Used AMAT / APPLIED MATERIALS SemVision CX #111258 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 111258

Vintage: 1998

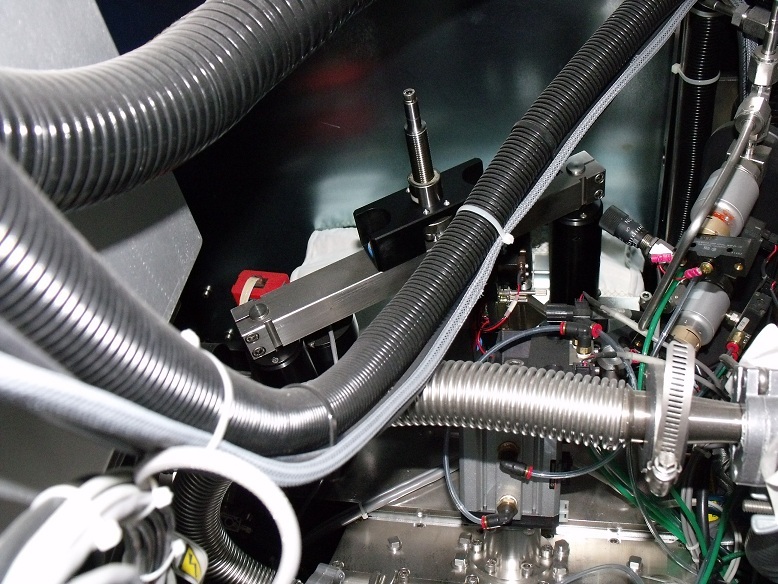

Automated SEM Review System, 8"

Includes:

- SEM resolution of 4nm at 1KV with SEM Perspective Imaging

- High Resolution Color Optical Microscope

- SEM 45 Degree Tilt and 360 Degree Rotation

- Automated Review Flow

- Two (2) 8" Cassette Stations

- Interface to Inspection Tools (KLA, Tencor, Orbot)

SEM Based ADC Package

SEMV-OPT2.

Integrated EDX Spectrometer Integrated Energy Dispersive X-Ray Spectrometer (Nitrogen Free Cooling)

SEMV-OPT3

COMMUNICATIONS OPTION:

SEC-II GEM Compatible Host Communication

Software: SEMVision CX

Unpatterned Wafer Review CX

SEMVision API Retrofit

SEMVision Cx Plus Beta

Warehoused

1999 vintage.

AMAT (APPLIED MATERIALS) AMAT / APPLIED MATERIALS SemVision CX is a fully automated mask and wafer inspection equipment that provides superior image capturing for the most challenging application requirements. It combines advanced optics, sensing, and imaging technologies to deliver a superior quality final product in an efficient and cost-effective manner. AMAT SemVision CX ensures critical parameters, such as minor misalignments, roughness, scratches, critical dimension accuracy, and surface planarity, are identified and tracked during inspection of mask and wafer stages. It is designed to provide a higher inspection speed and accuracy than any other system in the industry. It is designed to provide a consistent and accurate inspection result across multiple wafer and mask types. It consists of a high resolution camera that captures images of each wafer or mask in a few seconds. It can be used to inspect standard semiconductor wafers and masks, as well as masks that employ silicon-on-insulators, buried layers, and 3D ICs. APPLIED MATERIALS SEM VISION CX incorporates two innovative optical configurations, which are optimized for different types of device structures. It also uses a double-sided imaging unit that enables both front and back images to be captured simultaneously for comprehensive inspection. The machine also uses an advanced edge-detection algorithm to detect the edges of features on the wafer or mask accurately. APPLIED MATERIALS SemVision CX features a user-friendly graphical interface to facilitate easy tool navigation, as well as provide visual diagnostics and hierarchical list navigation. The asset is equipped with an USB port for data transfer, allowing for a fast and easy setup. AMAT / APPLIED MATERIALS SEM VISION CX is also equipped with software for data analysis which includes examination of defects, roughness, and other imperfections. It can also be used to measure surface roughness, flatness, and die size in order to provide final product accuracy. Additionally, the model can be used to perform wafer mapping, pattern recognition and traceability, metrology, and defect classification. Overall, AMAT / APPLIED MATERIALS (AMAT) SEM VISION CX provides enhanced mask and wafer inspection capabilities, resulting in faster throughput and improved efficiency in the production process. It has the ability to improve yield and reduce costly defects, helping manufacturers remain competitive in the ever-changing semiconductor landscape.

There are no reviews yet