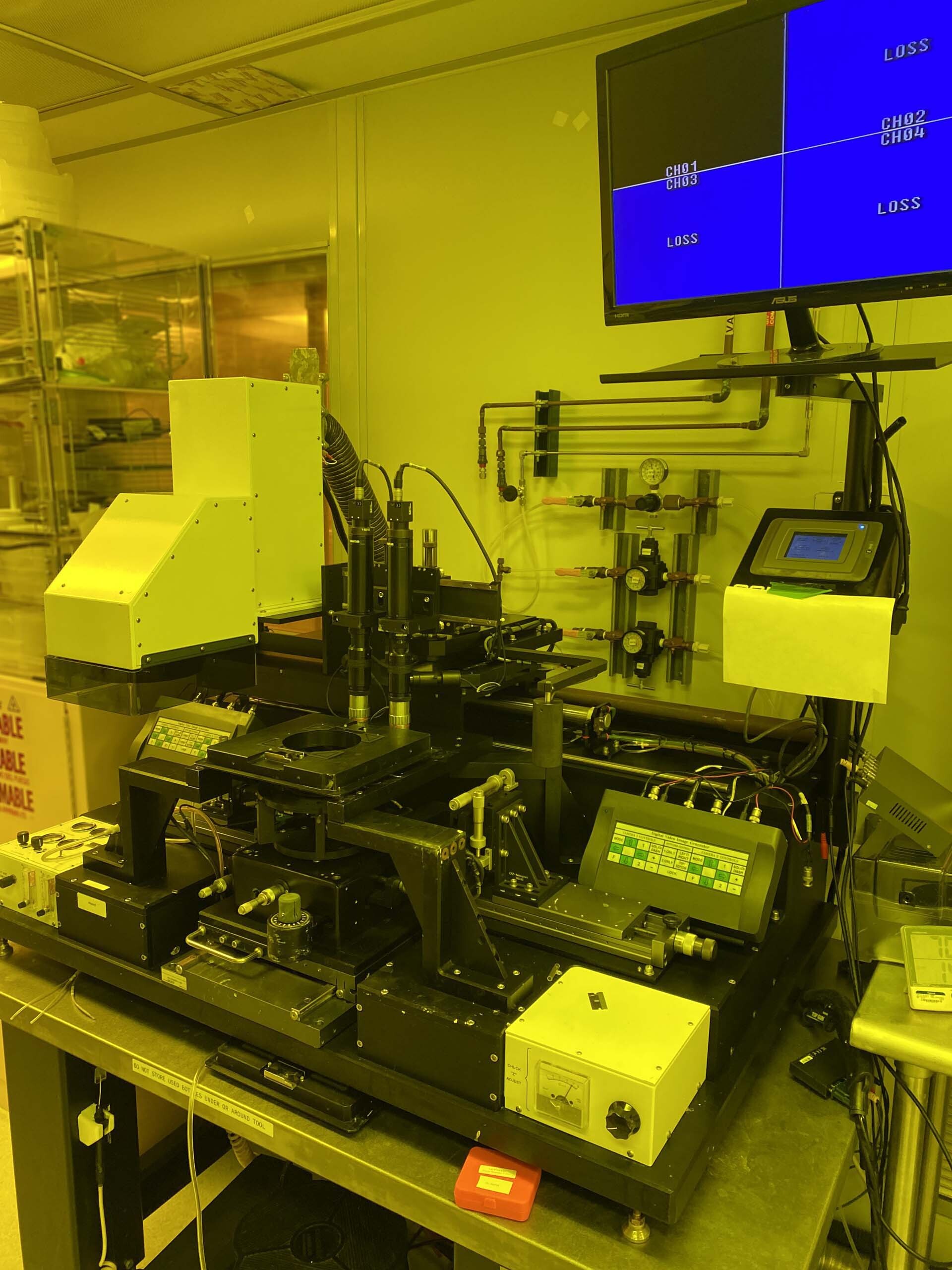

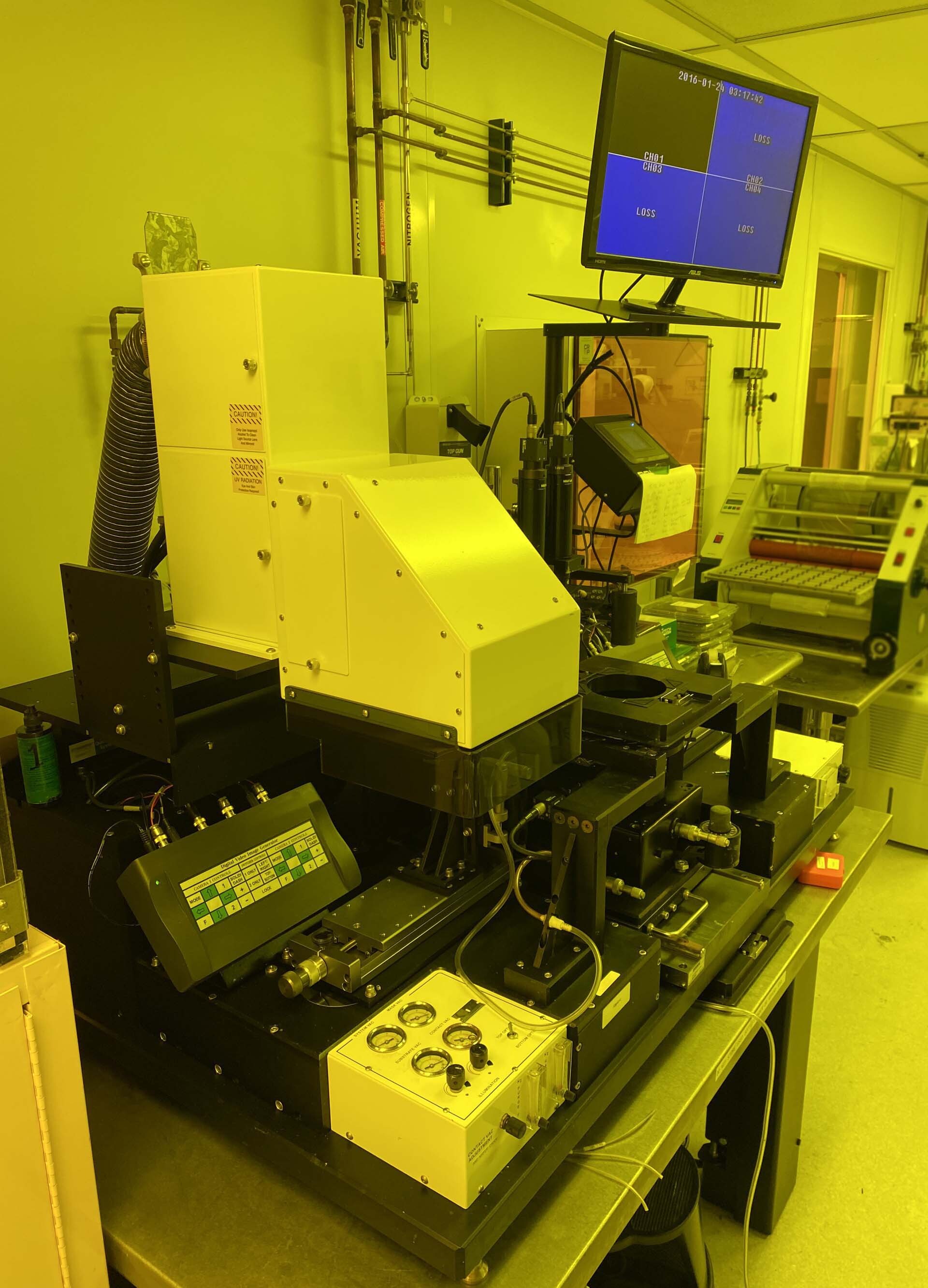

Used OAI 806 #293589824 for sale

URL successfully copied!

Tap to zoom

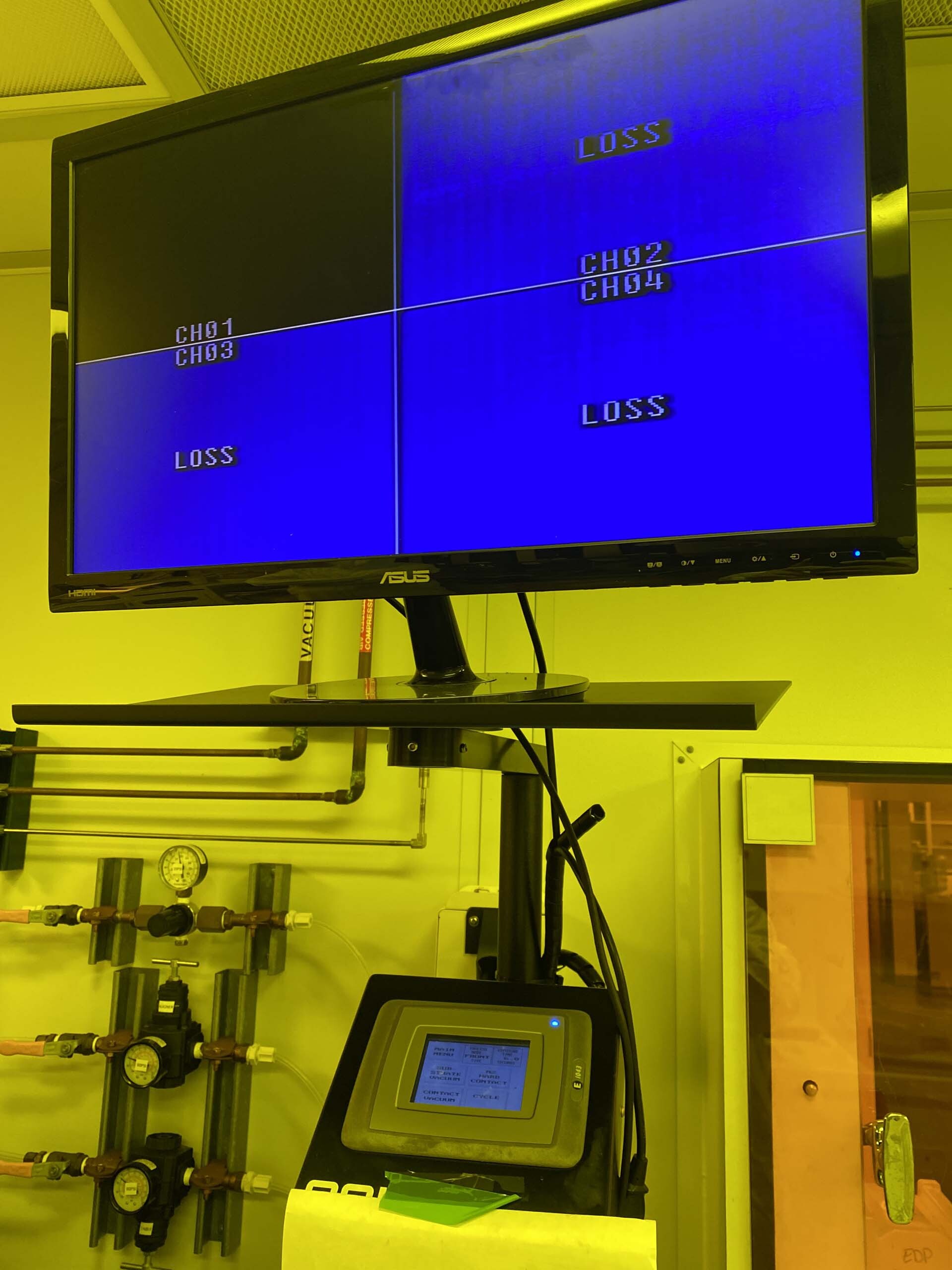

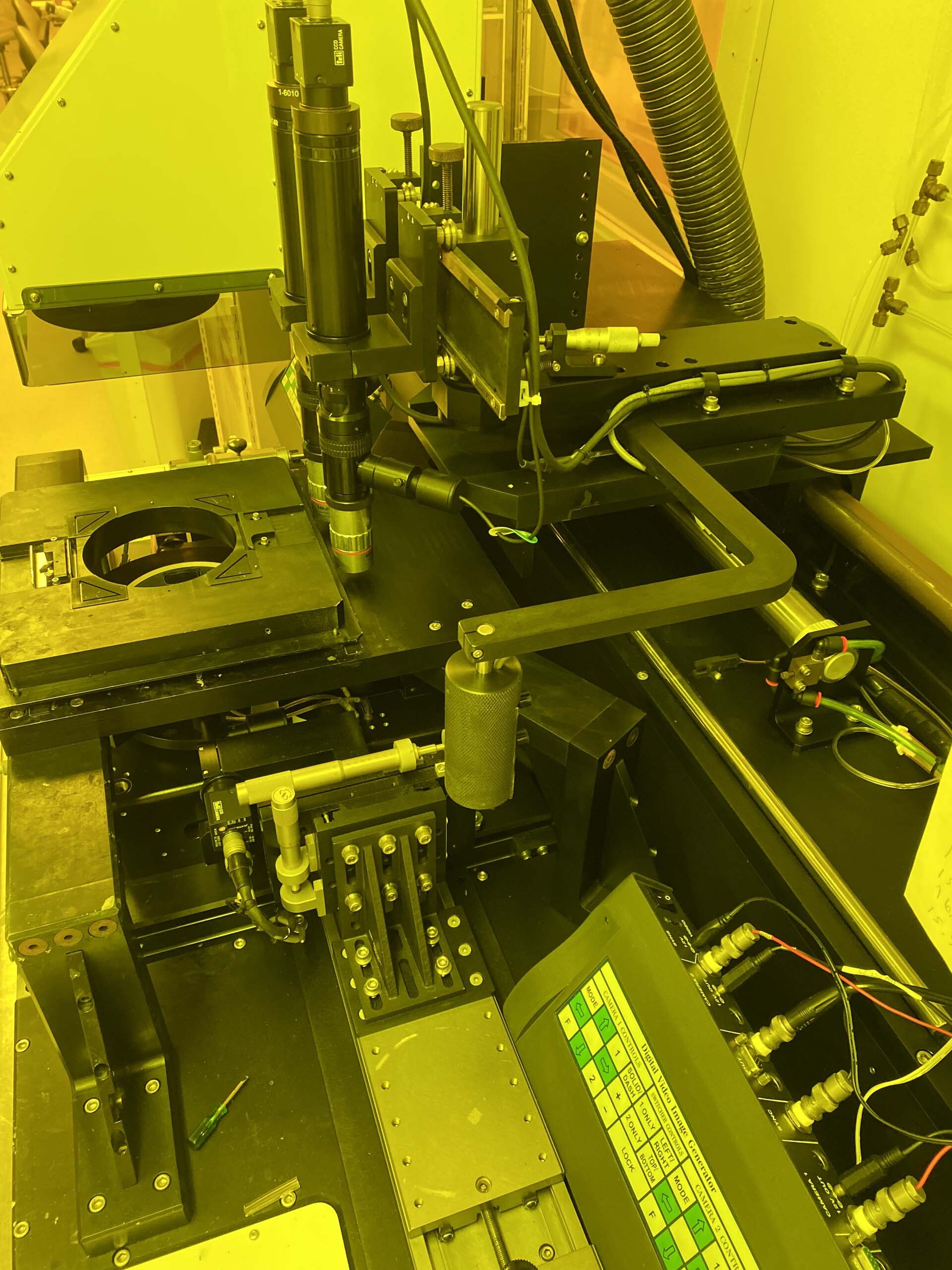

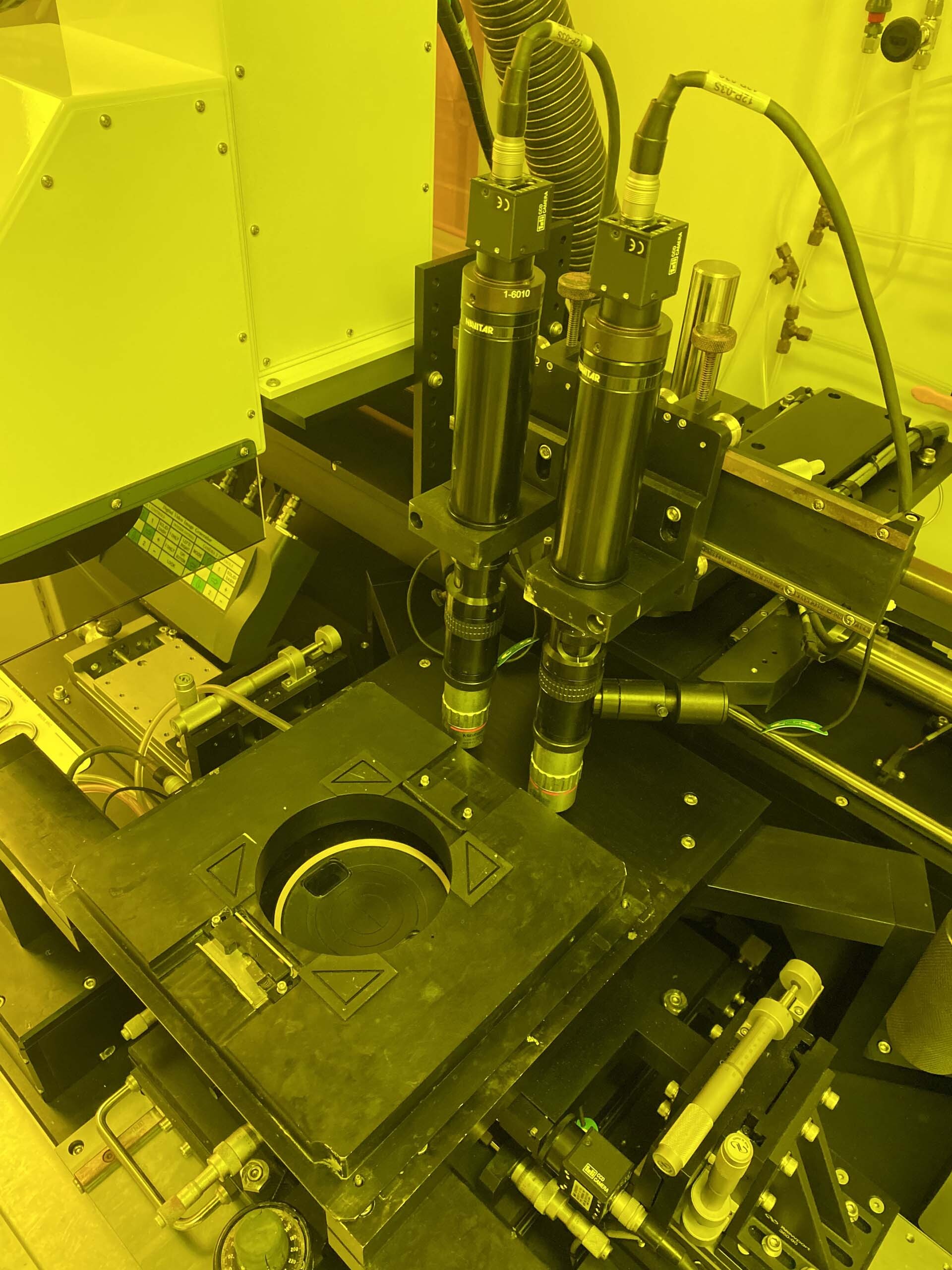

OAI 806 is an automated mask aligner designed to produce microstructures and micromechanical components at high volume. It is specifically designed to achieve the optimum resolution, accuracy and speed of production when producing multiple parts or components at once. 806 is an advanced projection lithographic equipment that uses a multiport reflection beam to produce contact masks. The pattern alignment system uses optical sensors to accurately and automatically align two masks. It also has a user-friendly graphic interface that makes programming easy. Additionally, the aligner has an integrated laser scan unit and an integrated exposure optical head for contact mask writing. The advantage of using OAI 806 mask aligner is that it can rapidly produce high density, three-dimensional microstructures and components. It has a resolution of less than 1 micron and can produce features such as airgap thicknesses of less than 0.2 micron. Additionally, the machine can expose multiple layers of substrates accurately and quickly and automate assembly processes, such as bond joining of microstructures and components. 806 aligner also utilizes a fast wafer loading and unloading process. This process involves placing a wafer chuck holder on two wheeled carts, which allows for easy and quick wafer loading and unloading. OAI 806 also offers high exposure accuracy and repeatability. The mask aligner uses air amplifiers and air dampers to control short shot exposure areas, while the optics is adjusted to meet exact emission energy requirements during the exposure process. In order to ensure optimal tool performance, 806 mask aligner is equipped with advanced selfdiagnostics. The on-board diagnostics monitor the asset抯 performance and will alert the user if any components malfunction. The integrated software further ensures the model remains efficient at all times. Overall, OAI 806 mask aligner is a robust and reliable automated mask aligner, offering cost-effective, high volume production. It is ideal for applications that require micron or submicron structures, as well as those that require rapid wafer loading and unloading, accurate and repeatable exposures, and automated assembly processes.

There are no reviews yet