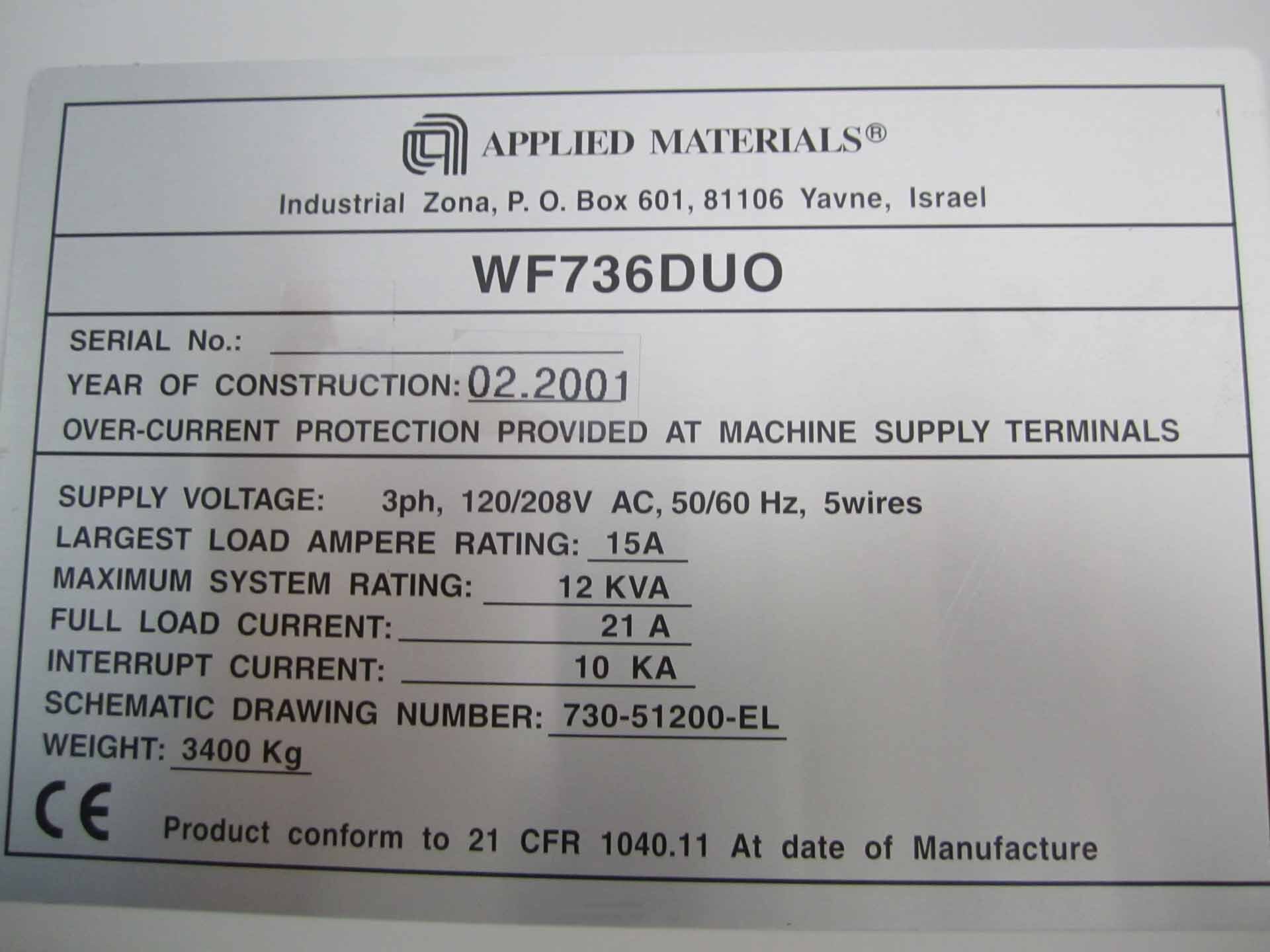

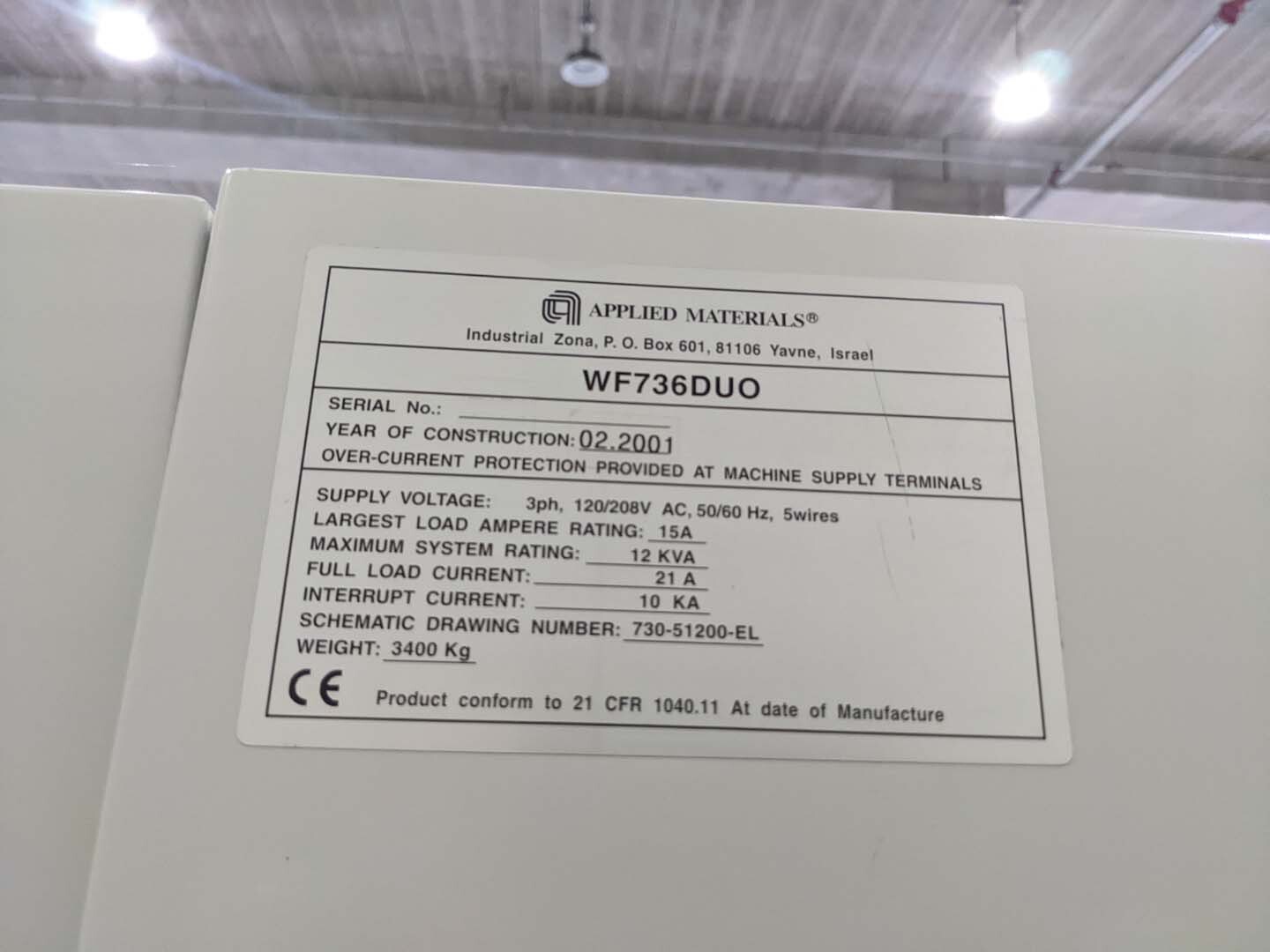

Used AMAT / APPLIED MATERIALS / ORBOT WF-736 XS DUO #293617607 for sale

URL successfully copied!

Tap to zoom

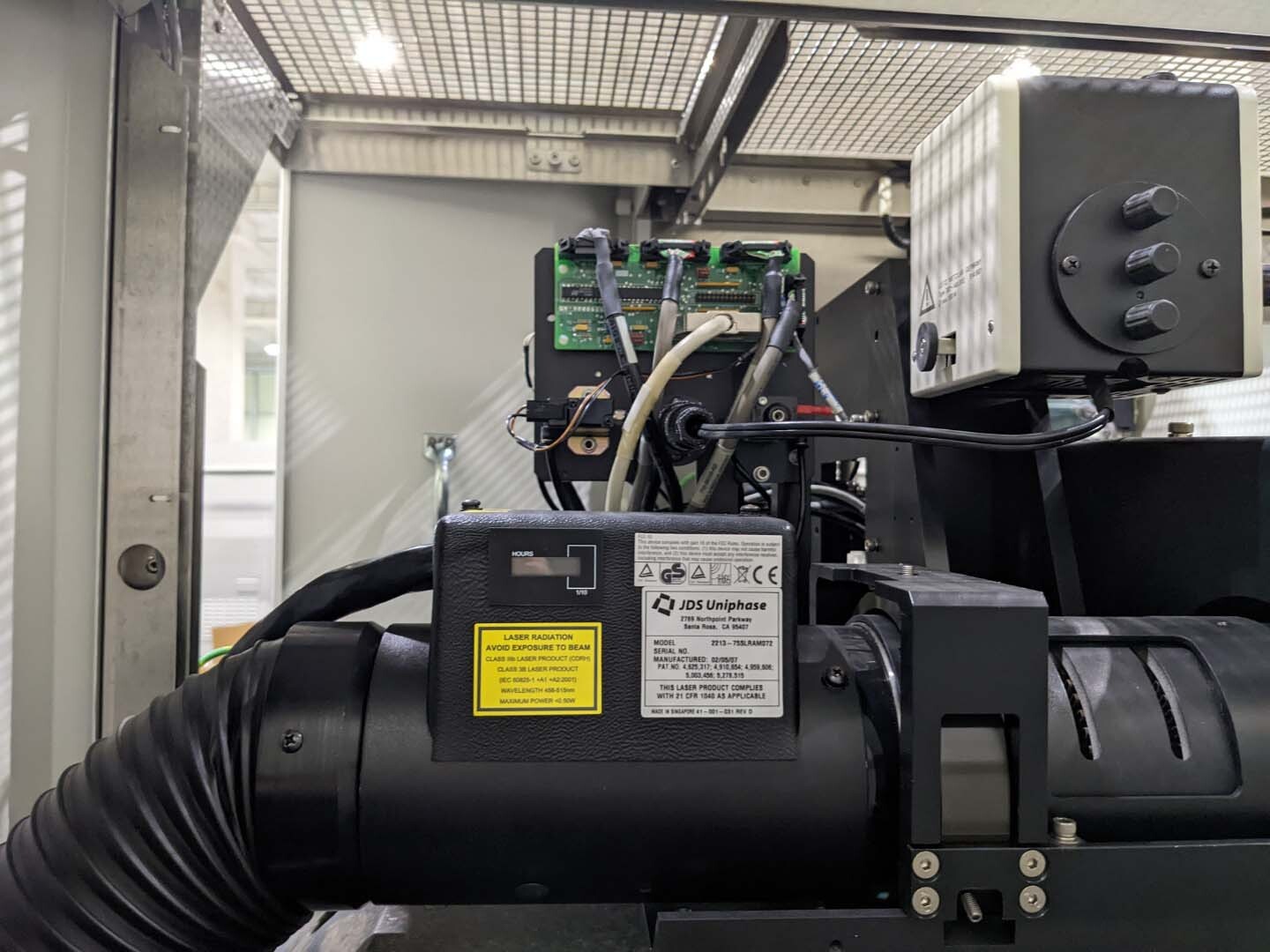

AMAT / APPLIED MATERIALS / ORBOT WF-736 XS DUO is a mask and wafer inspection equipment designed to provide superior performance and intuitive operation. The system offers a range of advanced features, including automated wafer alignment, high resolution image capture and analysis, automated defect identification and classification, and the capability to inspect the entire wafer within a single field of view. AMAT WF-736 XS DUO is equipped with a new dual-beam image acquisition module that utilizes both optical and electron-beam imaging modes to provide optimized data capture for various substrate types and features. The unit is integrated with a high resolution, full-field digital line scanner for producing bright field and dark field images up to 120Mpixel. In addition, the machine offers various automated functions such as intelligent recognition of defects by their 3D profile, accurate feature detection, and automated defect classification. The tool is powered by the latest in imaging and image processing technology. It incorporates an integrated image processing and analysis asset that offers advanced image filtering algorithms and statistical analysis to classify, measure and categorize defects. The model is also equipped with a Digital Bright Field Imaging Equipment which provides high contrast images that can be used to detect small defects on complex structures and layouts. ORBOT WF-736 XS DUO also features an advanced control software that provides enhanced and intuitive operation. This controls the application of the tool to the wafers, and allows for easy customization of the imaging parameters according to the user's needs. Moreover, the system is equipped with an advanced feature recognition unit that automatically detects and measures the parameters of die patterns on the wafer surface. WF-736 XS DUO provides an efficient and reliable solution for mask and wafer inspection in the demanding semiconductor industry. With its combination of powerful imaging technology and intuitive operation, the machine is capable of detecting a wide variety of critical defects, from 0.1um - 2um. It significantly reduces the time and costs associated with manual inspection, and enables efficient process flow in critical production environments.

There are no reviews yet