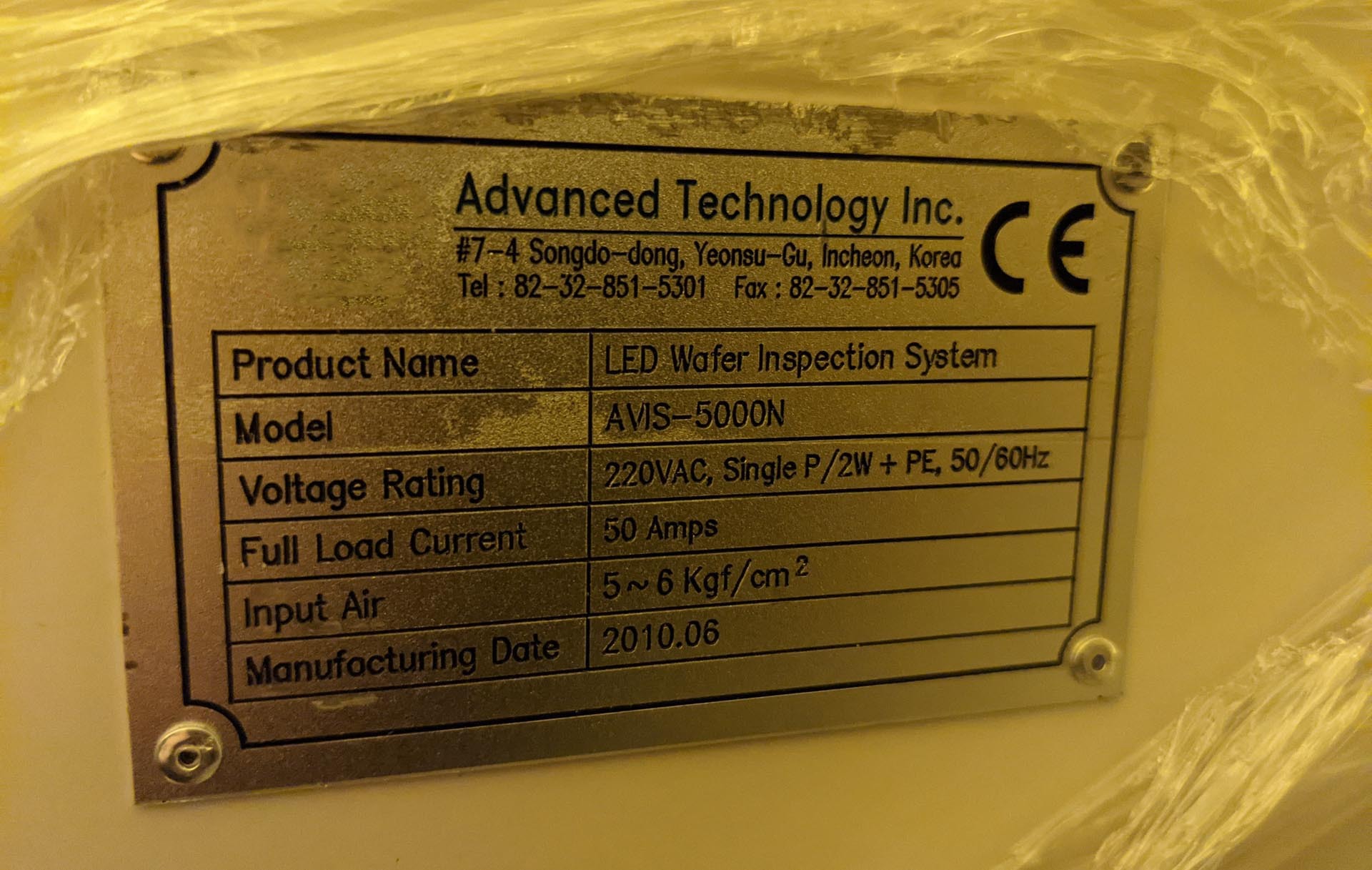

Used ATI AVIS-5000N #293590750 for sale

URL successfully copied!

Tap to zoom

ATI AVIS-5000N is a mask and wafer inspection equipment designed for semiconductor manufacturing facilities. The system is capable of performing a variety of wafer inspection tasks, including lithography, electrical, overlay and TEM (transmission electron microscopy) inspection. The unit is built around a 5-axis robotic motor machine that is able to move the wafer inspection heads across the entire wafer surface. The tool is capable of achieving sub-pixel accuracy, allowing for the detection of minute defects. AVIS-5000N utilizes both vision and touch sensor technologies to detect a range of defects. Vision technology allows for the identification of masking errors, such as extra or missing lines, and overlay errors, where objects on the wafer surface are not accurately positioned or aligned. The asset can also detect bridging, shorts and opens in electrical contacts, and non-uniformities in the crystalline structure. All of these defects can be detected in real-time, meaning that the wafer inspection can be completed without having to disassemble the entire wafer. ATI AVIS-5000N provides users with a range of features that make wafer inspection faster and easier. These include a fully automated masking/unmasking process, as well as automatic alignment of the wafer to the robotic stages. This makes the process of inspecting larger, more complex wafers a much smoother process. Additionally, the model offers an ergonomic control console, allowing operators to make quick adjustments to the inspection settings. AVIS-5000N is the ideal equipment for semiconductor manufacturers that require a comprehensive wafer inspection solution. With its range of features and technologies, ATI AVIS-5000N offers a reliable and efficient solution for identifying and rectifying wafer defects. Additionally, with its advanced safety and environmental measures, it offers a safe and clean environment for performing wafer inspections. The system is well suited to small-to-medium scale manufacturing facilities, offering a cost effective and efficient method for identifying defects in a production line.

There are no reviews yet