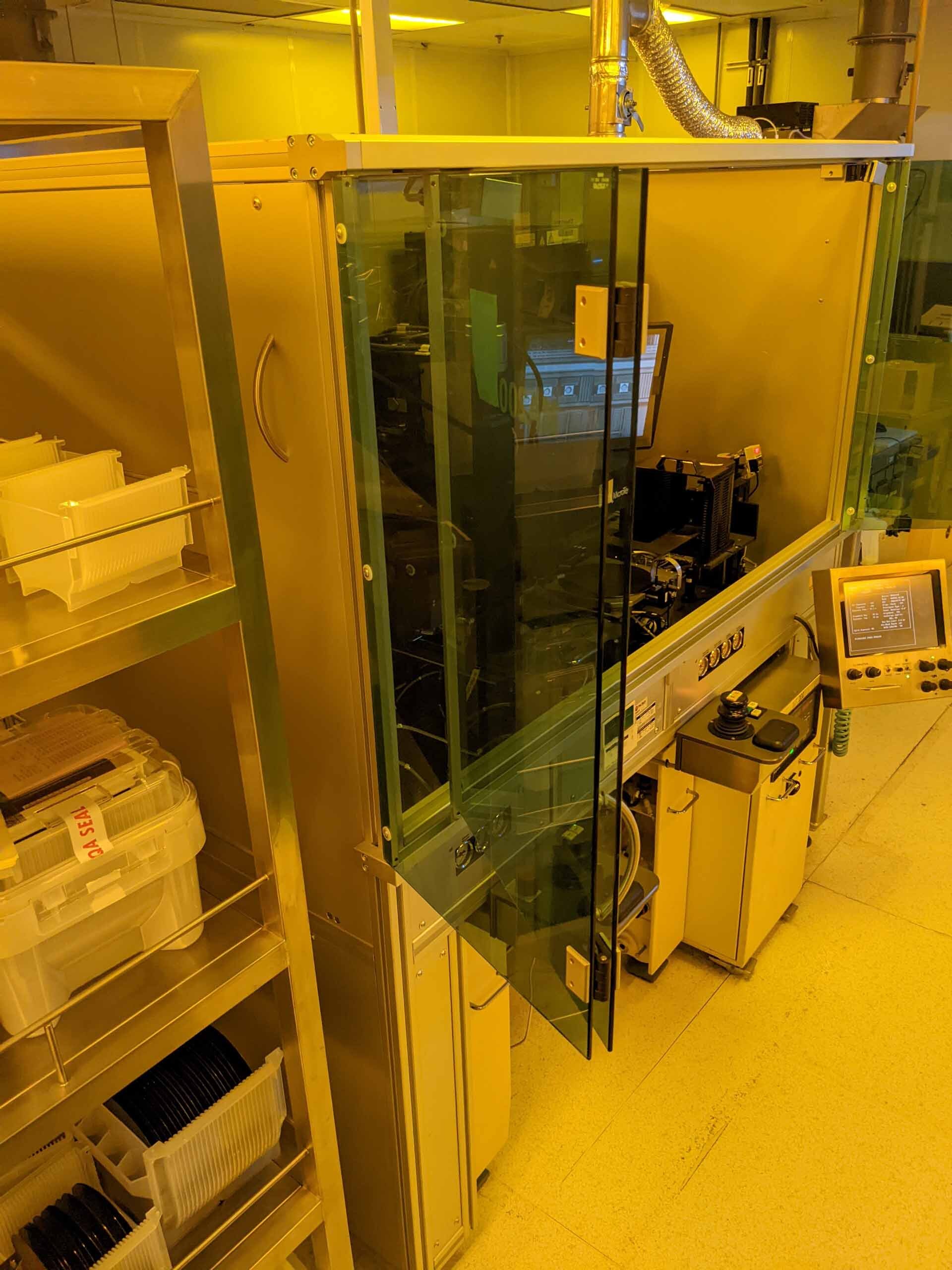

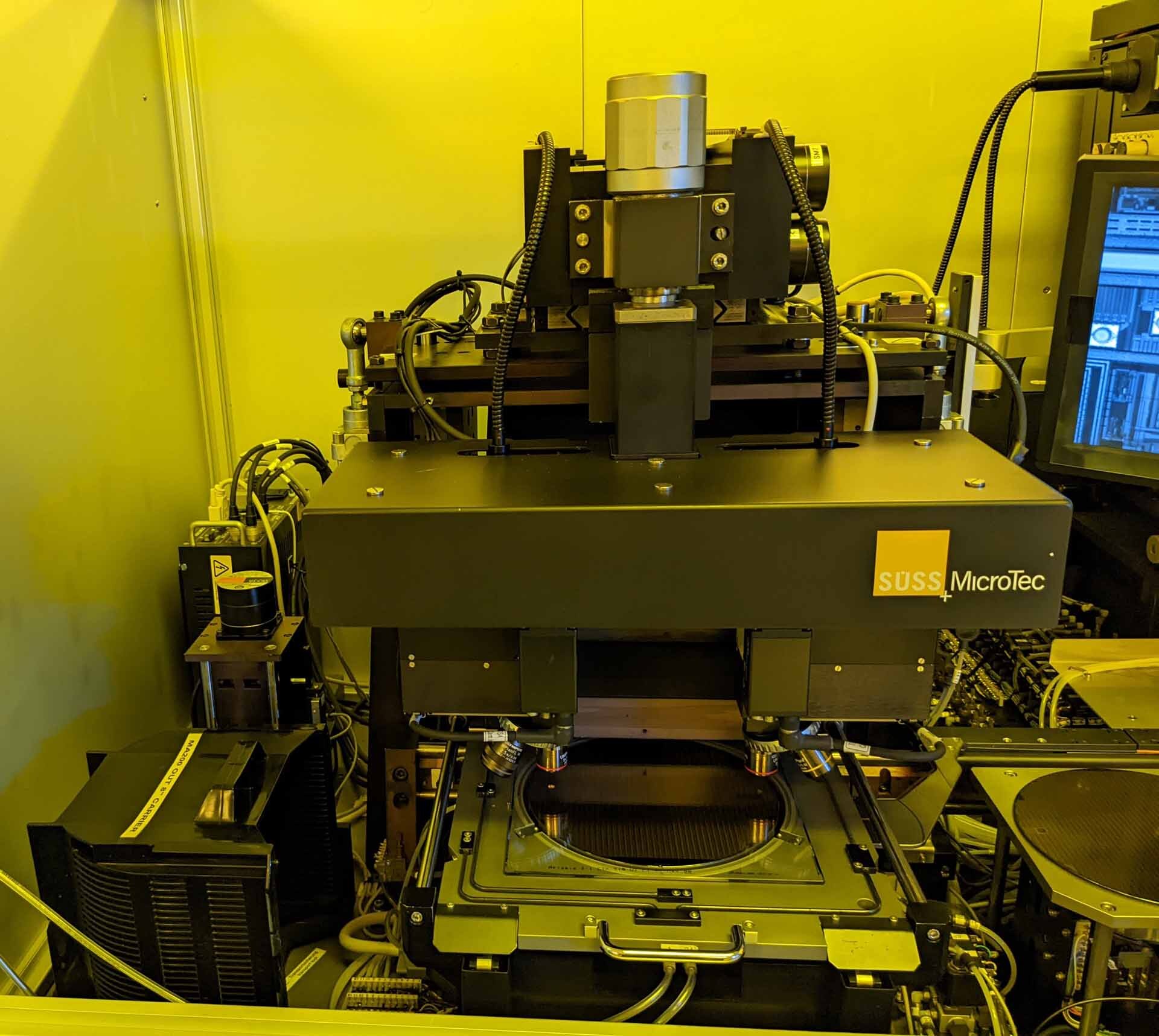

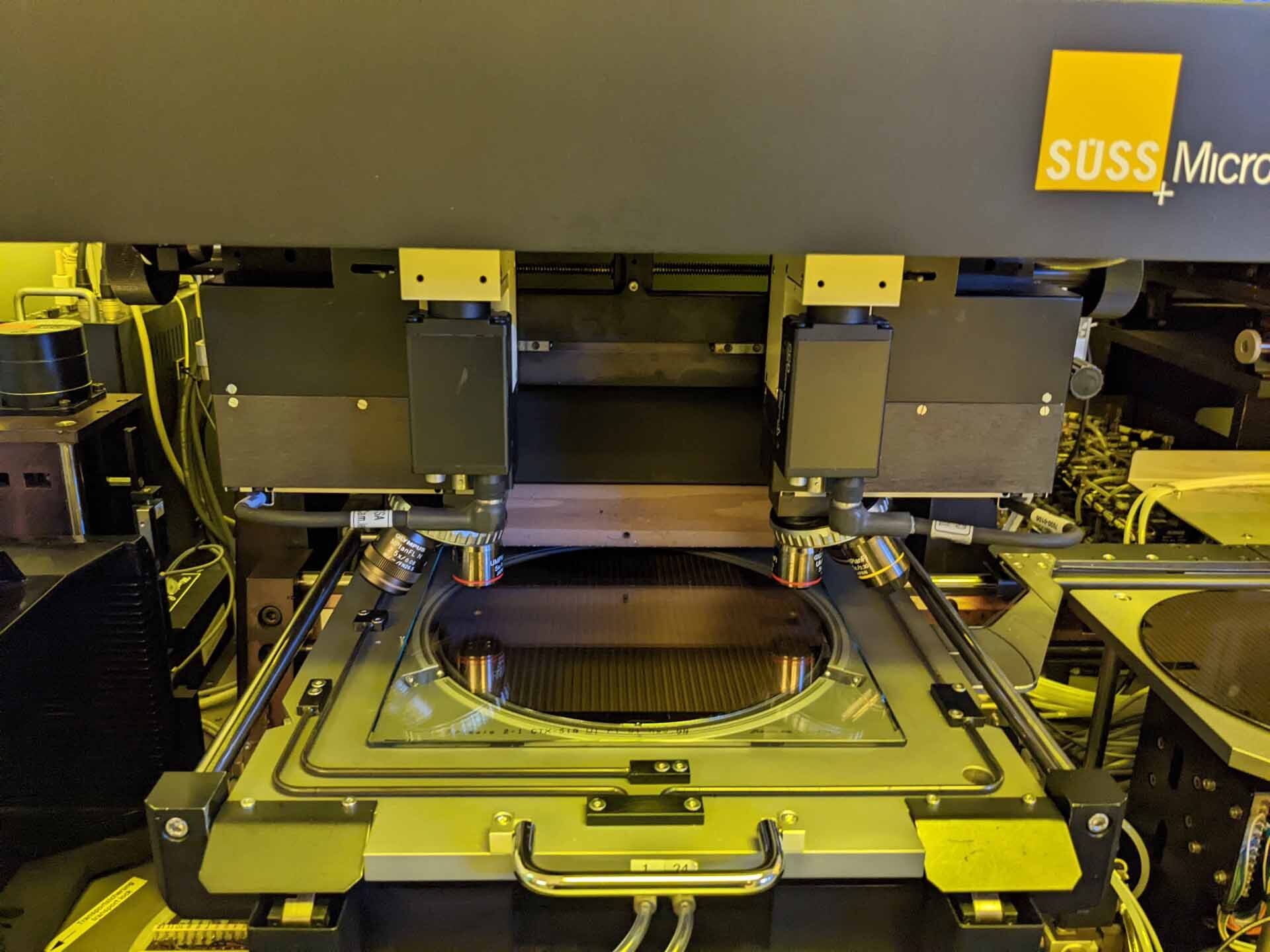

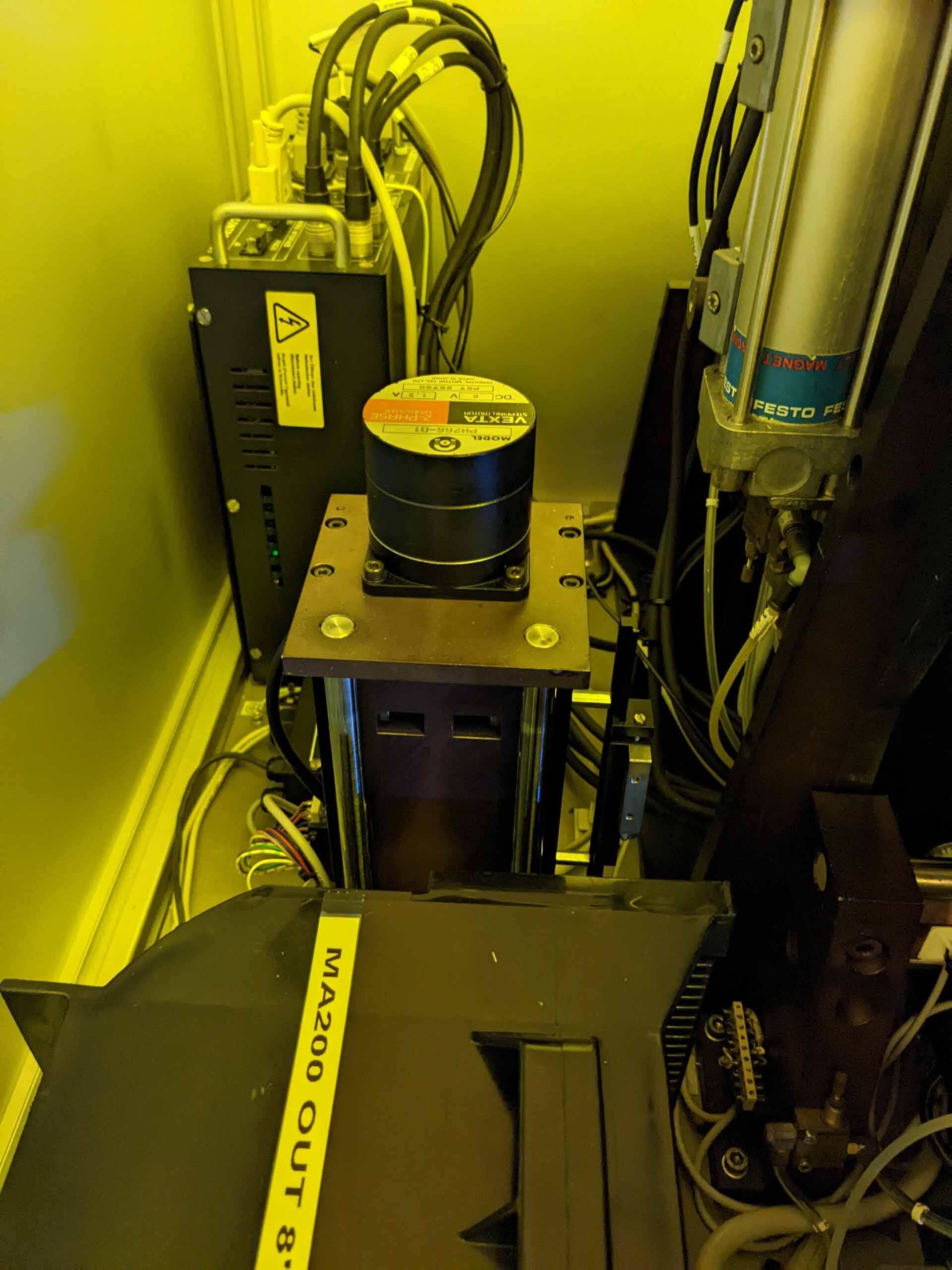

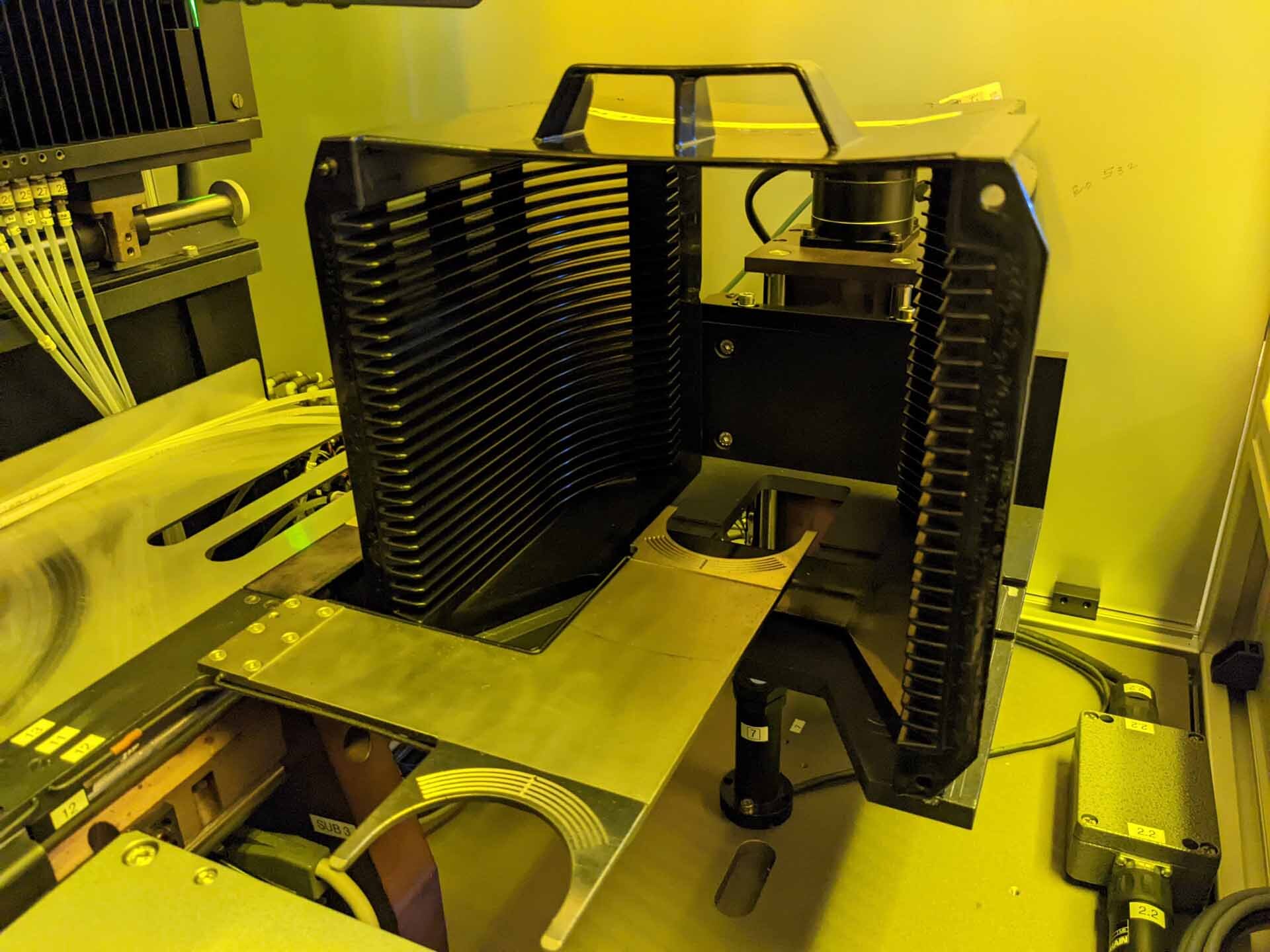

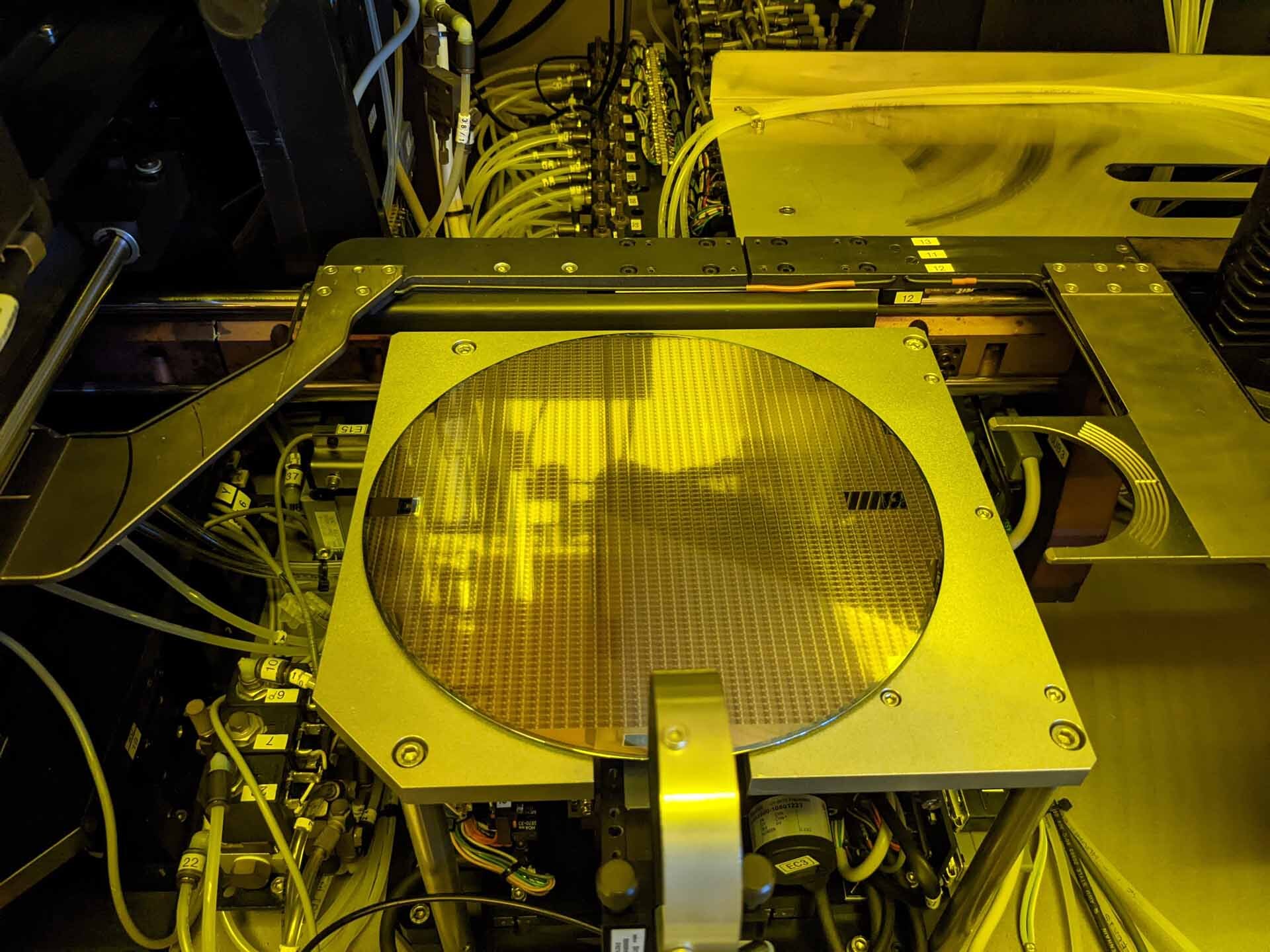

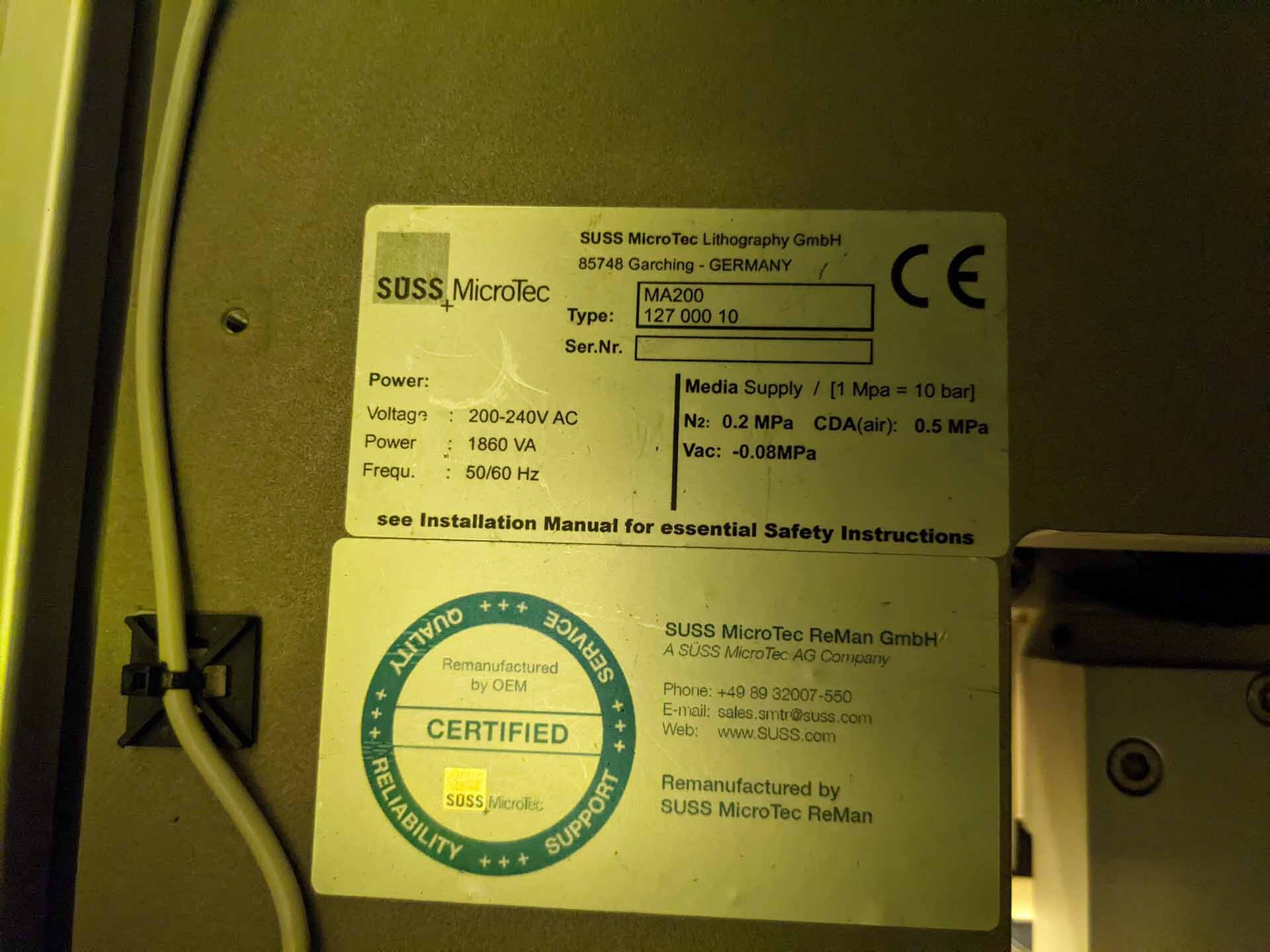

Used KARL SUSS / MICROTEC MA 200 #293618545 for sale

URL successfully copied!

Tap to zoom

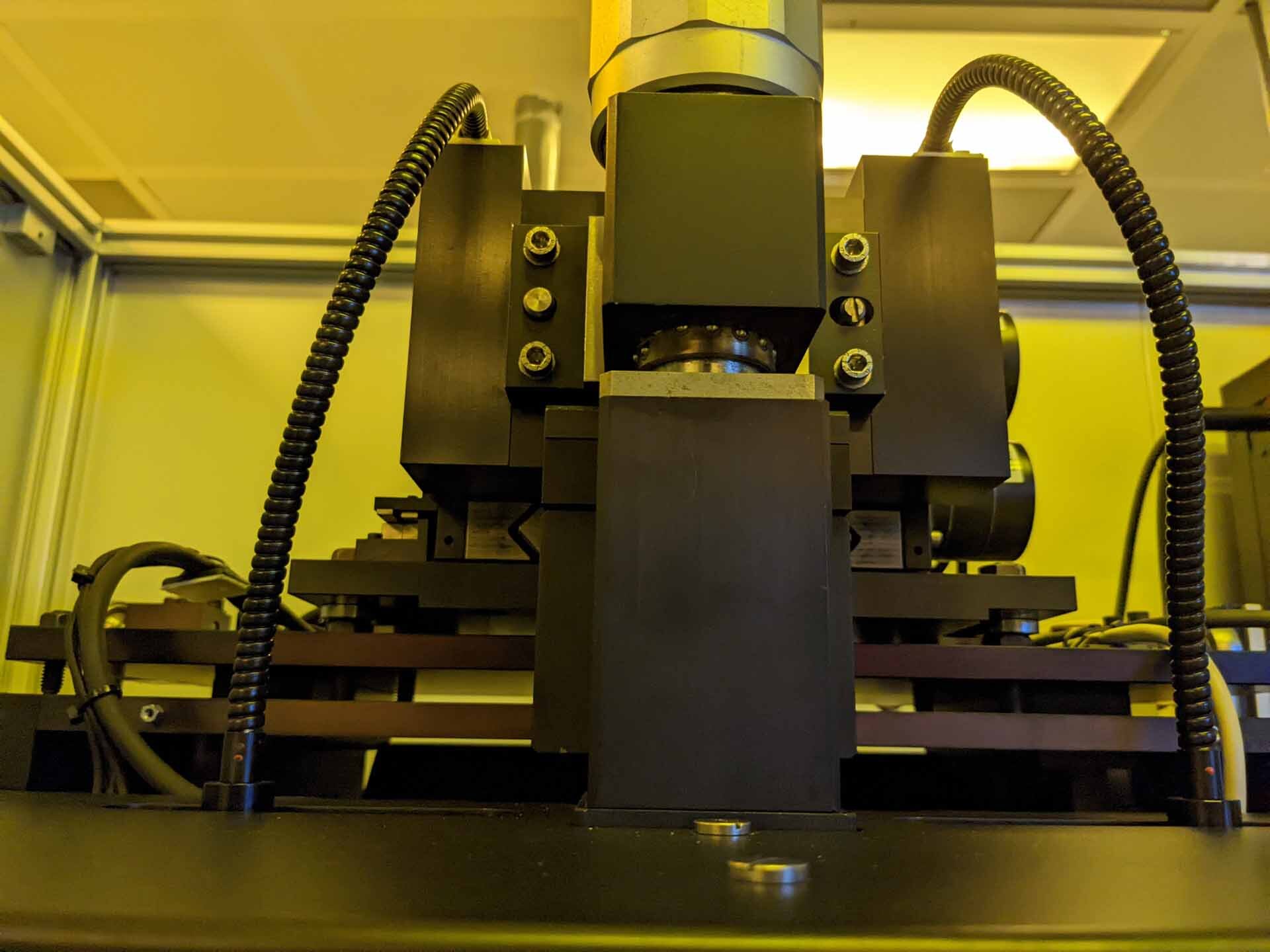

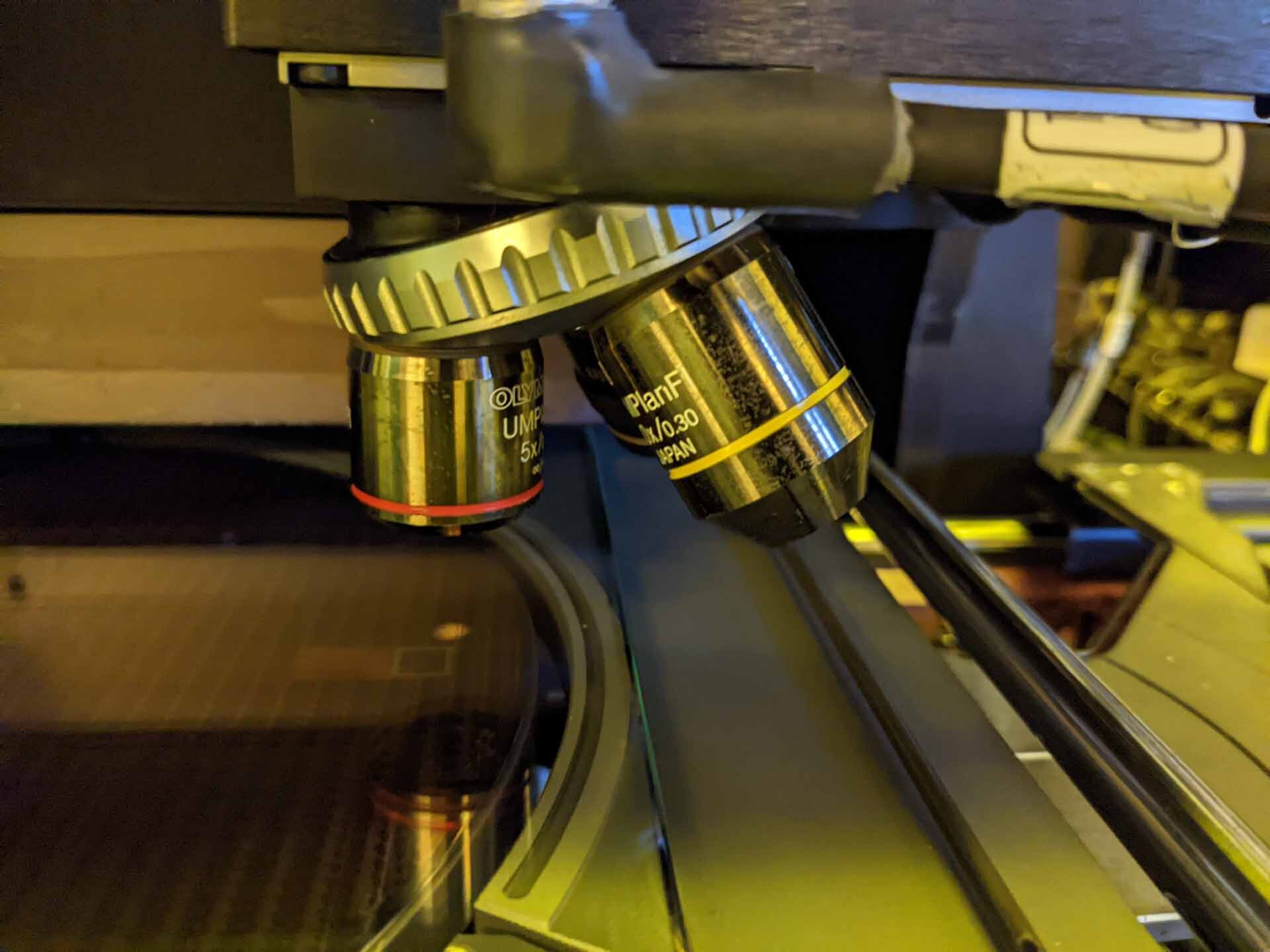

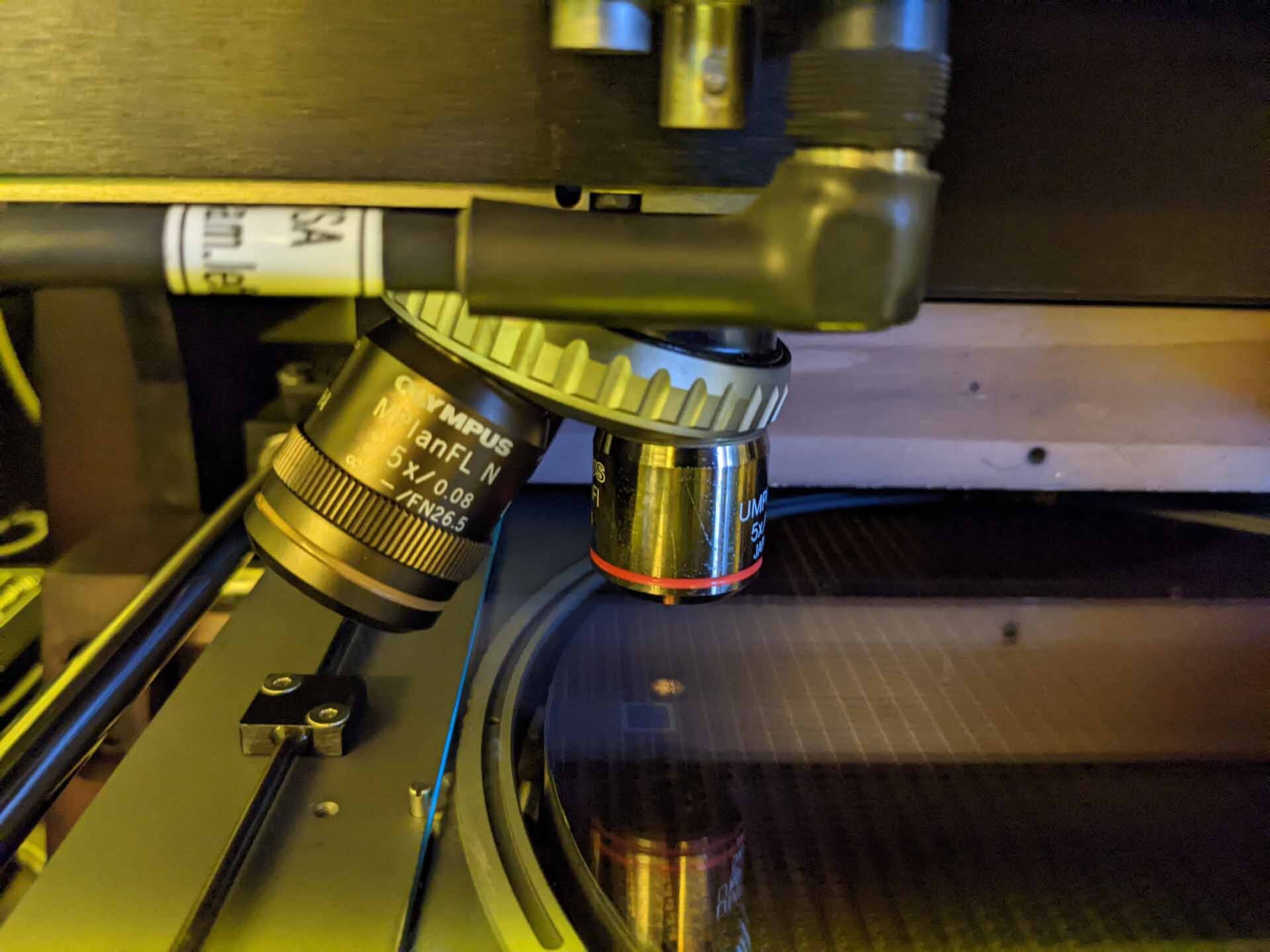

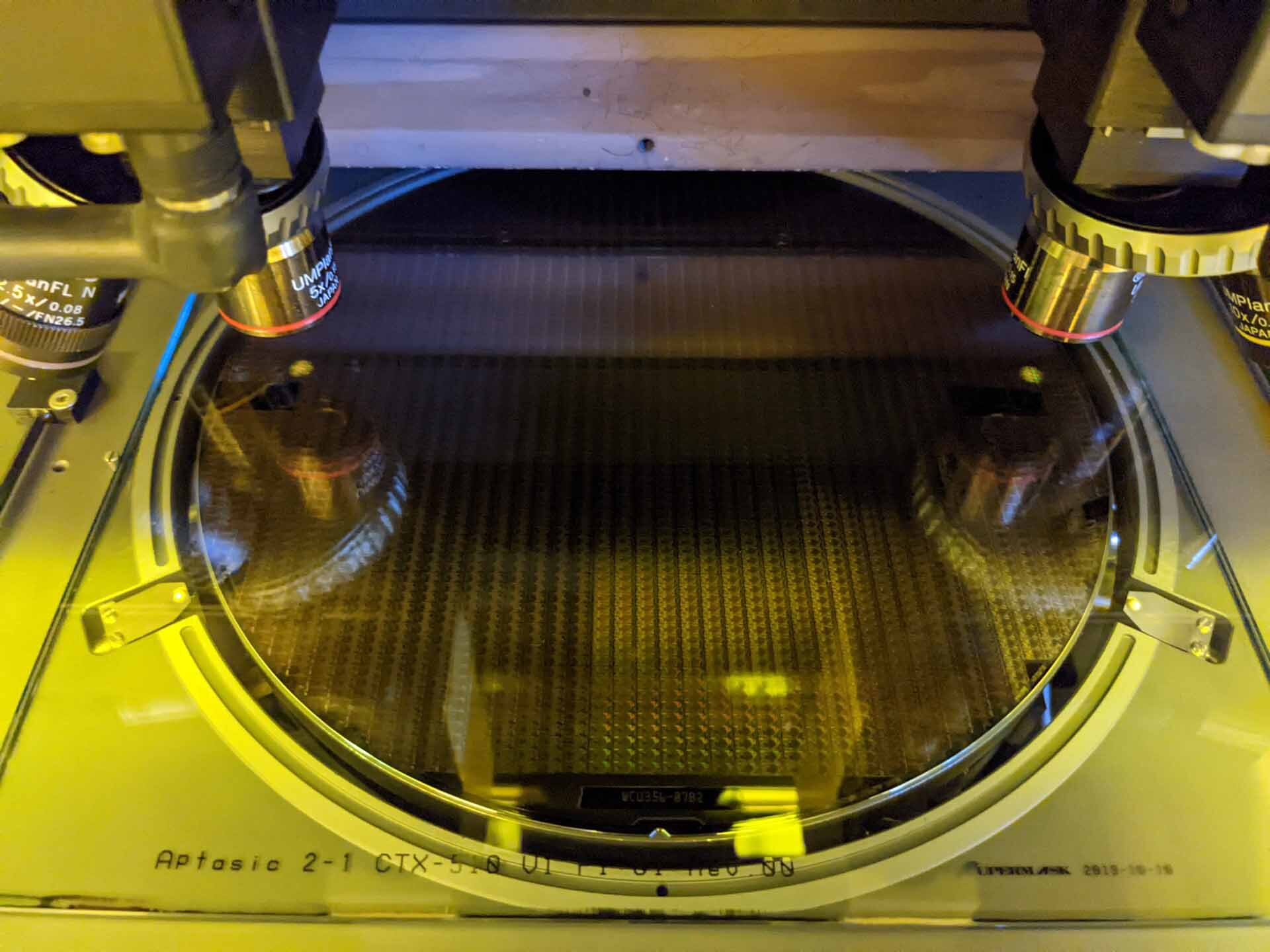

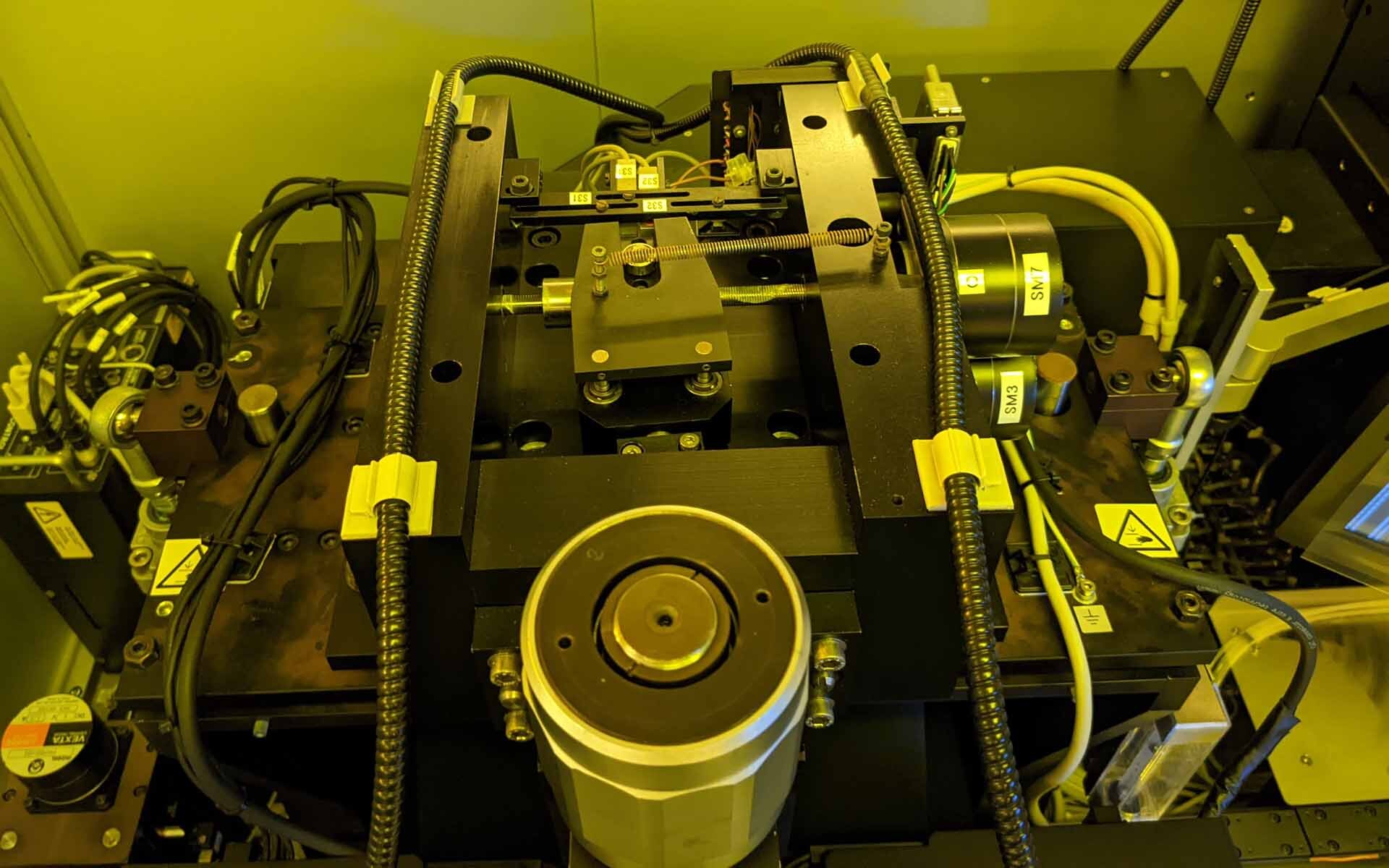

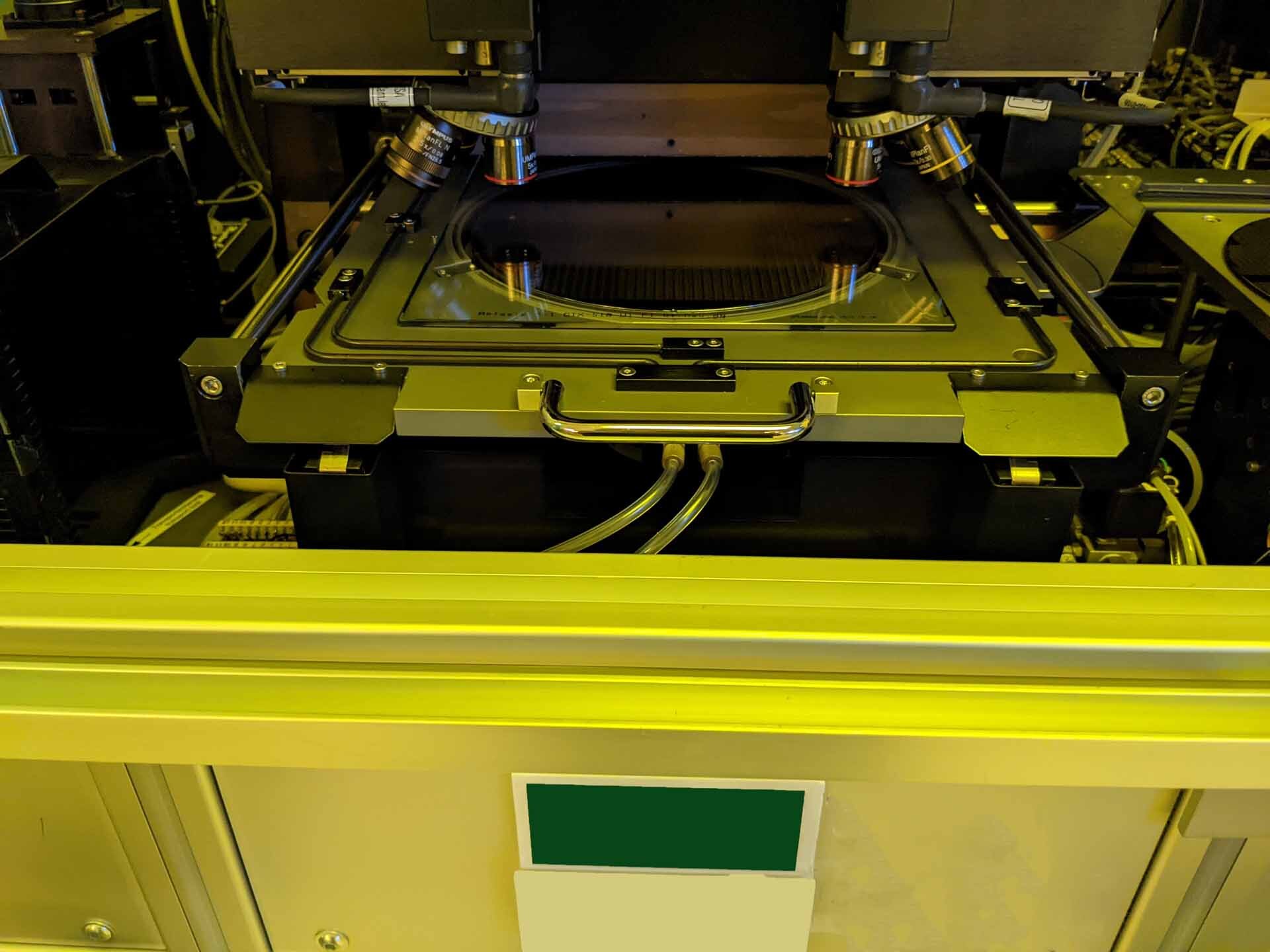

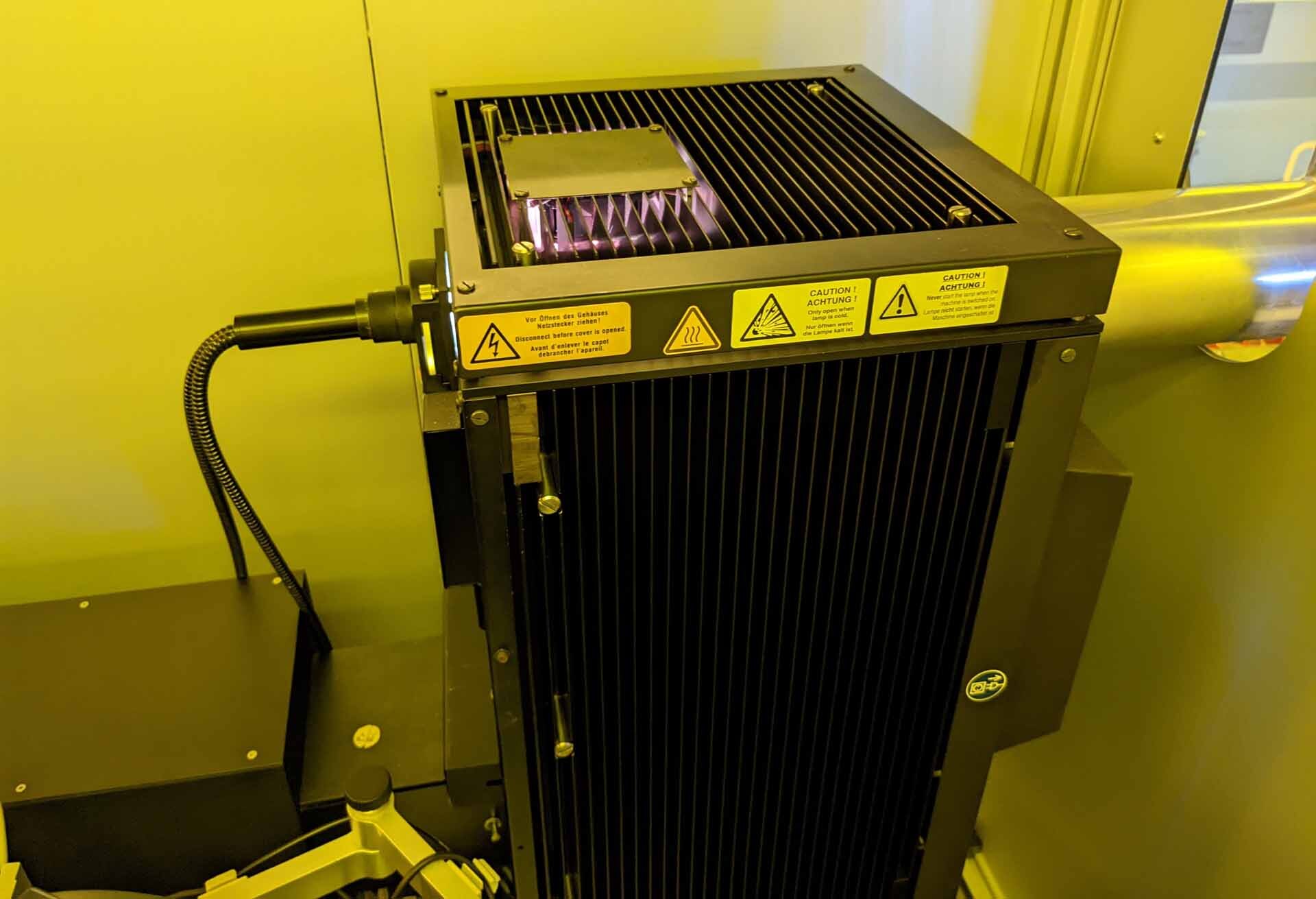

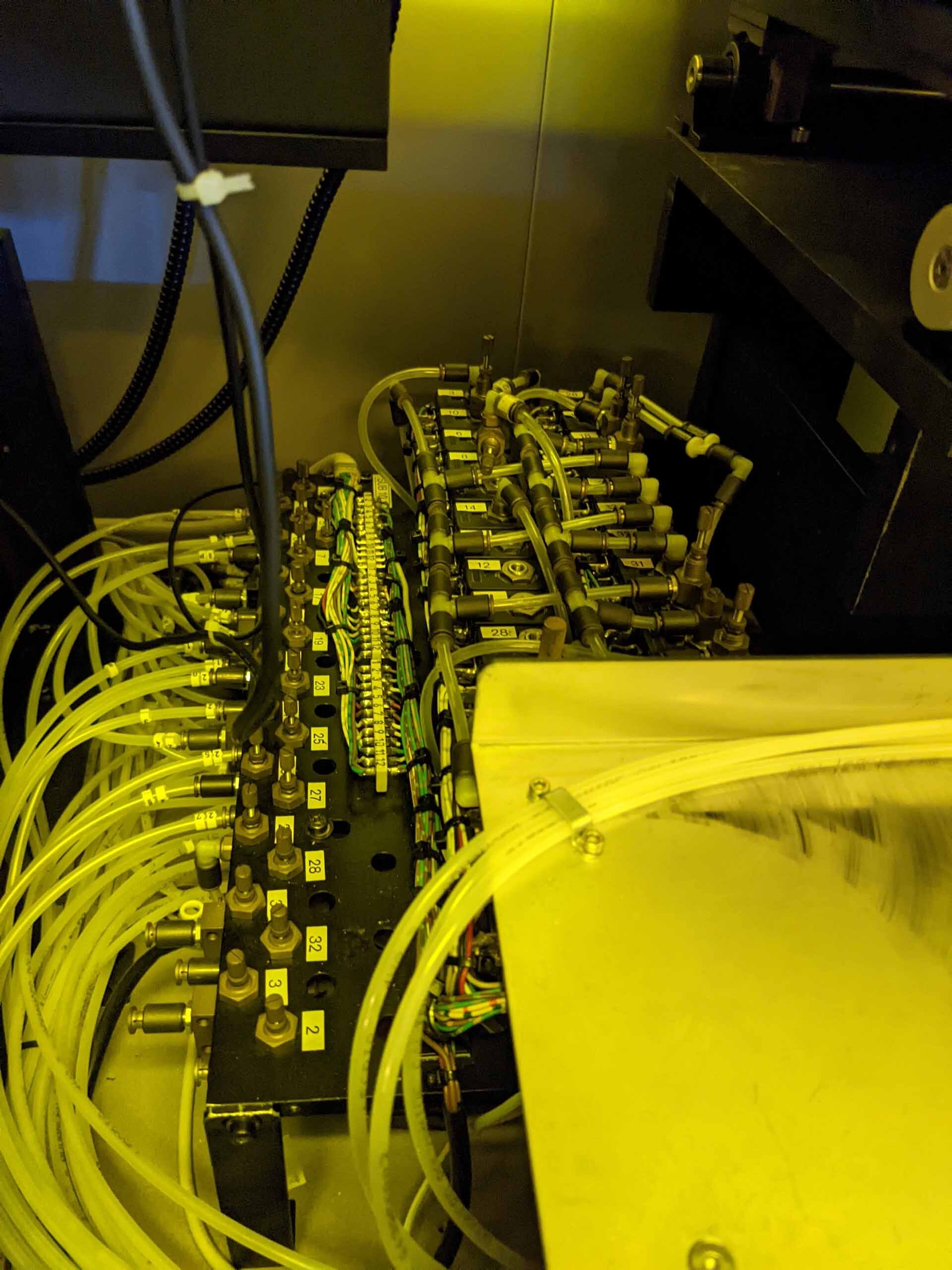

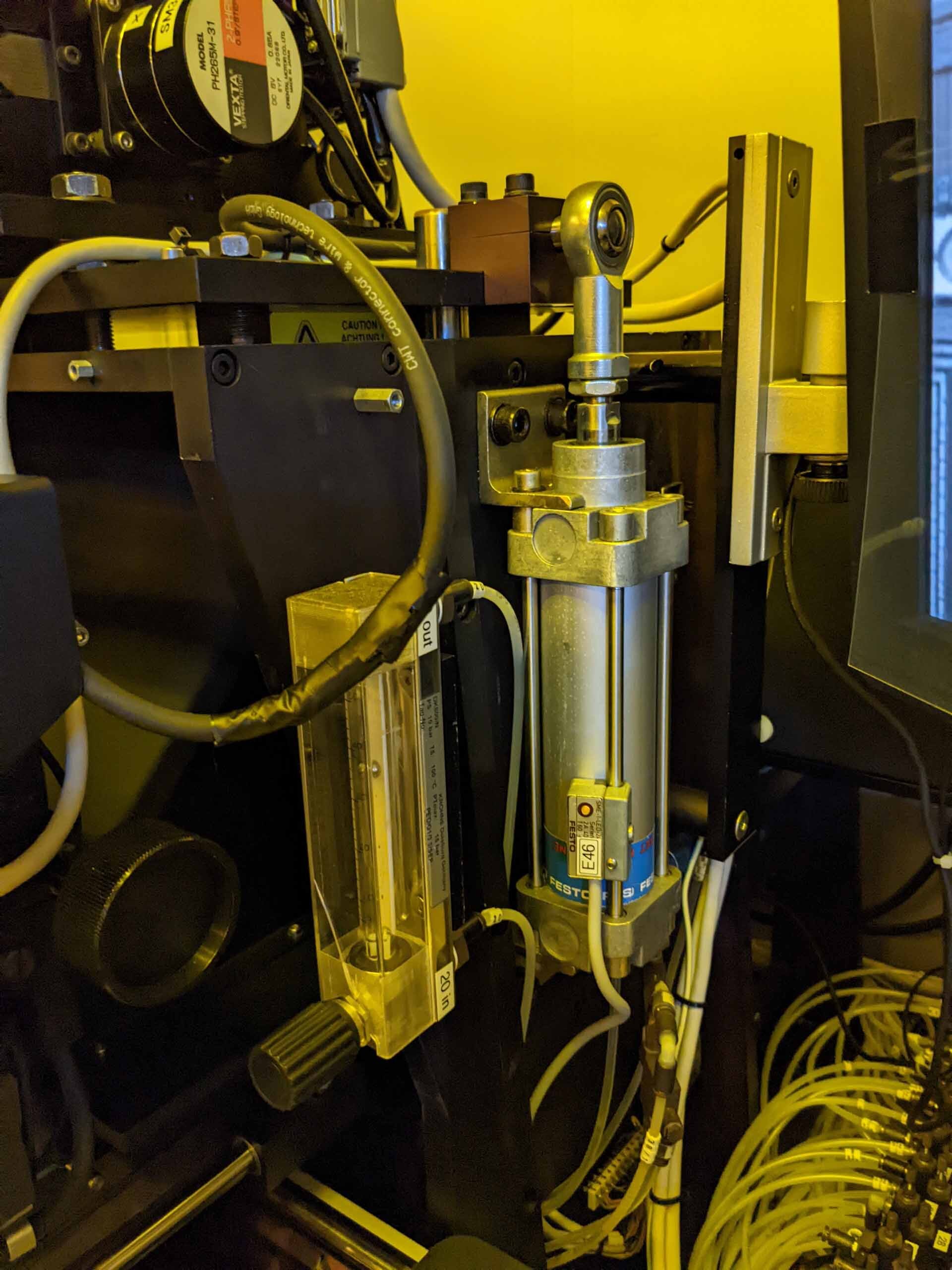

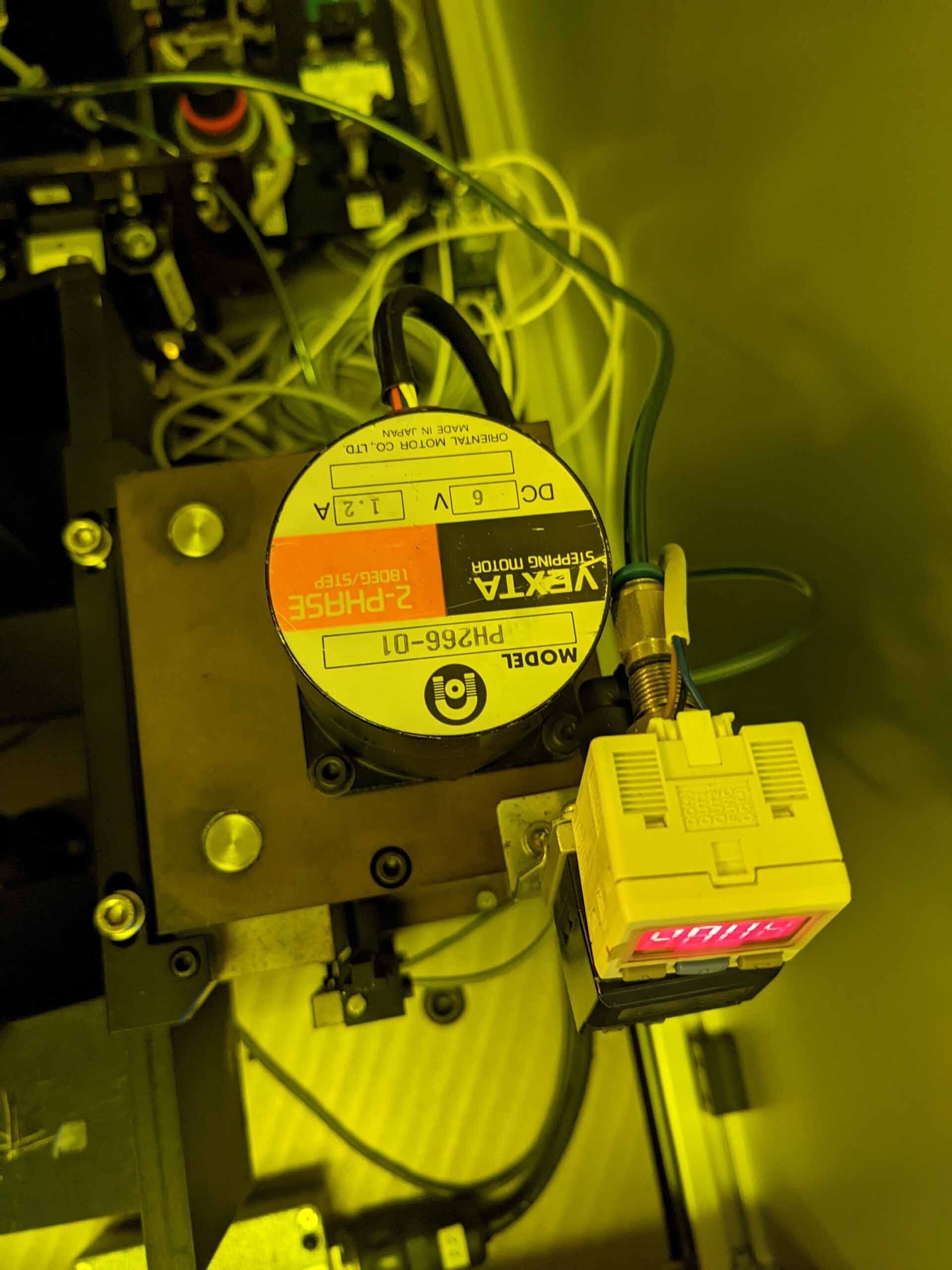

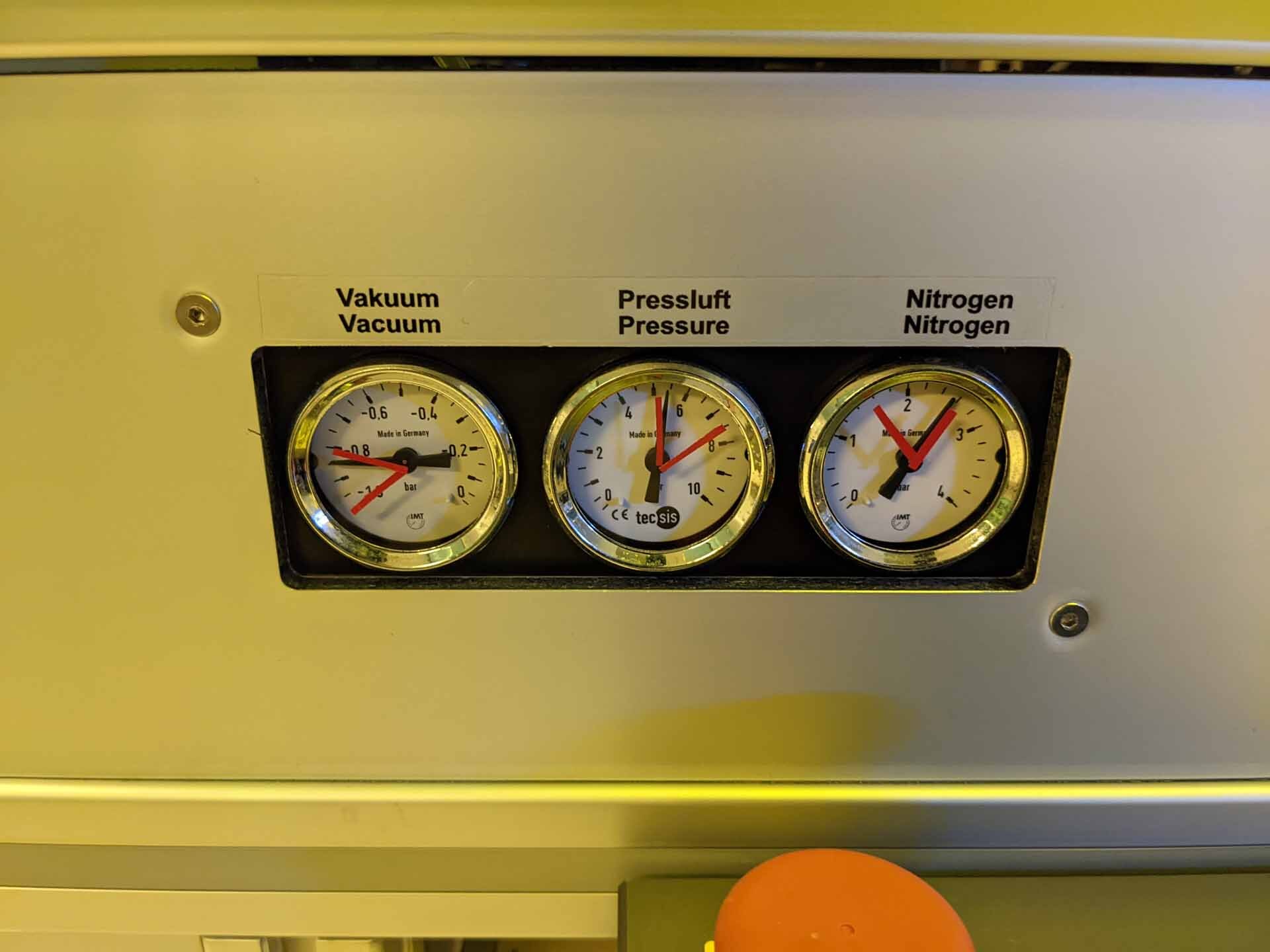

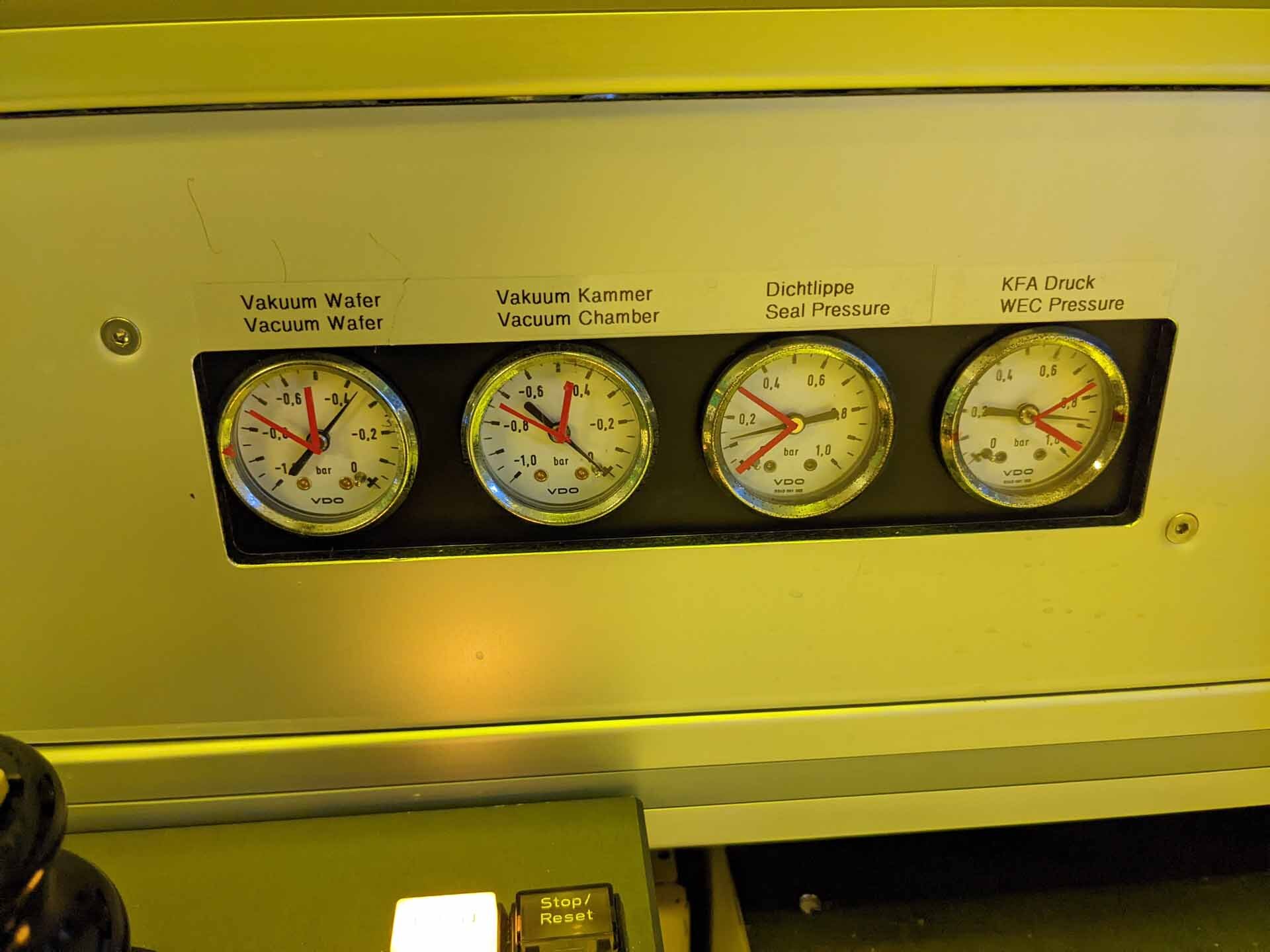

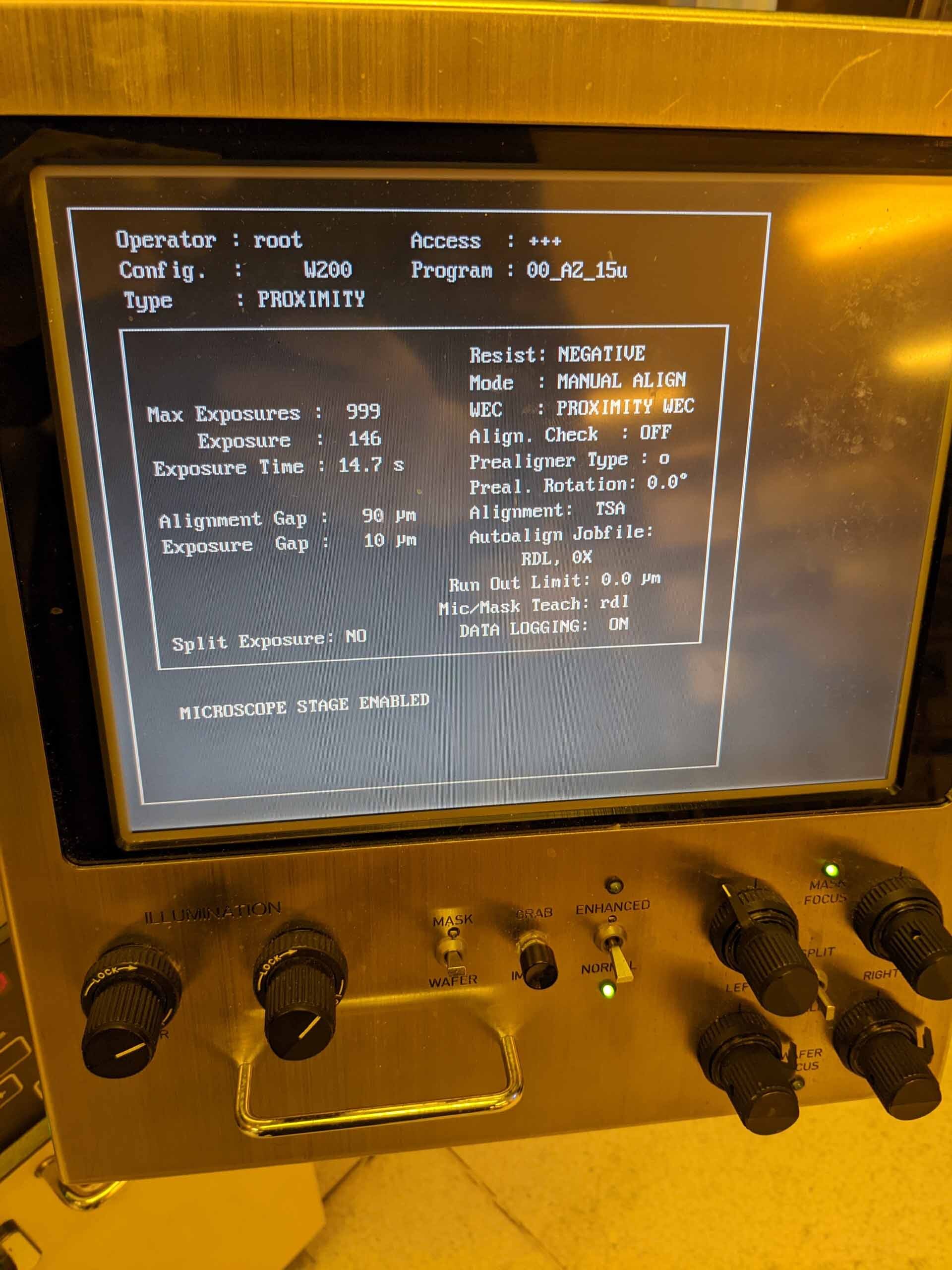

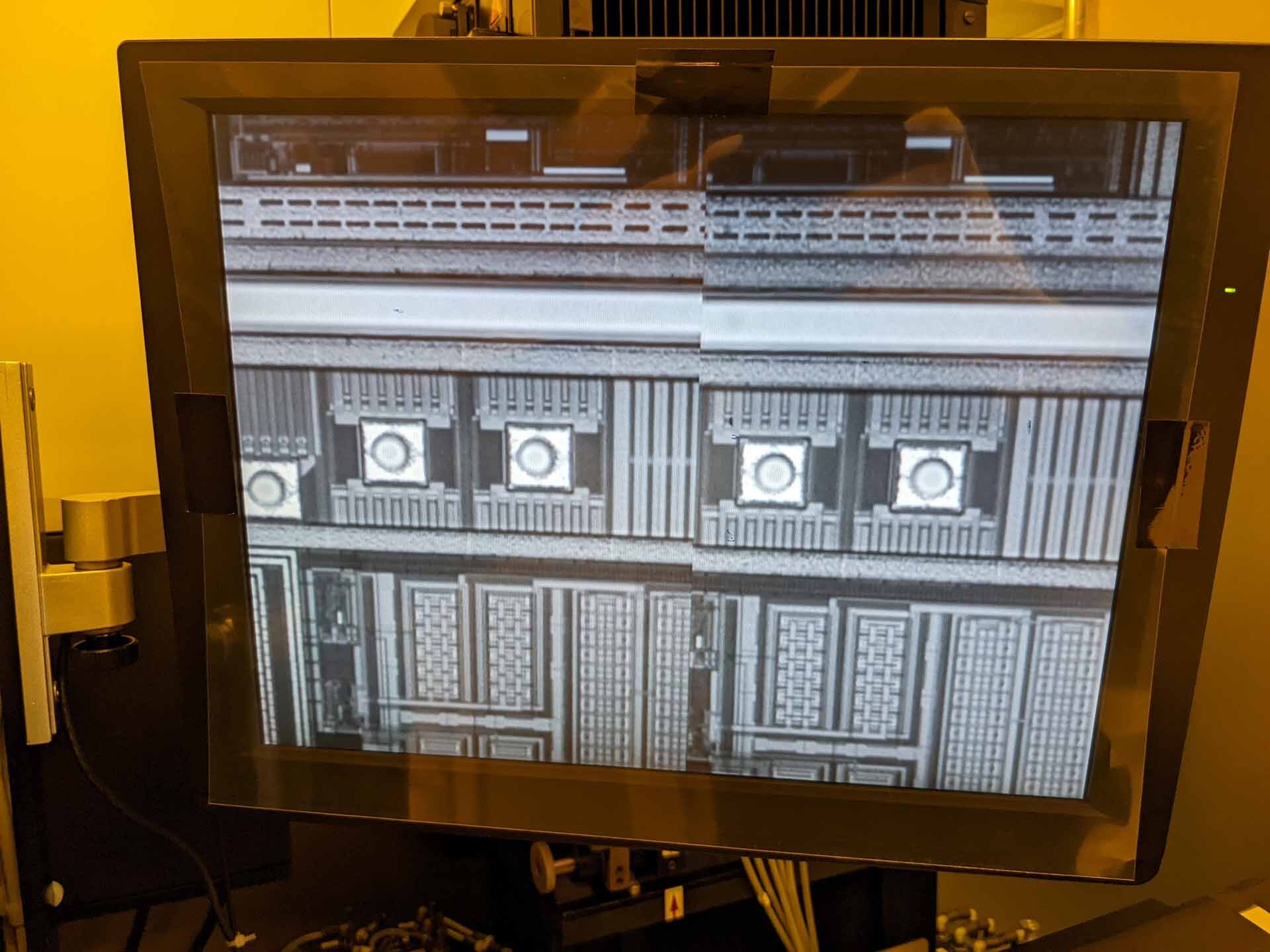

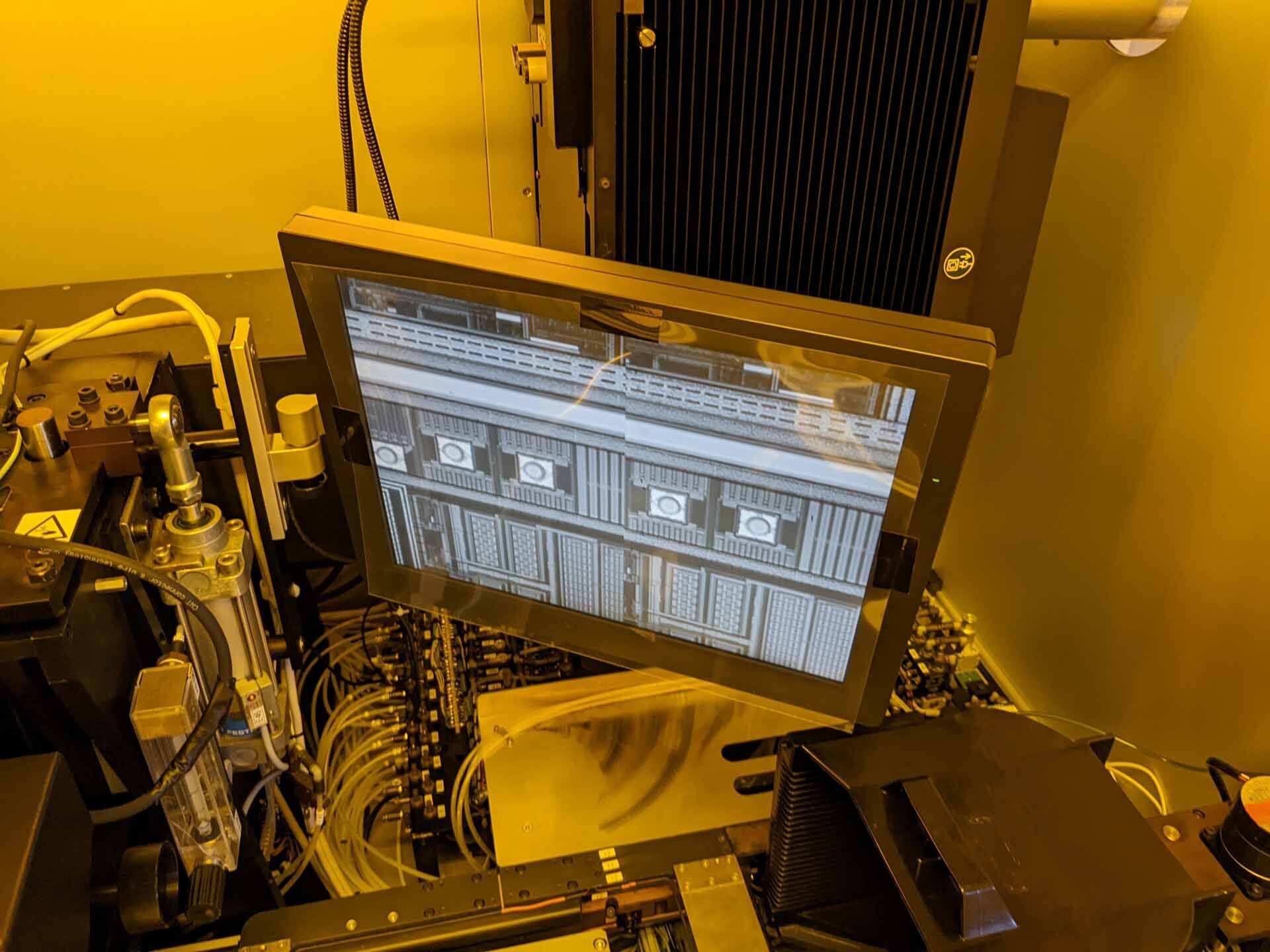

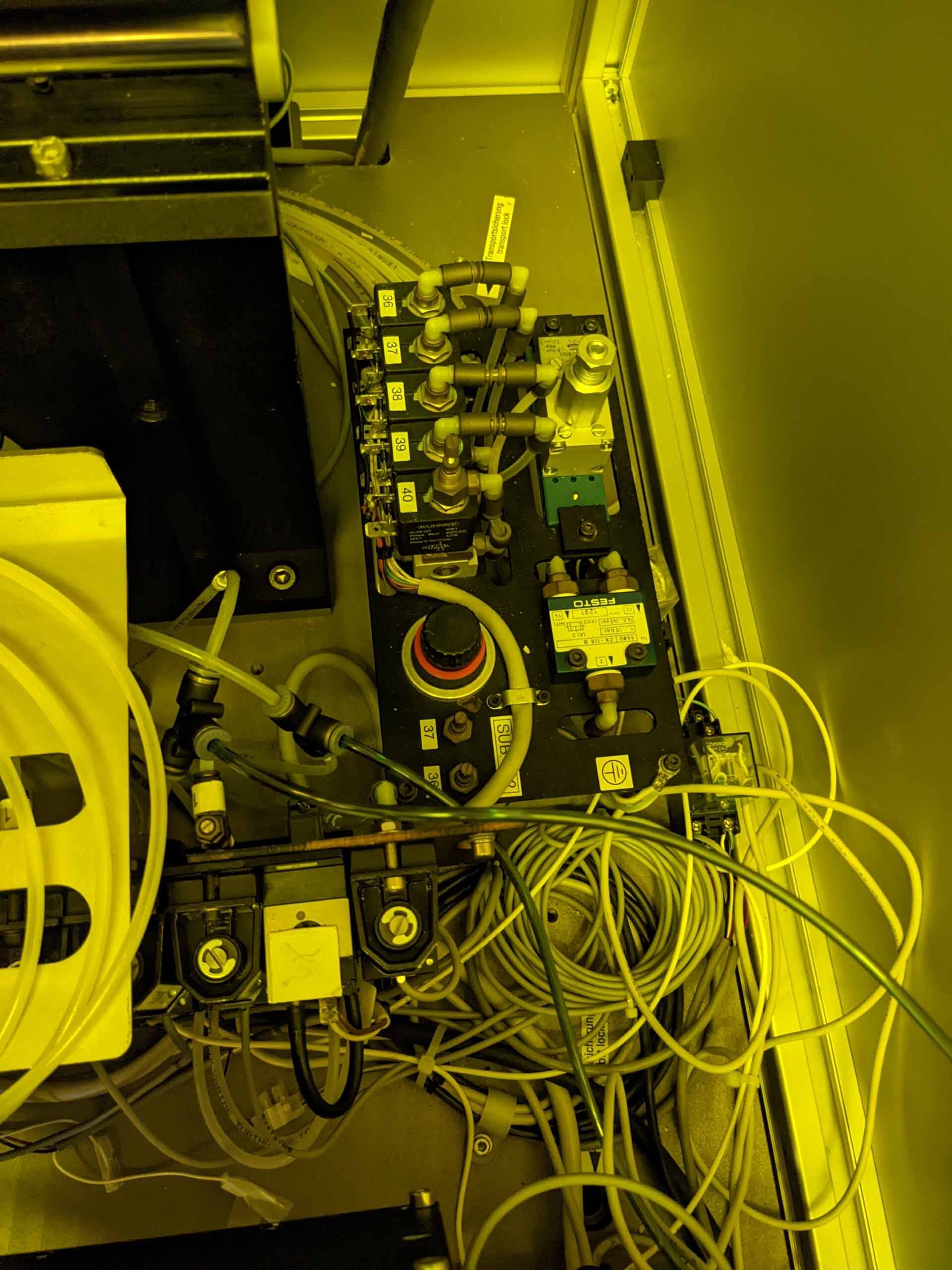

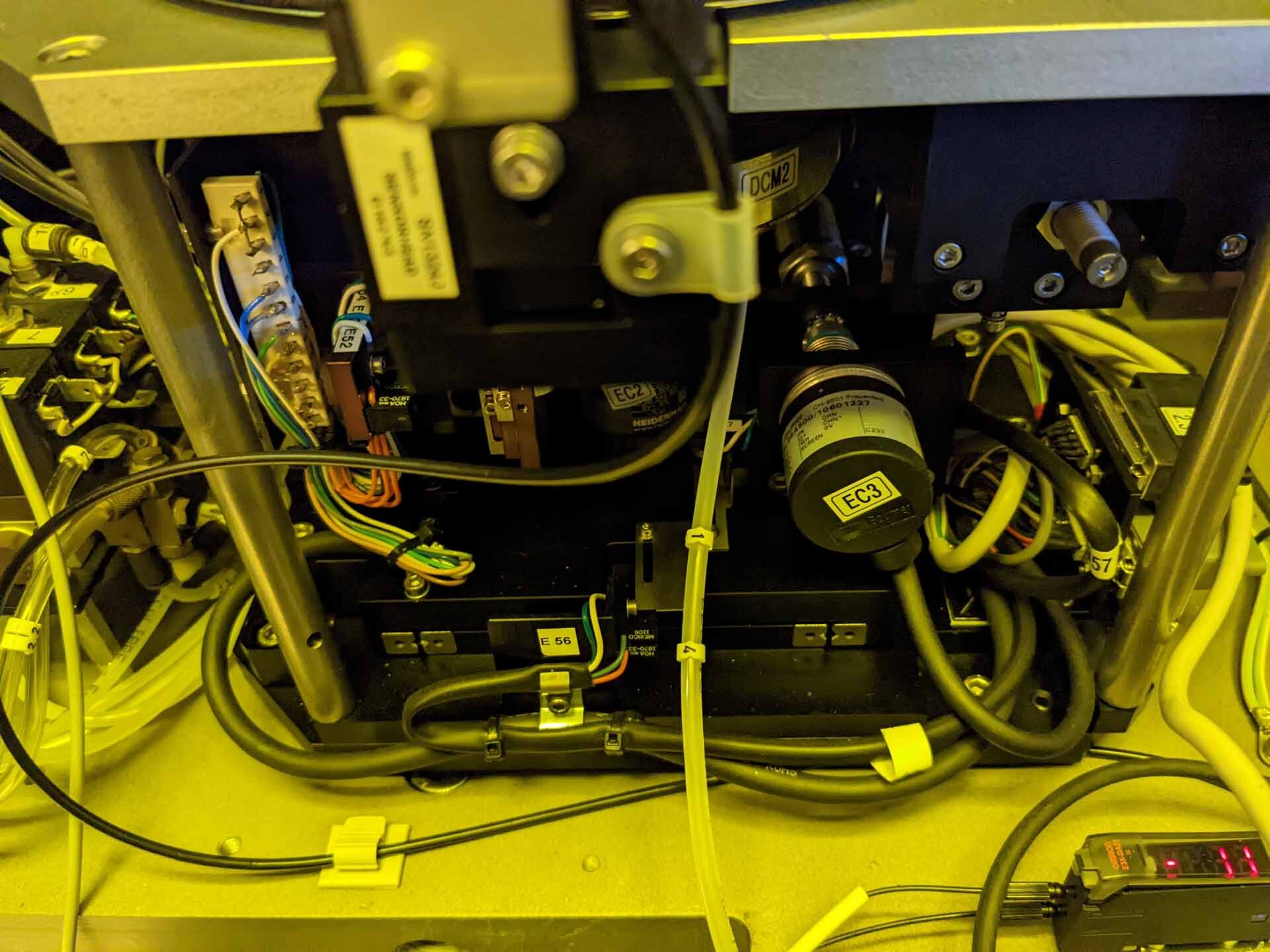

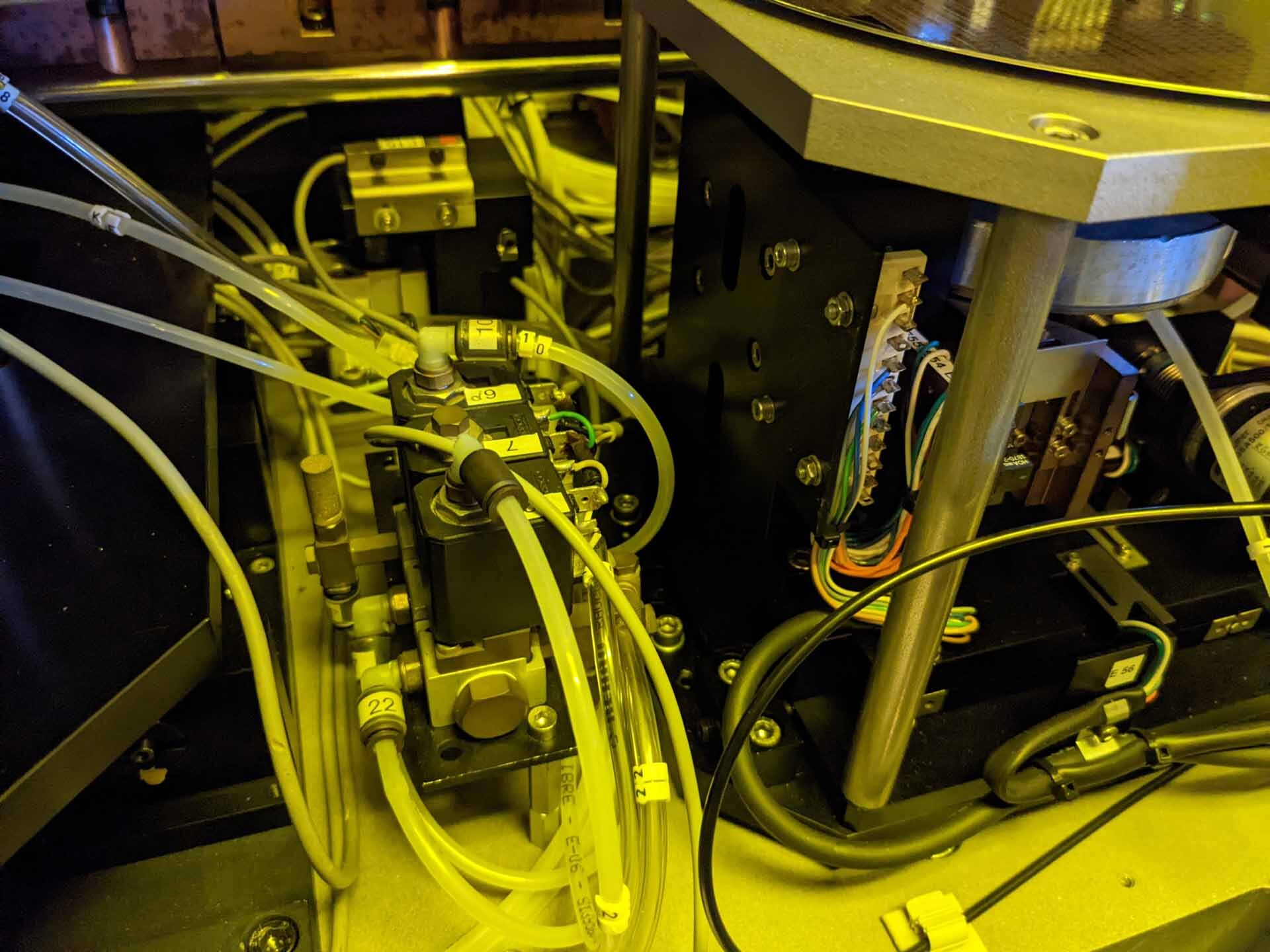

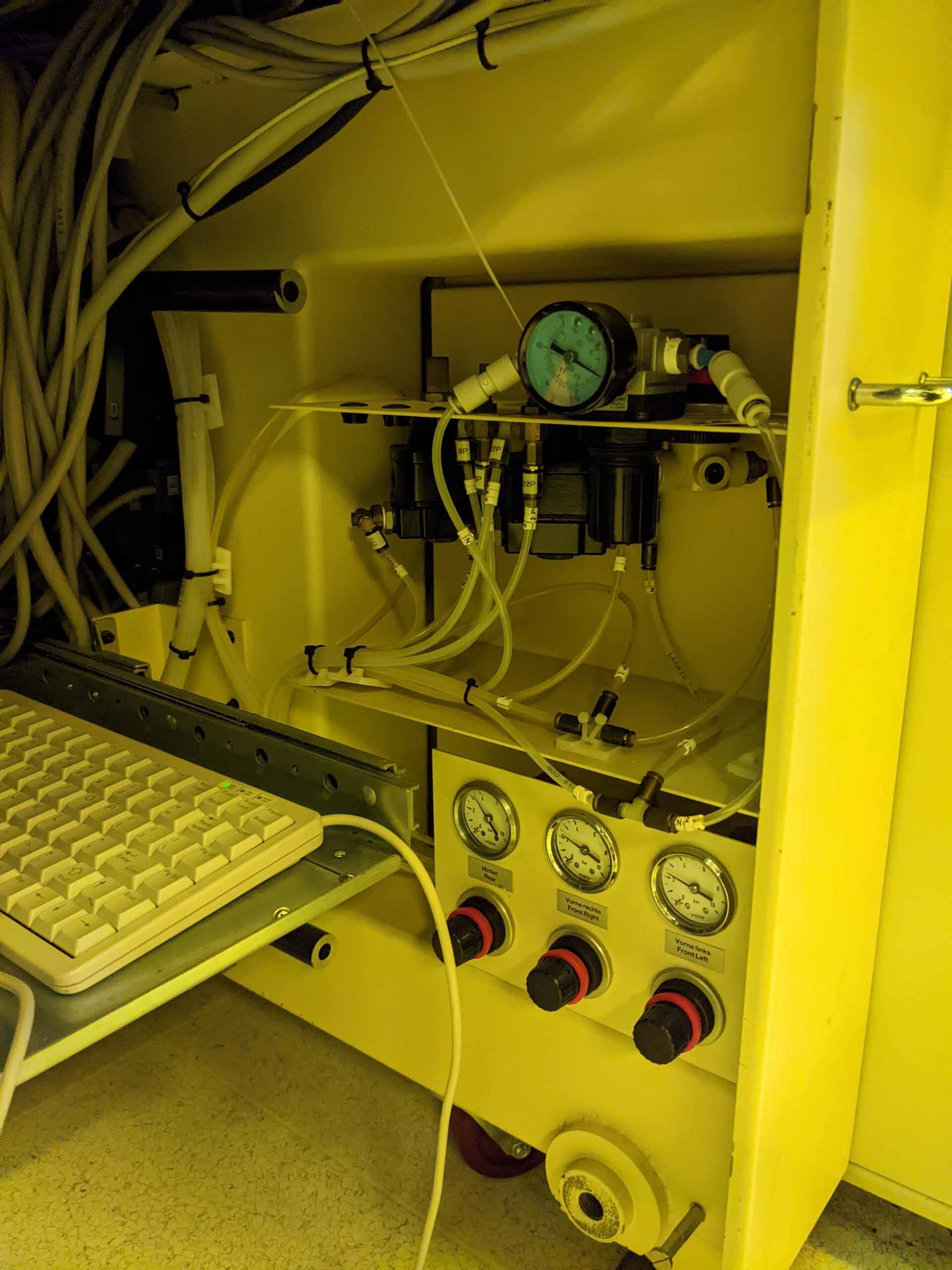

KARL SUSS / MICROTEC MA 200 is a mask aligner designed to expose, develop, and view the mask patterns and alignment marks used in Microelectronics Technology. It is used to create high-precision and intricate patterns on a wide range of substrates, such as photoresists, stainless steel, chrome surfaces, and polysilicon. The machine's Mainframe consists of a selection of optional components and can support up to four Substrate Bases, allowing for flexibility as well as a range of productivity and cost-saving options. Users operate the Mask Aligner through a Color TFT Touch-Screen, providing a convenient and intuitive interface. Different alignment methods are available, including edge following and special alignment techniques such as with off-axis shift to register IC features at a defined offset and at a user-specified accuracy. MICROTEC MA200 utilizes an advanced optical equipment with a wavelength of 365 nm, providing an integrated NA of 0.40. This system delivers excellent resolution, good field-by-field flatness and constant illumination. For pattern viewing, a high-resolution CCD sensor with 4096 x 4096px resolution is installed. For accurate alignment of critical contact hole patterns, a special Single-Pupil Aperture is available, which helps reduce the amount of light passing through the mask. This provides a distinct light edge that can be precisely aligned with the intended target area. KARL SUSS MA-200 is also equipped with an Automated Developing Station, which automatically transfers substrates to the Developer, replenishes the chemical, then returns them to the module. This eliminates process downtime, improving throughput. For further user-friendliness, self-calibration capabilities are provided with pattern verification, automatically comparing the alignment pattern or alignment marks with standard references stored in the unit. For further data protection, the machine includes an Autowrite Function, allowing for image processing parameters to be stored and recalled in the event of a power outage. This ensures that all settings and then information processed is preserved. Finally, MA-200 comes with a powerful Windows-based software, which is used to control the machine and manage process data. The software provides extensive reporting capabilities, along with comprehensive process data preview and post-processing options. The software can also transfer calibration parameters from one machine to another or from a pattern library to another, allowing for easy reproducibility.

There are no reviews yet