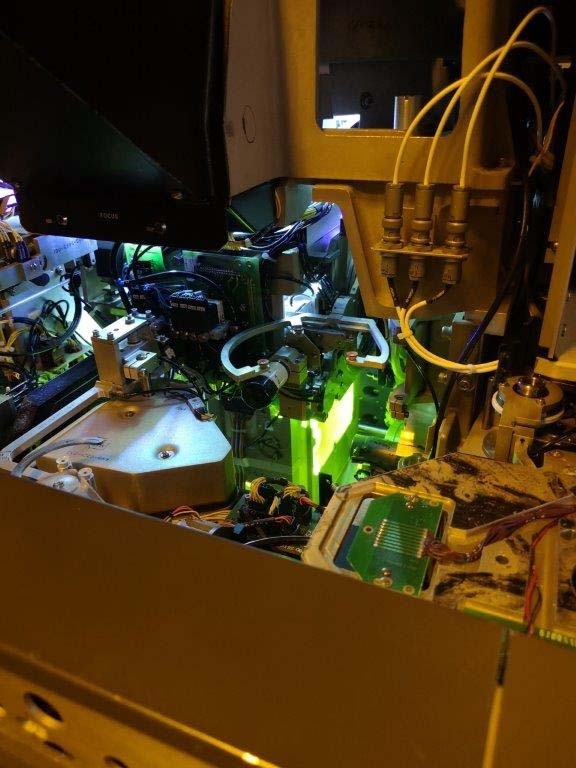

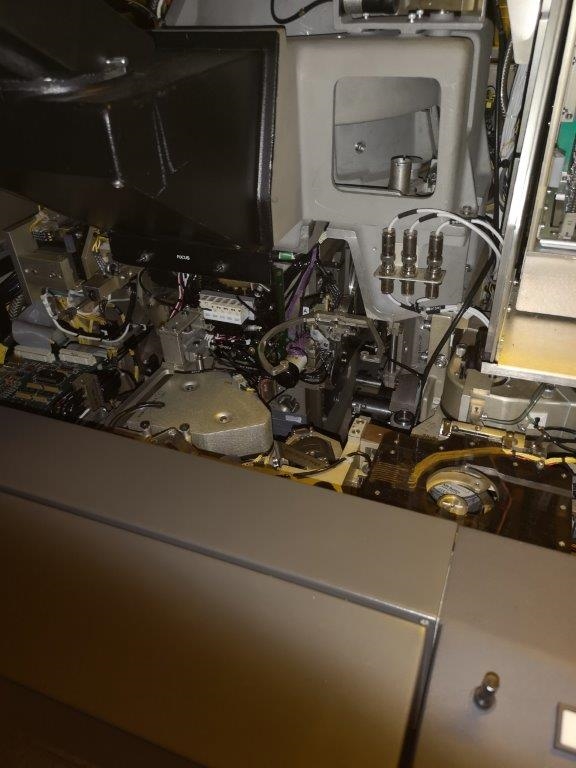

Used SVG / PERKIN ELMER / ASML Micralign 700 #9238309 for sale

URL successfully copied!

Tap to zoom

ID: 9238309

Wafer Size: 5"

Projection mask alignment system, 5"

PERKIN ELMER 651 / 551 HT

Auto Fine Alignment (AFA)

Pre-alignment system

Depth of focus: ± 6 Microns for 1.5 Micron wide lines and spaces (UV-4)

Distortion plus magnification tolerance: ± 0.25 Micron

Manual alignment: ± 0.25 Micron, 98% of data population

Automatic alignment and magnification compensation: ± 0.25 Micron range, 98% of data population

Uniformity of illumination: ± 3.0 % or <2 % for 2" and 4"

Throughput rate: ≥ 100 Wafers per hour (UV-40, OEM Spec.)

Resolution:

At 320nm - 440nm (UV- 4) 1.25 Micron wide lines and spaces

At 300nm - 350nm (UV- 3) 1.00 Micron wide lines and spaces

At 420nm - 280nm (UV- 2) 0.90 Micron wide lines and spaces

Overlay machine to machine: ± 0.30 Micron, 98% of data population

With automatic alignment and magnification compensation operating

Spectral range: 240 nm Through visible with standard secondary

Mini-mag system

Pick and place autoload (PAL)

High reliable mod 600 pre-aligner assy

PCE Mask carrier

PCE Cassette for test mask

HT Condenser

Manual included

Automatic fine alignment kit.

SVG / PERKIN ELMER / ASML Micralign 700 is a wafer-to-mask aligner technology that provides excellent lithography capability for manufacturing advanced integrated circuits. It is a state-of-the-art, high-precision alignment equipment that ensures the accuracy and quality of every process. The system features two independently-controllable stages: the x-y stage and the z-axis stage. The x-y stage is a high-precision θ/Φ stage with a digitally encoded, high resolution positioning unit that provides accurate, repeatable alignment of the wafer and the reticle. The z-axis stage provides a variable-precision machine to ensure that the nodal point distance between the reticle and wafer remains consistent during all alignments. The microscope optics are designed for high numerical aperture, providing superior resolution for precise alignment. The scanner tool design also provides a highly stable optical asset for accurate, repeatable alignment times. The scanner and the x-y stages are combined in a single unit, resulting in a compact footprint that offers improved stability and uniform irradiance. The model includes a sophisticated, high speed alignment computer that maintains the equipment speeds at a constant high speed operation, ensures accuracy and stability, and verifies alignment accuracy. The system also has an embedded wafer surface inspection unit that checks for any anomalies and defects that may affect the quality of the alignment. The software is user-friendly and intuitive, allowing users to quickly program and monitor the alignment process. Additional features include camera and imaging capability for critical device inspections and process adjustments. SVG Micralign 700 is an ideal tool for semiconductor manufacturers, providing best-in-class alignment accuracy and precision for any process step. It is a must-have technology for high-volume production of state-of-the-art integrated circuits.

There are no reviews yet