Used AUROS TECHNOLOGY API 2500M #293656625 for sale

URL successfully copied!

Tap to zoom

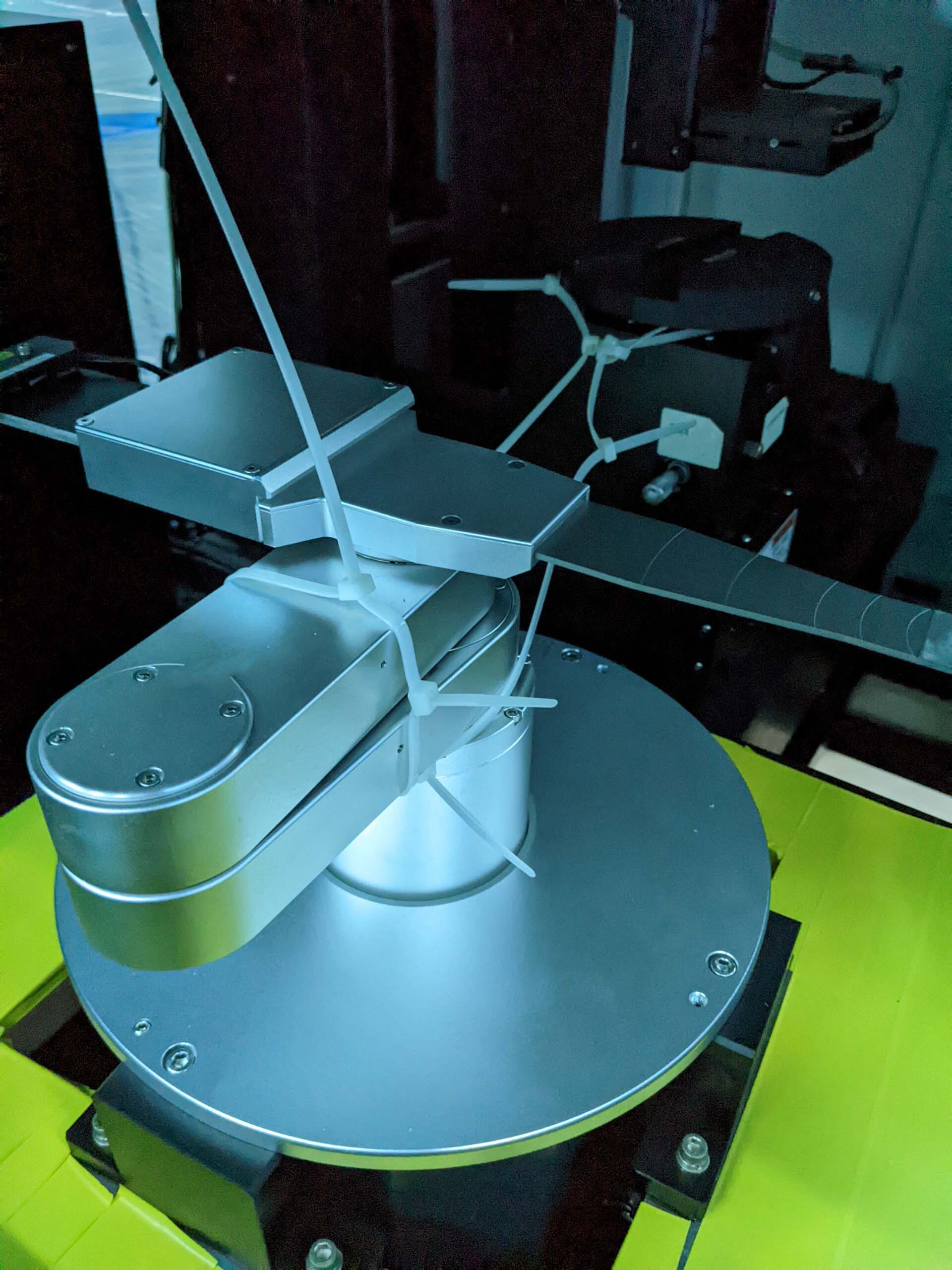

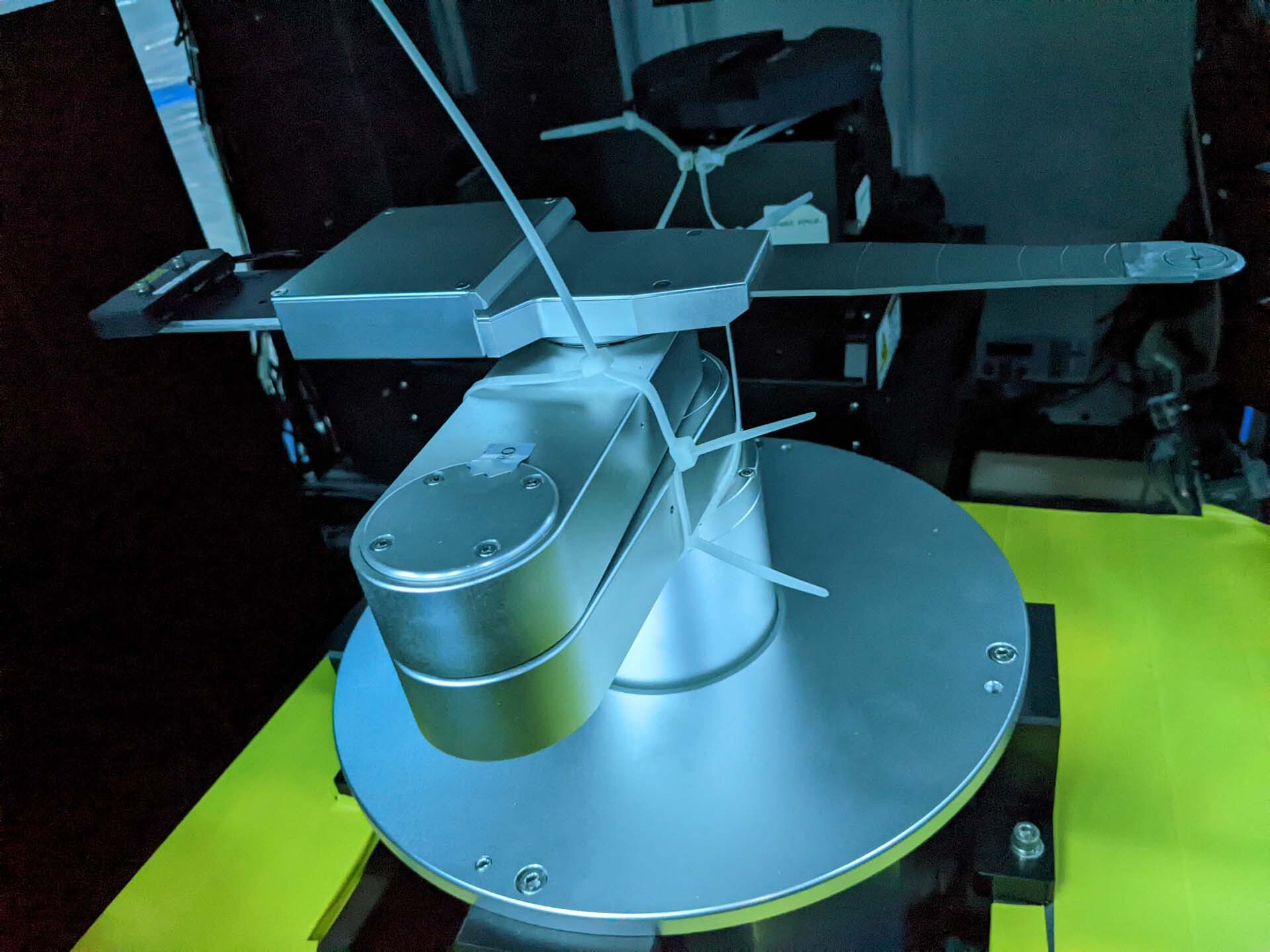

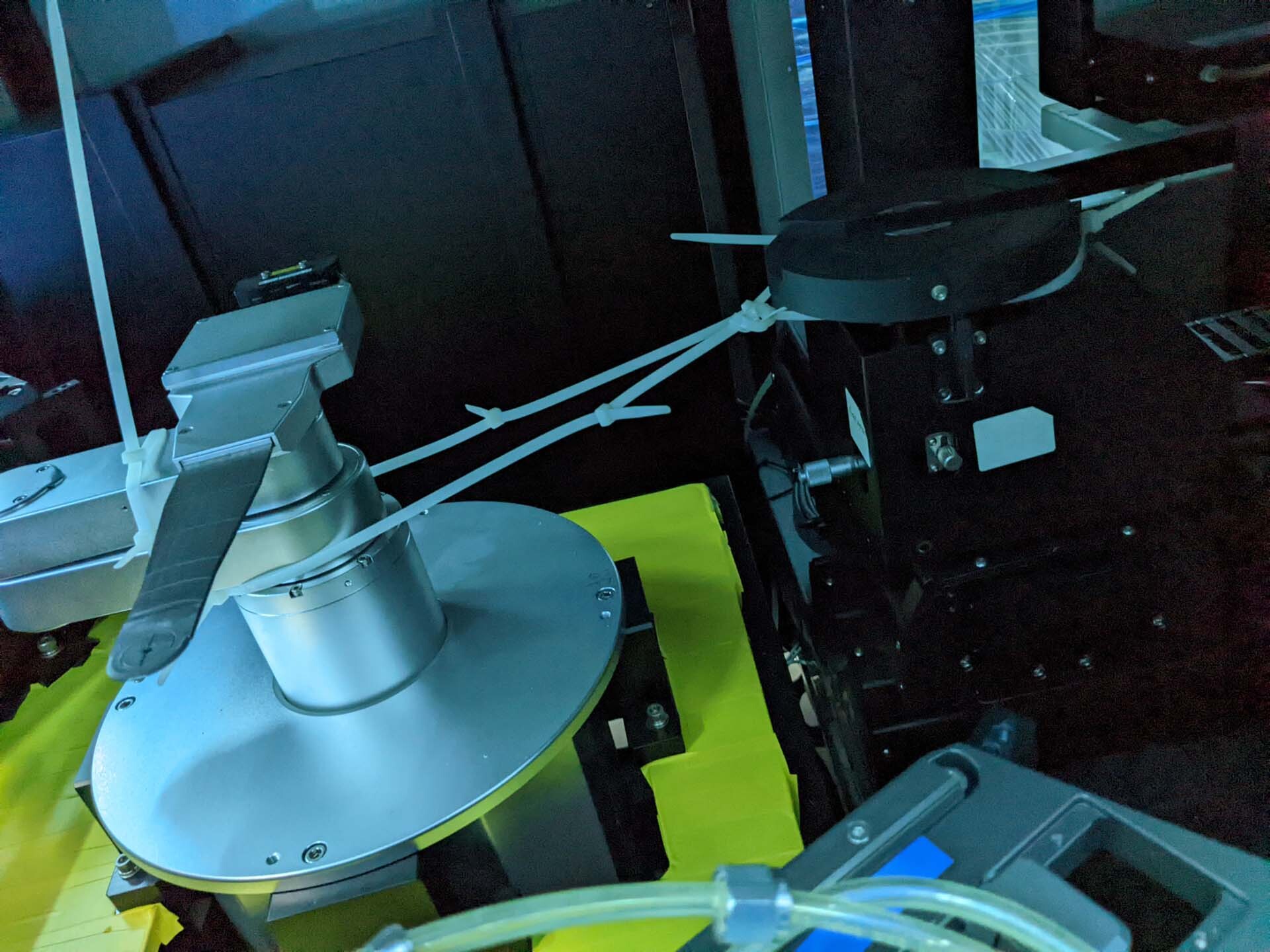

AUROS TECHNOLOGY API 2500M is a high-throughput mask & wafer inspection equipment designed for use in the semiconductor industry. It is designed to inspect and detect defects on mask and wafer surfaces, ranging from dust, contaminants, scratches, stains, line width variations, and other anomalies. The system features high-speed automated optical microscope and optics scanner technologies, providing superior performance and accuracy when inspecting wafers and masks. The unit is equipped with a state-of-the-art microscope, which utilizes a powerful imaging algorithm to identify microscopic defects on the surface of the substrate. The powerful imaging processor uses high-sensitivity and high-resolution optics to capture and quantify the anomalies. AUROS TECHNOLOGY advanced optics scanner technology is used to accurately capture, measure, and analyze defects on the mask and wafer surfaces. The machine offers two-sided, three-dimensional surface analysis, allowing for comprehensive inspection of both sides of the substrates. Additionally, the tool is designed to identify segmented defects, such as isolated voids, particulates, and other anomalies on the surface. The asset supports the inspection of both large- and small-scale substrates. API 2500M features a high-speed scan rate, providing quick imaging of mask & wafer substrates. The model is able to capture multiple images of the substrate in a single scan, providing more detailed analysis. In addition, the equipment is able to analyze and compare large data sets rapidly, allowing for more efficient defect identifications. The system is equipped with advanced workflow tools that are designed to automate the entire inspection process. This increases productivity and accuracy, reducing the overall time required for defect identification and analysis. By automating the inspection process, AUROS TECHNOLOGY API 2500M can improve the quality of the wafer and mask inspection, reducing the number of defects detected. Overall, API 2500M is a high-performance mask & wafer inspection unit, designed to identify microscopic defects on substrates, quickly and reliably. Utilizing advanced imaging algorithms, high-speed scanning, and automated workflow tools, the machine provides a comprehensive inspection solution for the semiconductor industry.

There are no reviews yet