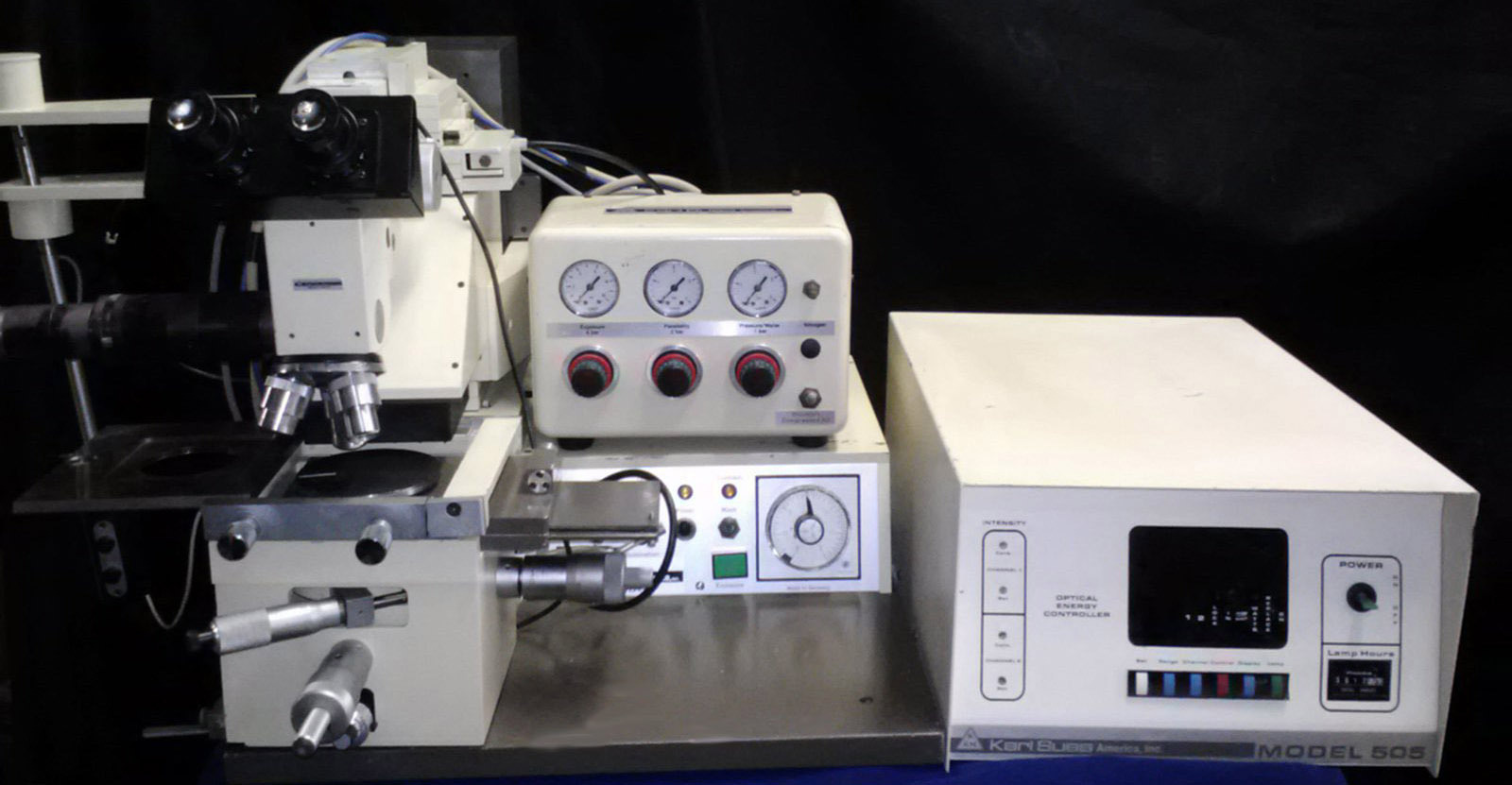

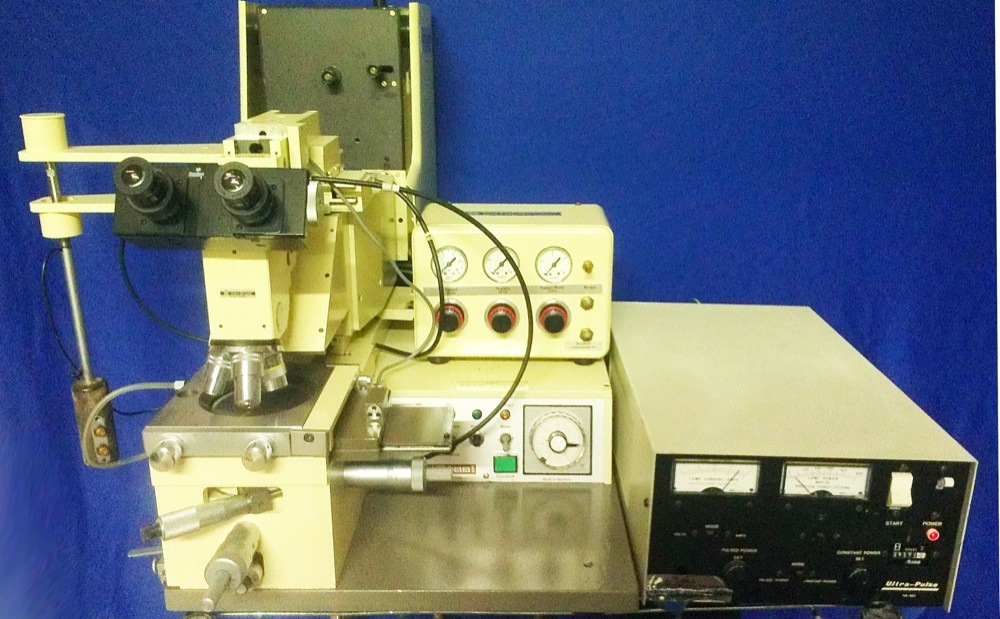

Used KARL SUSS / MICROTEC MJB-3 #9035395 for sale

URL successfully copied!

Tap to zoom

ID: 9035395

Wafer Size: 3"

Mask aligner, 3"

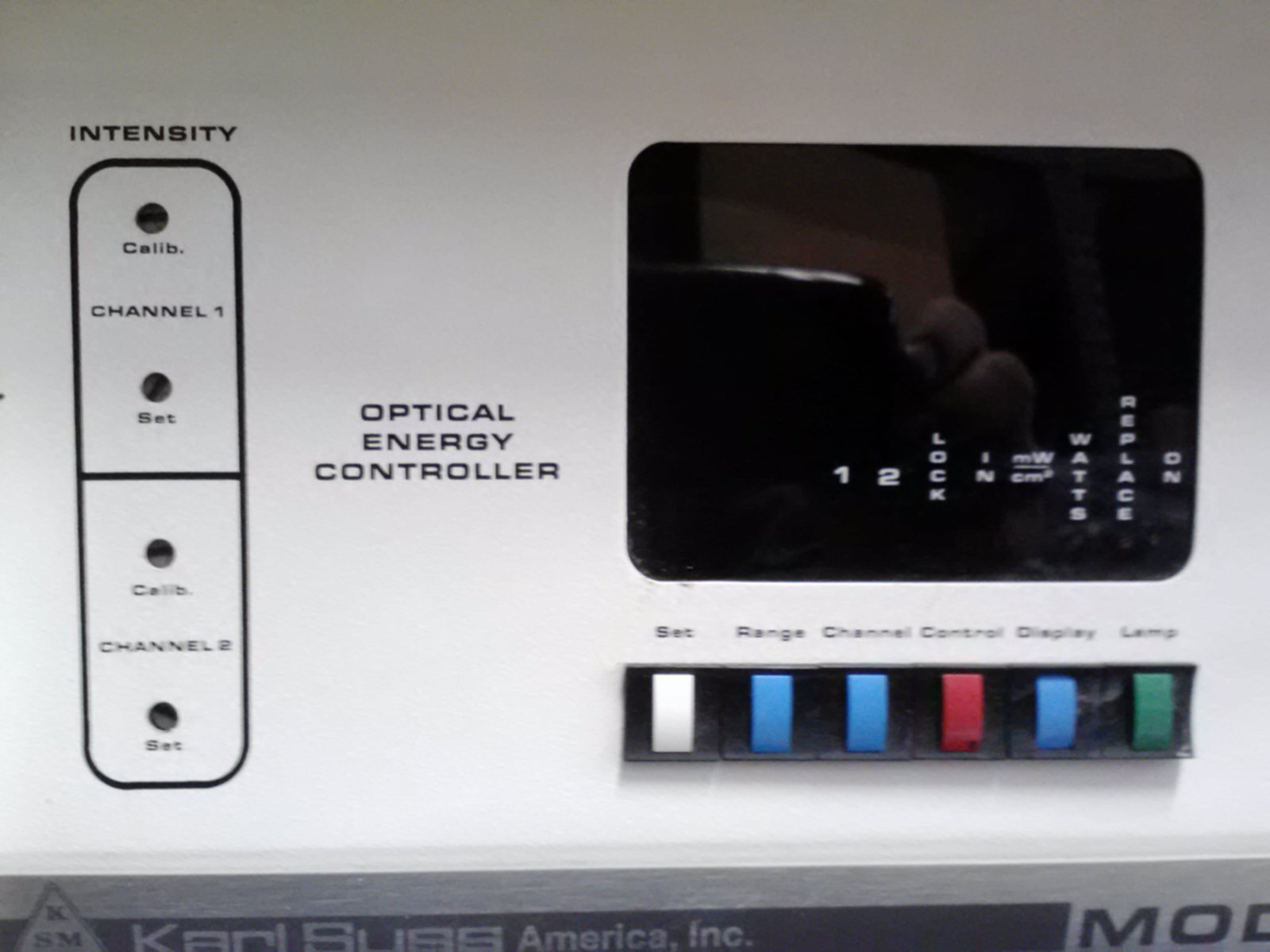

Upgraded touch screen

Mask holder, 2"-3"

Front alignment

Soft contact option

Objectives: 2.5x, 5x, 20x, 32x

Lamp: 200 W.

KARL SUSS / MICROTEC MJB-3 Mask Aligner is a compact, high-accuracy, fully automated, micron-level alignment equipment designed specifically for the production of semiconductor devices utilizing high-resolution photo-resist processes. It is able to perform realignment precision of 3 µm and overlay of 1-2 µm over an area of 4"x4". The system employs an advanced laser autofocus feature to detect the exact position of the wafer and lens before each alignment cycle, ensuring accuracy and repeatability of the wafer alignment positioning. MICROTEC MJB3 Mask Aligner is designed to handle the maximum resolution requirements of deep-UV, e-beam and ion-beam lithography. KARL SUSS MJB 3 aligner utilizes stepper motor and optical lever driven step-and-repeat assembly which includes support for zooming and mirroring. The alignment facilitates quicker processing times and prepares higher throughput, as it is equipped with a motorized wafer indexer unit for convenient wafer flip, or substrate exchange. MICROTEC MJB 3 mask aligner's control unit is composed of an integrated operation panel for easy operation and observation of the machine, and an IBM-compatible 386 PC for data logging and controlling, via a graphical user interface. The PC and the panel are hardwired together and interfaced with a touch-sensitive LCD monitor and a push-button selection tool. The asset is operated in a stand-alone mode and can also be integrated with a larger process control model. KARL SUSS MJB 3 Mask Aligner employs a two-axis micrometer stage control and galvanometer-driven laser control for alignment precision and accuracy. The equipment utilizes vertical and horizontal vacuum frames for masking, mask clamping and substrate holding, as well as a modular substrate holder and mask holder assembly with adjustable height and force clamps. Operator safety is incorporated in the design of MICROTEC MJB 3 system, due to its protective shielding, key interlocks and safety interlocks. The unit is designed for efficient energy consumption, with maximum rated power of 700 watts. The machine footprint of 95cm x 65cm is ideal for any semiconductor fabrication lab, and its numerous integrated features make it a streamlined and user-friendly tool for accurate and repeatable lithography.

There are no reviews yet