Used AMAT / APPLIED MATERIALS Excite #200467 for sale

URL successfully copied!

Tap to zoom

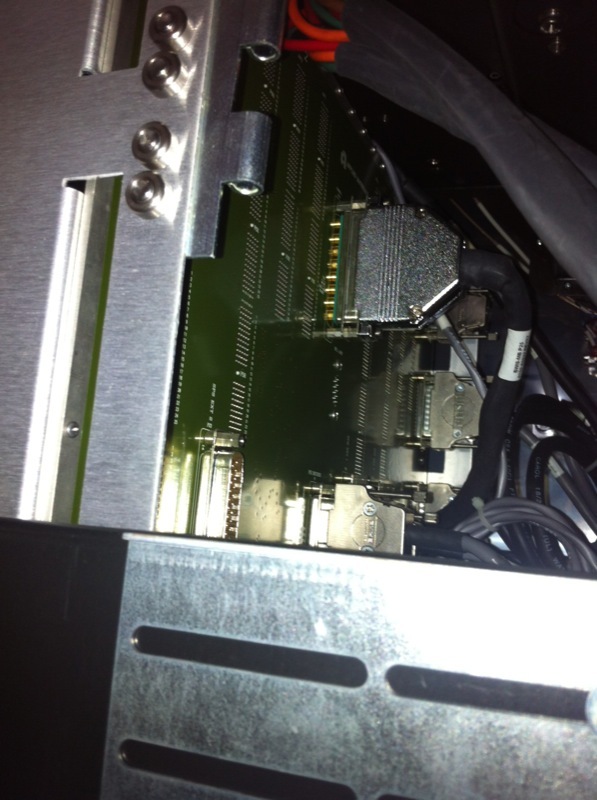

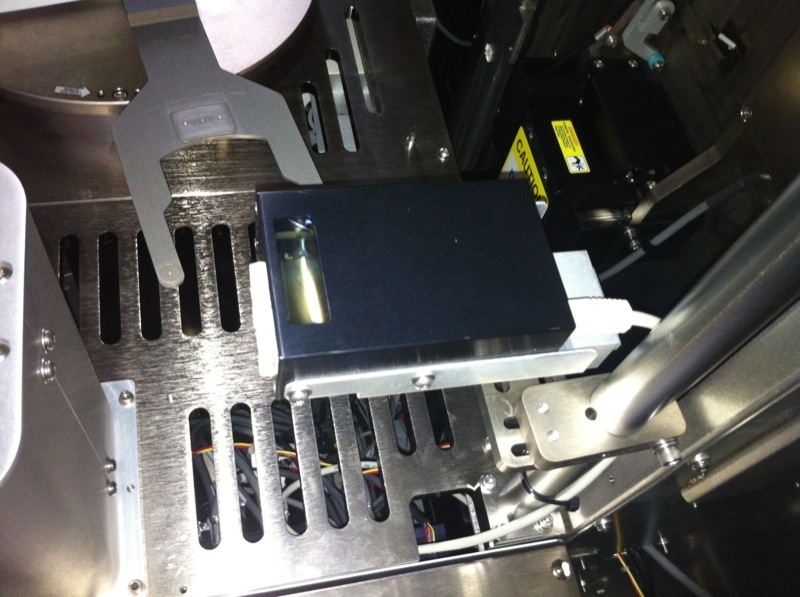

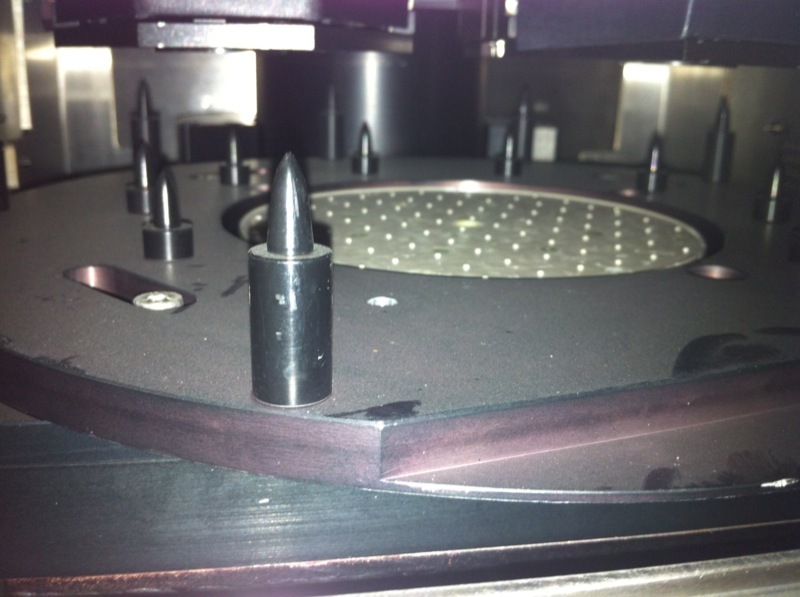

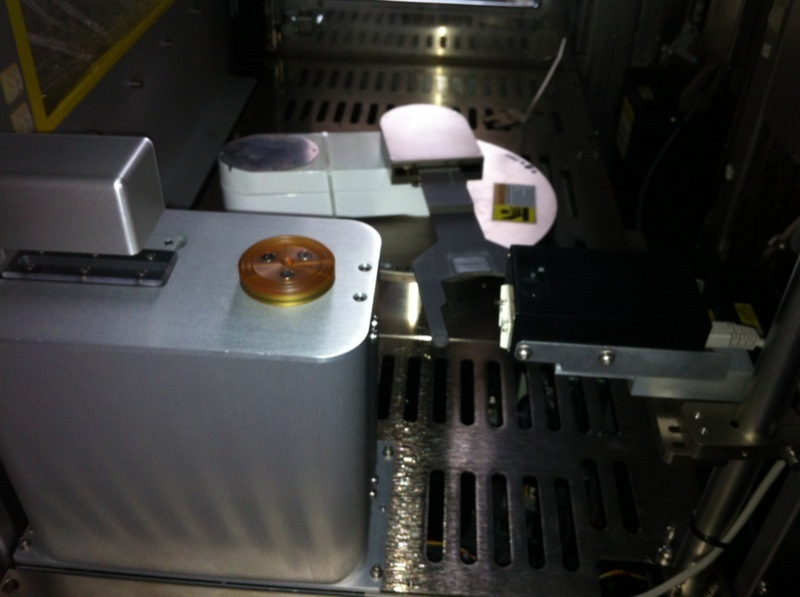

AMAT / APPLIED MATERIALS Excite is a mask and wafer inspection equipment for detecting and inspecting defects in a variety of semiconductor device applications. The system utilizes advanced laser technology to identify and semi-automate device inspection. It is designed to support a broad range of wafer and mask inspection configurations such as dielectric, substrate, squaring, overlay, lithography and electrical testing. AMAT Excite Unit utilizes precision optics and laser technology to provide consistent performance and reliable defect detection. The machine responds quickly to wafer and mask movements while providing an easy-to-use interface and intuitive user interface. The pixel-by-pixel inspection ensures that all areas of the device are thoroughly inspected. As the tool measures topography, defects in height, width and other parameters, it can quickly identify potential defects and provide feedback for optimal process control. The asset is perfect for semiconductor device manufacturers as it enables faster and accurate defect detection for improved product accuracy and yields. This increases utilitization of resources and increases product quality. The robustness and flexibility APPLIED MATERIALS Excite model provides for large area scanning is unrivalled by many other systems. The equipment is cost effective and provides high throughput wafer and mask inspections. The system also supports standard III-V wafer and mask inspections. The scanner is equipped with a variety of imaging detectors, broad dynamic ranges and advanced processing algorithms to accurately assess the physical characteristics of each defect. It also has a high scan rate and a variety of resolutions depending on the application. The unit can easily be re-configured for multiple applications and protocols. Moreover, the machine can be fitted with specialized optical components for specific types of inspections. It features sophisticated alignment features such as on-the-fly mapping and automatic geometry measurement. It also makes use of path correction algorithms to compensate for wafer tilt and surface irregularities. Additionally, the tool is compatible with many metrology tools and automated process tools. Excite asset is an invaluable tool for device manufacturers in the semiconductor industry. Offering high throughput surface analysis, spot defect capturing and surface probing, it is an ideal tool for high resolution defect detection. The advanced technology of the model permits accurate measurements, giving device makers an invaluable edge in the field of semiconductor device manufacturing.

There are no reviews yet