Used ORIEL 8097 #9251793 for sale

URL successfully copied!

Tap to zoom

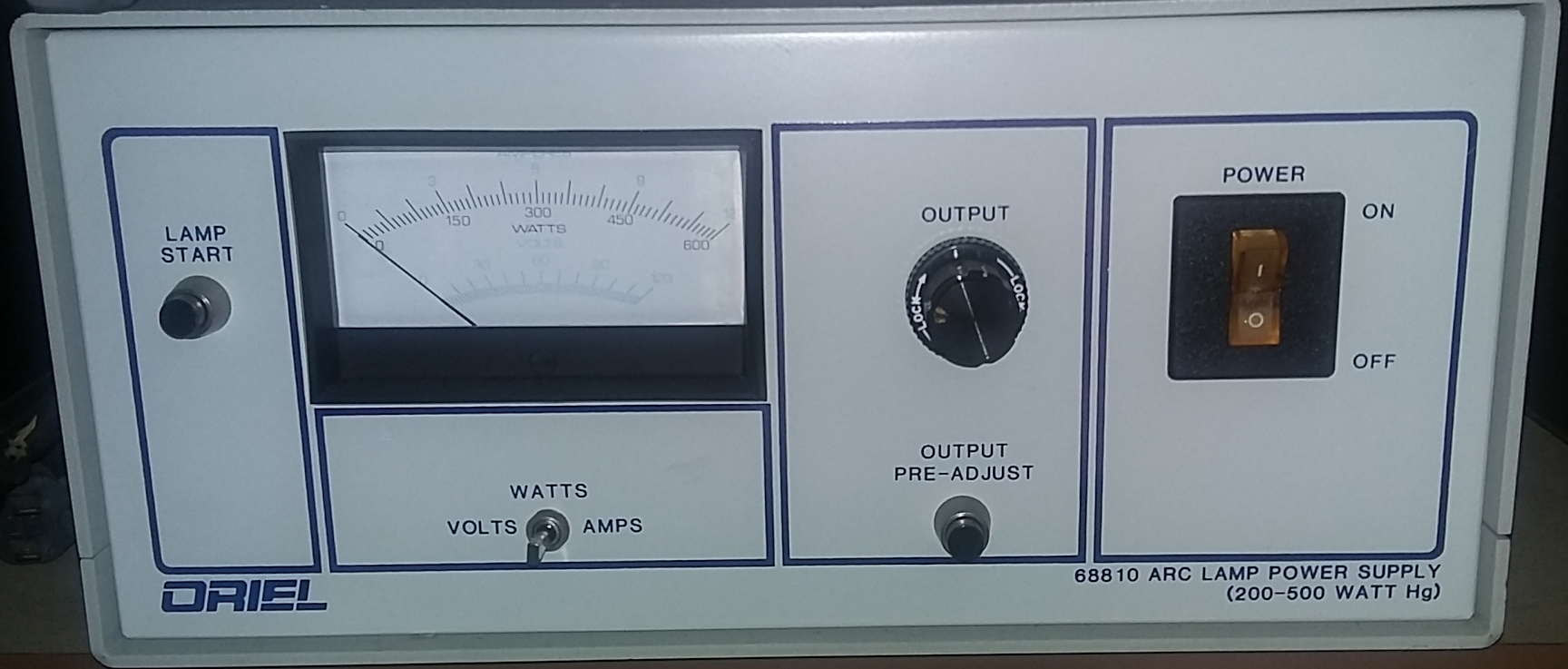

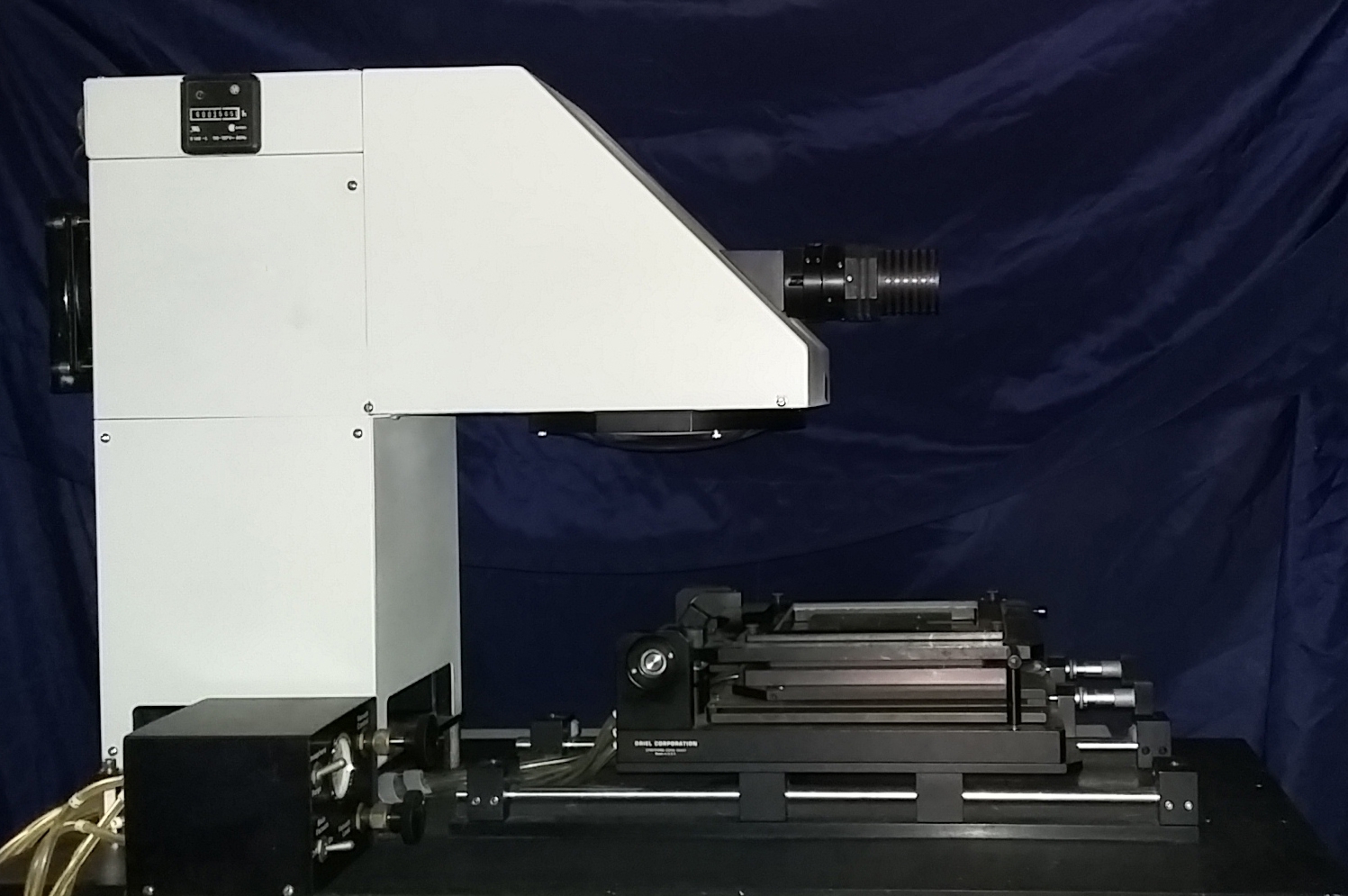

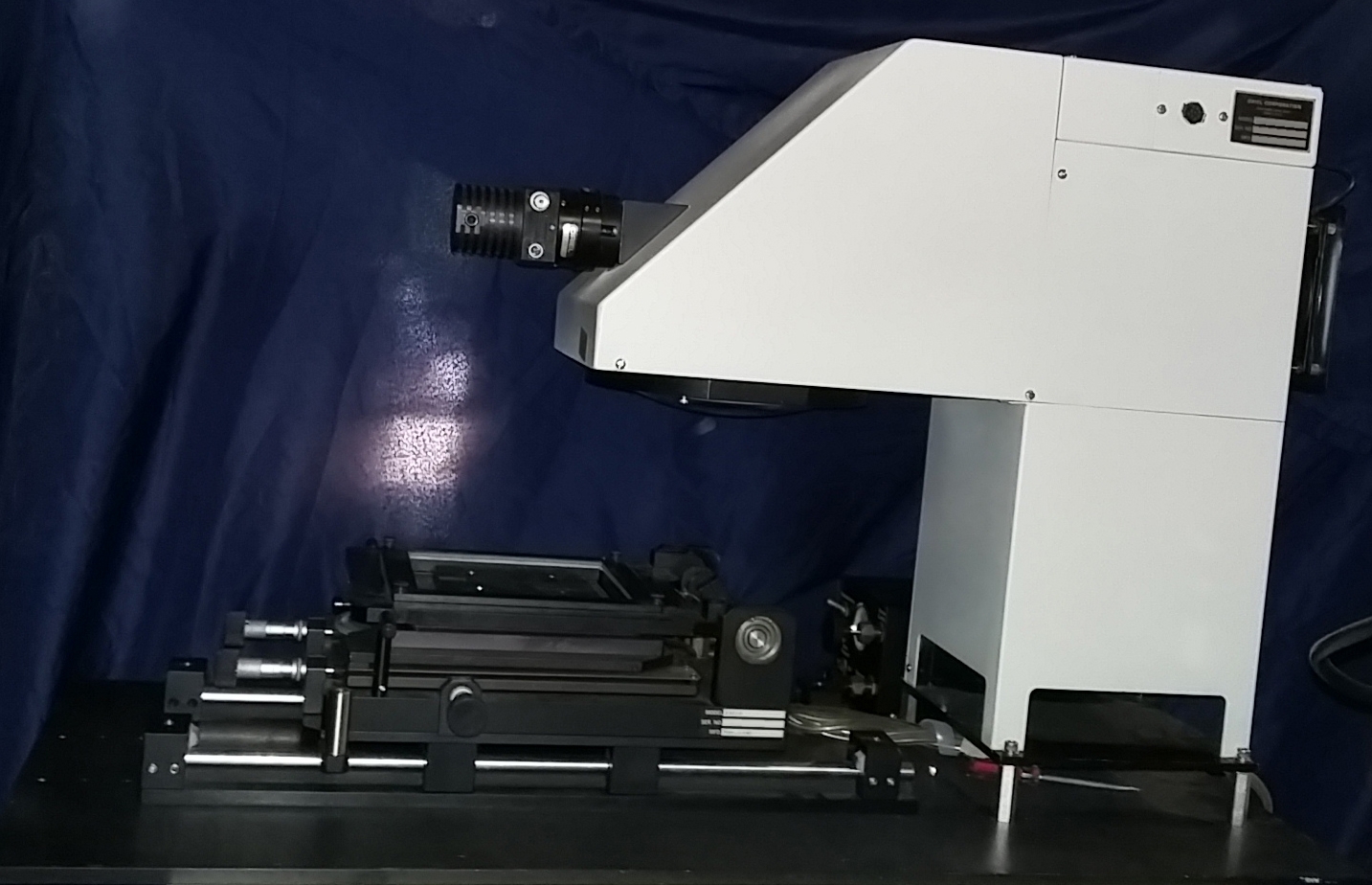

ORIEL 8097 Mask Aligner is the latest in fabrication technology that offers precision alignment and printing capabilities for Printed Circuit Board (PCB) prototypes and manufacturing. It is a process used to create repeatable and accurate components, from the smallest electronic components to larger boards and systems. It works by using Mask technology to accurately align and track patterns on the material being printed. Using UV-light sensitive electrolytic resist, 8097 can be programmed to recognize and track the patterns of a design, allowing for a uniform print layer. This process requires extremely precise alignment and calibration to produce accurate results. ORIEL 8097 utilizes advanced alignment algorithms, advanced motion control and advanced optical sensing capabilities to ensure the highest level of precision in each layer. 8097 is also equipped with advanced web-handling capabilities that allow it to move materials and objects quickly and safely. This allows for maximum output with minimal operator interference. The web-handling capabilities are also used to print on both sides of a board simultaneously. The result is improved accuracy and faster completion of tasks. ORIEL 8097 also features several safety features such as a variable speed range, adjustable vacuum limit, and a variety of additional security functions. The machine is designed to run at speeds of up to 500 parts per hour (PPM), and it also has a built-in power failure system. 8097 operates with two separate printing engines, allowing for multiple mask operations in parallel and for high throughput. The precision of the machine combined with its high speed capabilities make it a highly valuable tool in the PCB prototyping and production industry. ORIEL 8097 is a 1.8m x 2.1m x 1.26m three-axis mask aligner crafted from robust and reliable industrial components including stepper motors and encoders. The machine is easy to operate due to its intuitive control panel, which provides a graphical user interface with diagnostic and status feedback. With its integrated inspection system, 8097 is also well suited for quality assurance purposes by providing real-time data that can be used to detect defects. All of these features combined make ORIEL 8097 an essential tool for any electronics manufacturer looking for high-performance PCB fabrication.

There are no reviews yet