Used CARL ZEISS / HSEB MIT300 #293639397 for sale

URL successfully copied!

Tap to zoom

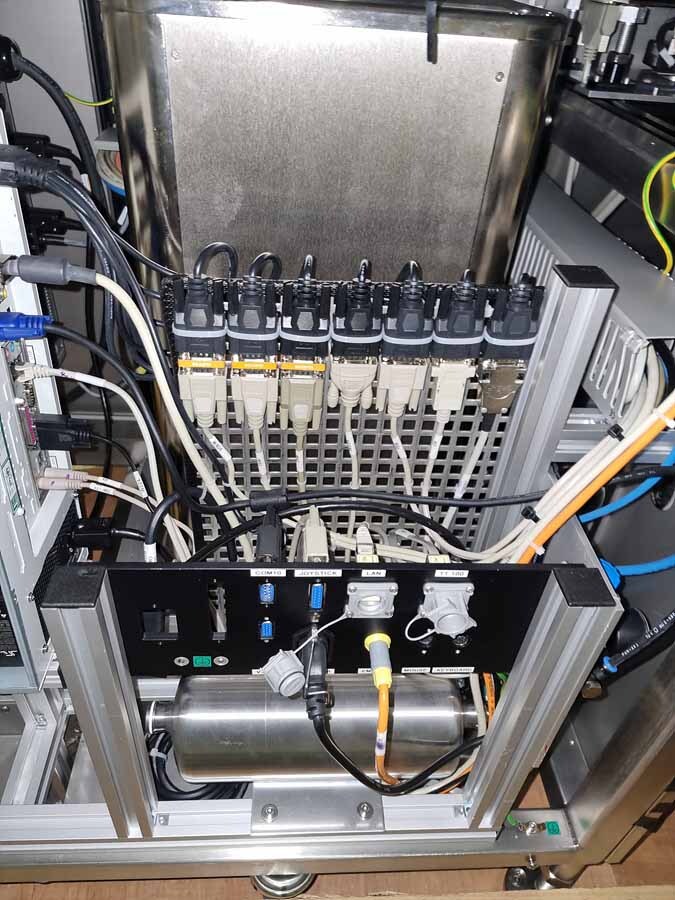

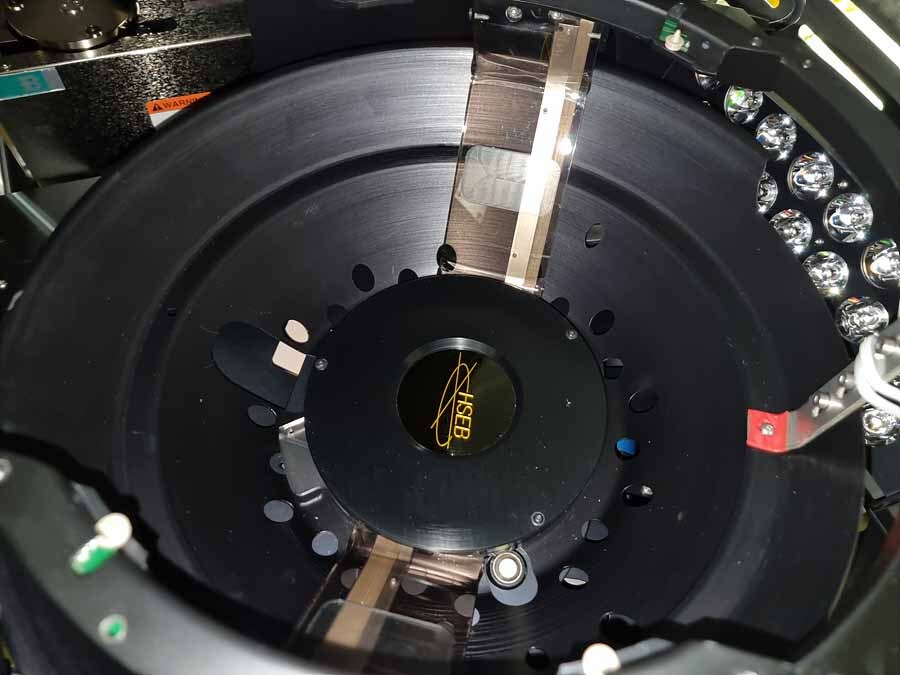

CARL ZEISS / HSEB MIT300 Mask & Wafer Inspection Equipment is a state-of-the-art system designed specifically for defect detection. Using a quickly-scanning optically adaptive unit, HSEB MIT300 is able to detect even the most minuscule flaws with unparalleled accuracy and flatness comparison. The machine contains a 16-megapixel head which captures a shot taken at a maximum frame rate of up to 5000 frames per second, making it well-suited for high-speed scanning applications. The camera also contains a pixel size of 8.3 µm and a dynamic range of 72 dB. Furthermore, the tool has the ability to provide intralithography and overlay measurements, providing the highest levels of wafer production uniformity measurements. The asset also includes a 4" proprietary optical model which consists of a planar phase optics with a full frame field of view. The equipment also comes with advanced image analysis algorithms, allowing for the reliable and rapid inspection of both mask and wafer defects. It further features an integrated X/Y stage system for quick and easy positioning and inspection of wafers in the scan field. Additionally, its robust mechanized stages make the unit less susceptible to environmental vibration from external sources, allowing for higher accuracy of the scan when compared to other systems on the market. In order to ensure maximum productivity, the machine is powered by an intuitive graphical user interface software which is tailored to the specific needs of mask and wafer inspection. The software comes with a series of built-in defect analysis and review tools, such as DICE image enhancement, Sub-Micron overlay measurements, customizable limit path for pass or fail classification and much more. Additionally, it offers real-time wafer analysis and defect inspection features, including auto identification of defects, algorithmic defect detection, and false defect recognition. The tool complies with ISO and SEMI standards, allowing for gentle handling of wafers and masks. The asset also operates in an environmental-friendly manner, with its low power requirements. It comes with a wide selection of options and hardware, such as an optical head for-ASML and 193i scan systems, optional automated report filing, custom-built software solutions and much more. Overall, CARL ZEISS MIT300 Mask & Wafer Inspection Model is a high-end equipment which offers state-of-the-art inspection capabilities. Its advanced optical system, built-in software and numerous additional options make it an ideal choice for meeting today's demanding requirements when it comes to defect detection.

There are no reviews yet