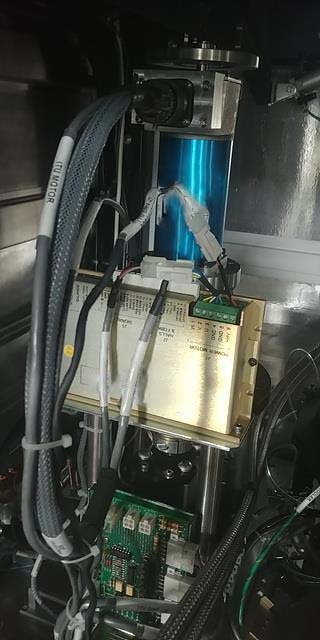

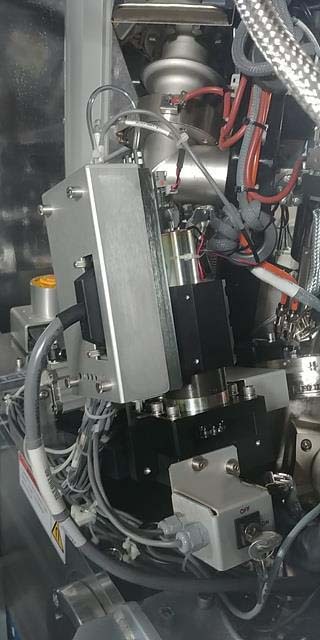

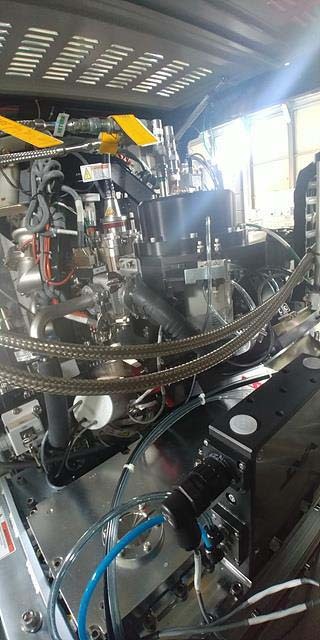

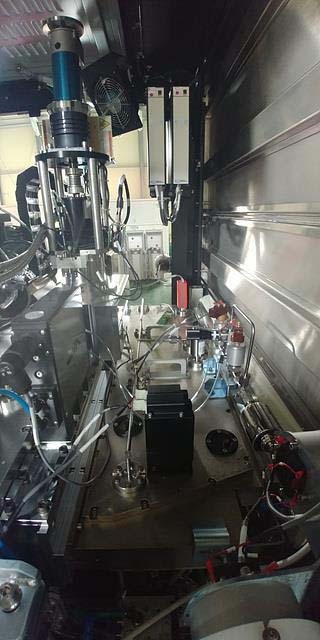

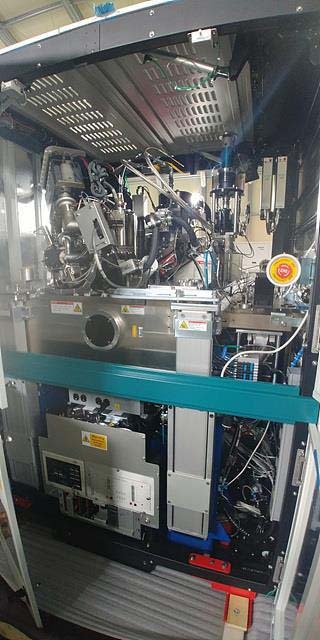

Used AMAT / APPLIED MATERIALS SemVision CX #9298565 for sale

URL successfully copied!

Tap to zoom

ID: 9298565

Wafer Size: 12"

Vintage: 2004

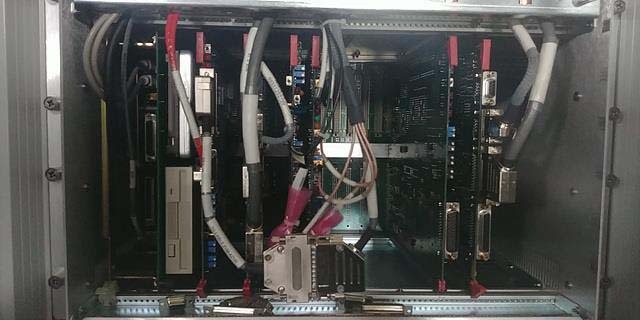

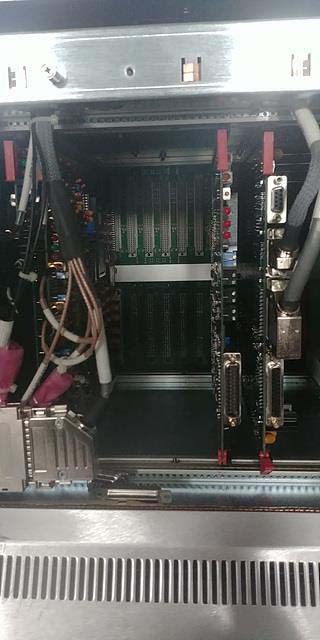

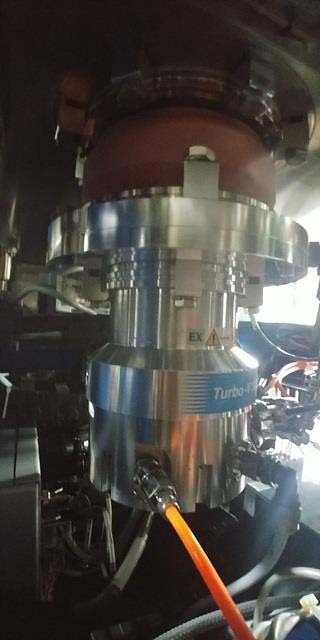

Defect review system, 12"

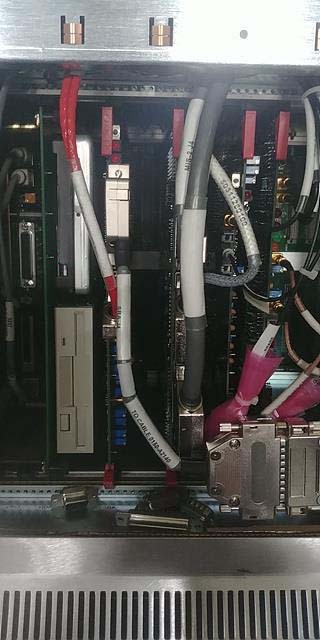

Hard Disk Drive (HDD) Not include

2004 vintage.

AMAT / APPLIED MATERIALS SemVision CX is a powerful mask and wafer inspection equipment designed to simplify defect detection, classification and analysis. It offers a comprehensive suite of wafer inspection tools that can quickly identify defects with high accuracy and precision. The system's advanced image-processing algorithms enable rapid, reliable defect characterization and classification, providing valuable production data for improved process monitoring and quality control. AMAT SemVision CX unit features automated scanning and inspection, dynamic focal plane focus, and real-time defect visualization. The machine also can collect scan-based defect metrics that reveal root causes without any user intervention. Defect histograms make it easy to monitor production trends over time and yield data analysis, while automated defect classification ensures high throughput and quality control. The tool's high-resolution imaging capabilities are designed to detect the finest anomalies, including scratches and residues, even on ultra-small patterns. The asset image resolution of up to 30nm also enables detection of extraordinarily small defects. This makes the model well-suited for inspection of even the most sophisticated designs, including 3D-stacked chips and sub-2xnm nodes. Additionally, APPLIED MATERIALS SEM VISION CX equipment provides fast and accurate inspections at multiple stage points of the production process, enabling users to quickly resolve defects before the yield is compromised. Its superior lens control and motion detection capabilities provide outstanding performance in both static imaging and high throughput production. The system's ergonomic touchscreen and intuitive user interface make it easier for operators to perform various inspection jobs. The unit's features can be extended with additional defect classification and specific review algorithms. These algorithms consist of automated defect characterization and classification, and advanced edge contrast enhancement and false-defect reduction. This facilitates greater understanding of the defect causes and faster resolution of problems. SemVision CX machine is ideal for both development and production environments, enabling customers to achieve higher yields faster. The tool's advanced and convenient utilities support rapid process optimization, which in turn results in improved production cycle time and cost savings. The asset is also highly reliable and robust, providing unlimited scalability and unprecedented error-detection capabilities.

There are no reviews yet