Used TAMARACK 191 #9181537 for sale

URL successfully copied!

Tap to zoom

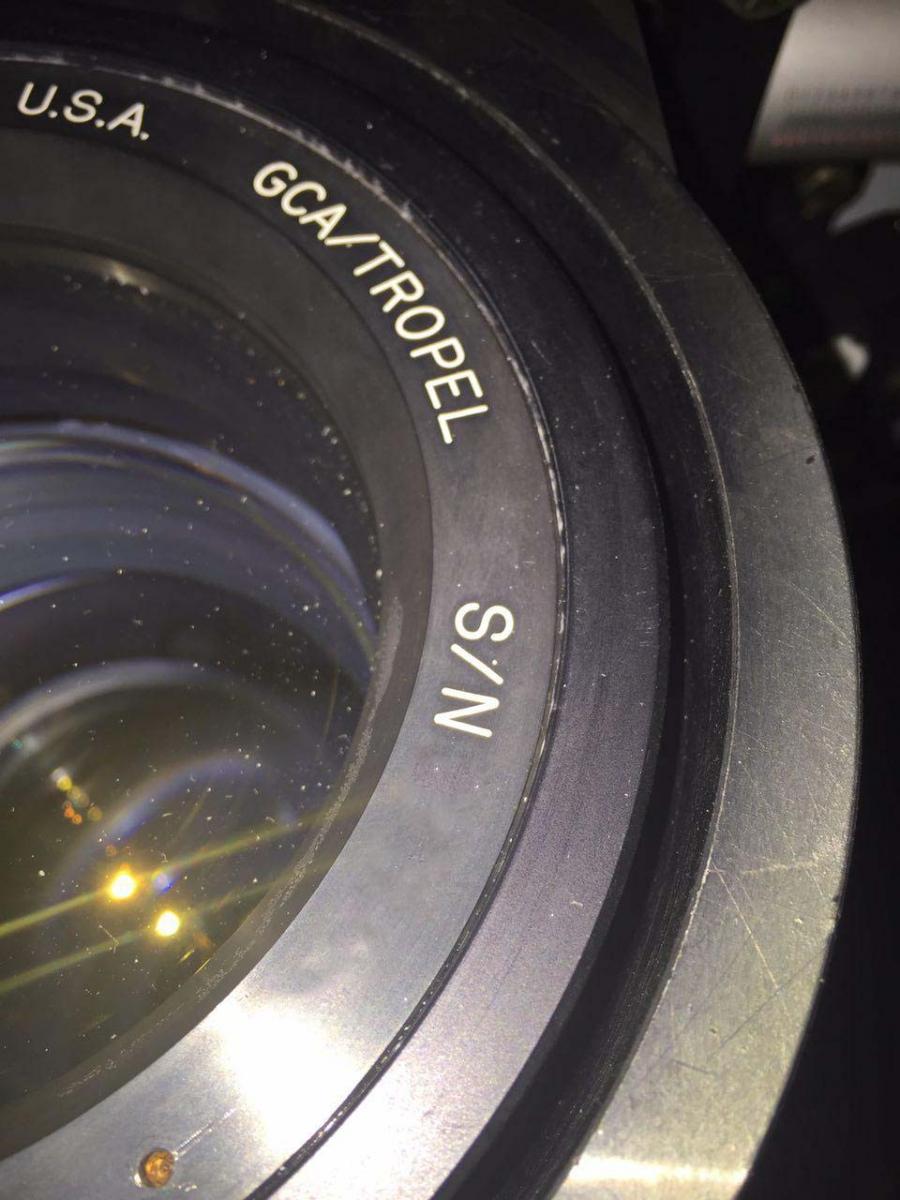

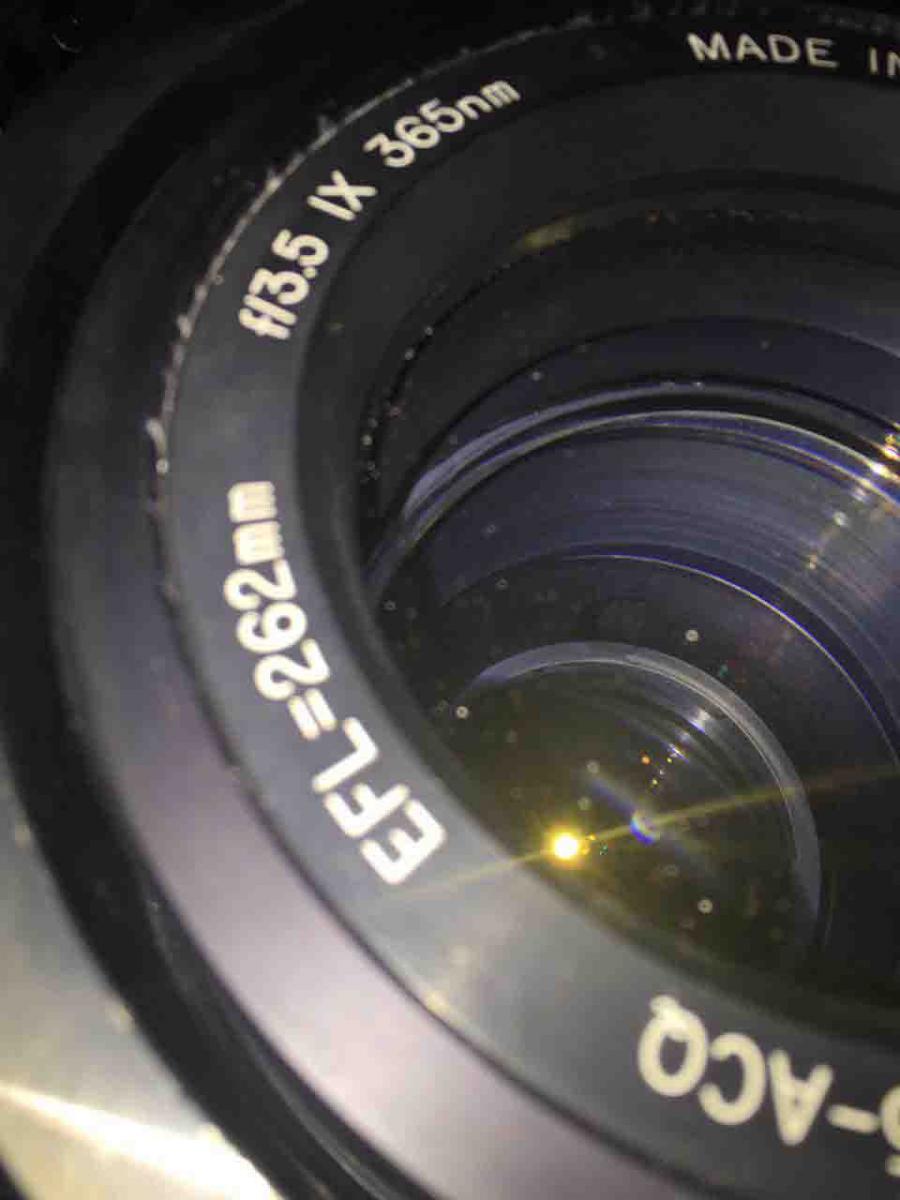

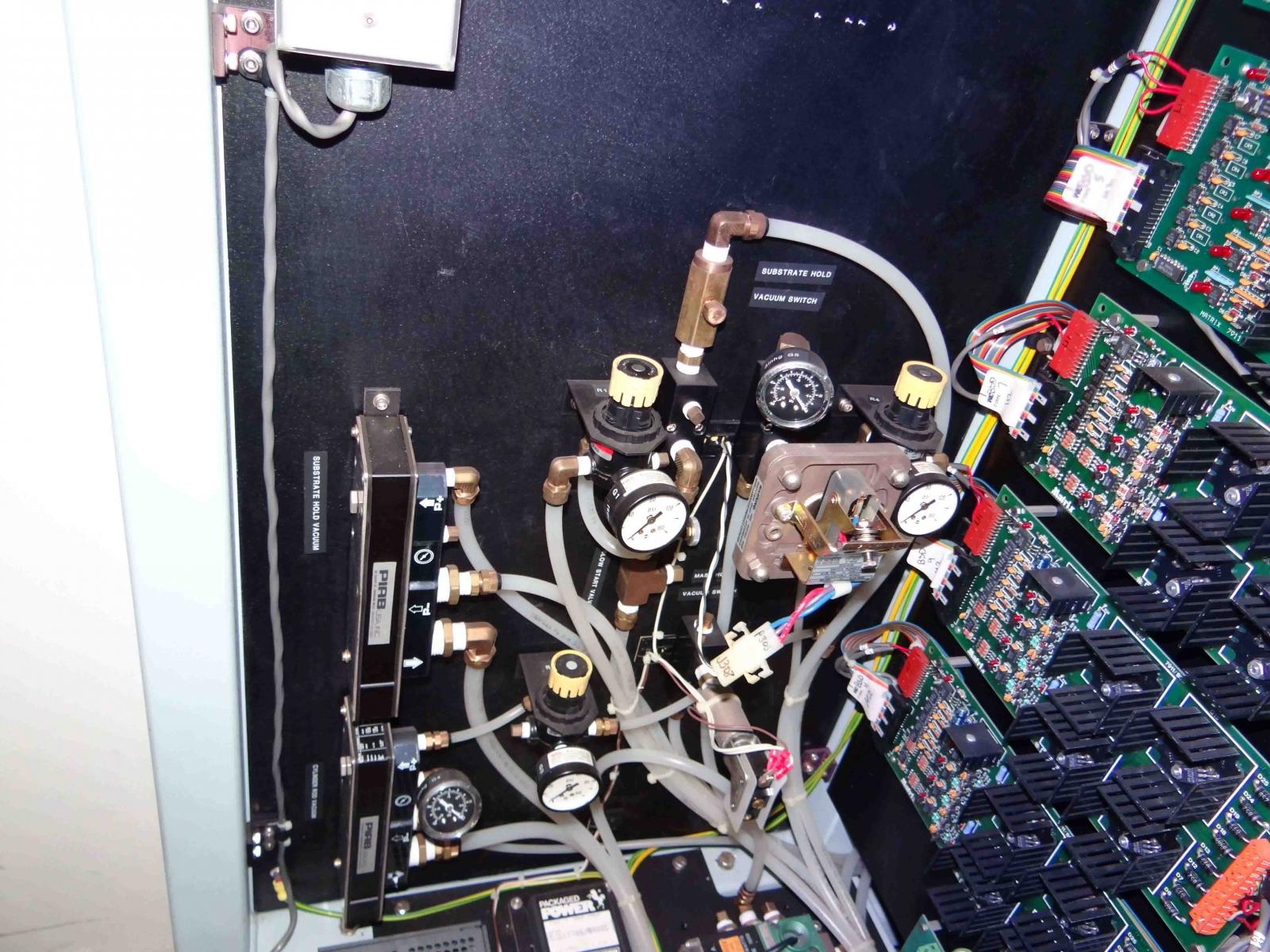

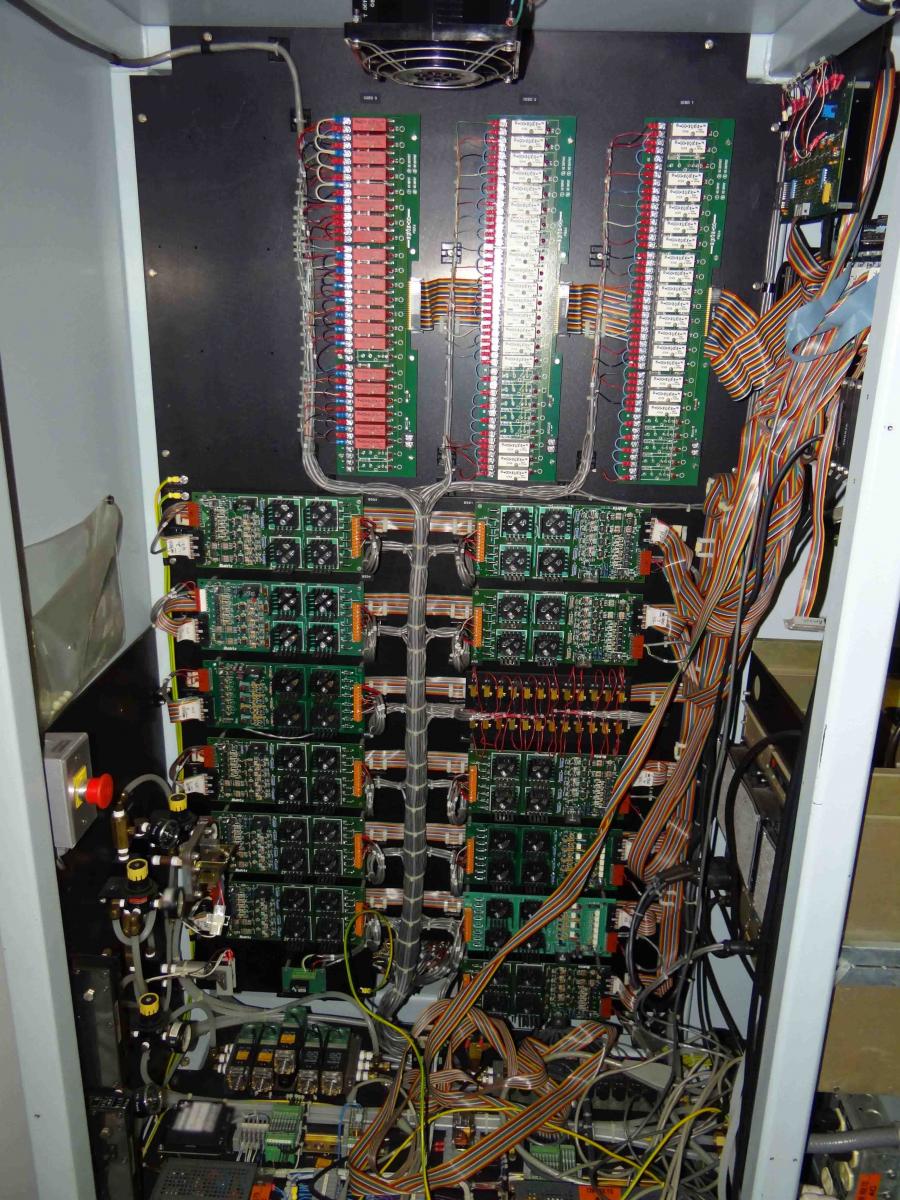

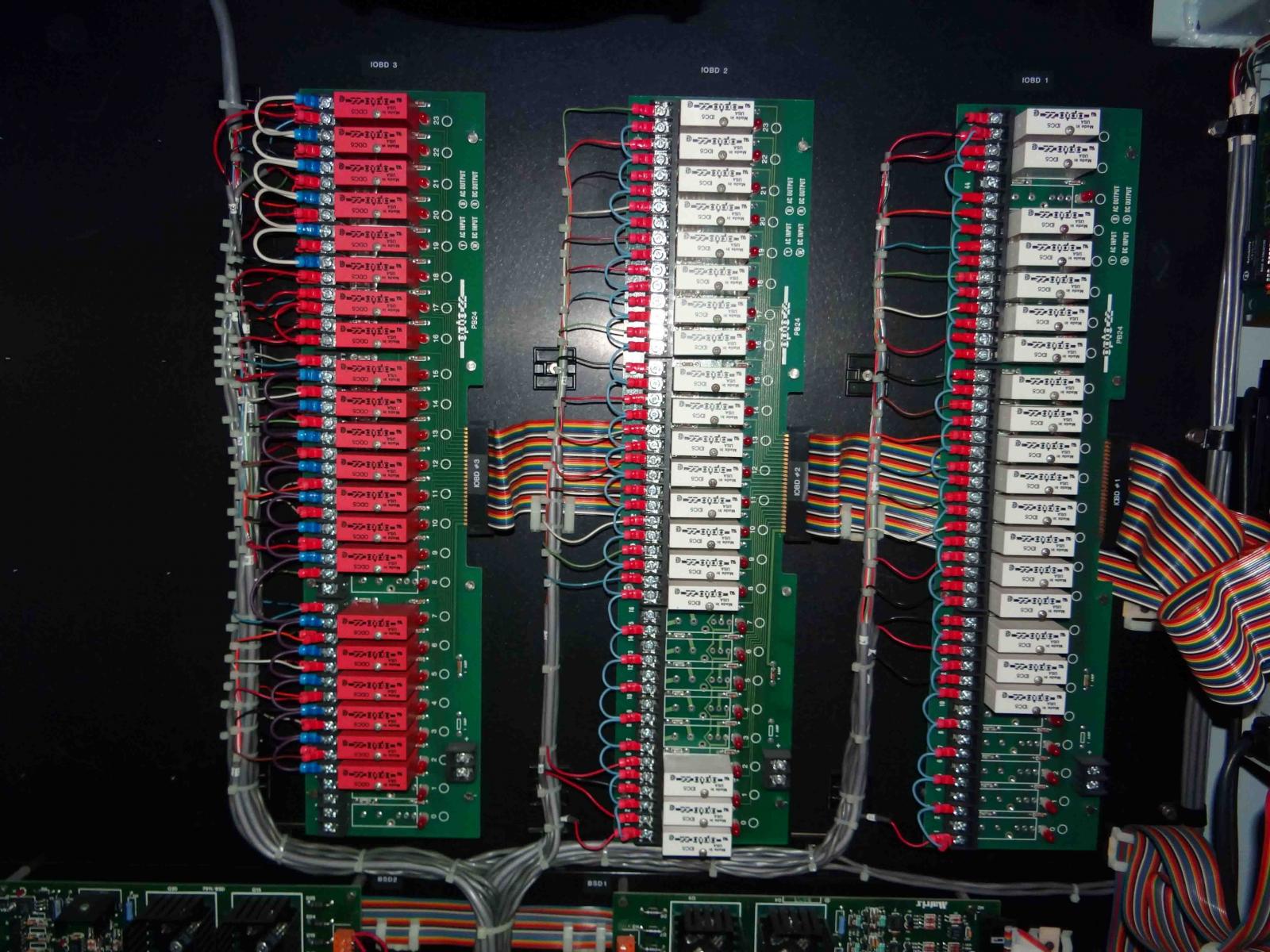

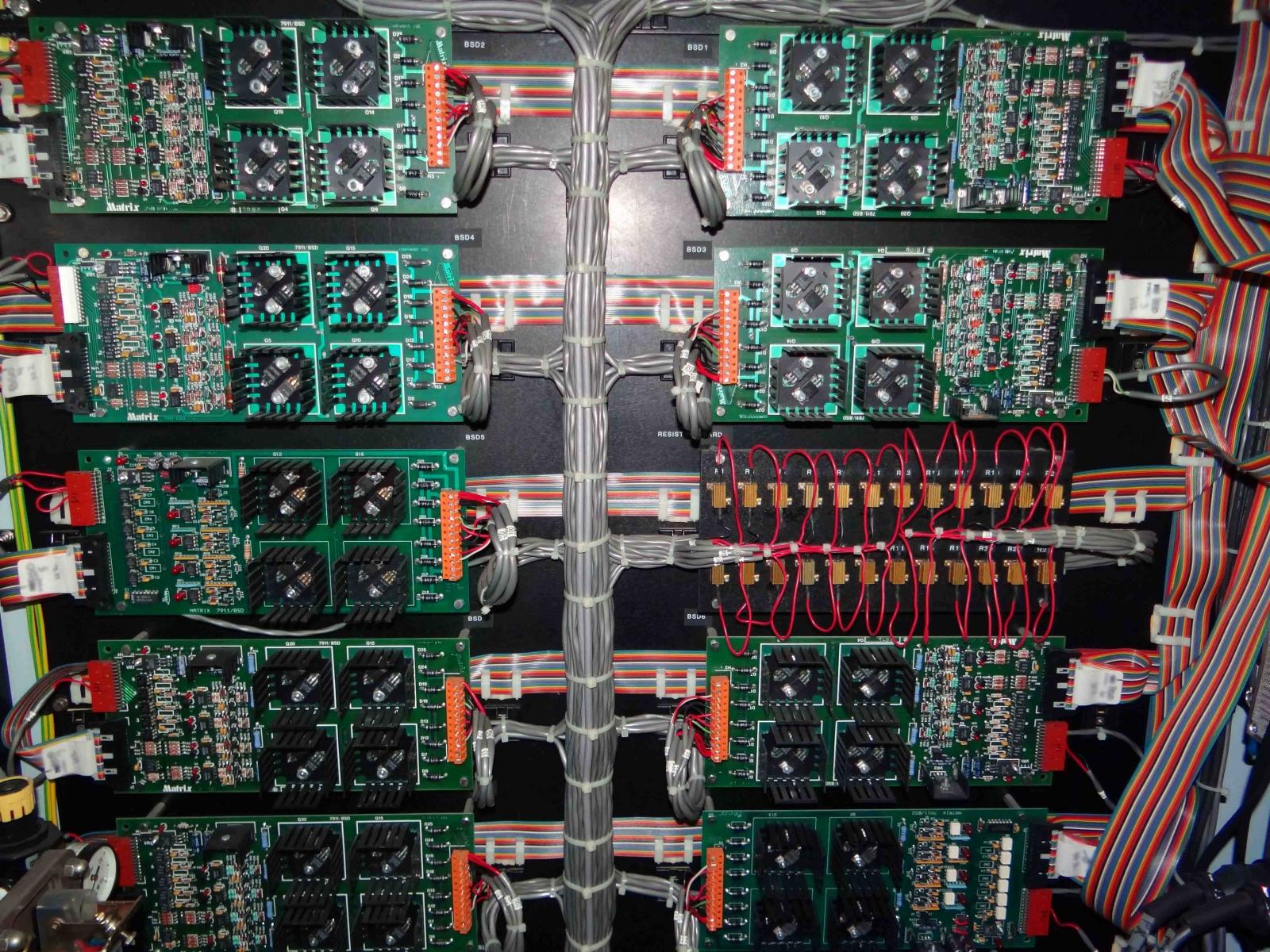

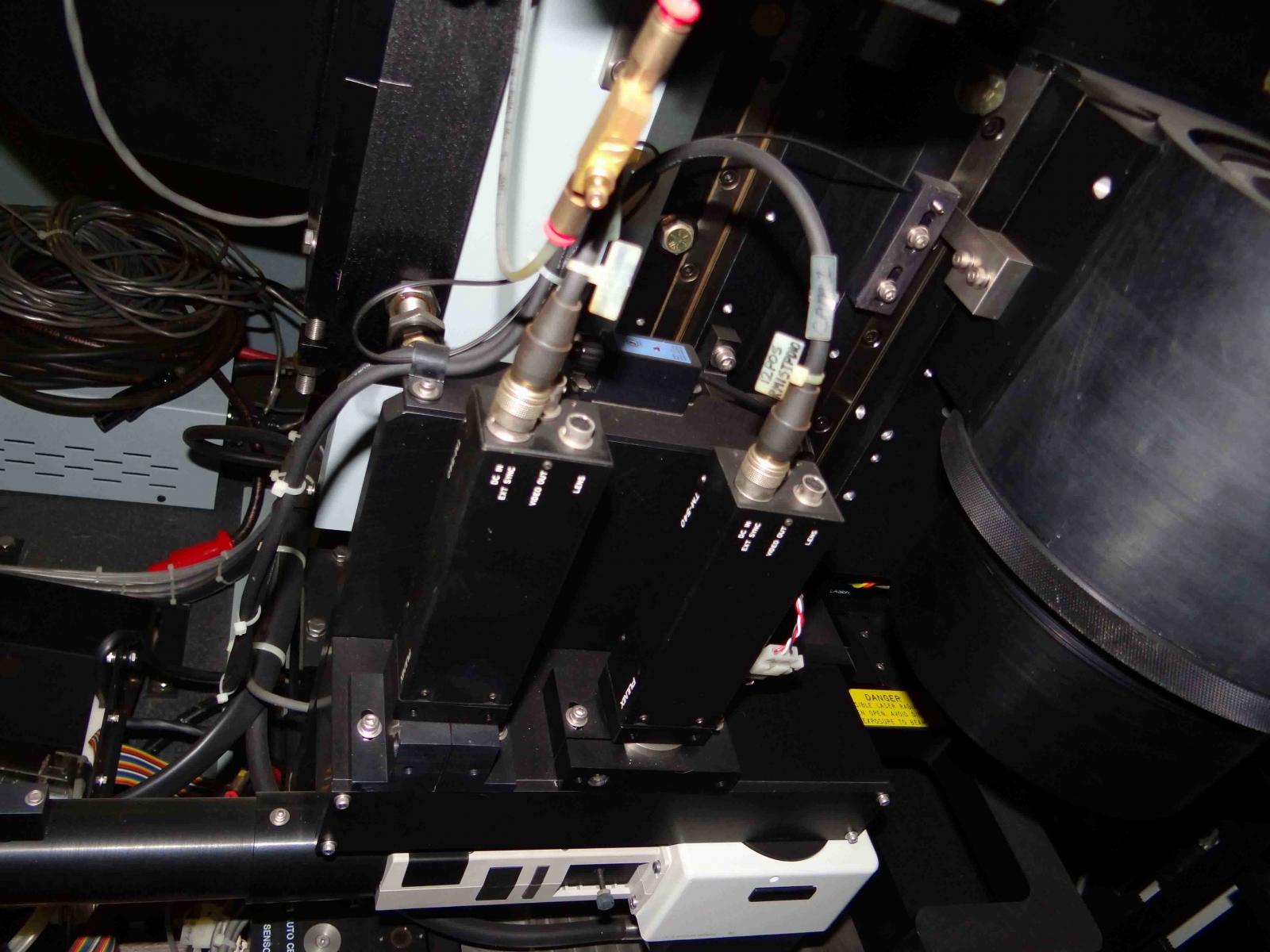

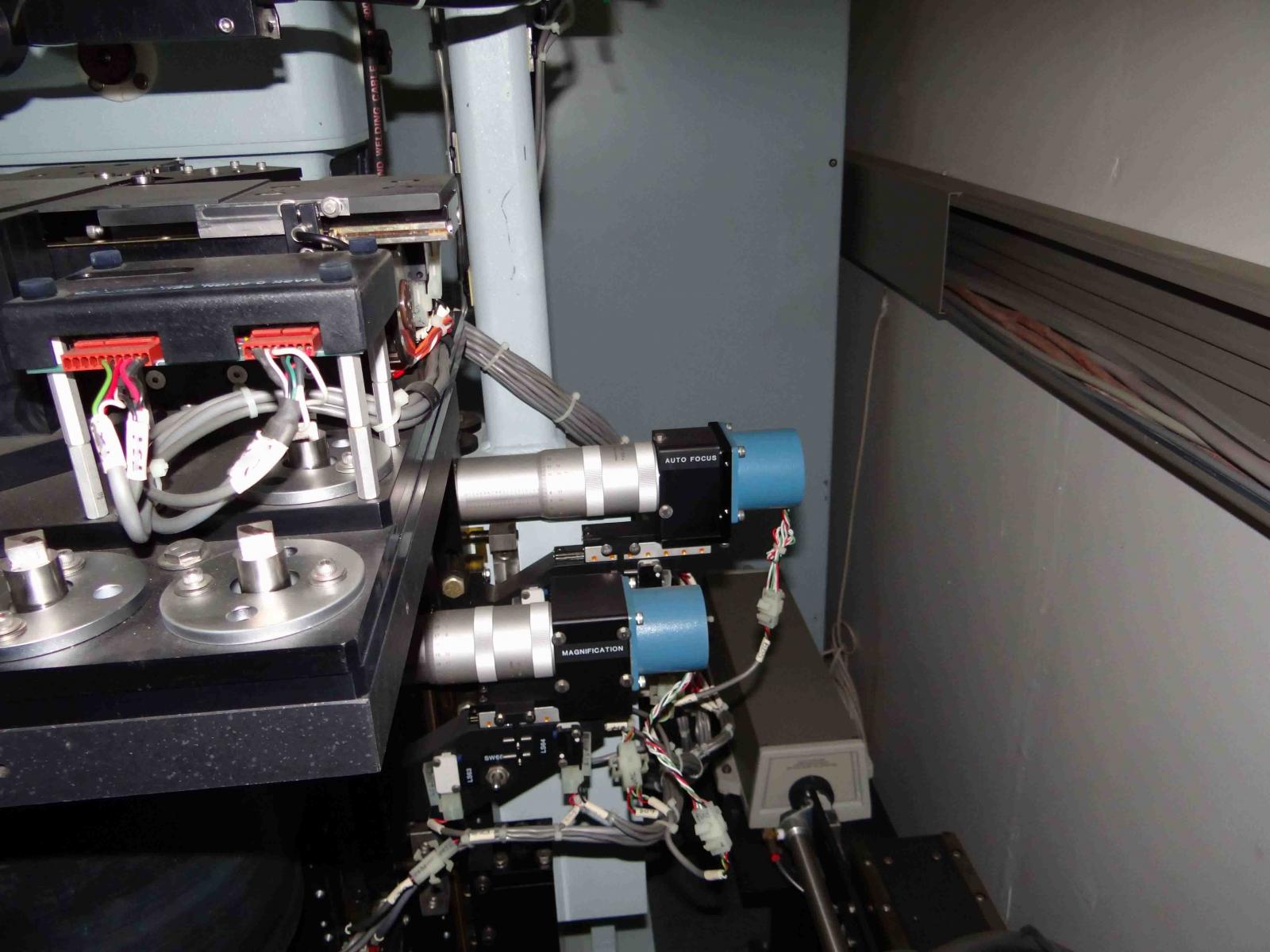

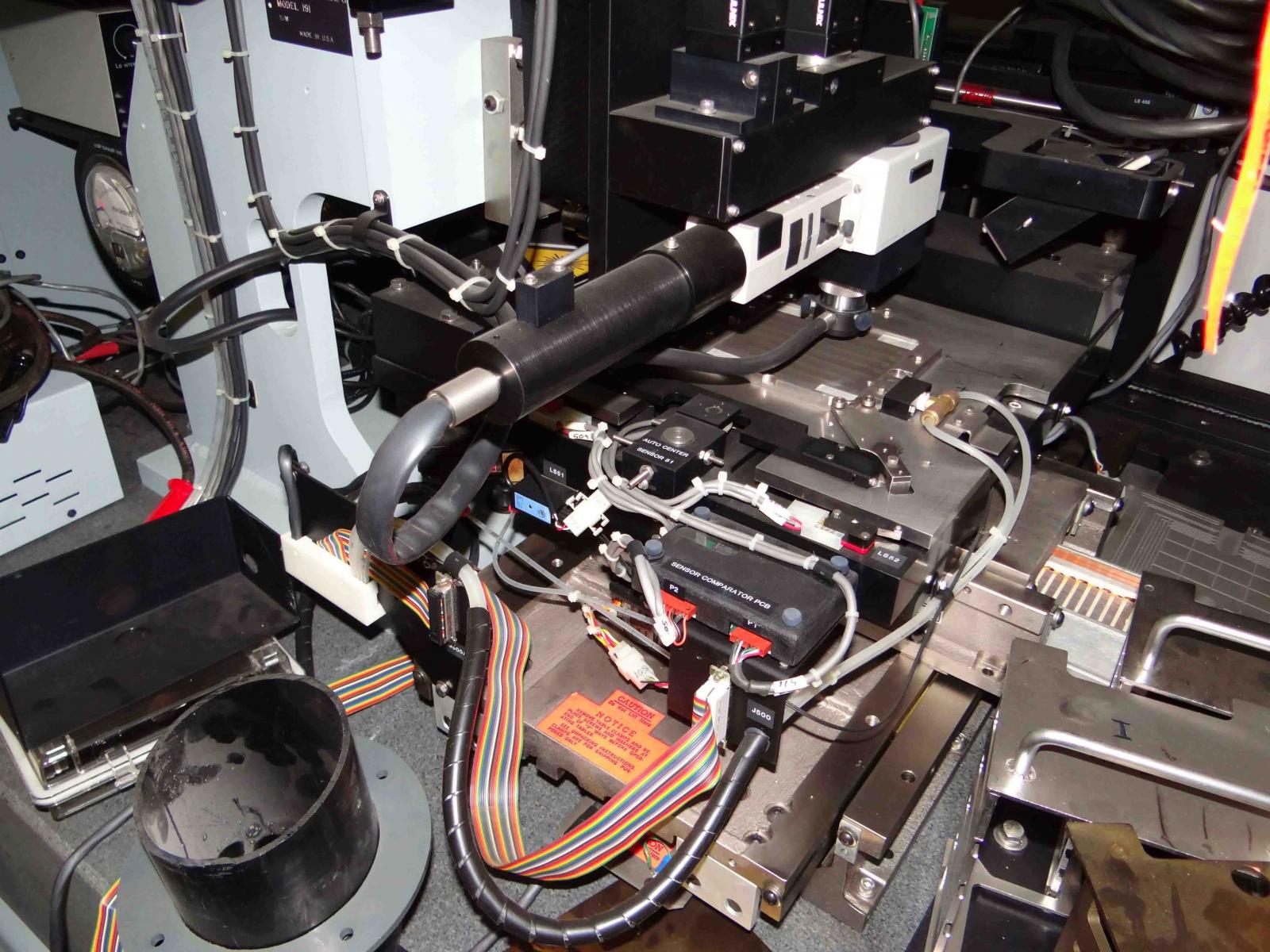

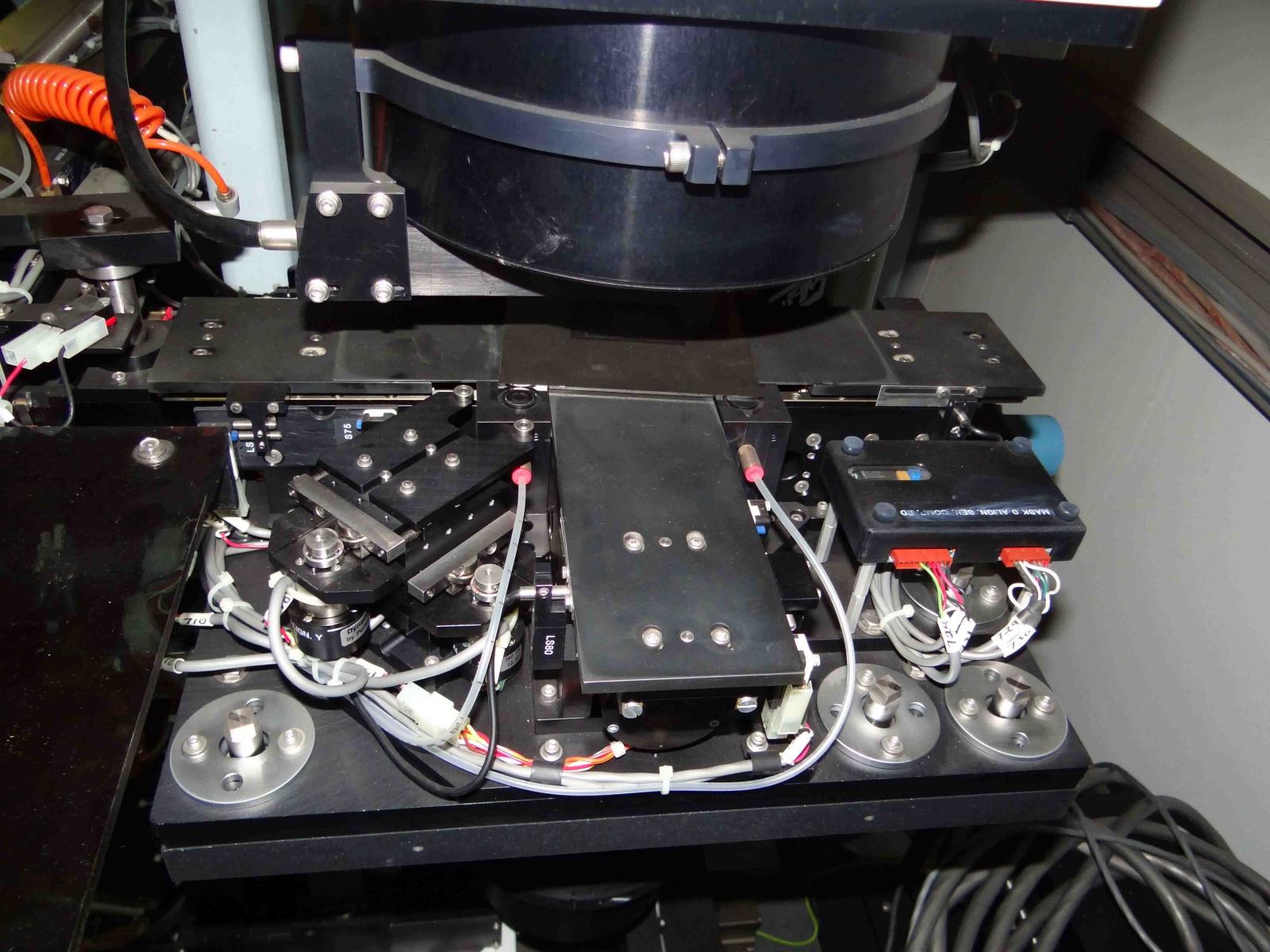

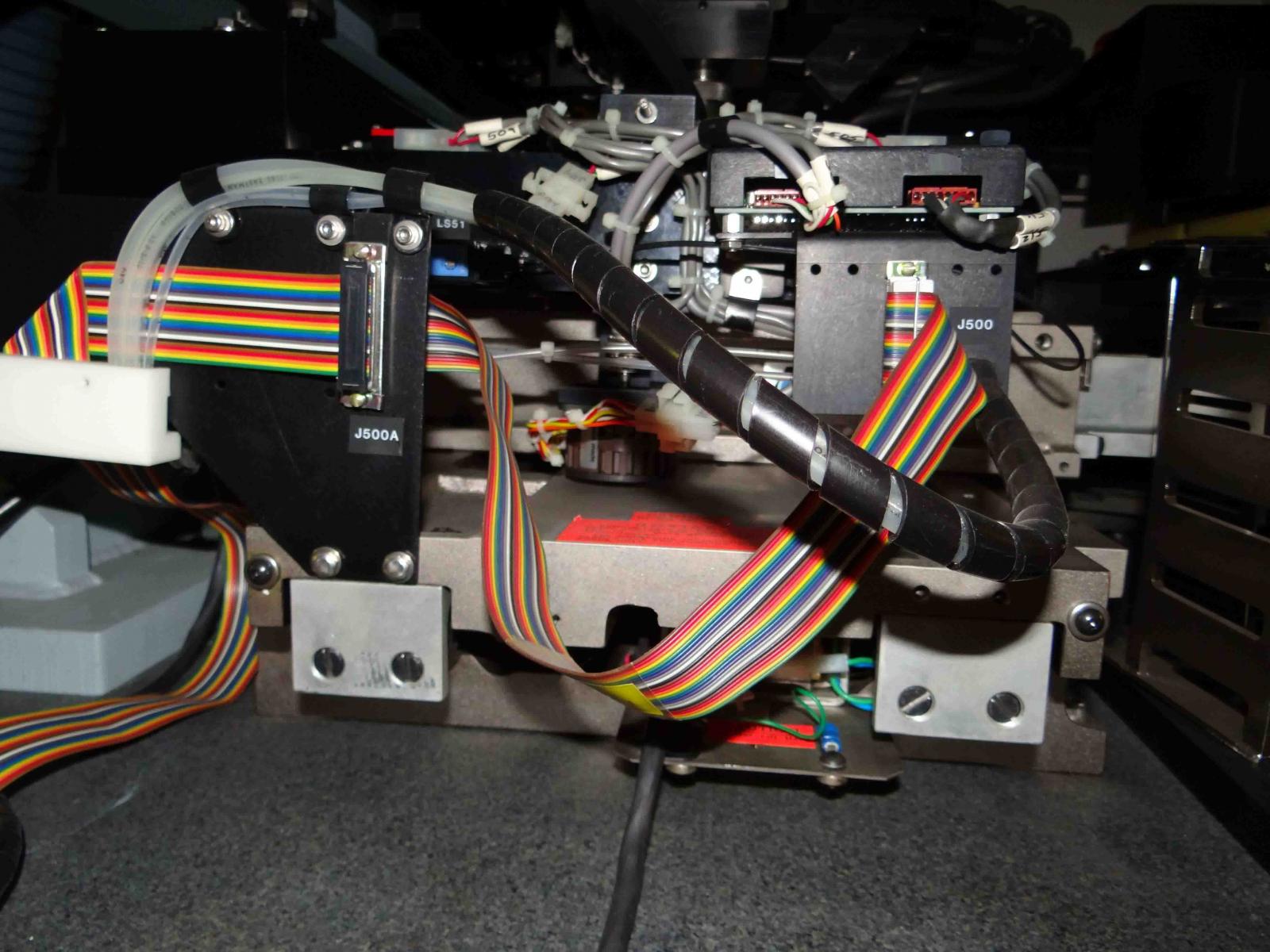

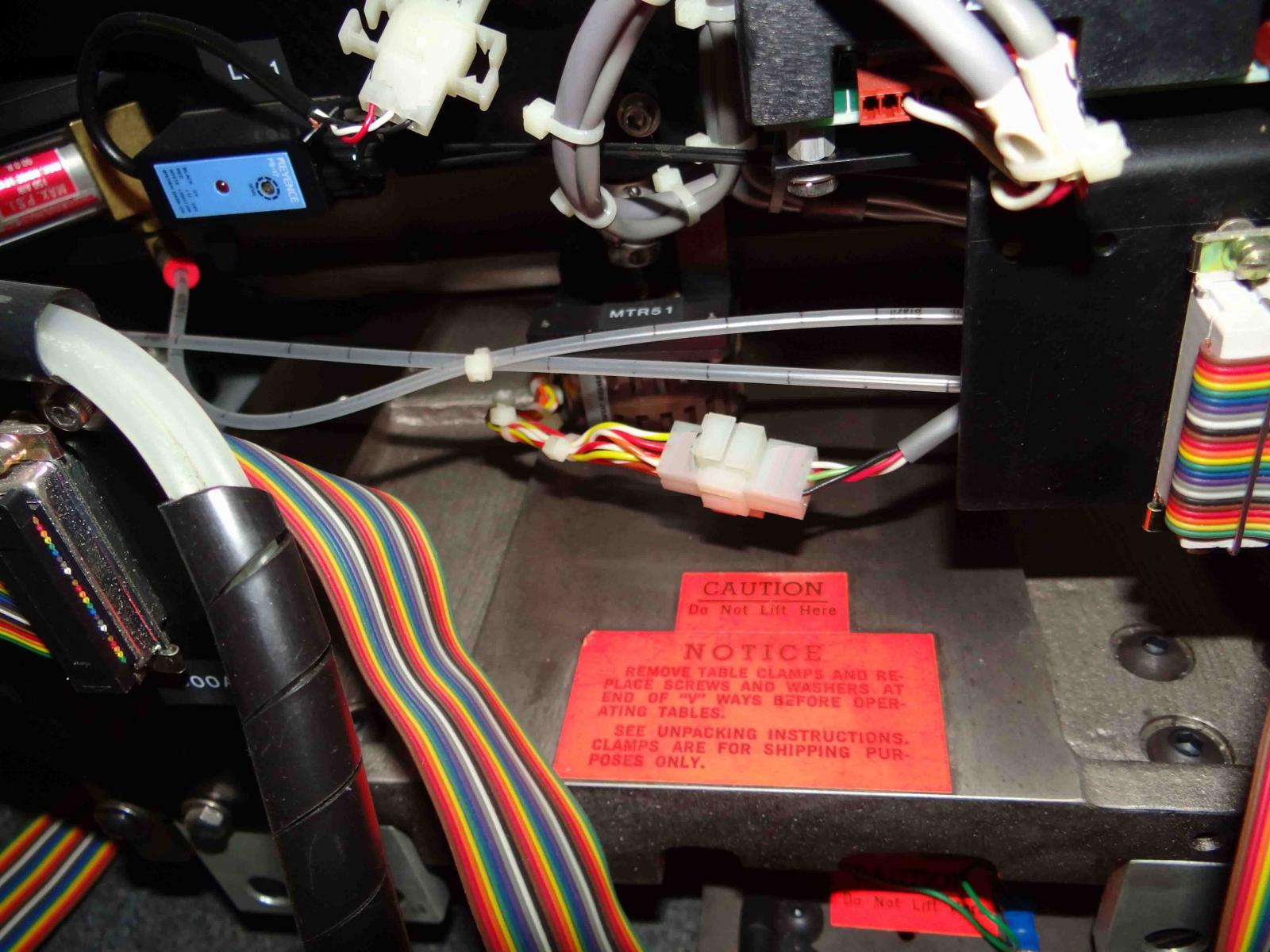

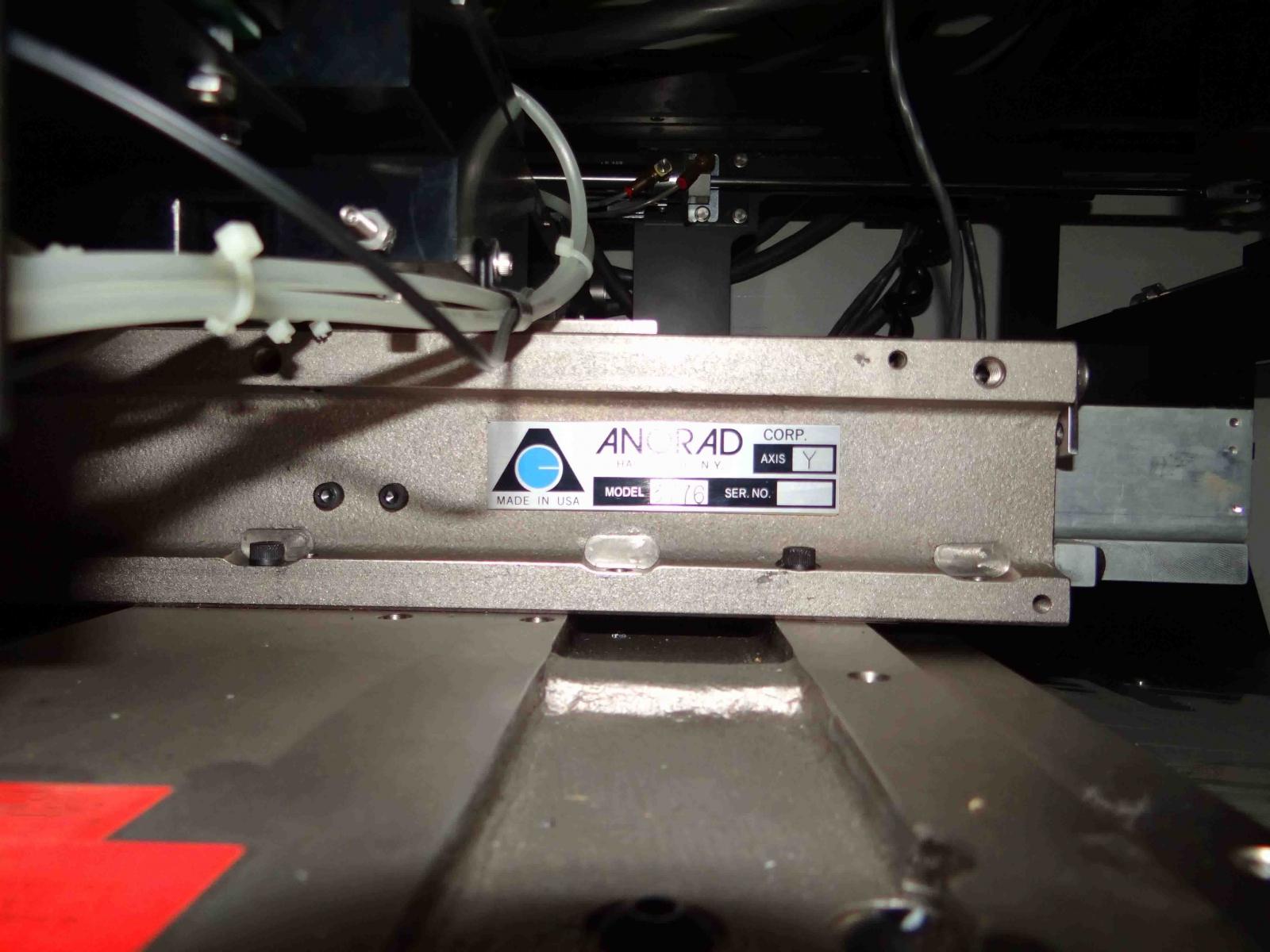

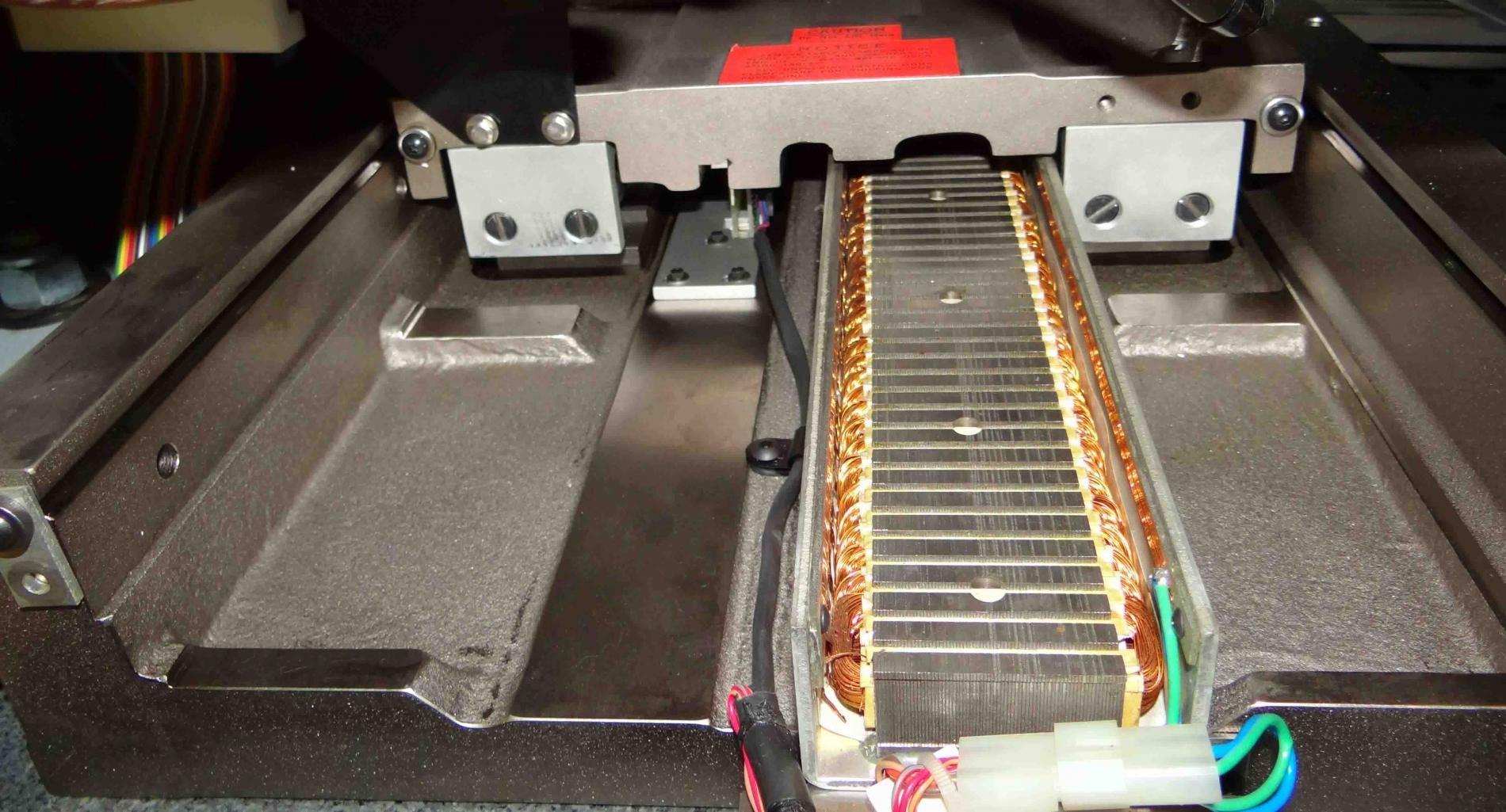

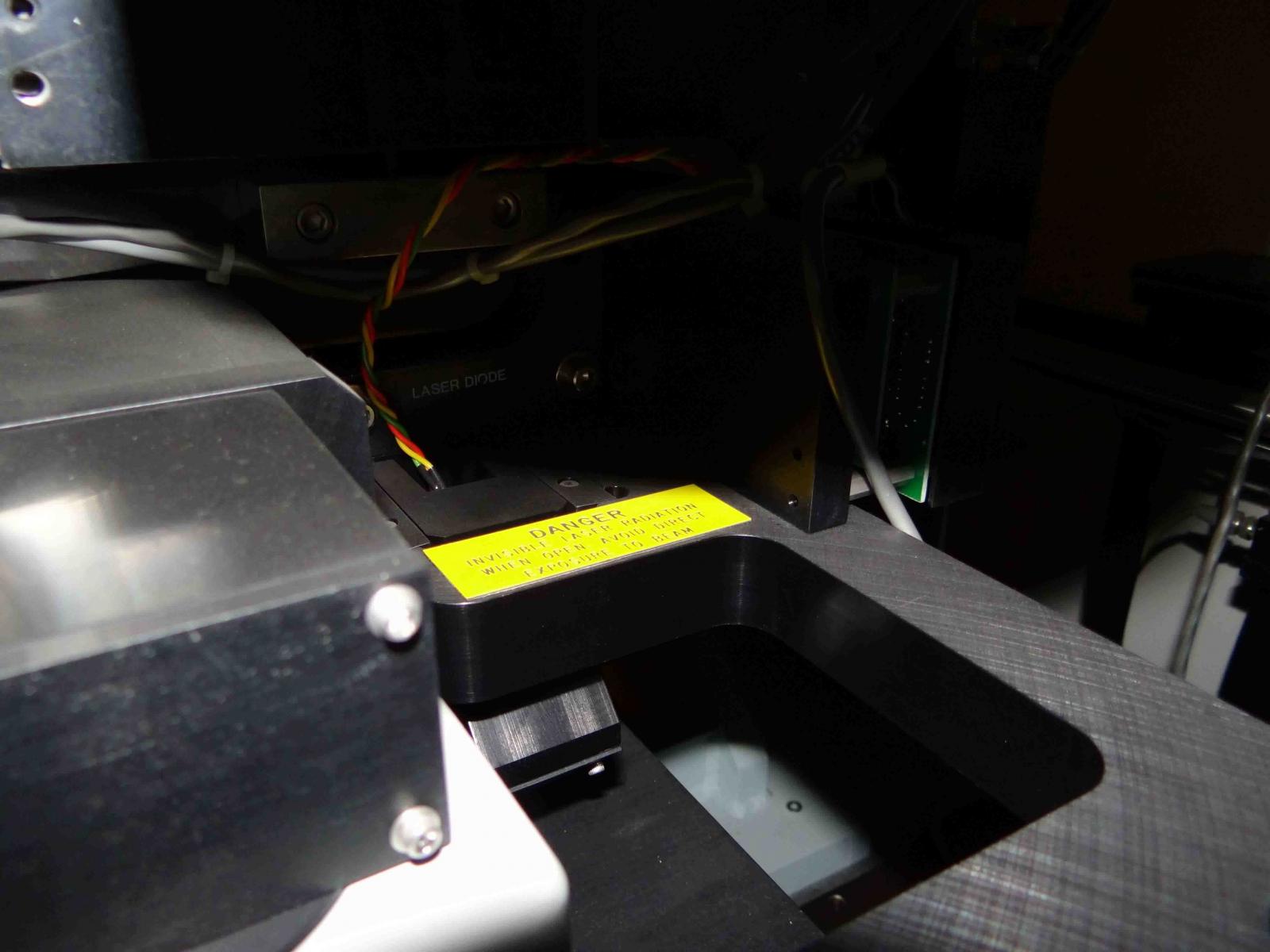

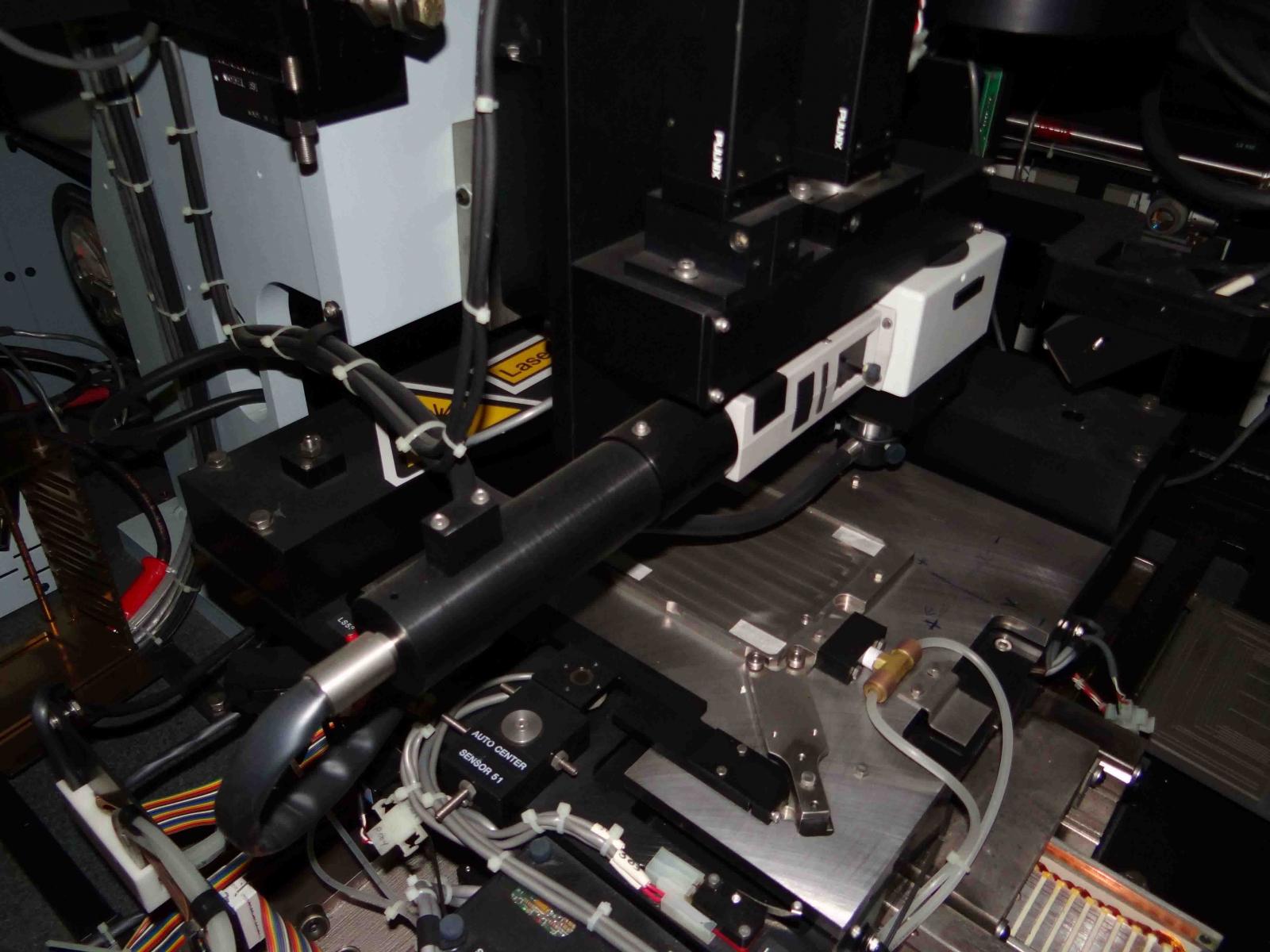

TAMARACK 191 is a mask aligner designed for use with reticles. It is a powerful two-stepper positioner with a minimum step size of 0.5 m and a minimum overlay of 0.25 m. The main function of 191 is to achieve accurate optical photolithography. It uses advanced sensor mechanics to accurately transfer data from the aligned reticles to the wafer stage in order to fabricate components on the wafer. A series of optical sensors work in conjunction with the pattern to ensure precise alignment before exposure. This includes a combination of infrared laser, interferometric measurement, and digital imaging technology to detect the accuracy of alignment and provide alignment correction feedback to the mask aligner. The user is able to control parameters such as reticle size, alignment accuracy, tilt and skew, and exposure settings. This makes it possible to accurately match the reticles to the finely-tuned process requirements. The system also includes a 25-position Auto Indexer, which is a robotic arm that has the capacity for a series of two-step positions and can automatically exchange between two reticles. It provides high speed, repeatability, and accuracy to the alignment process. In addition, TAMARACK 191 is equipped with an Autofocus system that utilizes multiple image processing algorithms to detect the smallest features accurately. It is capable of focusing on pattern features down to 0.5 m. 191 can also be used with many different substrates such as Si, GaAs, LiNbO3, GaN, and GaP, and can handle temperatures up to 300°C. TAMARACK 191 is an excellent choice for producing high yield, high precision, and high throughput devices. With its high accuracy, repeatability, and automation capabilities, it is the perfect tool for high-end production runs.

There are no reviews yet