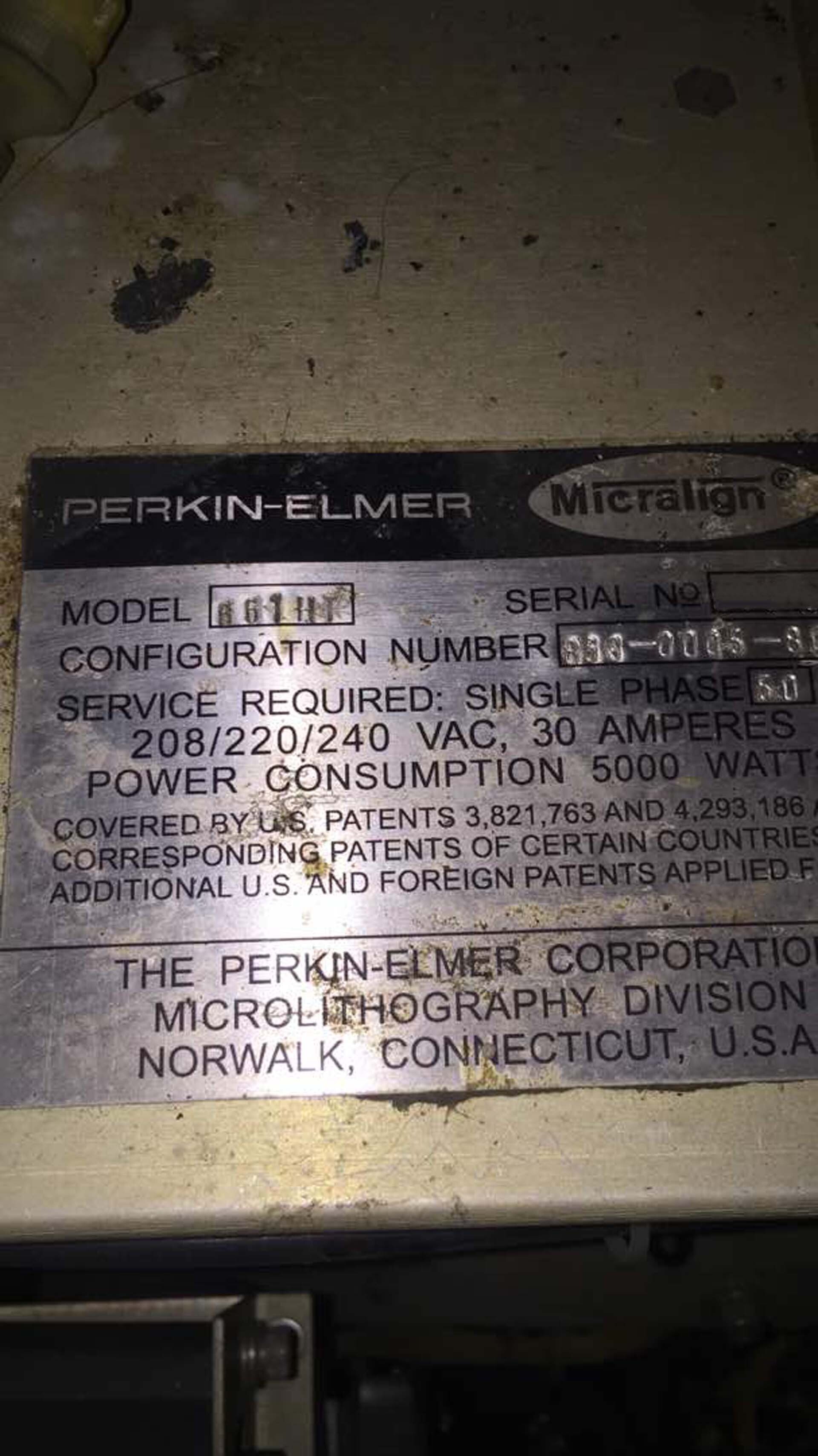

Used SVG / PERKIN ELMER / ASML 861 HT #9358413 for sale

URL successfully copied!

Tap to zoom

SVG / PERKIN ELMER / ASML 861 HT Features is a fully automatic mask aligner manufactured by SVG. The equipment is designed for advanced semiconductor processing, such as photolithography, electroplating, imaging, and pattern transfer. SVG 861 HT offers a variety of features, including support for substrates up to 8 inches in size, a high-resolution laser-based aligner, and an advanced optical chip bonding system. ASML 861 HT features a robust, motion-stabilizing dual-stage target translation table that is driven by precision linear motors. The unit incorporates both a piezo stage and a vertical motion that enables motion along three axes, which helps to maintain optimal alignment throughout the entire alignment routine. The result is greatly improved accuracy and repeatability when compared to traditional stepper systems. The machine also has a built-in dual-arm robot that automates the loading/unloading process, enabling a high-throughput workflow. The robot also provides a bridge between 861 HT and a wide range of materials, such as photomasks, substrates, spin-coaters, and other process equipment. The result is a mask-aligner that can run a variety of process steps in an efficient manner. PERKIN ELMER 861 HT is also equipped with an advanced laser-based alignment tool. This asset utilizes a blue light laser and two precision detectors to quickly locate the edges of the substrate in order to achieve precise alignment. The model can accommodate a wide range of materials without making any modifications, including various types of photomasks. SVG / PERKIN ELMER / ASML 861 HT also offers advanced optical-chip bonding that is capable of bonding up to five chips at once. The resulting product is high strength, repeatable, and has minimal misalignment from chip to chip. The bonding process is also fast, thanks to the use of a high-speed galvanometer. SVG 861 HT is also equipped with a highly sensitive laser profile monitor that is used to verify the quality of the substrate. The data gathered by the monitor is used to ensure correct focus and exposure settings for the optical chip bonding process and for overall consistency. All of this helps to ensure the highest level of product yield and the lowest level of contamination. Overall, ASML 861 HT is an advanced, fully-automated mask-aligner that offers a wide range of features that enable efficient, high-quality semiconductor processing. The dual-arm robot, laser- based aligner, and optical chip bonding equipment help to make the system versatile and highly productive. Furthermore, the laser profile monitor adds an extra layer of protection against contamination and yield losses due to misalignments.

There are no reviews yet