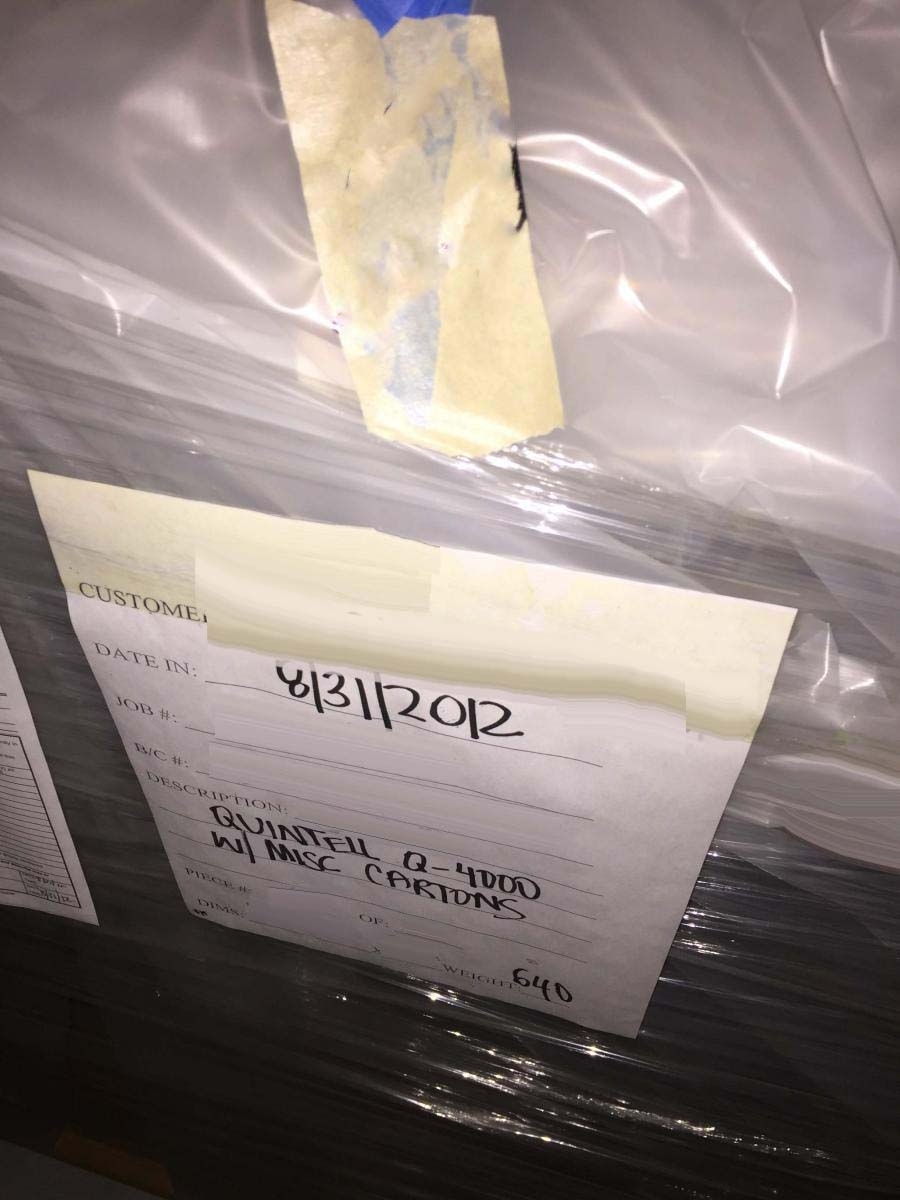

Used QUINTEL / NEUTRONIX Q 4000 #9131039 for sale

URL successfully copied!

Tap to zoom

QUINTEL / NEUTRONIX Q 4000 is a state-of-the-art mask aligner designed for the fabrication of high precision microelectronic components. This equipment combines an optimized wafer handling and machine interface with an advanced galvanometric scanner to provide highly accurate alignments and exposure of patterns (masks) onto substrates. At the heart of QUINTEL Q 4000 is its highly precise wafer placement and scanning capabilities. It utilizes a six-axis wafer transfer stage and an advanced, low-inertia galvanometer scanner that can tilt and rotate as required to achieve highly accurate results. The equipment also features precision motion controllers and a precision encoding system for precise scanning along the X, Y, and θ axes; an encoder resolution of up to 0.5μm; acceleration and velocity up to 8m/s2; and repeatability of up to 0.01mm. The wafers themselves are placed onto the transfer stage and scanned via the galvanometer scanner to carry out the mask alignment process. The unit is able to synchronize the three axes in order to accurately align the mask to the wafer with precise positioning adhering to the highest accuracy. The alignment machine is capable of exposing patterns with various levels of magnification thanks to its optics array consisting of lenses, prisms, and quartz laser light sources. NEUTRONIX Q-4000 is able to process wafers with a range of sizes and thicknesses, from 1 to 8 inches in diameter with a maximum thickness of 10.0 mm. The tool's field size is also adjustable, with a standard field size of 50×50mm, extending up to 130×130mm. Additionally, the asset is equipped to handle multiple wafer processes such as spincoating, thermal drying, and backside alignment. Furthermore, the model is powered by a Windows NT-based software package, which provides the user with the complete automation of numerous wafer preparation and mask alignment functions. It features a fully graphical user interface with a wealth of on-screen information and menus to facilitate the user. This information includes real-time updates on wafer motion, objectives, field size, alignment status, scan parameters, and more. Q-4000 is a reliable, state-of-the-art mask aligner for users who require precise alignment of patterns onto wafers for the fabrication of microelectronic components. With its six-axis wafer transfer stage, advanced and low-inertia galvanometer scanner, and Windows NT-based automation software, NEUTRONIX Q 4000 is designed to provide accuracy and reliability to all applications.

There are no reviews yet