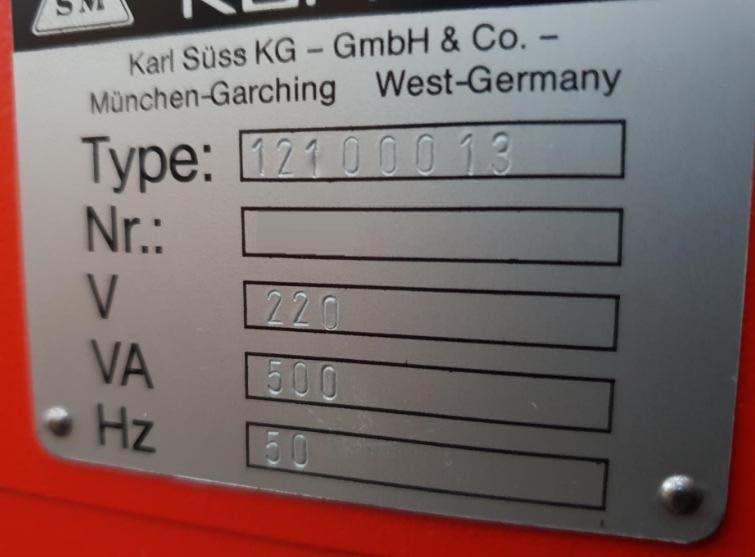

Used KARL SUSS / MICROTEC MA 4/6 #9258606 for sale

URL successfully copied!

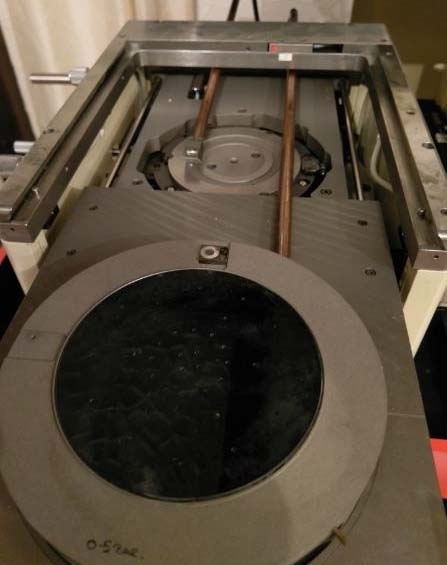

Tap to zoom

ID: 9258606

Wafer Size: 6"

Vintage: 1993

Mask aligner, 6"

Substrates, 6" x 6"

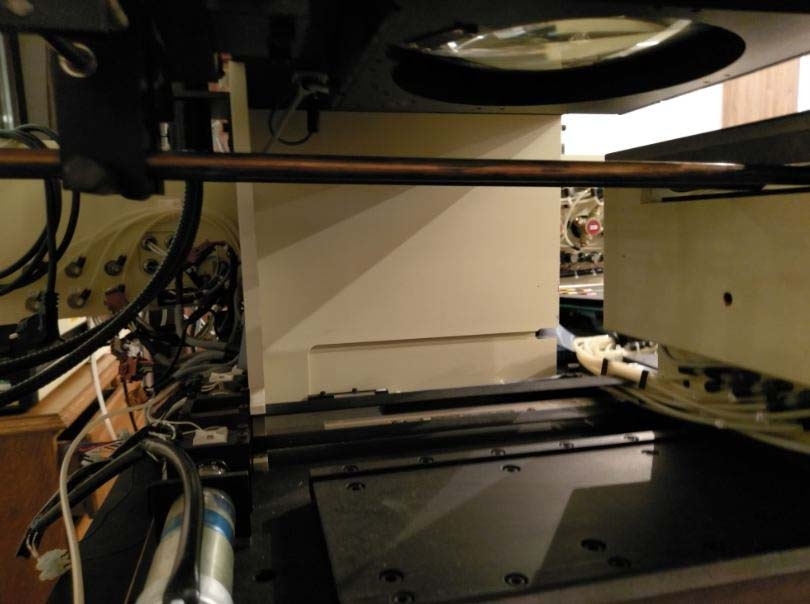

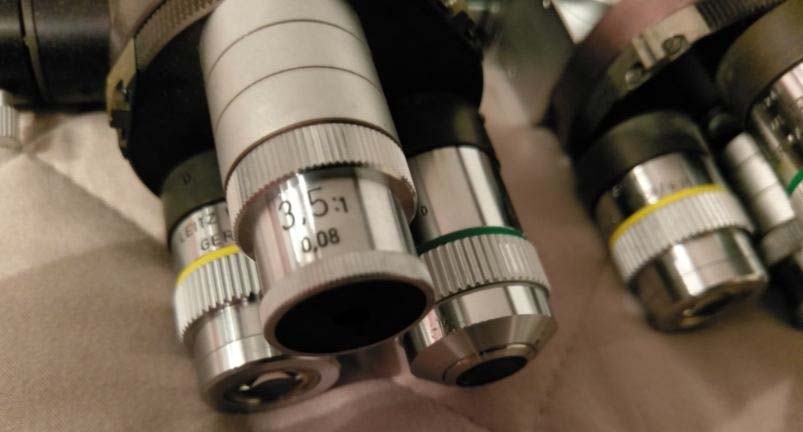

M206 / M236 Split field microscopes

Objectives: 5x, 10x, 20x

Eyepiece Magnification: 10x

Micrometer spindles

UV Ranges with optimized diffraction reducing systems

Splitfield topside microscope with turret

C-Mount for IR camera adaption

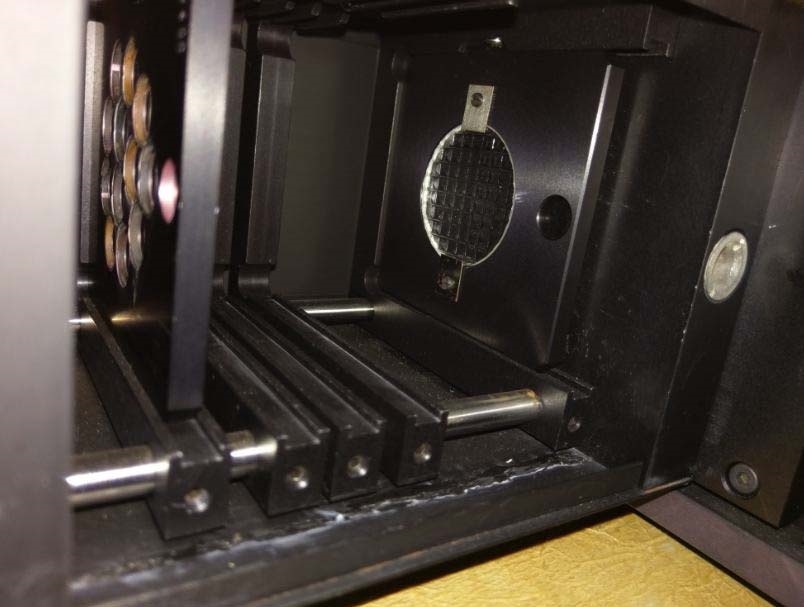

Alignment stage with loaded IR chuck

IR Illuminators and tube stage for target positioning

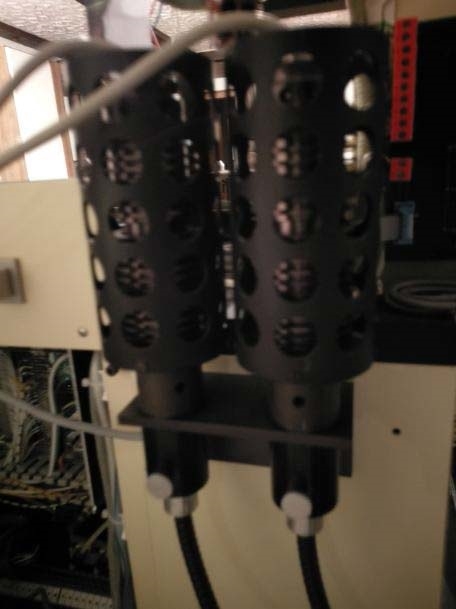

IR Tubes

Spare parts

Tool kit

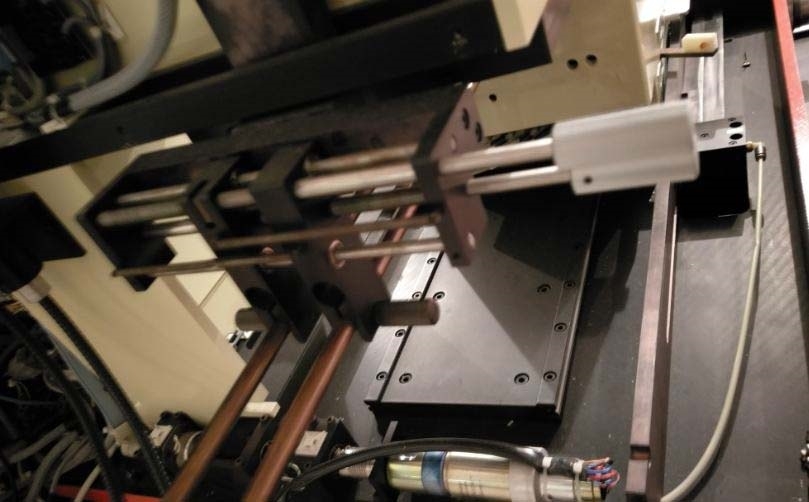

X-Drive

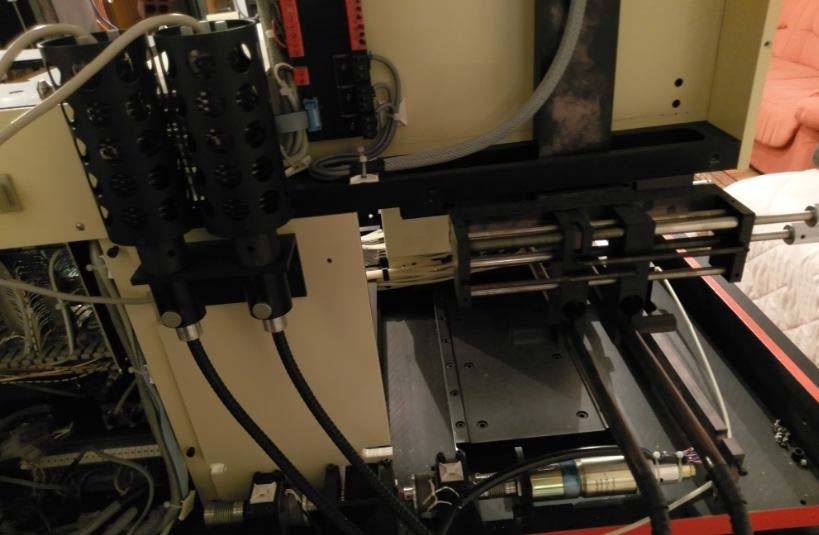

IR Tool:

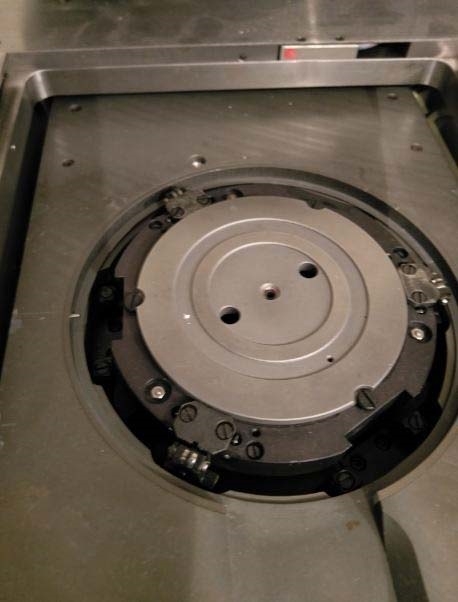

Chuck

Maskholder

Spacers for maskstage clamp

Stage:

X, Y Theta

Z Alignment

Wedge error compensation

Microscope manipulator with adapter

Movement synchronized with alignment

Lamp house LH 1000: 350 W / 1000 W lamp

With optical tube and mirror house / Eclipse mirror

CRT Display

Serial dialog operator interface

Substrate size: 1" x 1" - 4" x 4", Pieces

Mask size: 7" x 7"

Exposure system:

Vacuum contact and proximity

Gas separation: 0-90 um

Gas adjustment resolution: 1 µm

Contact pressure: 0.02 - 1.0 N/cm²

Exposure optics:

Wavelength / Range / Source

UV400 / 350 mm - 450 mm / 1000 W Hg

UV300 / 208 mm - 350 nm / 1000 W Hg

Alignment:

Top Side Alignment (TSA)

Accuracy: TSA down to 0.5 µm

Back side alignment

Accuracy: BSA down to 1.5 µm

Alignment stage:

Alignment range X: ±5 mm

Alignment range Y: ±5 mm

Alignment range θ: ±3°

Mechanical resolution XYθ: 0.05 μm

UV400 With high peak intensity at 365nm and 405 nm

Exposure area: 6"

CIC500 for 350W HBO

Maximum intensity at 365nm: 19 ±4% mW/cm²

Maximum intensity at 405nm: 30 ±4% mW/cm²

Power supply: 110 V / 220V, 50/60 Hz, 1500 W

1993 vintage.

KARL SUSS / MICROTEC MA 4/6 is a general purpose mask aligner that provides a highly accurate method for patterning microscale and large-scale features onto a substrate. This advanced technology assists users in creating intricate patterns that are critical for any application, ranging from printed circuit boards to metal-oxide semiconductor (MOS) fabrication and beyond. MICROTEC MA 4/6 features a range of alignment accuracy from ±2µm to ±20µm, allowing the highest of standards of alignment to be reached when creating intricate and advanced patterns. The design also encompasses a 12-axis positioning equipment that provides optimal positioning and manipulation of the patterning field - a critical factor for nanolithography applications. KARL SUSS MA 4 / 6 comes equipped with long lifetime 'Air Bubble Free' bubble systems which provide total stability of the optics and wafer table, providing the highest level of repeatable results for years of operation. The lens imaging is provided by a long-life, low power consumption high-NA optics system. This includes a variable field-of-view that can be adjusted from diameters of 20µm to 30µm. Additionally, KARL SUSS / MICROTEC MA 4 / 6 offers on-unit support, user-friendly front-panel menus, and PC integration to ensure ease of use. The machine is also equipped with front pre-alignment module, image analysis capabilities and a particle-monitoring tool. The exposed wafer surface is measured for dimensional accuracy, ensuring accurate alignment with the pattern. There is also a selection of active gas purging systems, like Sep-Purge or TurboPurge that prevent gas accumulation in the asset which ensures tough operating conditions. In conclusion, MICROTEC MA 4 / 6 is a high precision mask aligner model suited for a variety of applications requiring accurate imaging. Its range of accuracy, 12-axis positioning equipment, long lifetime bubble systems, and excellent optics make it an ideal solution for nanolithography applications. The system also offers features such as pre-alignment, image analysis, on-unit support, PC integration, and particle-monitoring that provide ease of use and produce highly accurate results.

There are no reviews yet