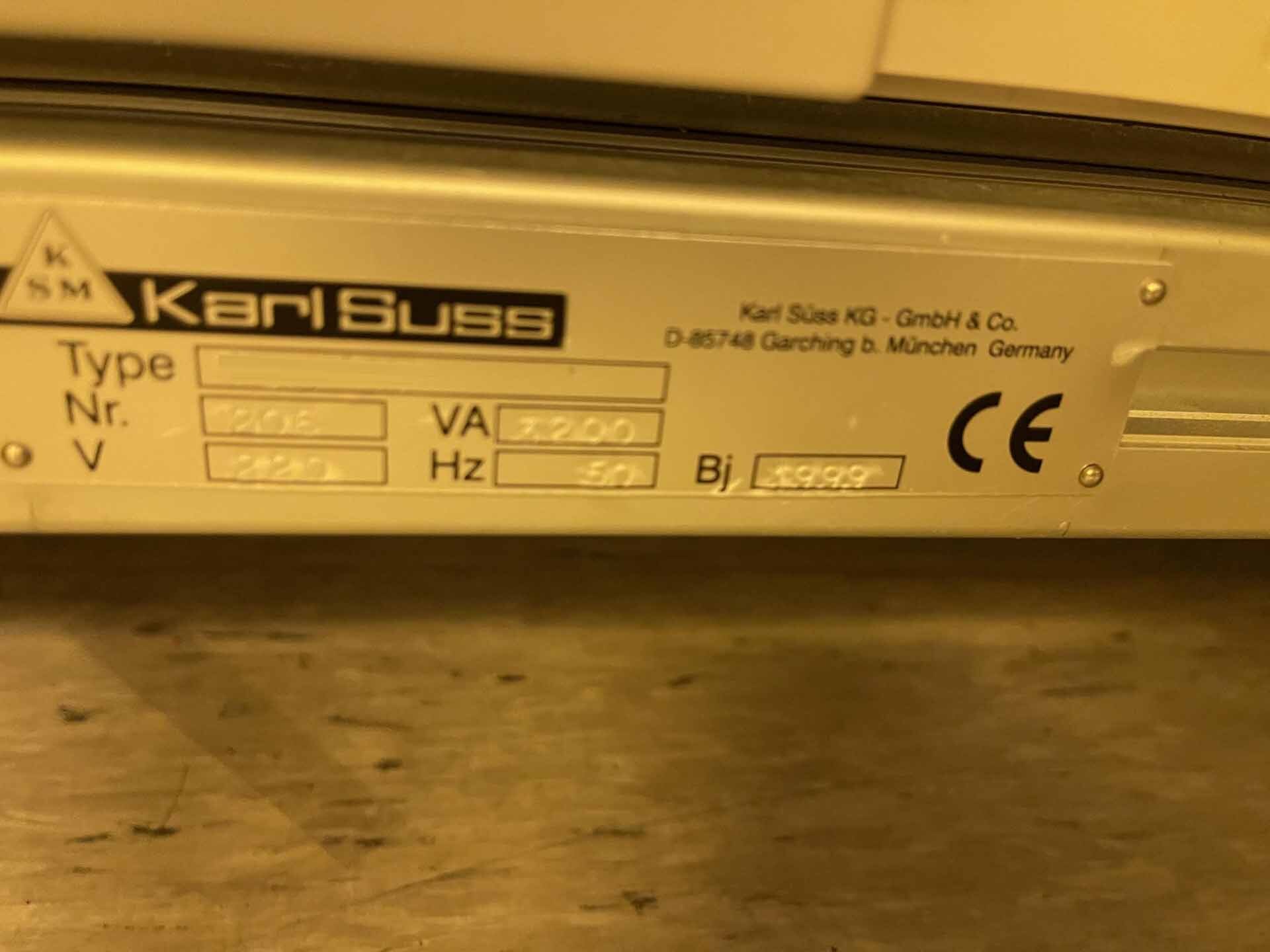

Used KARL SUSS / MICROTEC MA 200 #9373260 for sale

URL successfully copied!

Tap to zoom

ID: 9373260

Wafer Size: 8"

Vintage: 2000

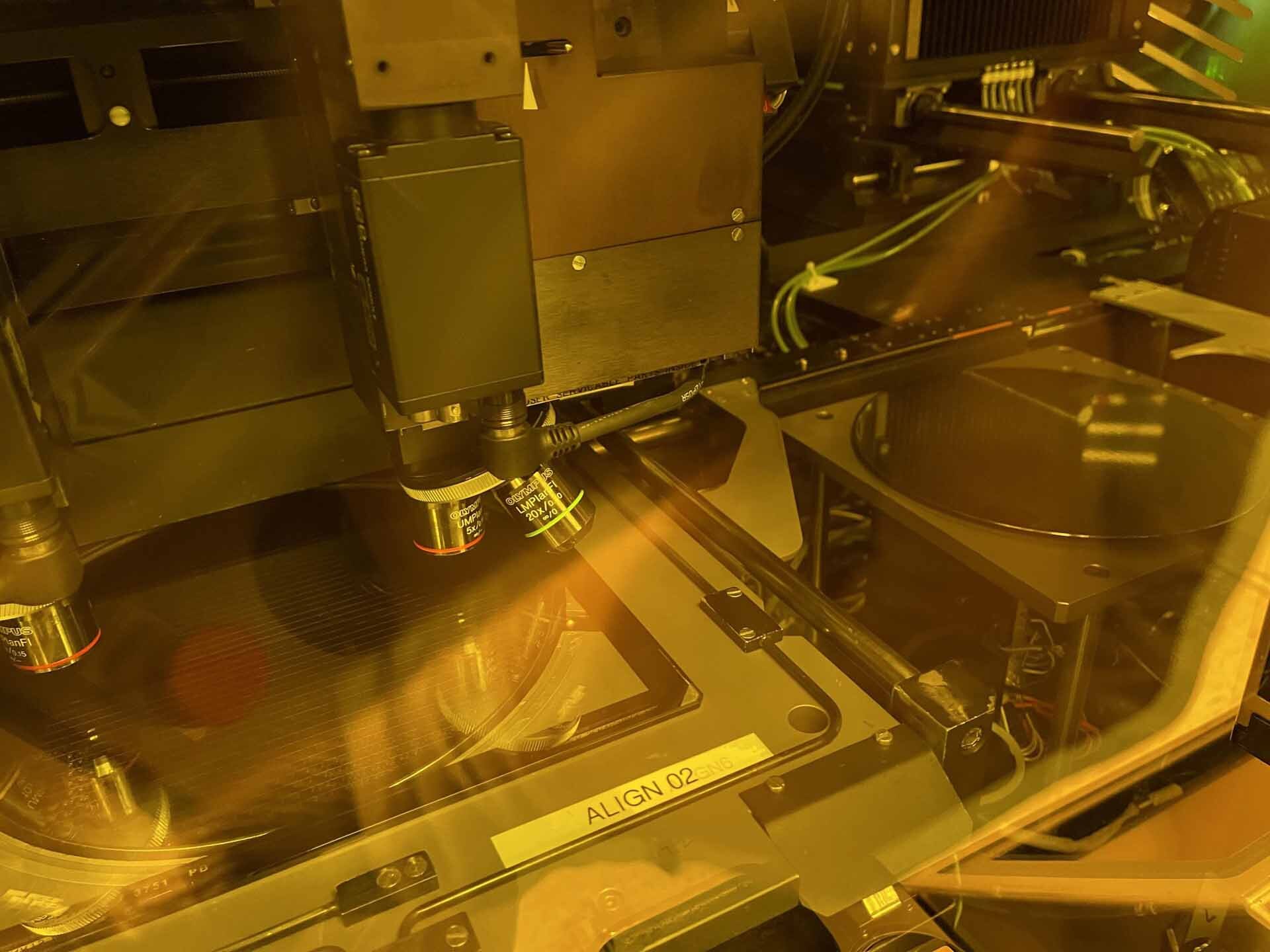

Mask aligner, 8"

Topside alignment

Cassette to cassette

Field proximity mask holder for corner masks, 9"

With exposure area, 8"

Vacuum chuck: Thermal proximity chuck, 8"

Mask holder: 9" x 9"

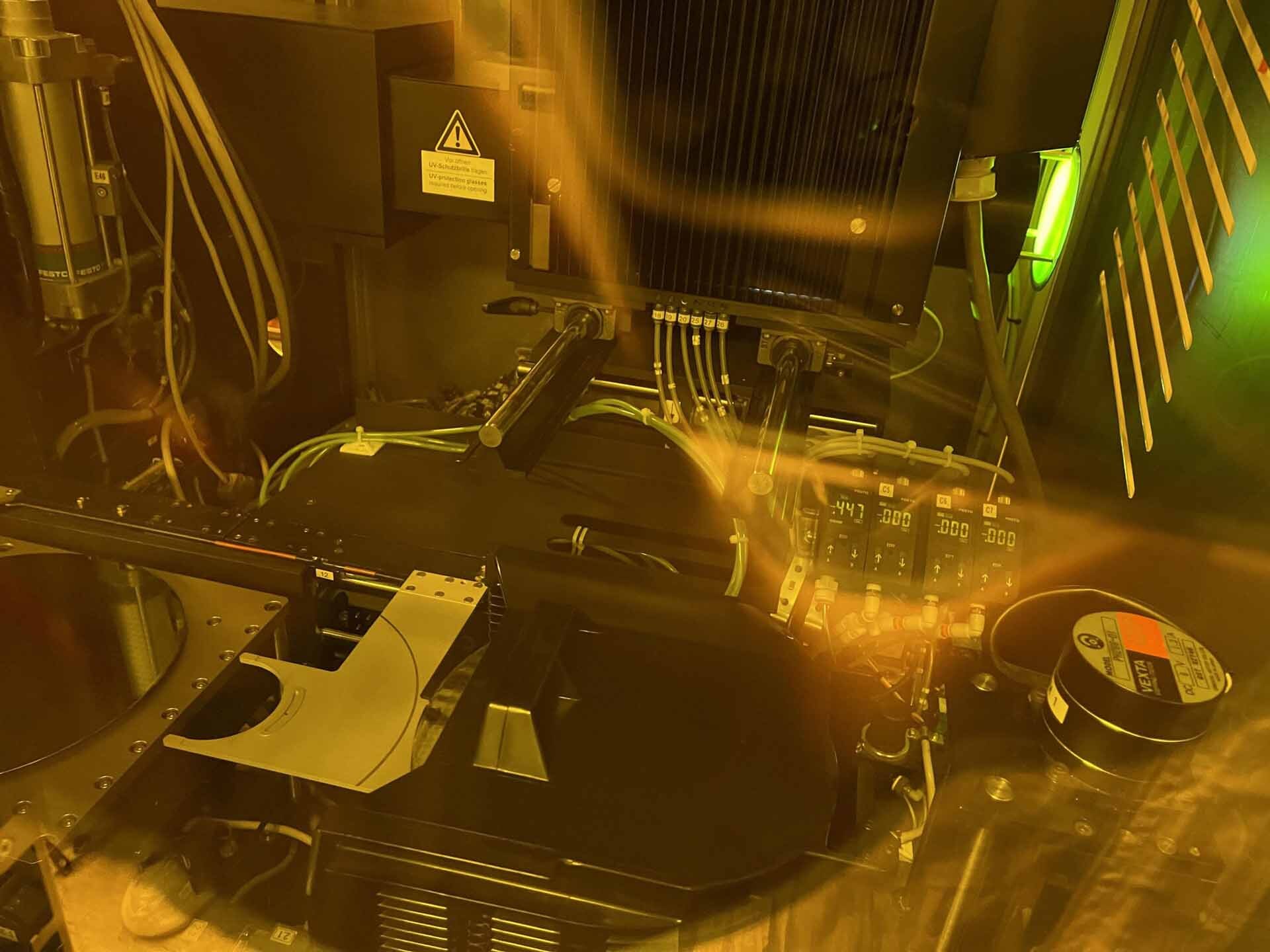

LH5000 Lamp house: 5000 Watts

KARL SUSS CIC 5000 Power supply

UV400 Optics (For 365nm and 405 nm exposure)

With G-Line filter

Objectives: 5x, 10x

AL3000 Auto alignment system

DVM8 Microscope

JULABO Chiller

Isolation table

User manual

1000 Intensity meter with 365 and 435 nm probes

2000 vintage.

KARL SUSS / MICROTEC MA 200 is a mask aligner used to accurately position and then transfer patterns onto a desired surface which can include semiconductor substrates or photomasks. The mask aligner is capable of aligning features down to 0.2 micrometres and has the capability to overlay and align features that are several hundreds of micrometres in some cases. The machine is incredibly accurate and efficient, allowing for very specific and repeatable alignment of features on the substrate. The machine itself consists of an XY stage, a four-axis manipulator which is used for aligning and positioning the substrate and mask, and a bright field and dark field microscope with a minimum resolution of 0.5 micrometres. The machine includes a built in computer system which allows the user to program alignment points and control the machine. The programmable alignment features are incredibly precise and allow for a wide range of alignment operations such as circle to circle, rectangle to rectangle and circle to line. The machine also includes a laser diode alignment, which uses a laser to provide the user with reference points for exact alignment of the mask and substrate. The user of MICROTEC MA200 has the ability to control all four axes of the machine simultaneously and automatically or manually adjust the position of the substrate and mask. The user also has the capability to adjust the exposure of the machine according to the substrate and the device. KARL SUSS MA-200 is used extensively in the semiconductor industry as it provides a quick and accurate way of transferring patterns onto substrates. The machine is fast and efficient, allowing the user to achieve a high yield and low turnaround time while still maintaining high accuracy and precision of the transfer. Additionally, the laser diode alignment allows for a high degree of accuracy when aligning the mask and substrate, ensuring that the transfer of patterns is exact and repeatable.

There are no reviews yet