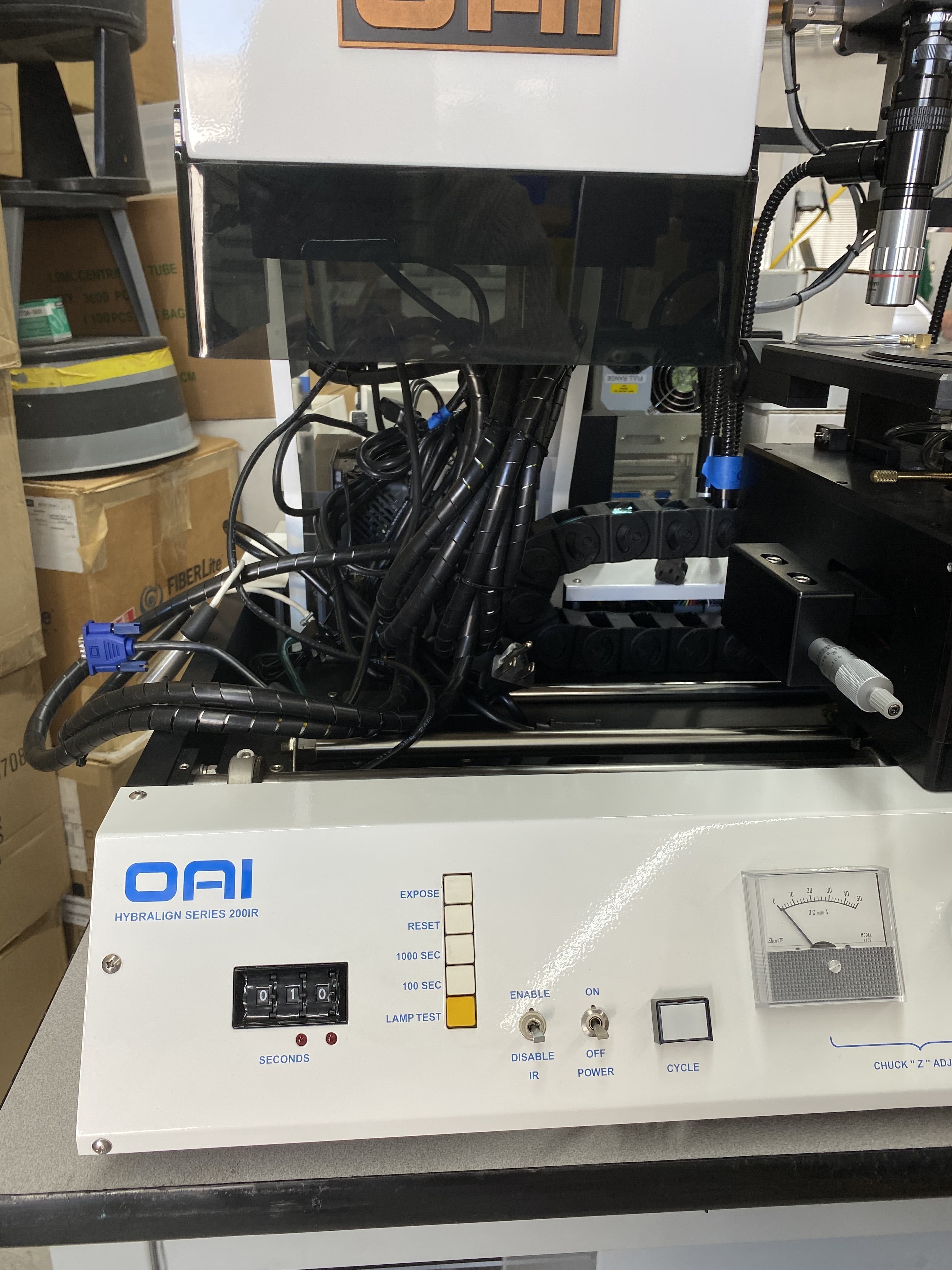

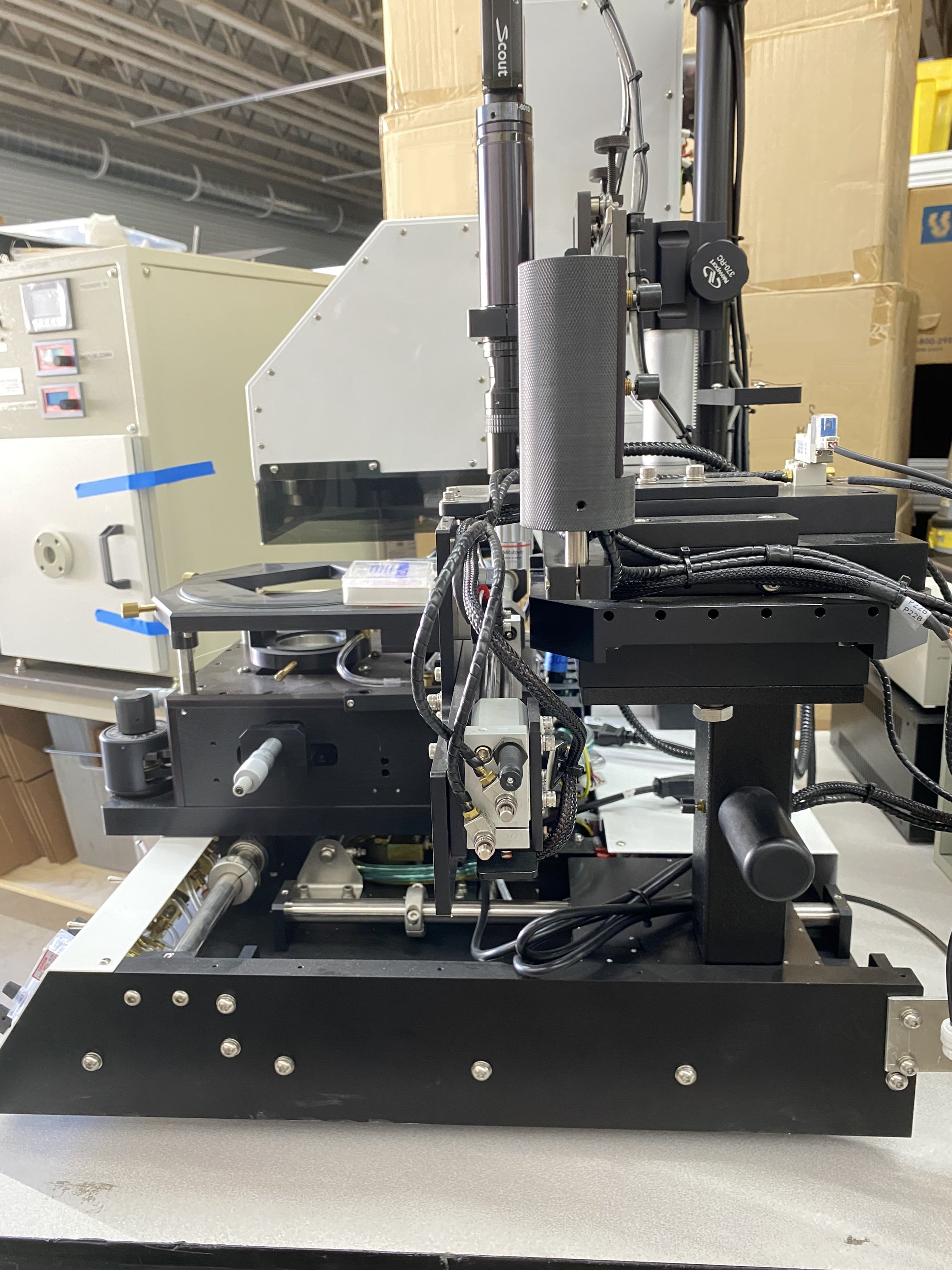

Used OAI 200 #9401975 for sale

URL successfully copied!

Tap to zoom

ID: 9401975

Mask aligner

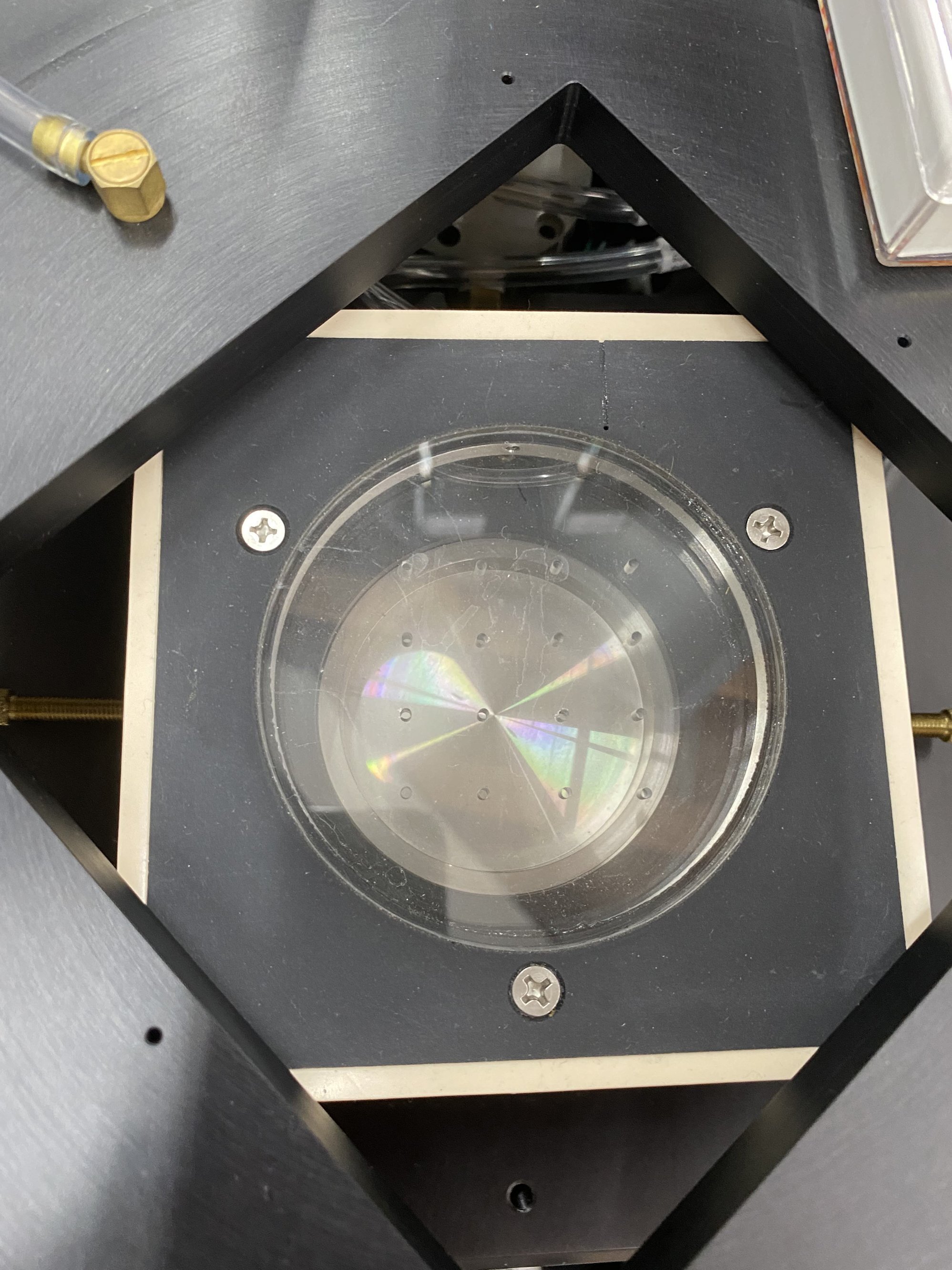

Mask size: 2" x 2" up to 5" x 5"

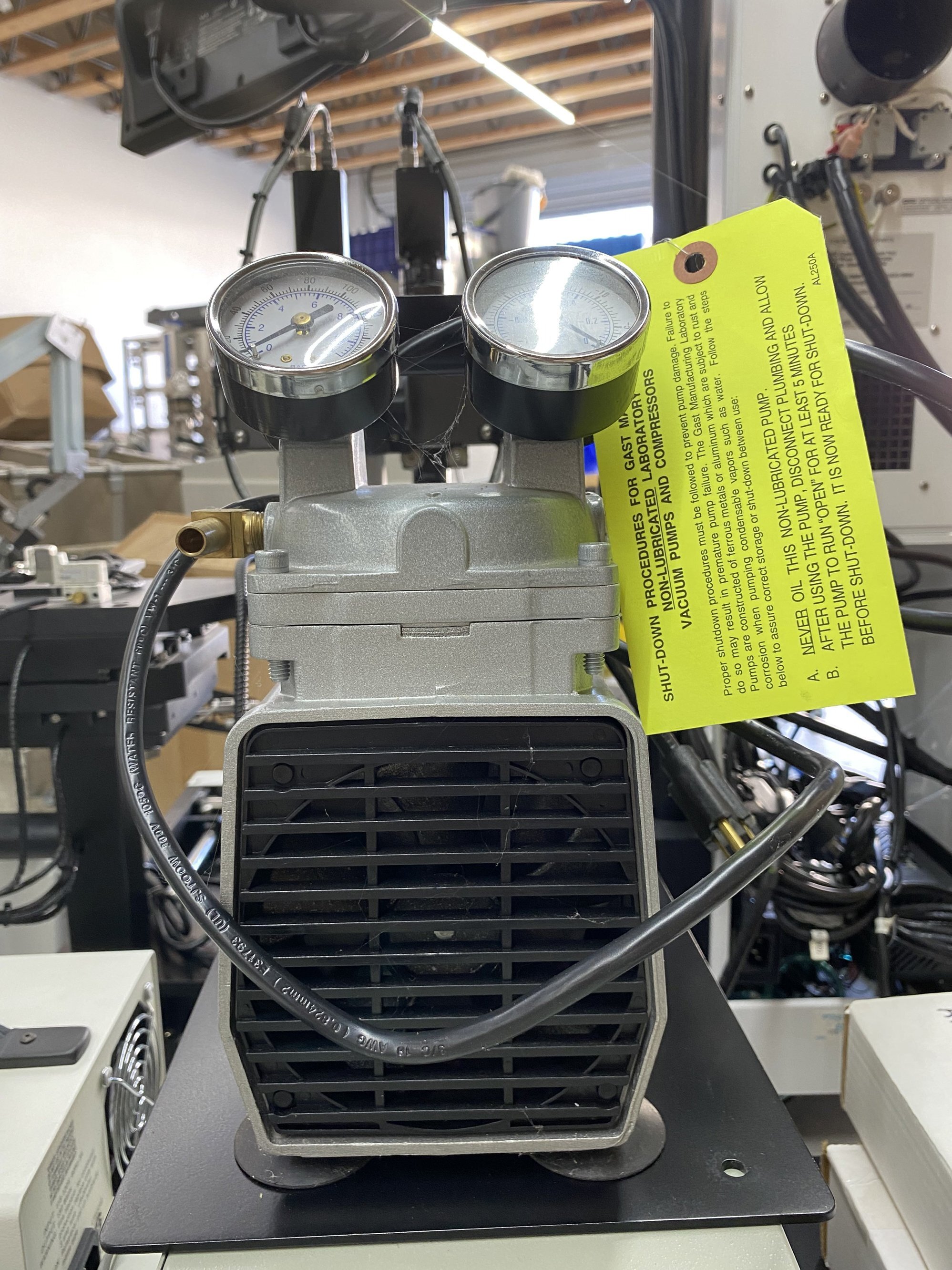

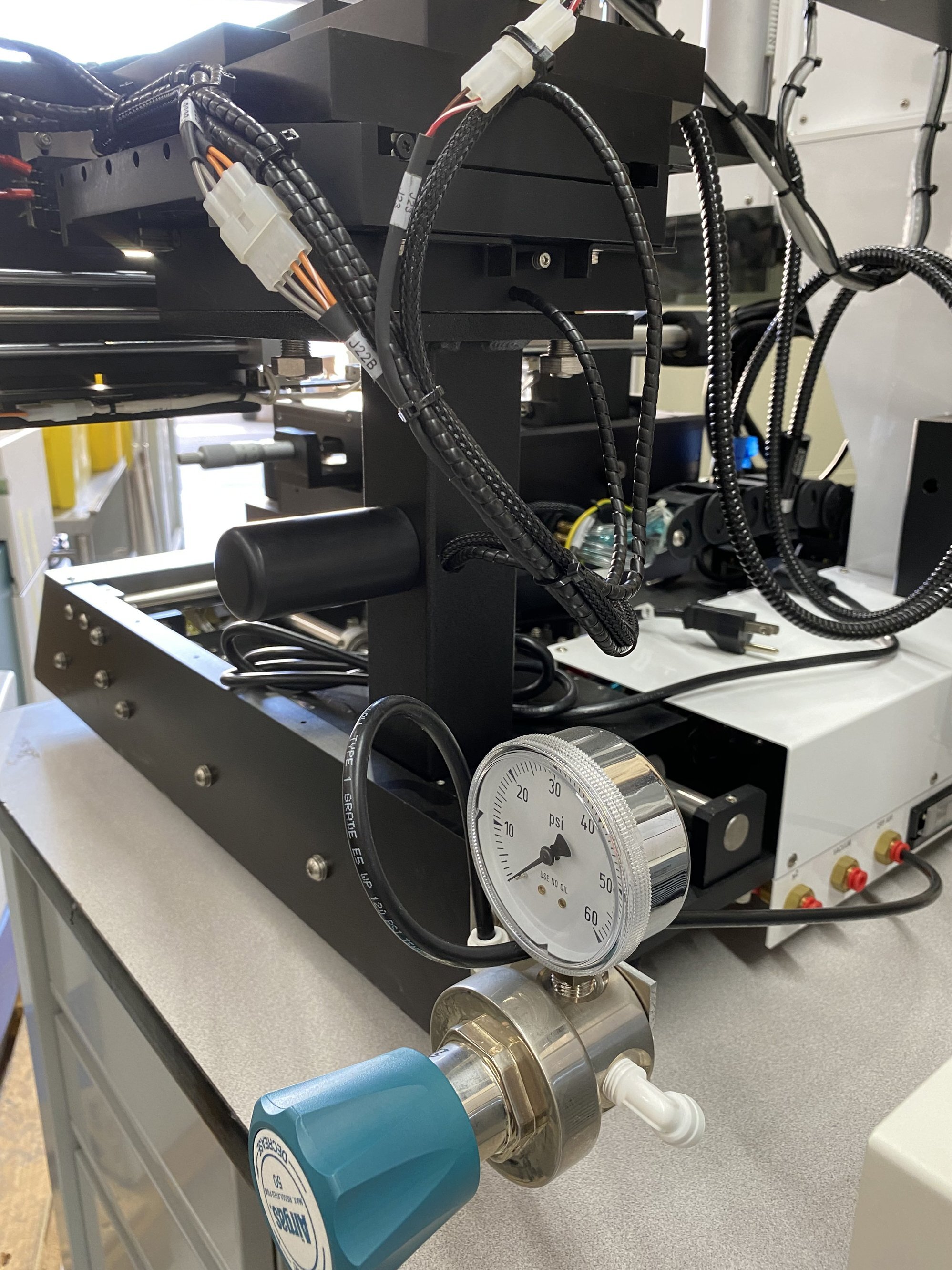

Nitrogen consumption: 0.35 m³/h

Does not include vibration isolation table

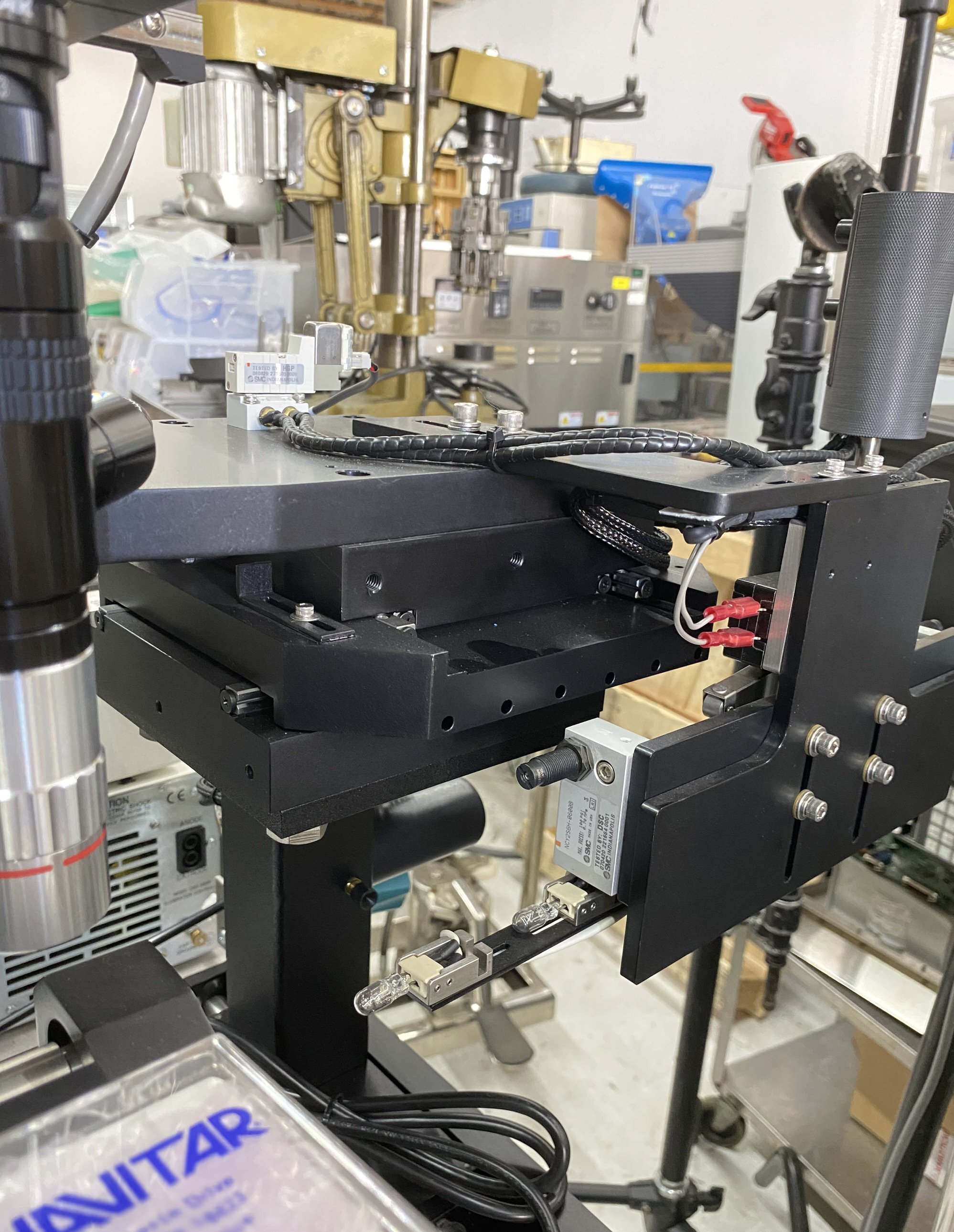

Substrate size:

Round, 1" Up to 4"

Square, 5 mm x 5 mm up to 4" x 4"

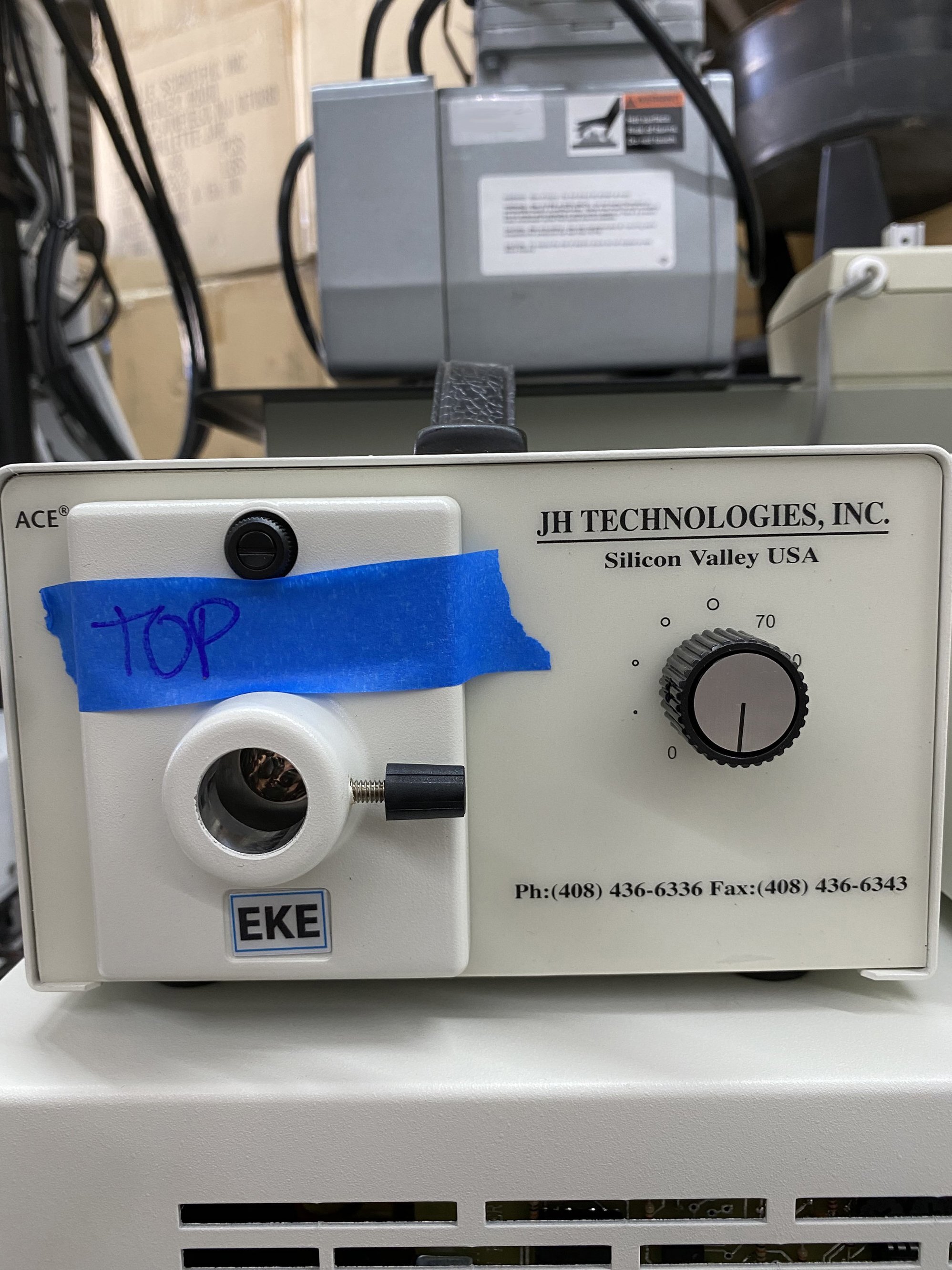

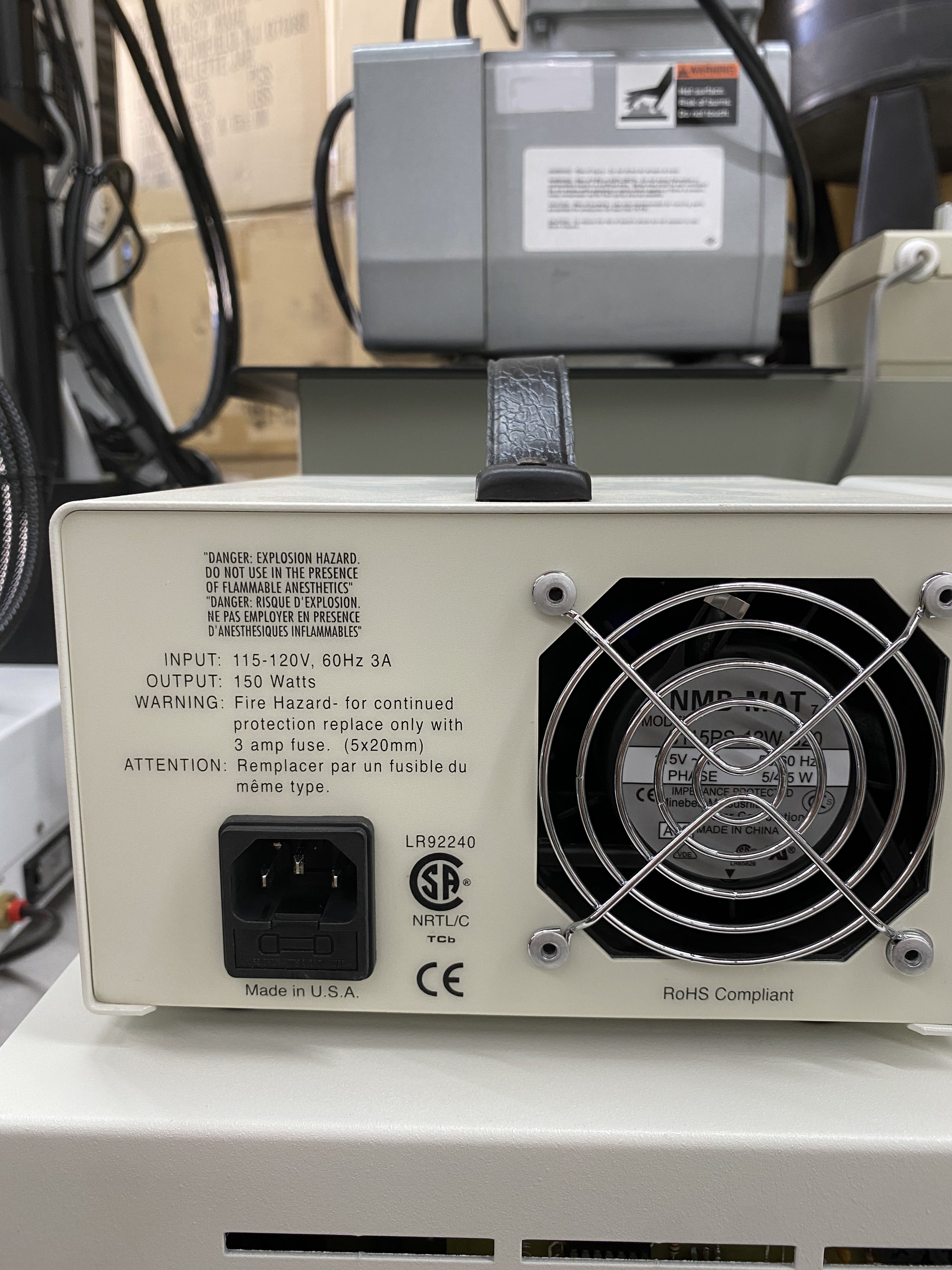

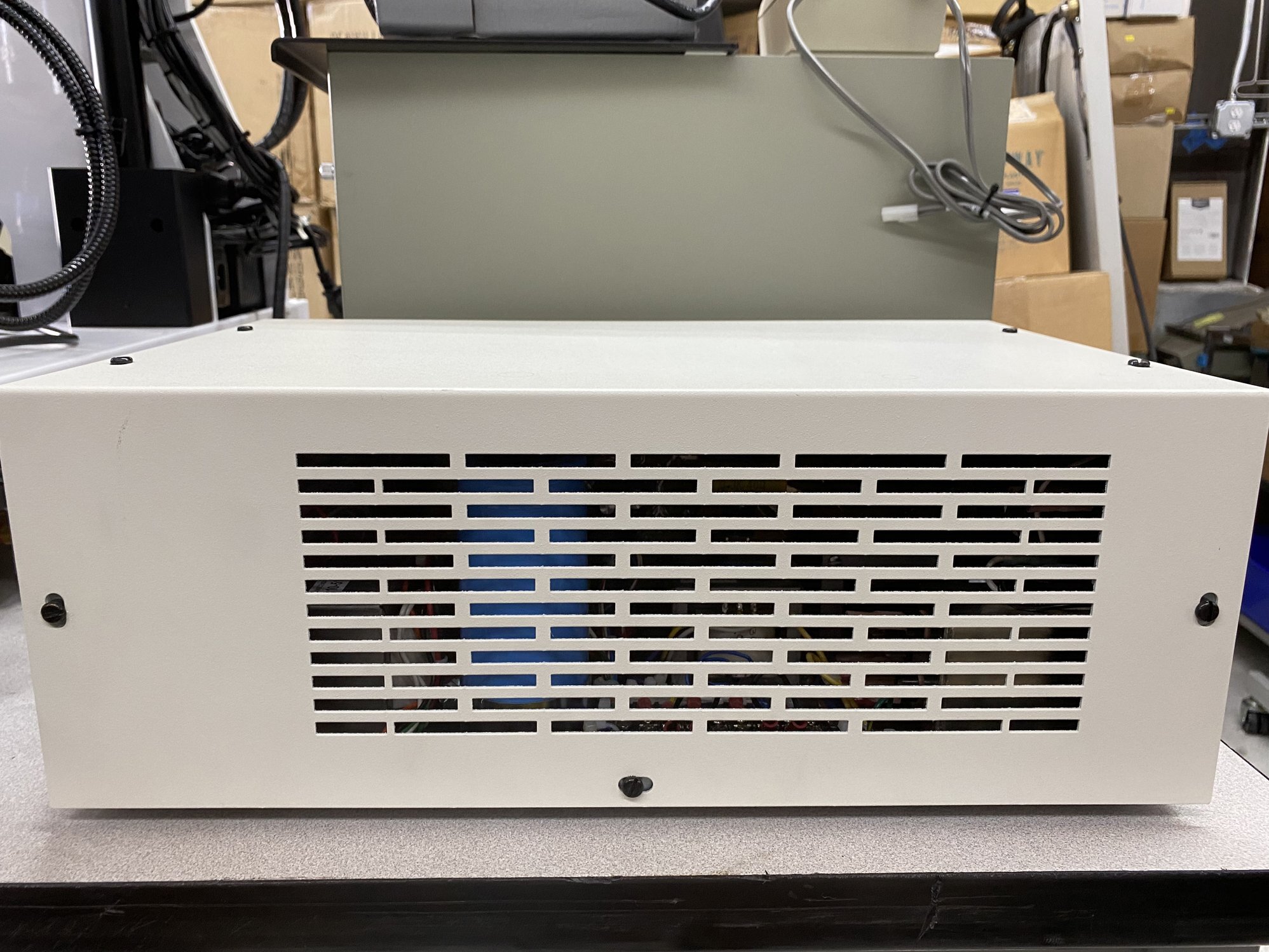

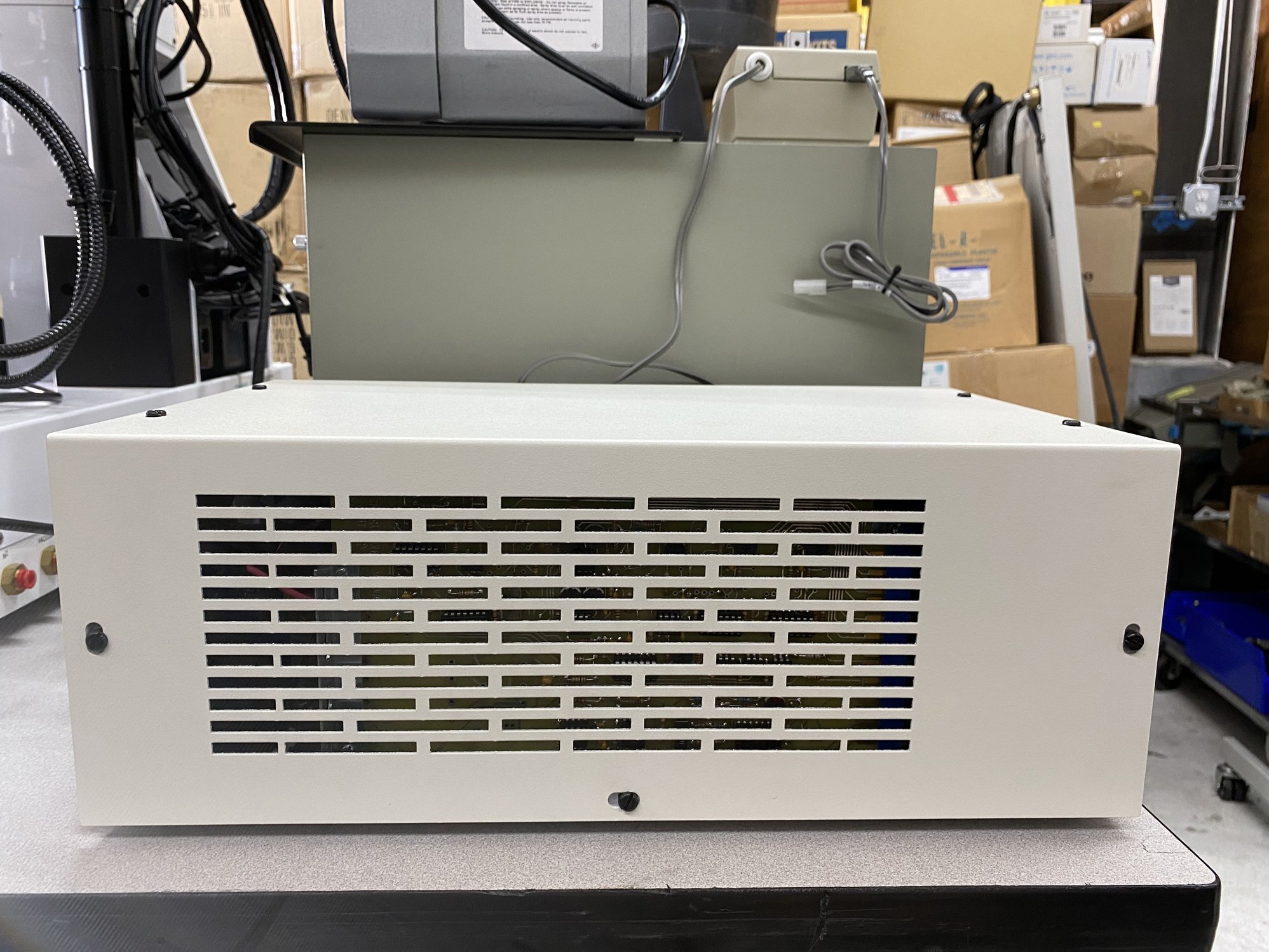

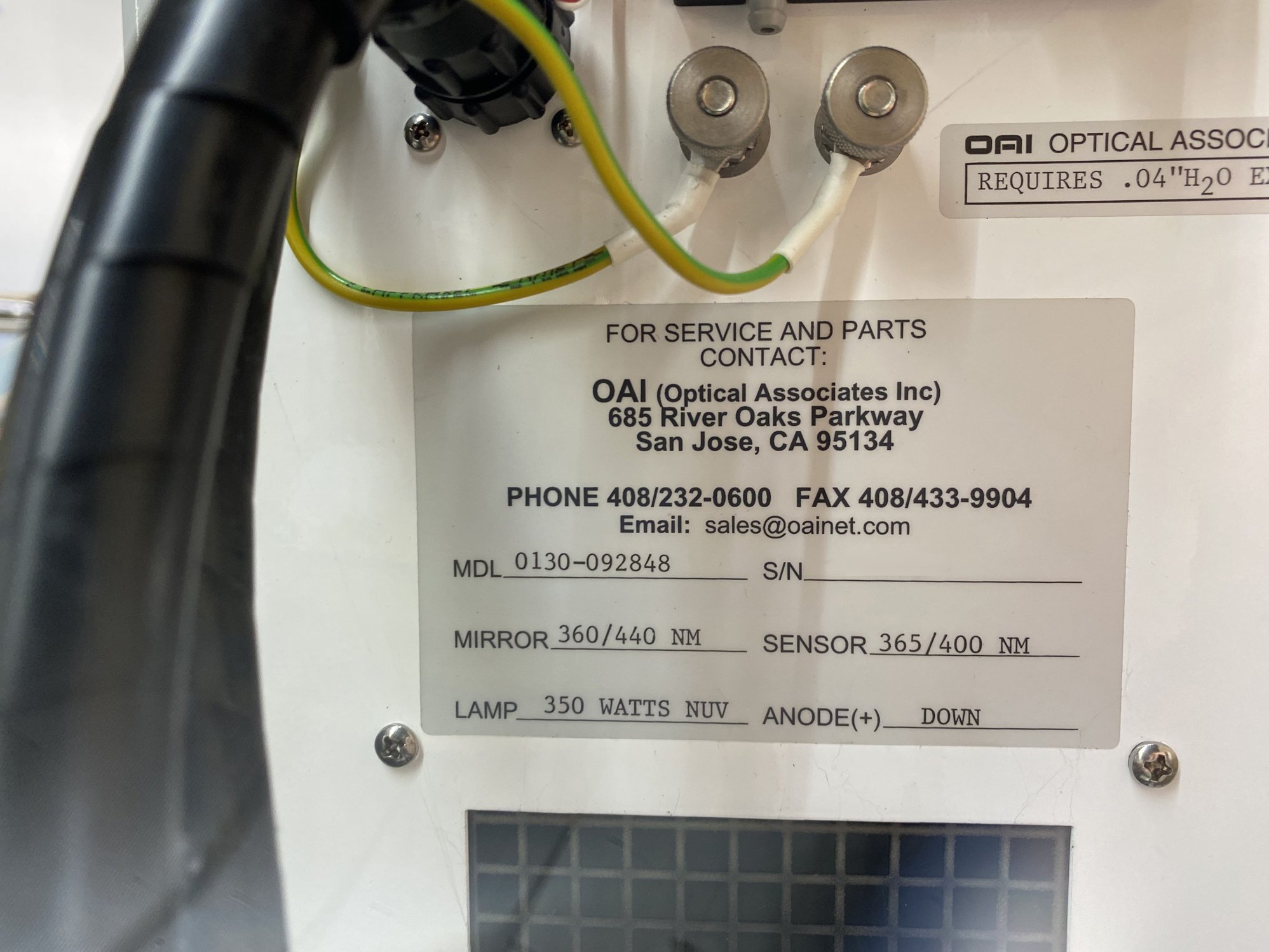

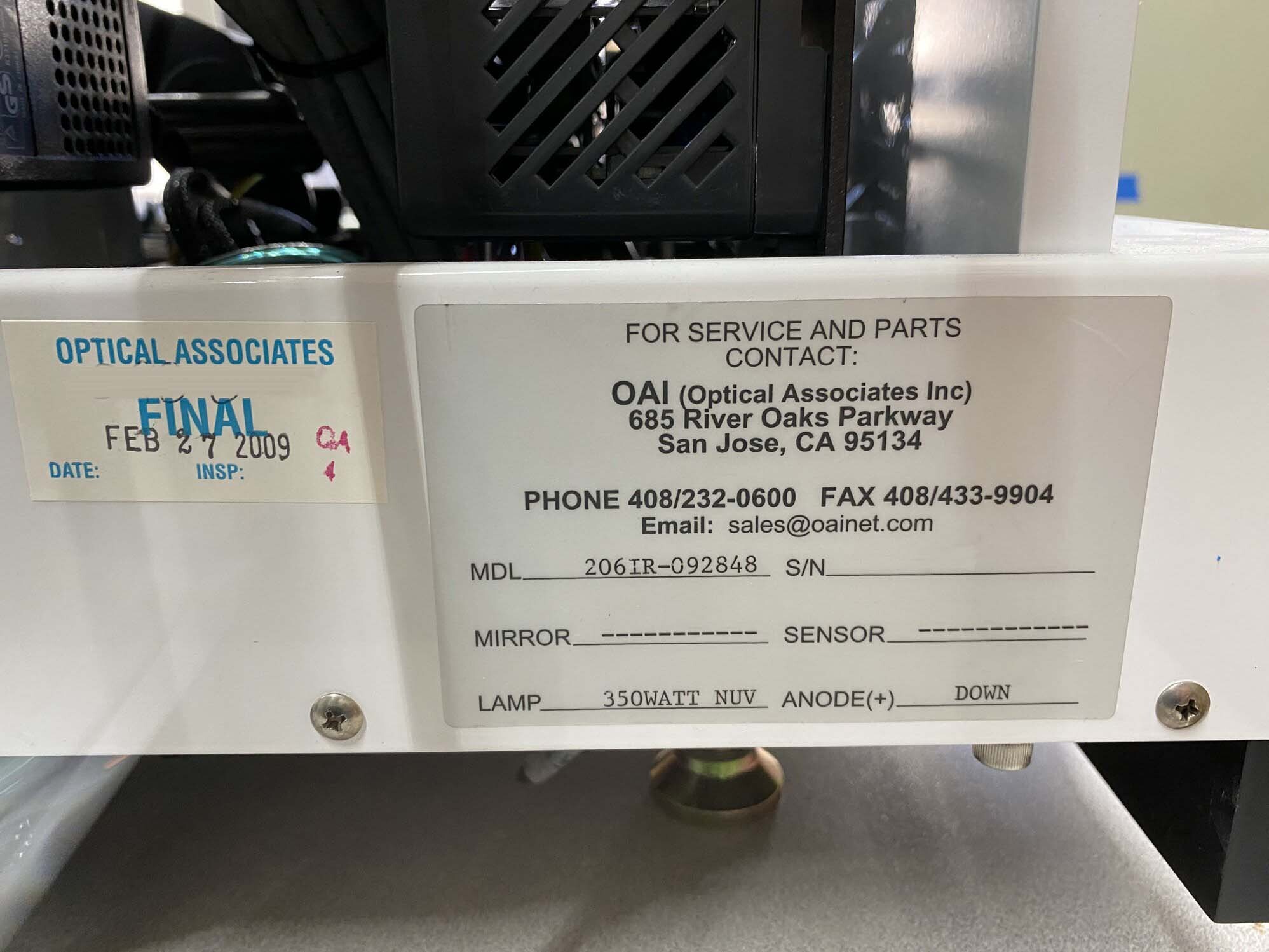

Exposure system, 350 W:

Lamp house

Lamp power

Intensity spectrum of UV400: 350 nm to 450 nm

Print resolution at UV400:

Soft contact: 2 µm

Hard contact: 1 µm

Vacuum contact: <0.8 µm

Gap exposure: >3 µm

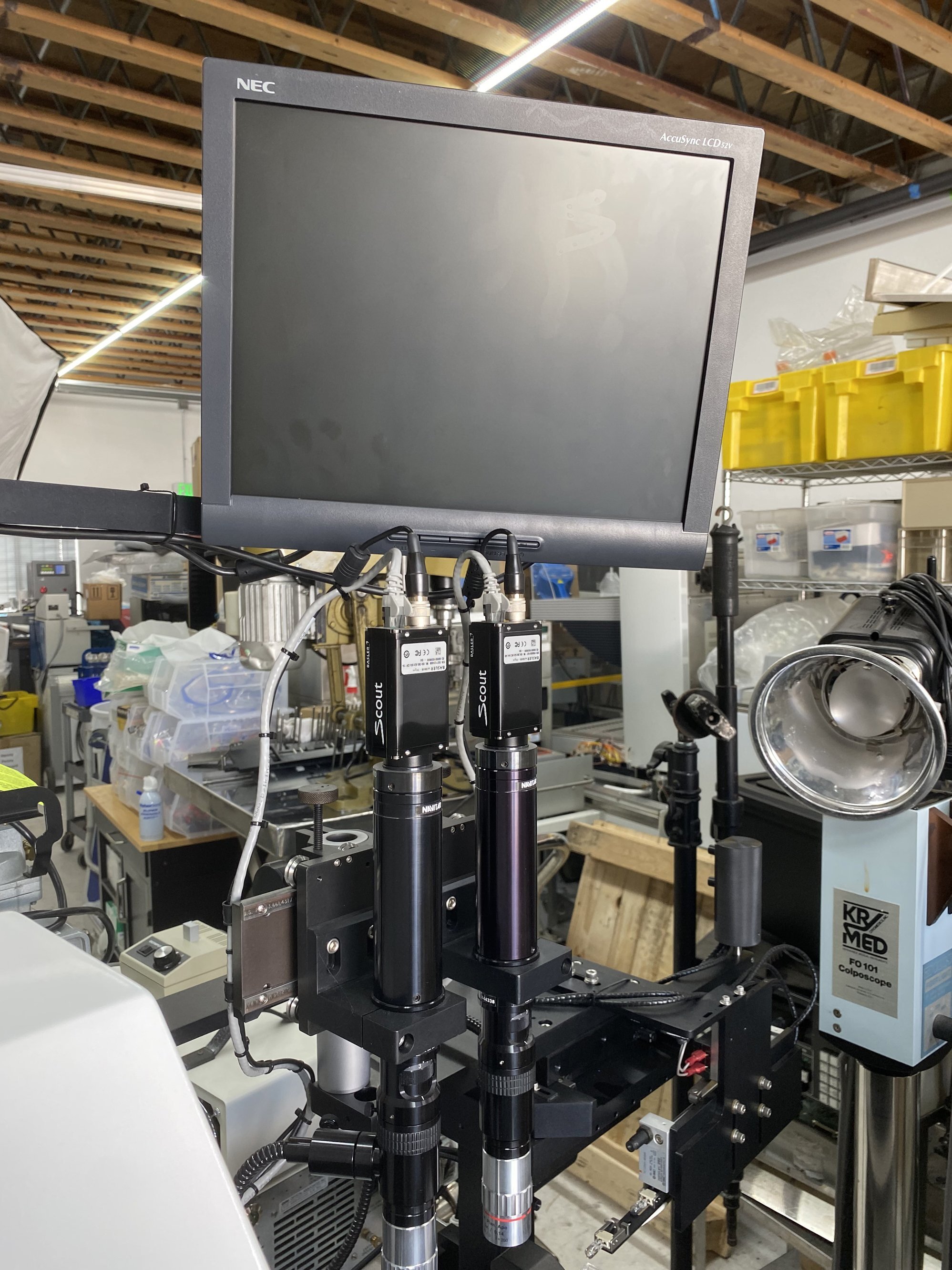

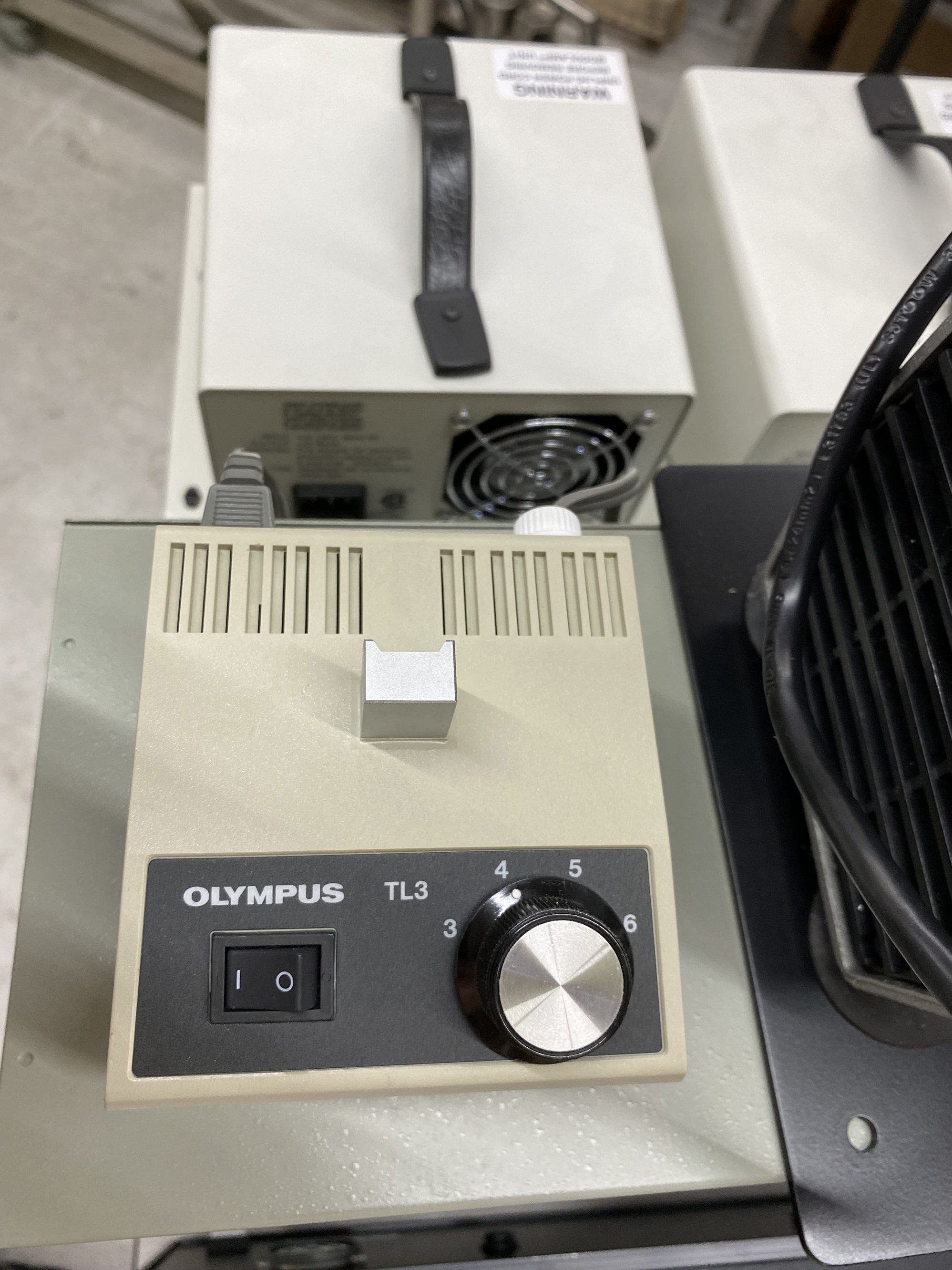

Double transmitted illumination: (2) IR Cameras

Microscope manipulator:

Travel range (X, Y, Θ): ±5 mm, ±5 mm, ±5°

Mechanical resolution (X, Y, Θ): 0.1 µm, 0.1 µm, 4x10^-5.

OAI 200 is a full-field mask aligner that is used in the photolithography industry. It is a highly accurate, semi-automated exposure system designed for the production of high density integrated circuits. 200 uses UV exposure to transfer circuit patterns onto a substrate in a single step and is one of the essential tools used in the fabrication of integrated circuits. The aligner comes with two independent stages, each with a work area of OAI 200 mm x 200 mm, which allows exposure of smaller fields and faster chip turnaround times. At the heart of the aligner is a combination of a high resolution imaging system, CCD camera and the NOVA-B microprocessor. This combination ensures exposure accuracy and stability, with an alignment accuracy of up to 1.5 µm. OAI 200 can perform exposure of both wet and dry photoresist materials, as well as photosensitive materials, such as sensitive dry film. The machine is fitted with a motorized wafer stage to ensure exact object positioning, and provides variable alignment parameters, such as field size and image exposures. The exposure time can also be adjusted for different materials. 200 also comes with a range of software capabilities, such as automatic exposure control, laser dicing and an alignment optimization algorithm. Additionally, the manual and automatic exposure modes allow for alternations between batch and single-run exposure, as well as adjustment of operating parameters. In general, OAI 200 is a highly accurate and efficient mask aligner that is suitable for integration with a range of other processing tools. It provides accurate exposure times, high resolution imaging and fast throughput due to its high-performance imaging and processing system. Furthermore, it has excellent alignment accuracy and low cost of ownership, making it an ideal tool for the photolithography industry.

There are no reviews yet