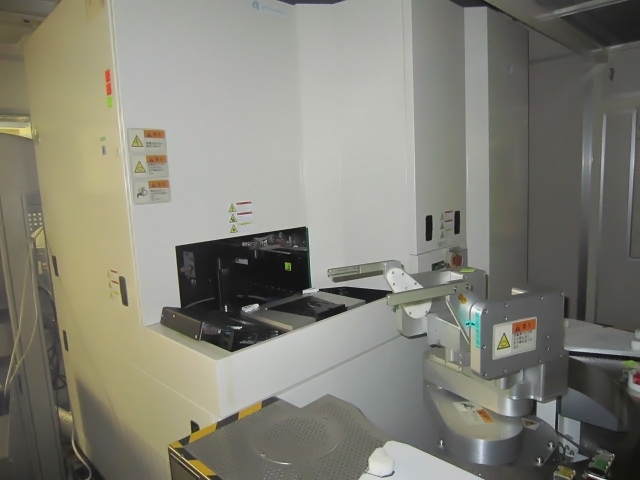

Used AMAT / APPLIED MATERIALS / ORBOT WF 736 XS #9011672 for sale

URL successfully copied!

Tap to zoom

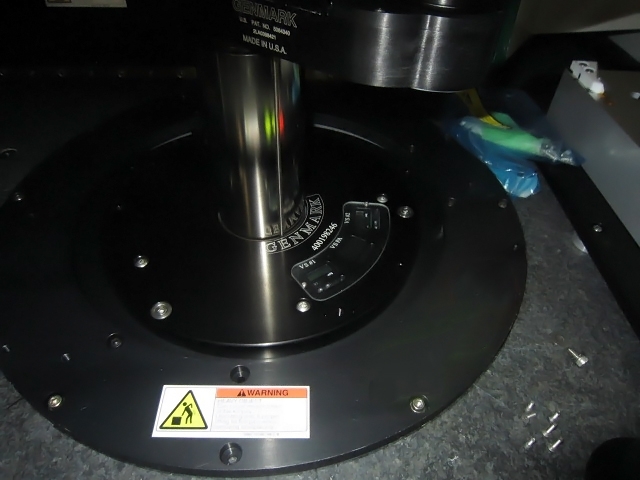

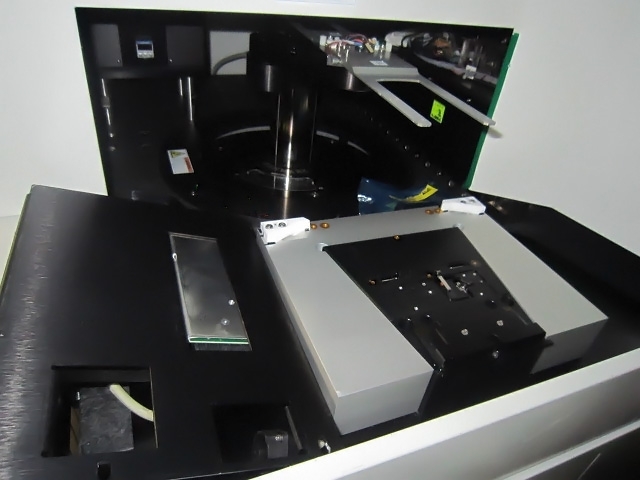

AMAT / APPLIED MATERIALS / ORBOT WF 736 XS is an automated mask and wafer inspection equipment designed to provide engineers with high performance defect detection and in-depth analysis. The system uses a combination of non-destructive imaging techniques, such as scanning electron microscopy (SEM), confocal microscopy, and fluorescent imaging, to quickly detect problems on the surface of wafers or masks in the semiconductor fabrication process. AMAT WF 736 XS features a number of advanced features which allow for the efficient detection of defects on both wafers and masks. The unit utilizes an image recognition algorithm to identify shape, features, and other characteristics of potential defects, and then automotive-grade AI is used to classify them and detect their locations on the surface. Additionally, a pixel-accurate morphometric defect recognition machine with a high-precision objective lens helps engineers to identify and diagnose problems with even the smallest defects. It has a highly sensitive optical tool with a spatial resolution of 5 nm, making it capable of detecting very fine shapes and contours of micro-structures. The asset also has an automated scanning mechanism, which can precisely detect and measure defects in large areas of up to 15 x 15 cm. ORBOT WF 736XS also features smart wafer indexing, allowing multiple wafers to be examined without having to re-calibrate the model. In addition, the equipment provides engineers with flexibly adjustable contrast and local contrast enhancement for better defect recognition. It also uses a variety of defect analysis tools, such as contour analysis, optical proximity correction, image classification, and 3D defect reconstruction. Furthermore, various visualization modes, such as magnified view and 3D mode, enable users to view defects in different ways. Overall, AMAT WF 736XS is an advanced automated mask and wafer inspection system, designed to detect and analyze defects with extreme precision. By employing various imaging techniques, high-precision optical systems, advanced defect recognition algorithms, and several visualization modes, the unit helps engineers to quickly and accurately identify defects in order to achieve optimal results.

There are no reviews yet