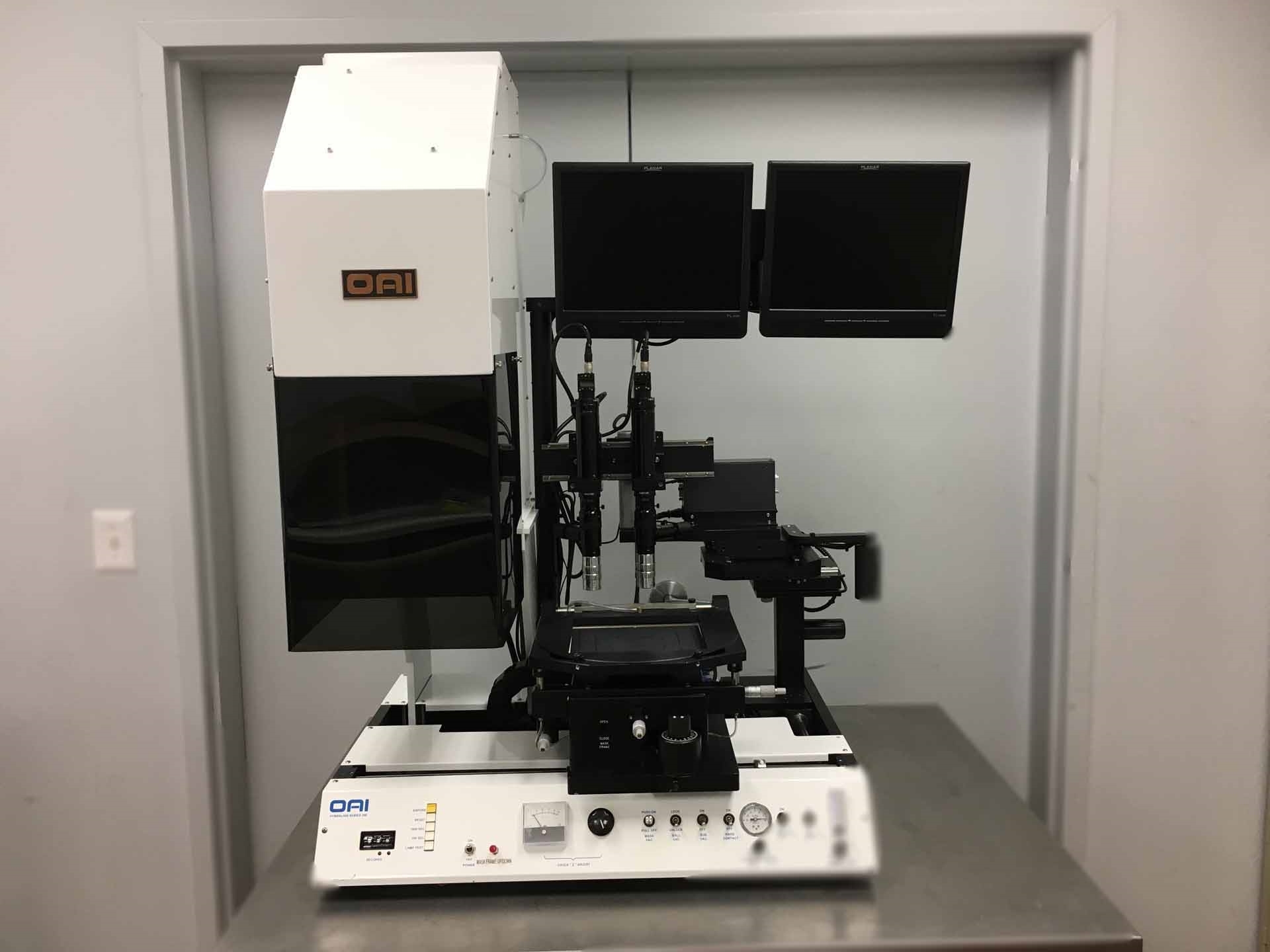

Used OAI 208S #9219993 for sale

URL successfully copied!

Tap to zoom

ID: 9219993

Wafer Size: 8”

Mask aligner, 8”

2000 Watt NUV bulb

365nm / 400nm Wavelength over 20 mW / Cm²

9" x 9" Square final lens for 8" x 8" exposure

Mask holder: 9" x 9"

Square substrate holder: 8" x 8"

(2) NAVITAR Video tubes

MITUTOYO Objectives: 5x

(2) Flat panel displays

LED Illumination cameras.

OAI 208S is a mask aligner, which is an industrial photolithography machine that projects a predetermined pattern onto a silicon wafer in order to create circuit topology of integrated circuits in the process of chip manufacture. 208S is a high precision machine which provides a finely detailed and accurate transfer of the projected pattern to the wafer. OAI 208S model has a dual steering equipment which offers improved rail stability and processing accuracy. This model also has an Optical Rectification System that provides corrections for the angular distortion of the mask pattern. In addition, 208S has a broad alignment field which supports large and complex design patterns. OAI 208S is a full-field photolithography machine that uses a HeNe gas laser for exposing the pattern on the wafer. The two axes of the machine are programmable for the direction of the mask pattern, ensuring improved accuracy of alignment. The wafer is held on a chuck and is exposed to UV light from the laser through a filter. After the wafer has been exposed to the light, a transparent, liquid cooled window is used for focusing. This window helps maintain accuracy throughout the exposure process. 208S has a Direct Image Overlay that improves accuracy. This feature is important because it eliminates the need to create a separate mask for every layer of the chip. Instead, the pattern of one layer is compared to the previously exposed layer, and the necessary adjustments are made. The exposure process is automated and monitored using a Digital Image Control Unit (DICS). This machine allows for the adjustment of light level and exposure pattern while the wafer is being exposed. The data can then be stored and analyzed in order to ensure consistent results for repeating processes. Overall, OAI 208S is a highly accurate and reliable photolithography machine designed to produce identical integrated circuits quickly and effectively. It is able to quickly and accurately project a predetermined pattern onto a silicon wafer, and can be adjusted for a range of designs. This mask aligner provides a reliable method of producing identical circuits over and over again.

There are no reviews yet