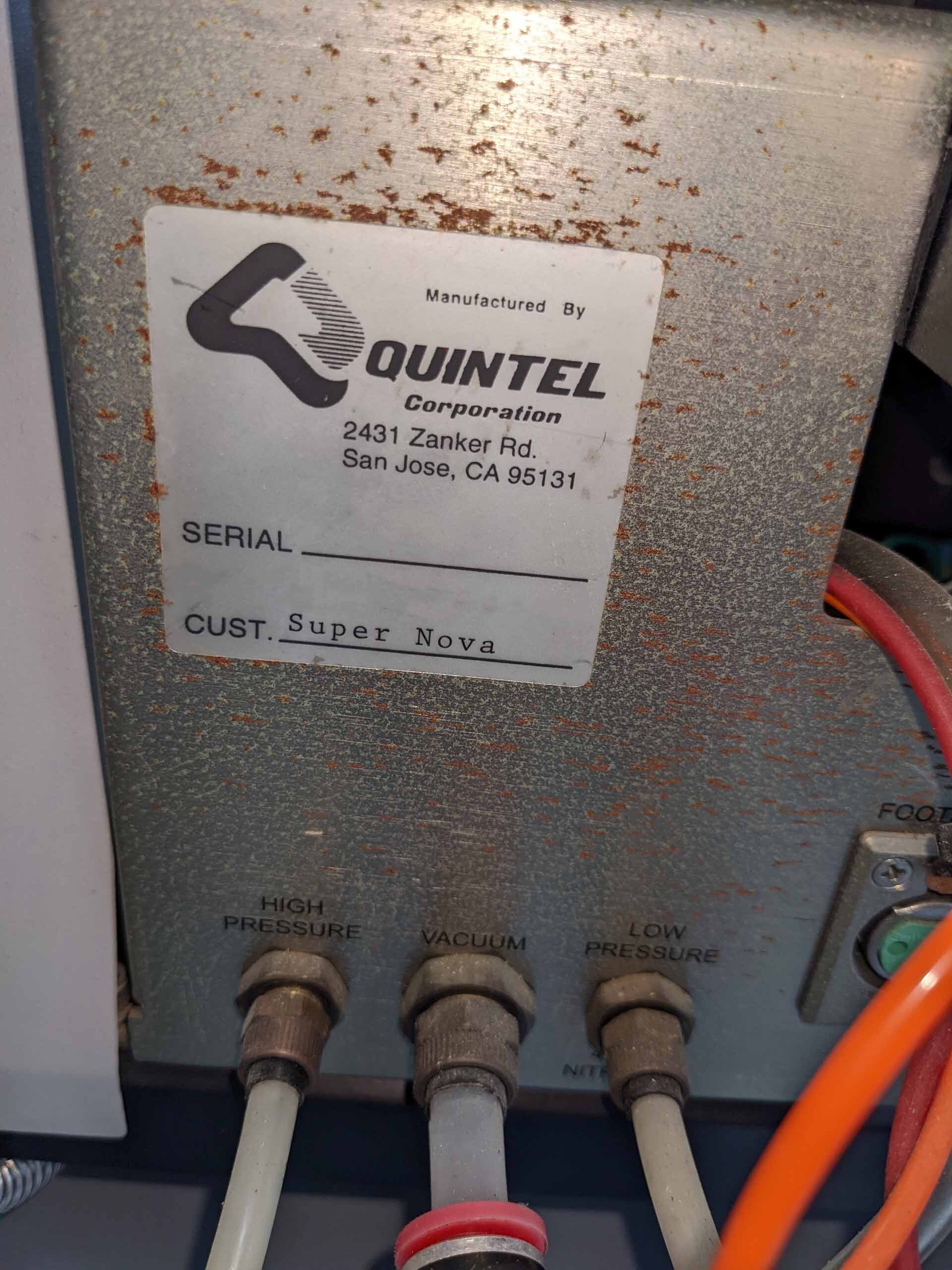

Used QUINTEL Q4000 Super Nova #9236254 for sale

URL successfully copied!

Tap to zoom

ID: 9236254

Vintage: 2003

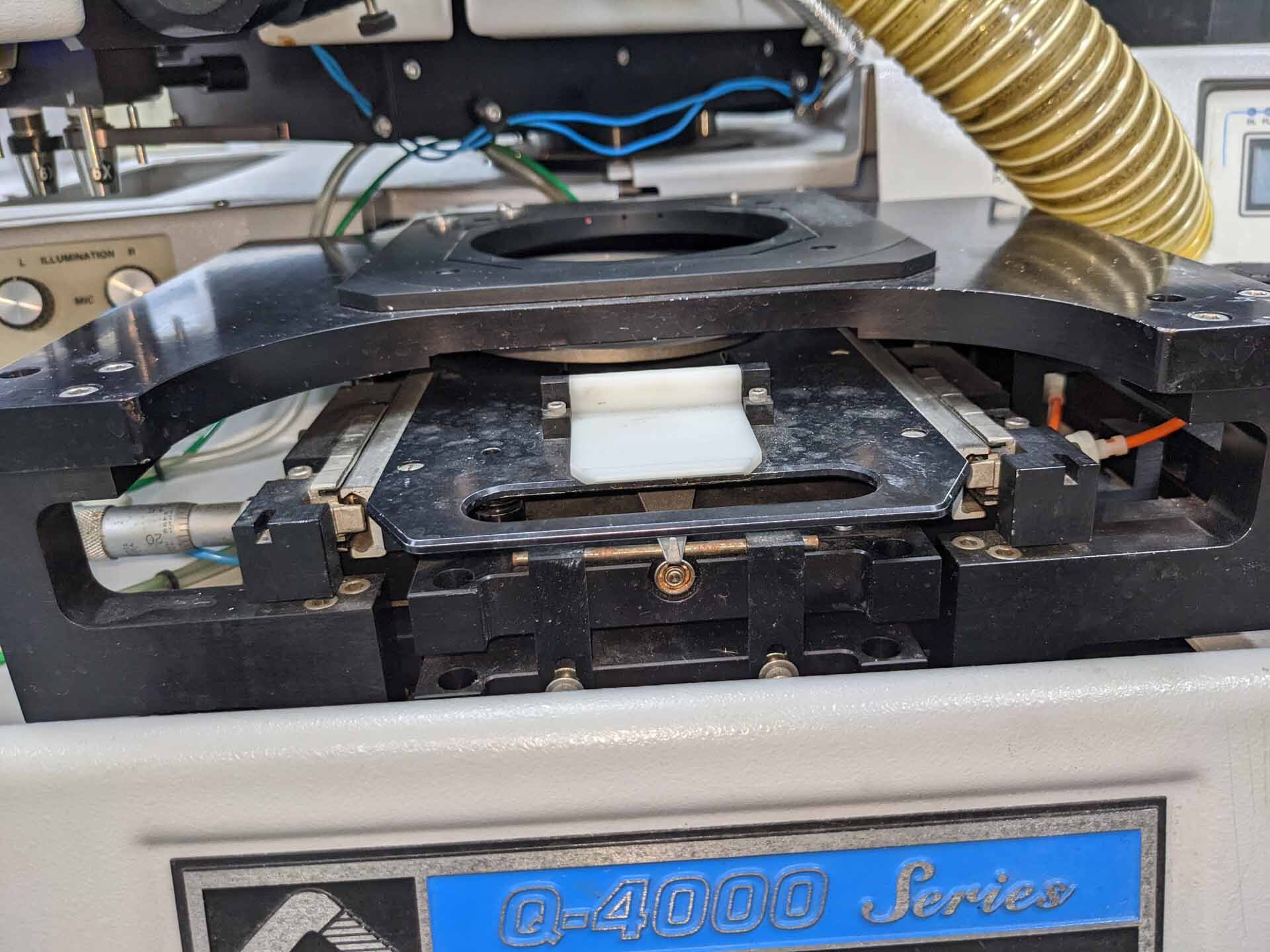

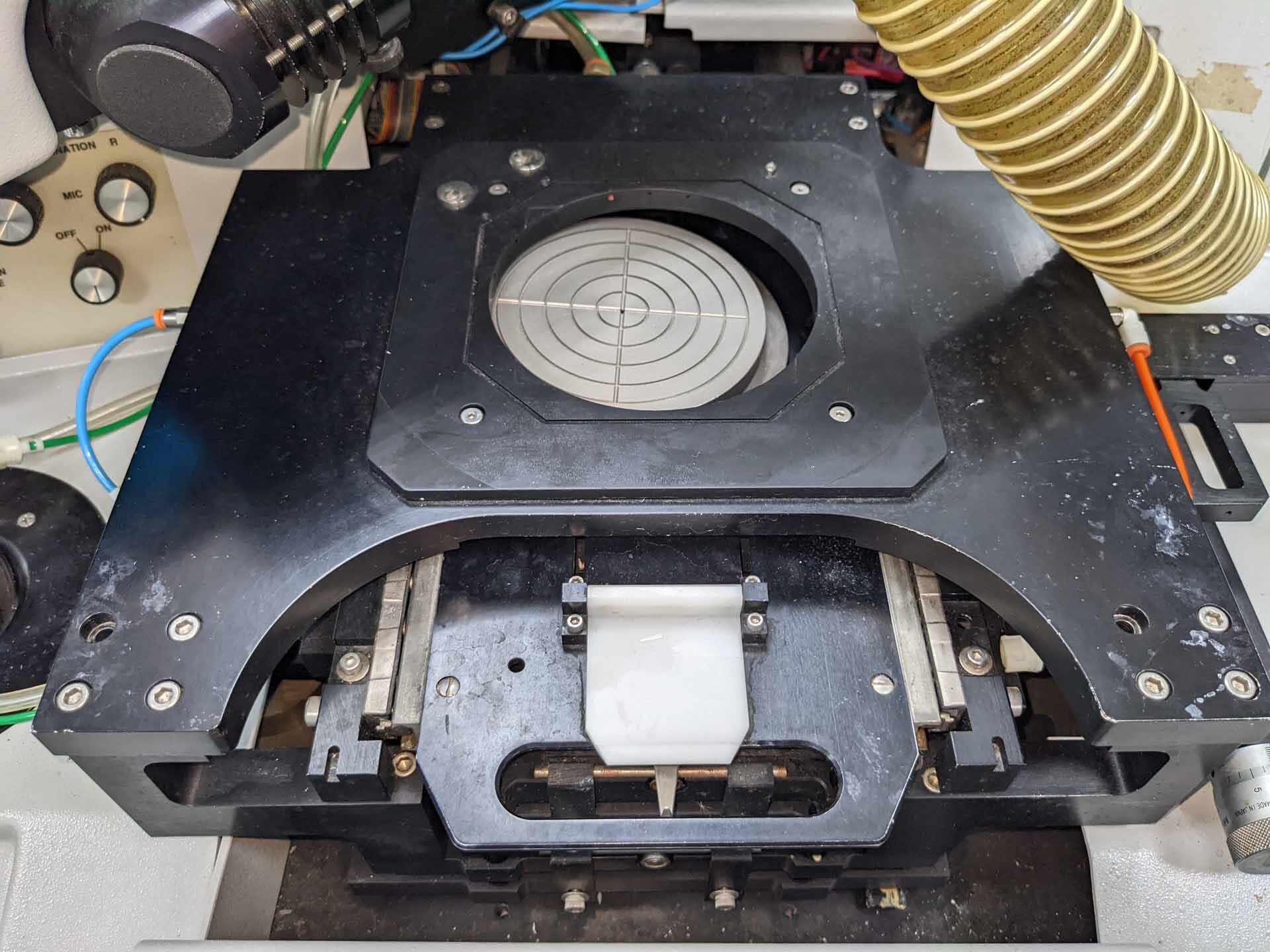

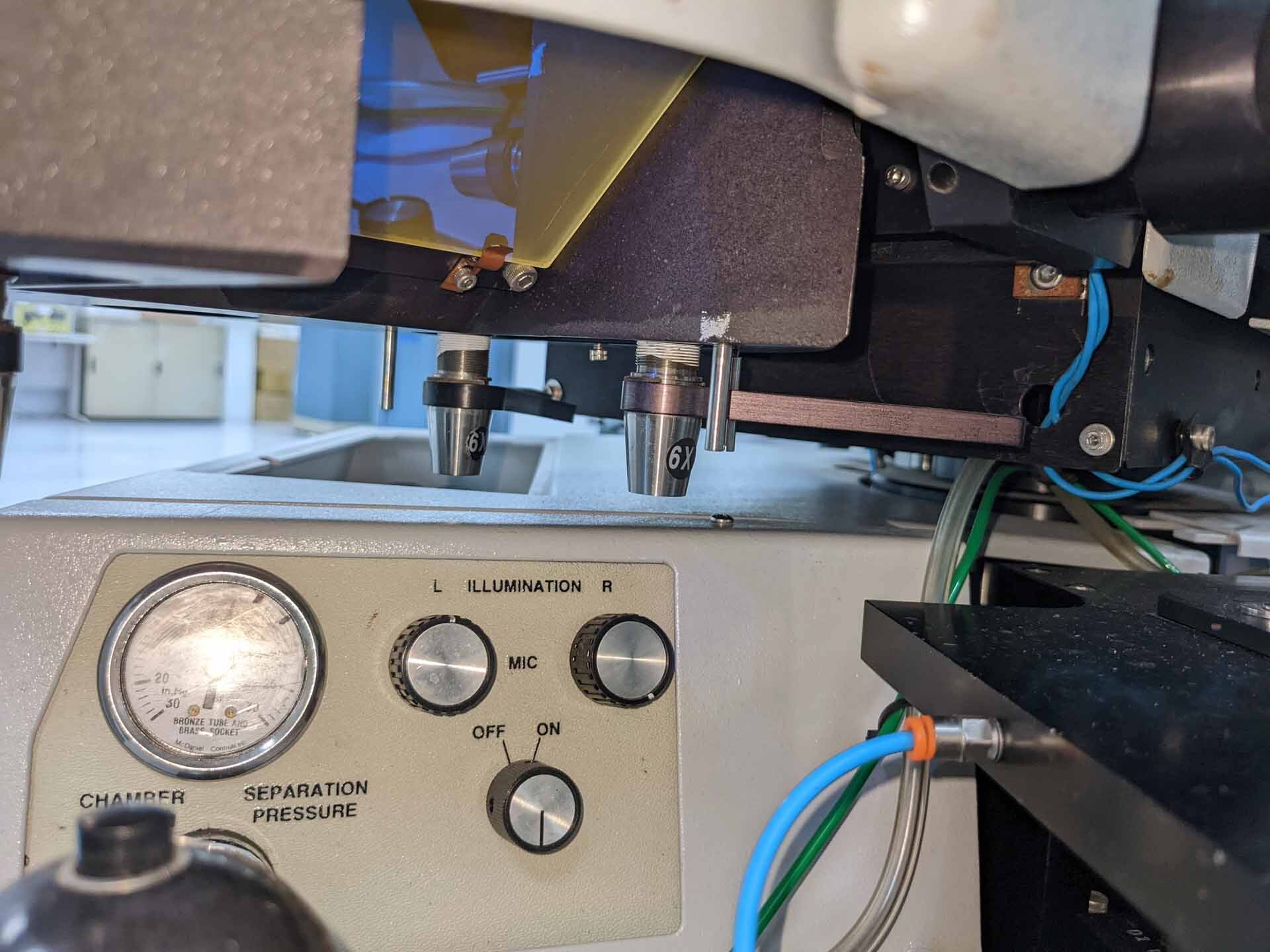

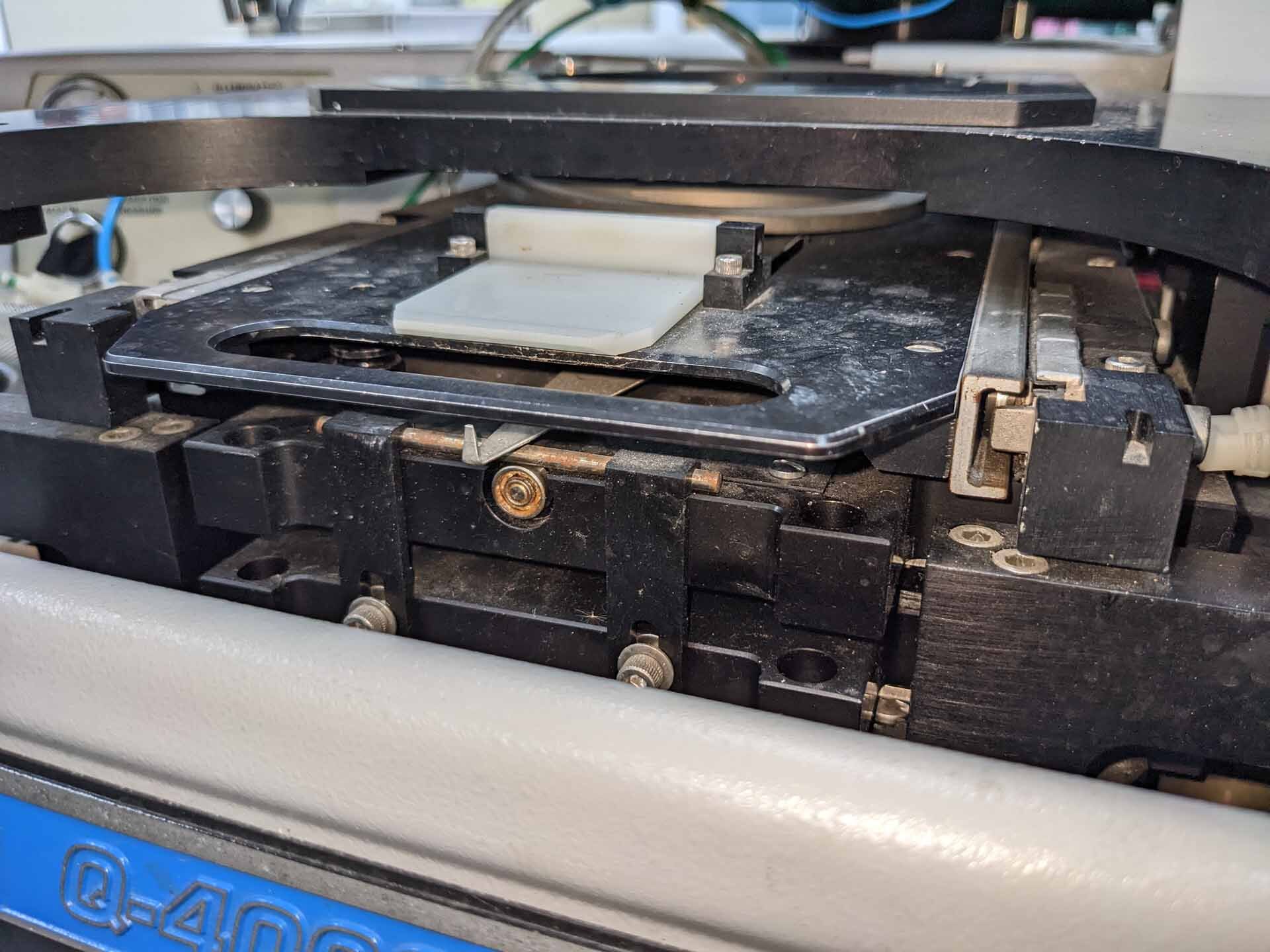

Exposure machine

Objective lens needs to be replaced

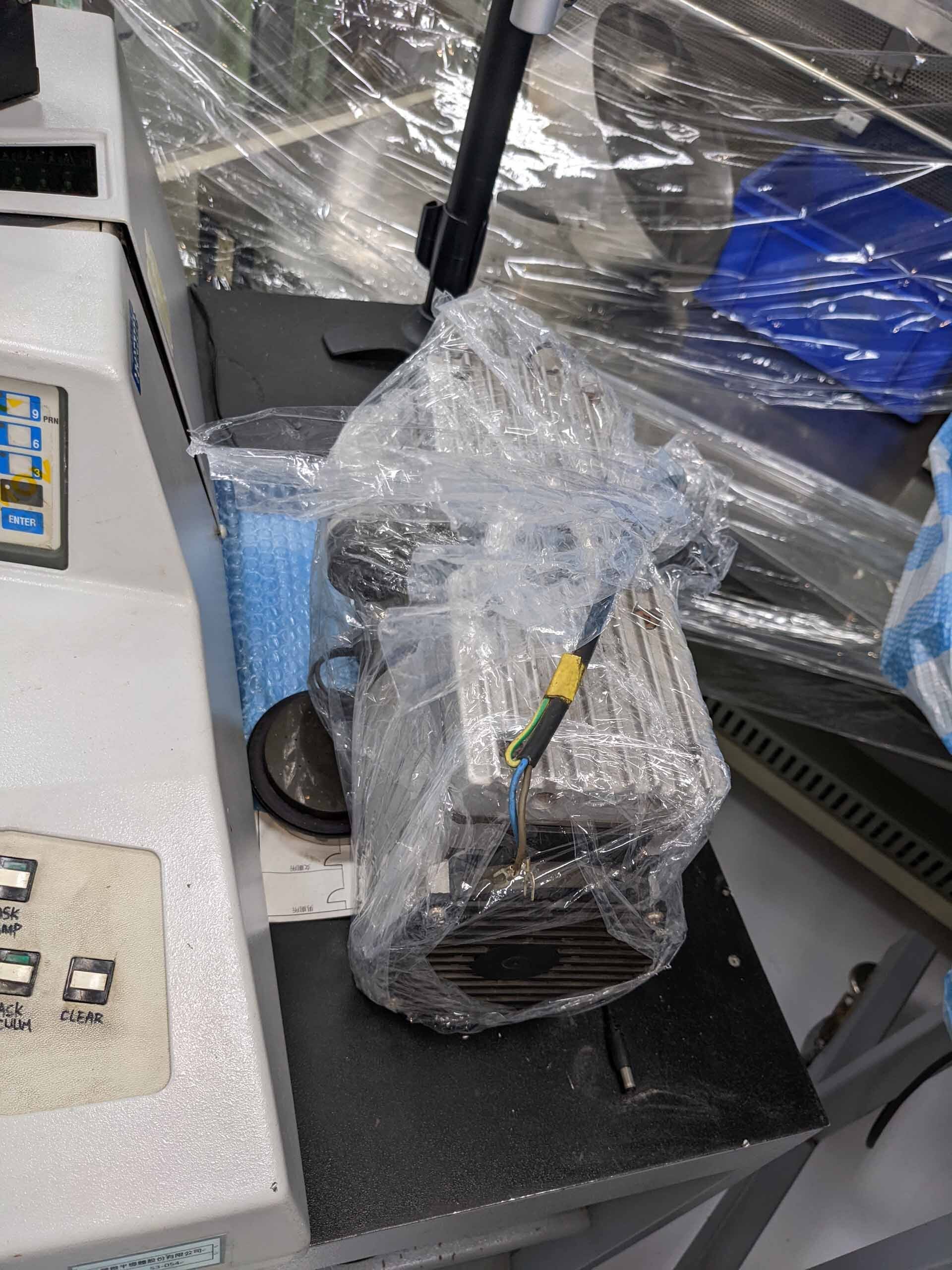

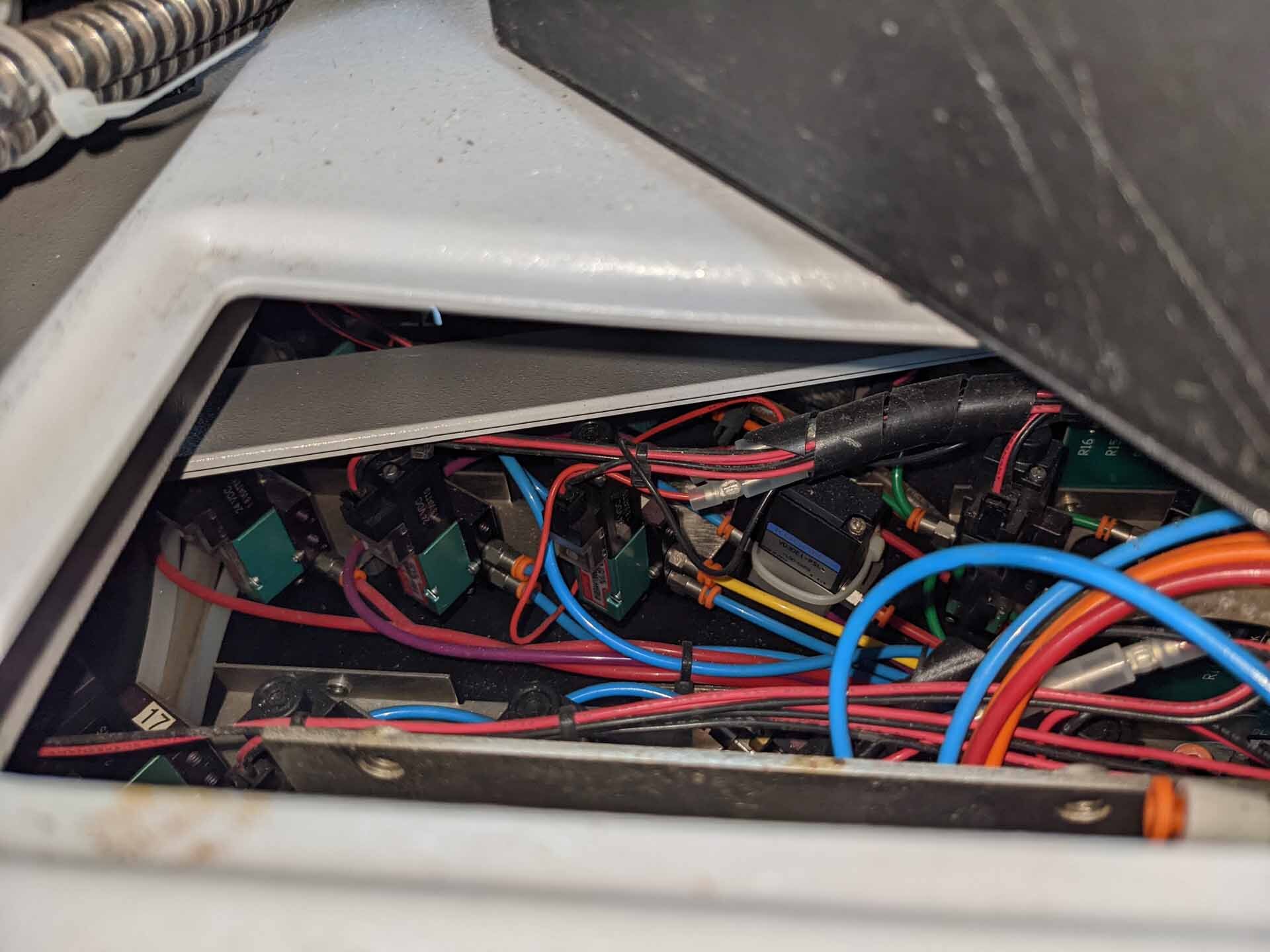

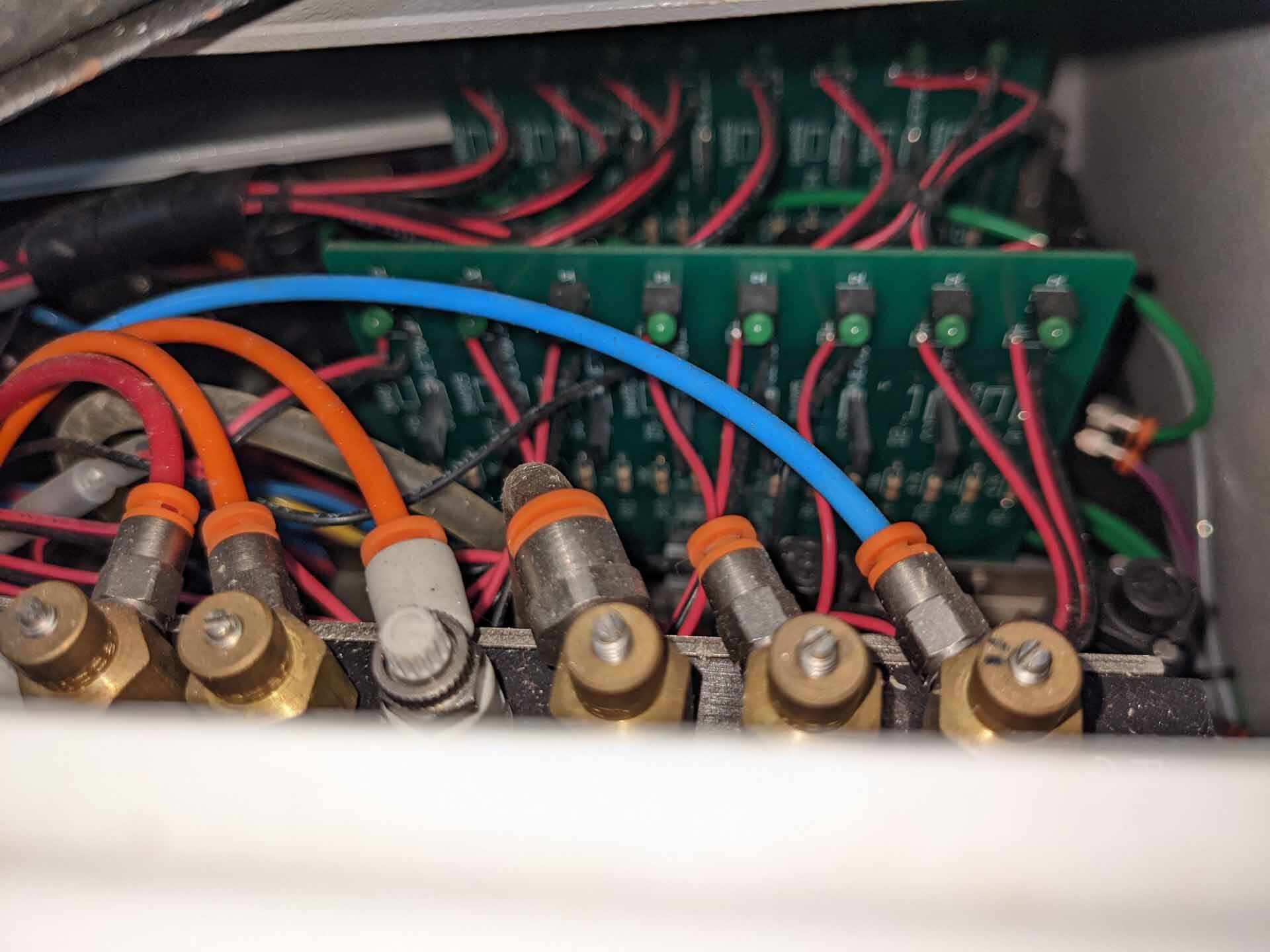

Controller missing

2003 vintage.

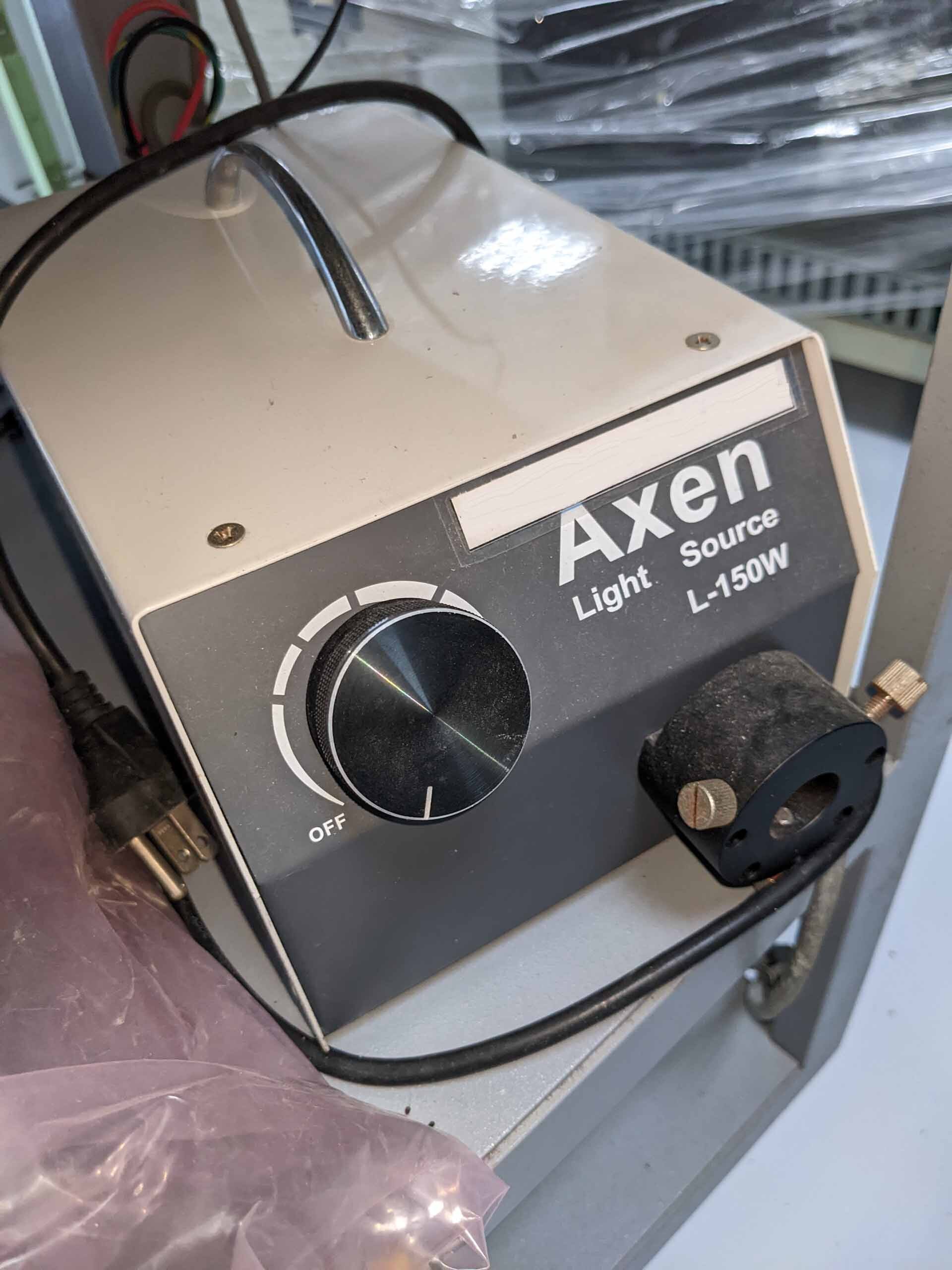

QUINTEL Q4000 Super Nova is a mask aligner which is used in precision photolithography to create patterned materials using an extreme UV exposure source. It is an advanced tool in the field of semiconductor lithography, providing high resolution and throughput in the nanometer scale. The Q4000 utilizes a high resolution projection lens equipment to achieve accurate patterning. This optical system is composed of a low frequency optical group, and a high frequency optical group. The low frequency group includes the long focal length lenses used for initial optical focusing of the beam. The high frequency optical group's primary elements are flown zoom with aperture, turreted doublets with aperture, and a volume reflector, along with a series of chambers and filter components. This allows precise adjustment to the imaging properties of the unit, without mechanical motion. The illumination source of the Q4000 is a medium power laser. This laser specializes in efficient laser pulse management and low line edge roughness (LER), resulting in superior imaging performance. The illumination control machine ensures uniform exposure distribution accuracy across the wafer while providing exposure dose control. The exposure dose is monitored and adjusted by the alignment tool. This asset includes an automated alignment procedure for aligning a mask or reticle onto a wafer or substrate. It's able to measure specimen registration, reduce any misalignment, and locate various pattern features that may be used for correction. The model also includes an alignment energy monitor, which uses laser beam energy to detect any changes in the alignment accuracy and what corrections may be needed. The control equipment of the Q4000 provides fully integrated patterning control. With high resolution pattern editing, data de-skewing, and high throughput autoscribe editing software, the pattern editor allows programming mask and wafer geometries with synthetic, pixel array and real world stored patterns. This ensures accuracy of patterns being transferred with clean edges and sharp transitions. The Q4000 allows tight process control and provides high precision for patterning in the chip manufacturing industry. Its high resolution, throughput and energy beam control system all contribute to its successful use in the industry. It provides superior patterning performance for the creation of electronic components, particularly in the field of nano-scale chips.

There are no reviews yet