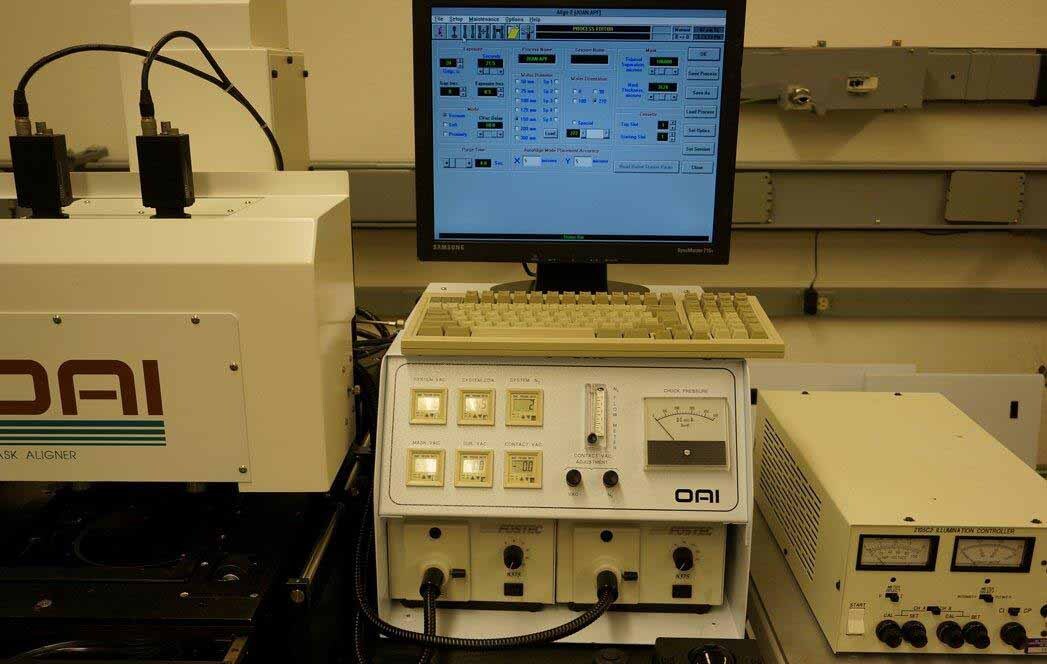

Used OAI 5008 #9155197 for sale

URL successfully copied!

Tap to zoom

ID: 9155197

Wafer Size: 6"

Mask aligner, 6"

Top side alignment

Manual wafer load

Cassette to cassette handling

Resolution: 5um in proximity mode

Dual field CCTV alignment with motorized X, Y illumination

Variable intensity

Objectives: 5x or 10x

Cognex vision system

Dual focus w/zoom capability

Auto alignment

Auto proximity

Pre-alignment

X, Y, & Theta motion

Software version: 2.0.1

Lamp: 500 watt DUV

Power supply: 500W

Includes:

Mask holders

7" x 7" Square

Vacuum chucks

Round chuck, 6".

OAI 5008 is a high-precision mask aligner designed for next generation photolithography applications. It is a full-field UV-exposure equipment that uses light source and stepper technology that is capable of supporting a wide range of wafer sizes, from 100mm to 8-inch (200mm) substrates. 5008 is built to ensure accurate exposure of the photomask onto the wafer. It does this by using stepper positioning accuracy, and by providing a repeatability of ±0.5 μm. The system offers a large dynamic range in exposure energy, from 0.2 millijoules to 20mJ, and a wide range of multiple exposure options. The unit features a laser interferometer machine which provides absolute alignment, and a contour illumination optics tool which enables uniform exposure quality. Furthermore, it has automatic vision alignment with a maximum accuracy of 1.5 μm as well as automated alignment optimization algorithms. The asset also has various control systems which offer a wide range of features to enhance its performance. It features a Process control software which has various features such as exposure parameter control, exposure management, and monitoring, and performance report in order to ensure a consistent and high performance. In addition, it also has an Advanced Process Control (APC) model with Statistical Process Control (SPC) and Real-Time Optimary (RTO) modules to precisely monitor and improve process performance. OAI 5008 is a top-of-the-line mask aligner which offers excellent accuracy, reliability, and consistency. Its high-precision features make it the ideal choice for a photolithography equipment. The system is highly configurable, allowing it to fulfill the needs of different types of lithography processes. It is also efficient, providing high throughputs with low defect levels.

There are no reviews yet