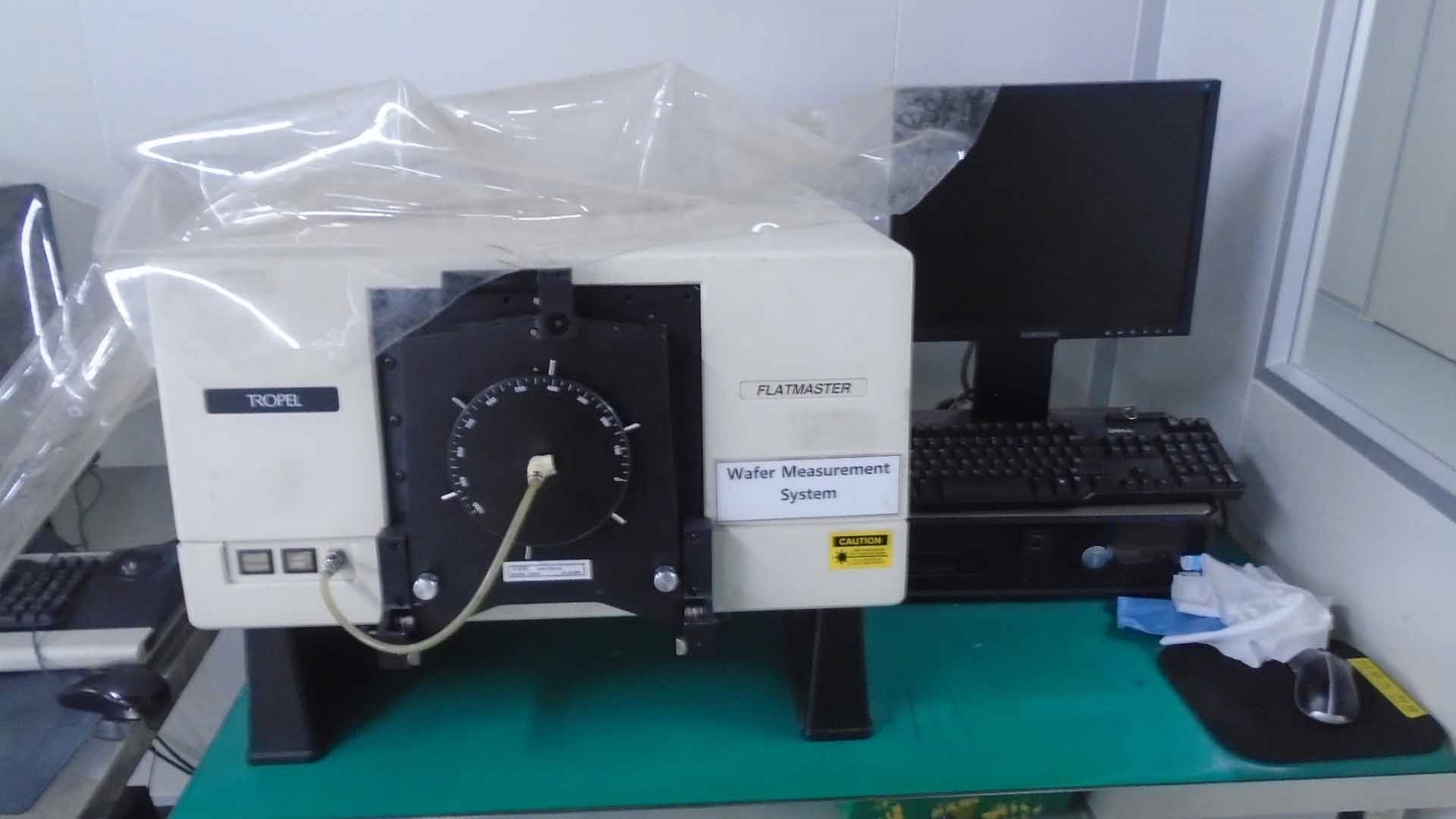

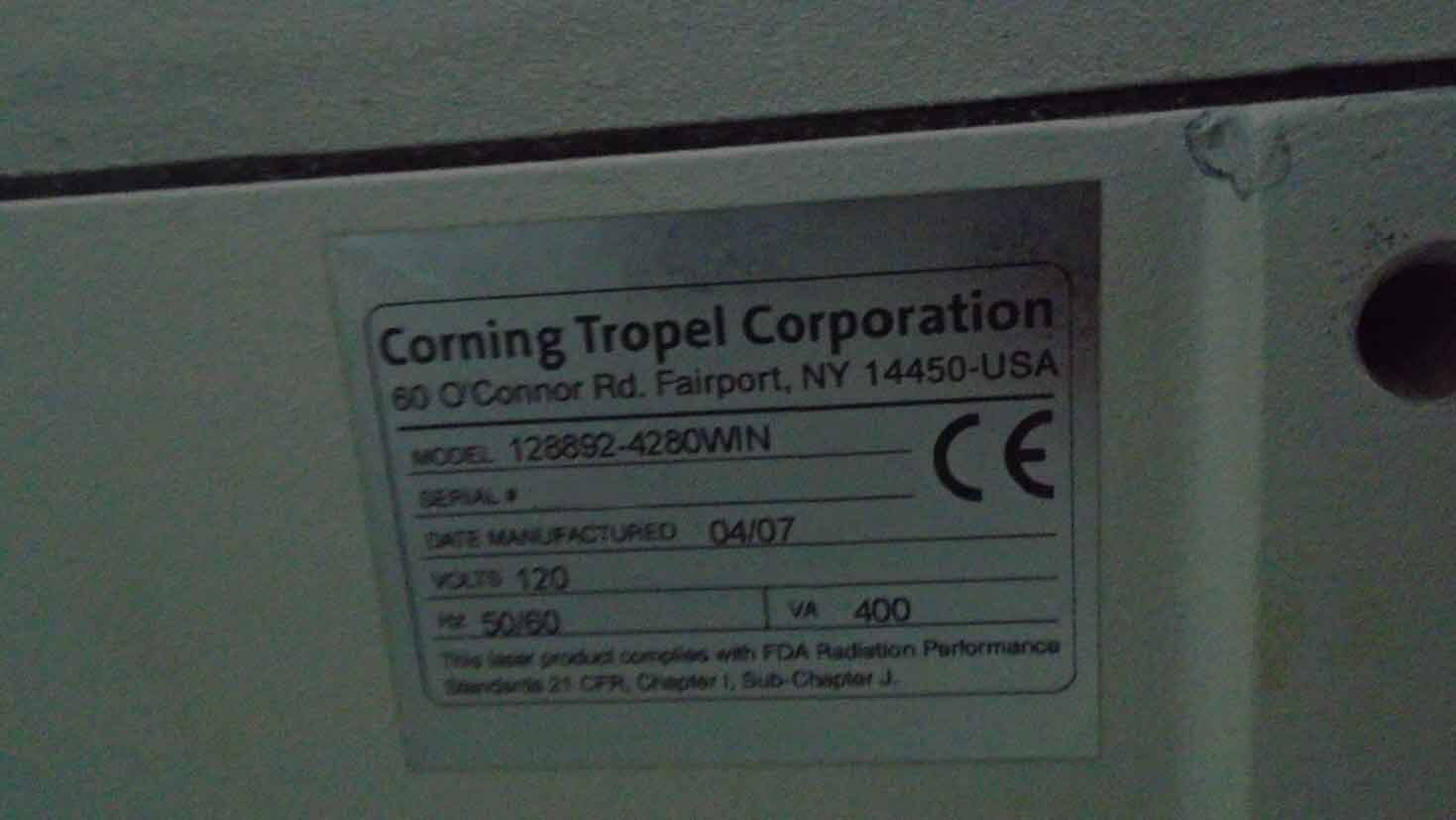

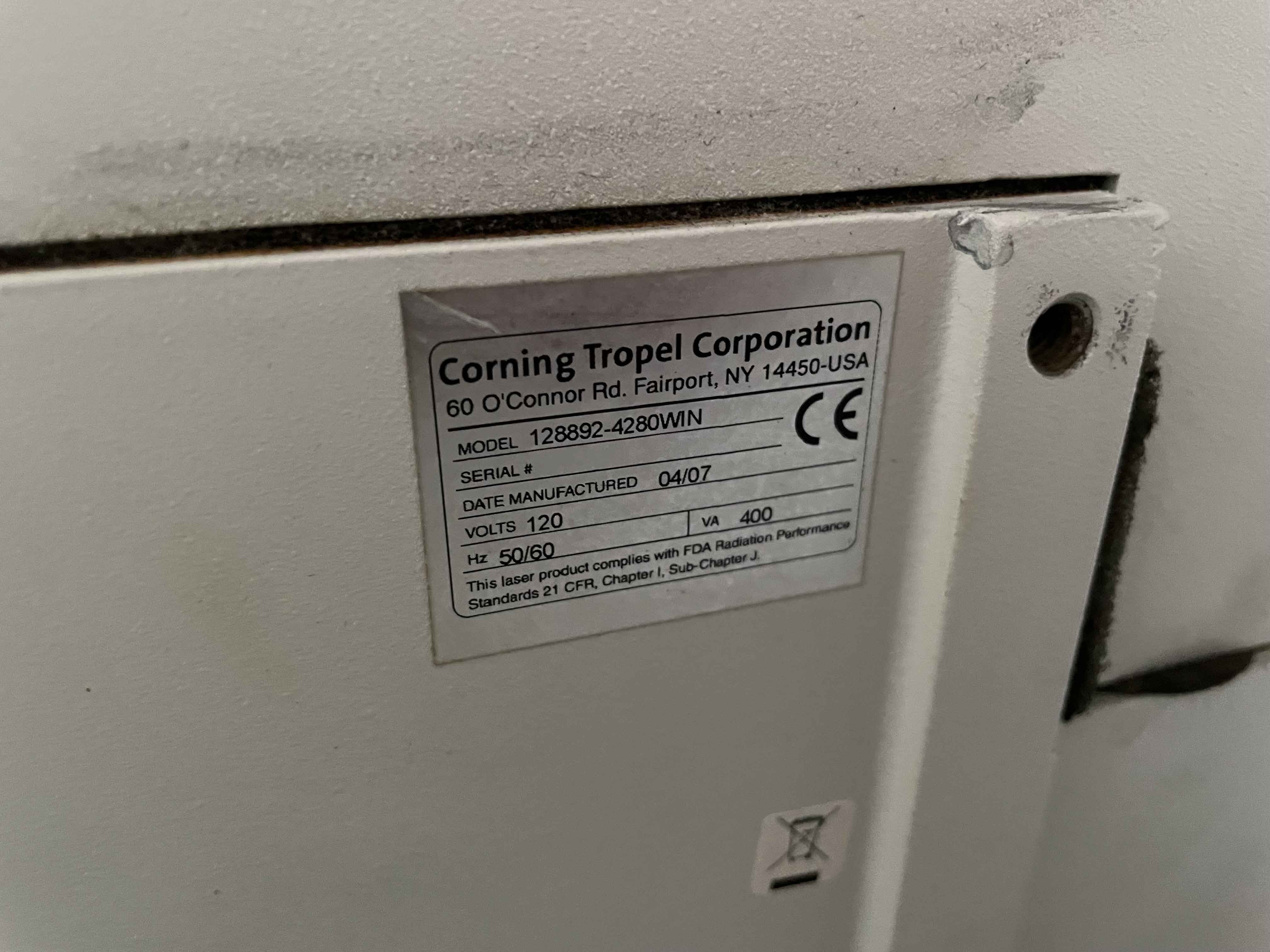

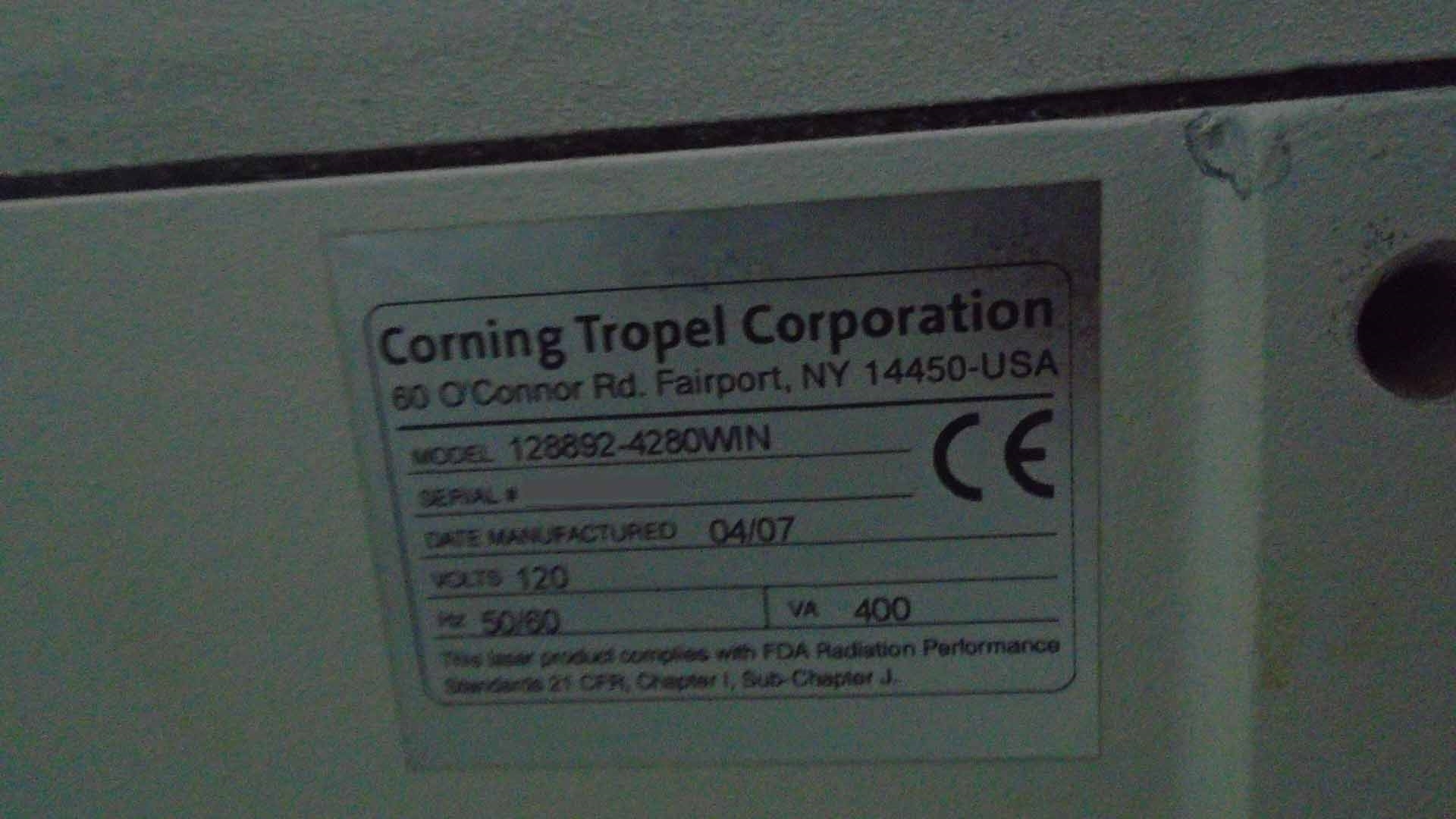

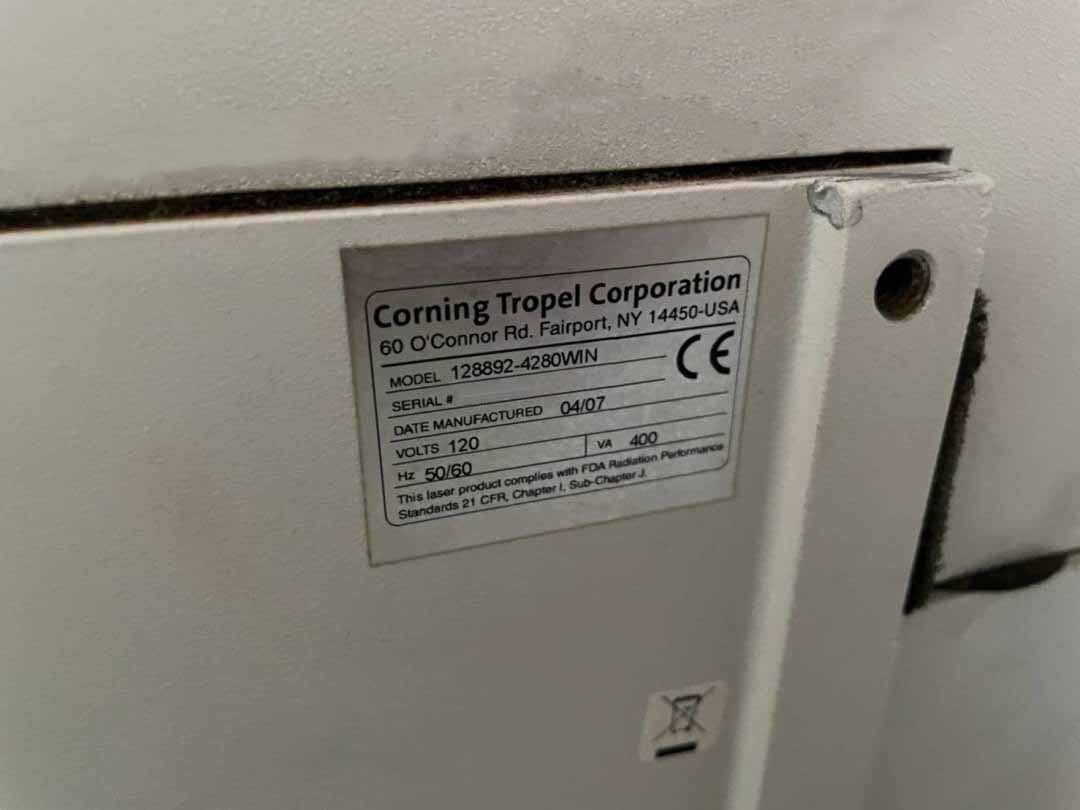

Used CORNING / TROPEL Flatmaster #9254077 for sale

URL successfully copied!

Tap to zoom

ID: 9254077

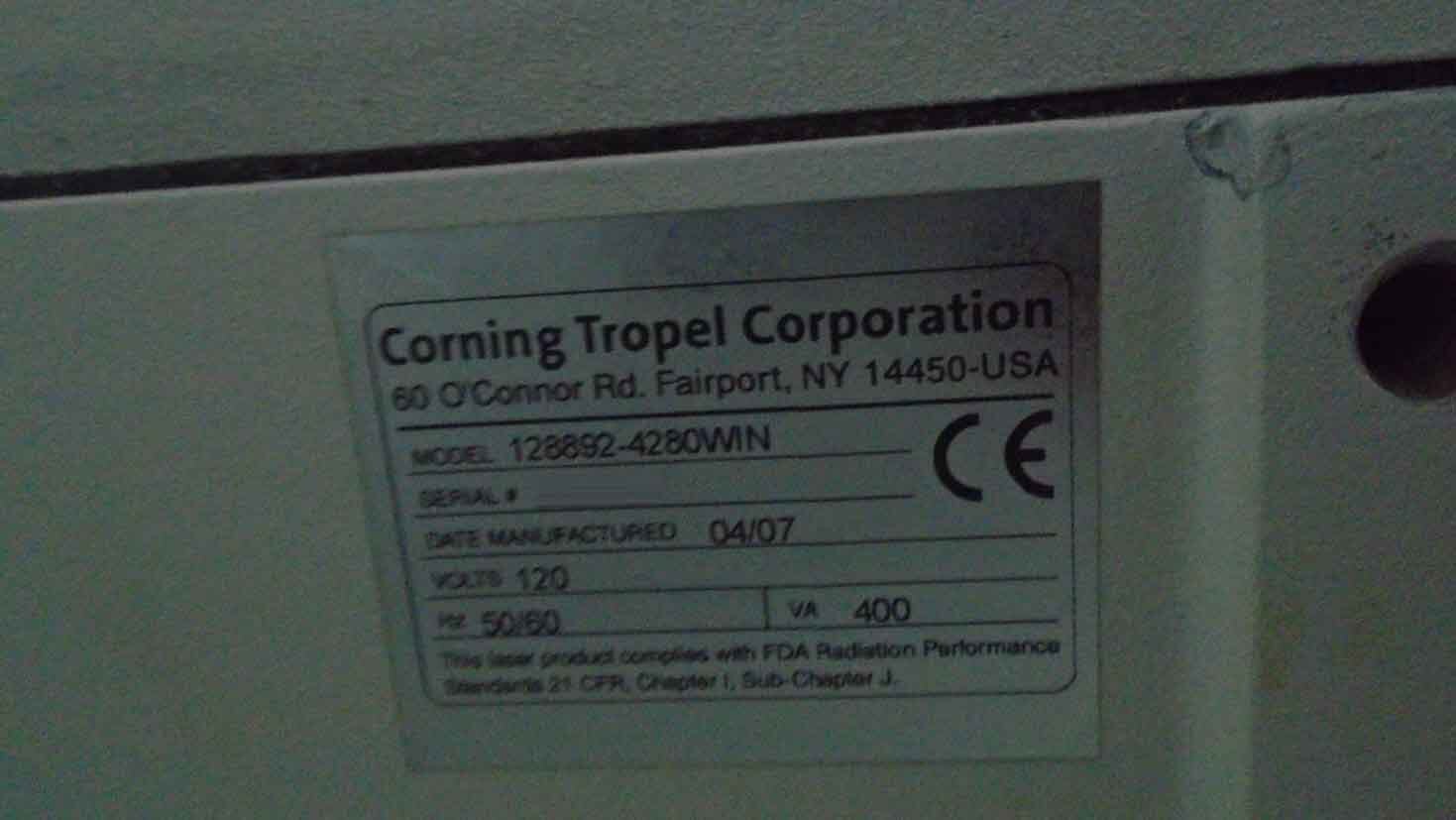

Vintage: 2007

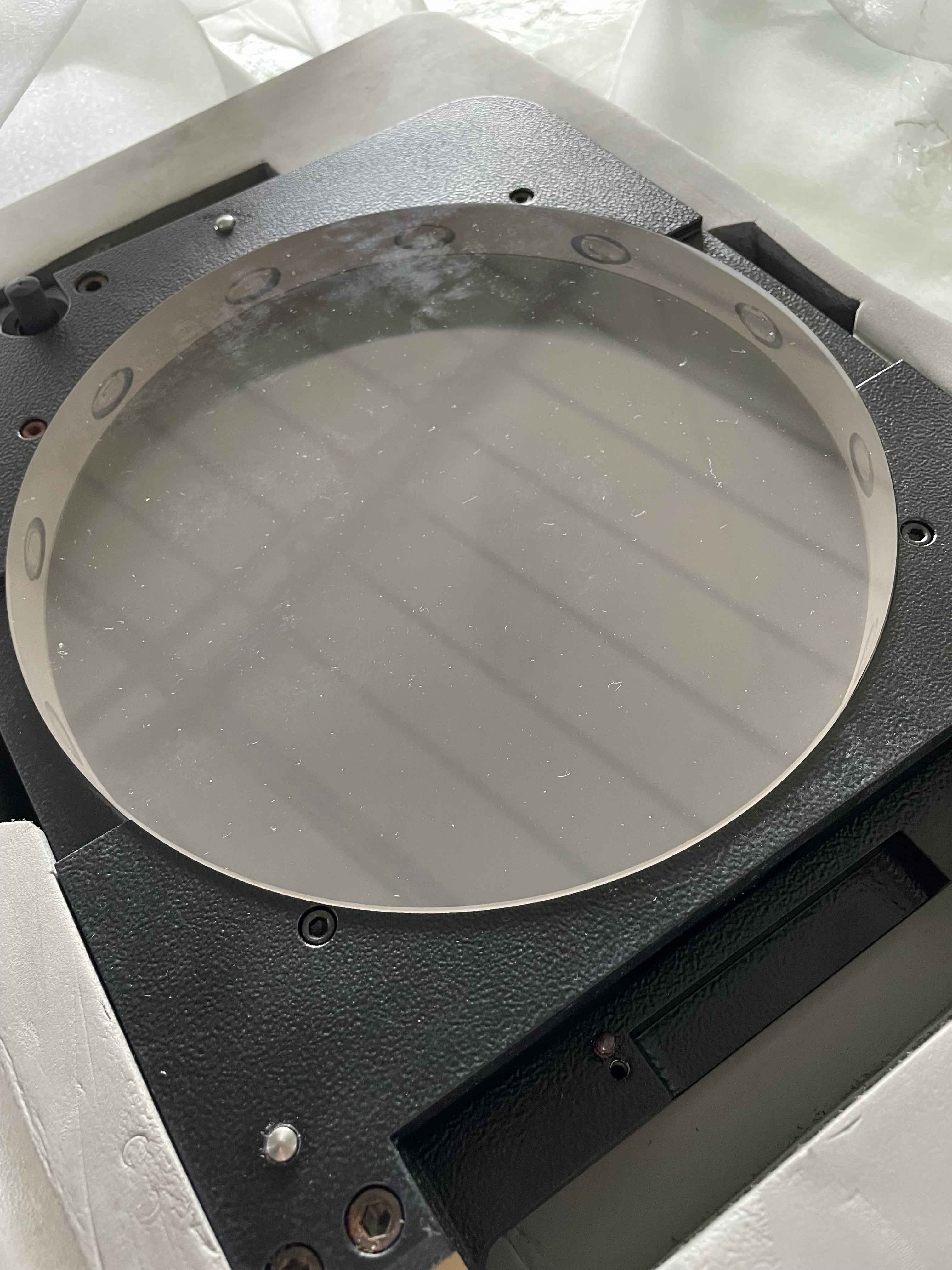

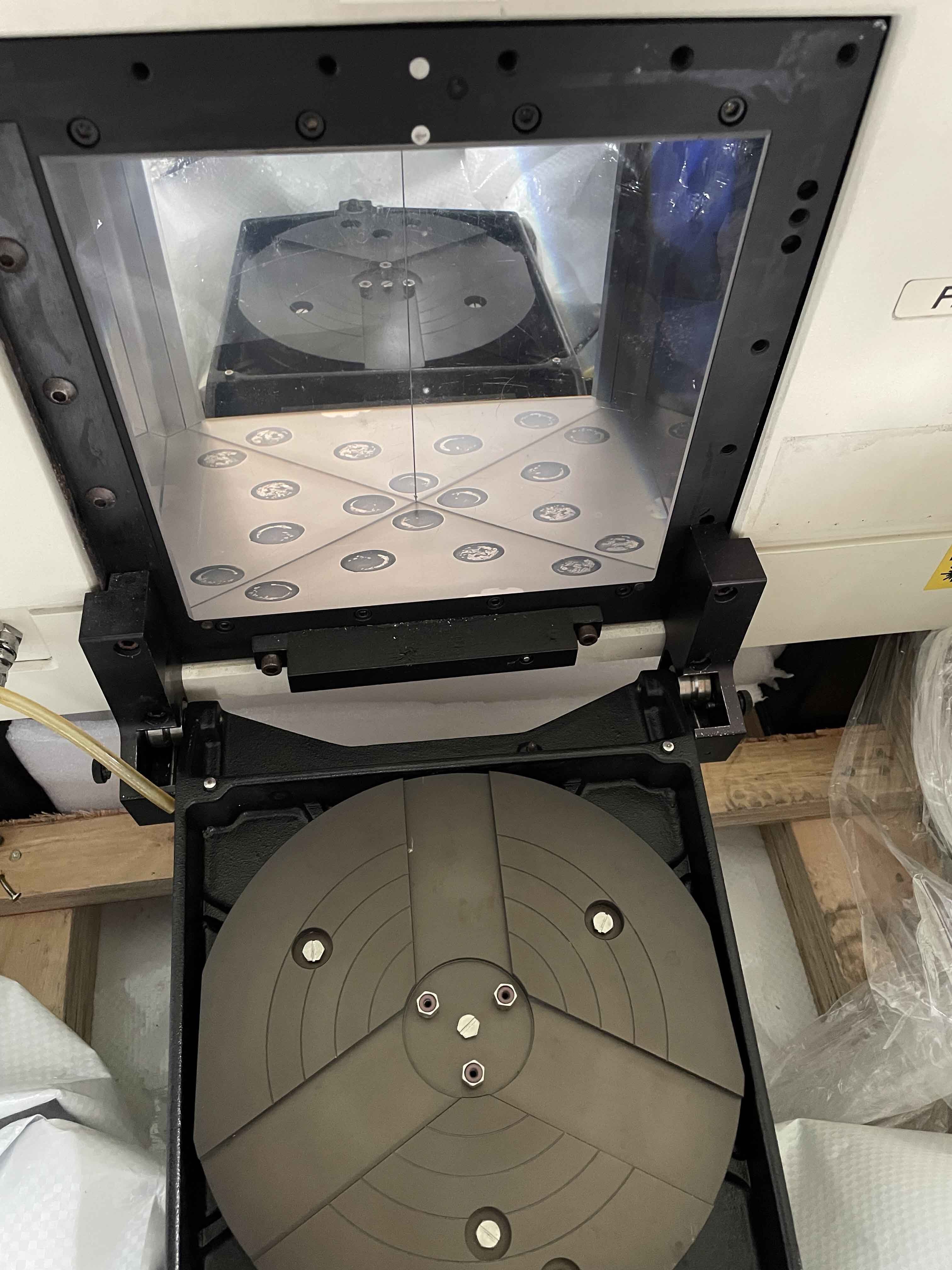

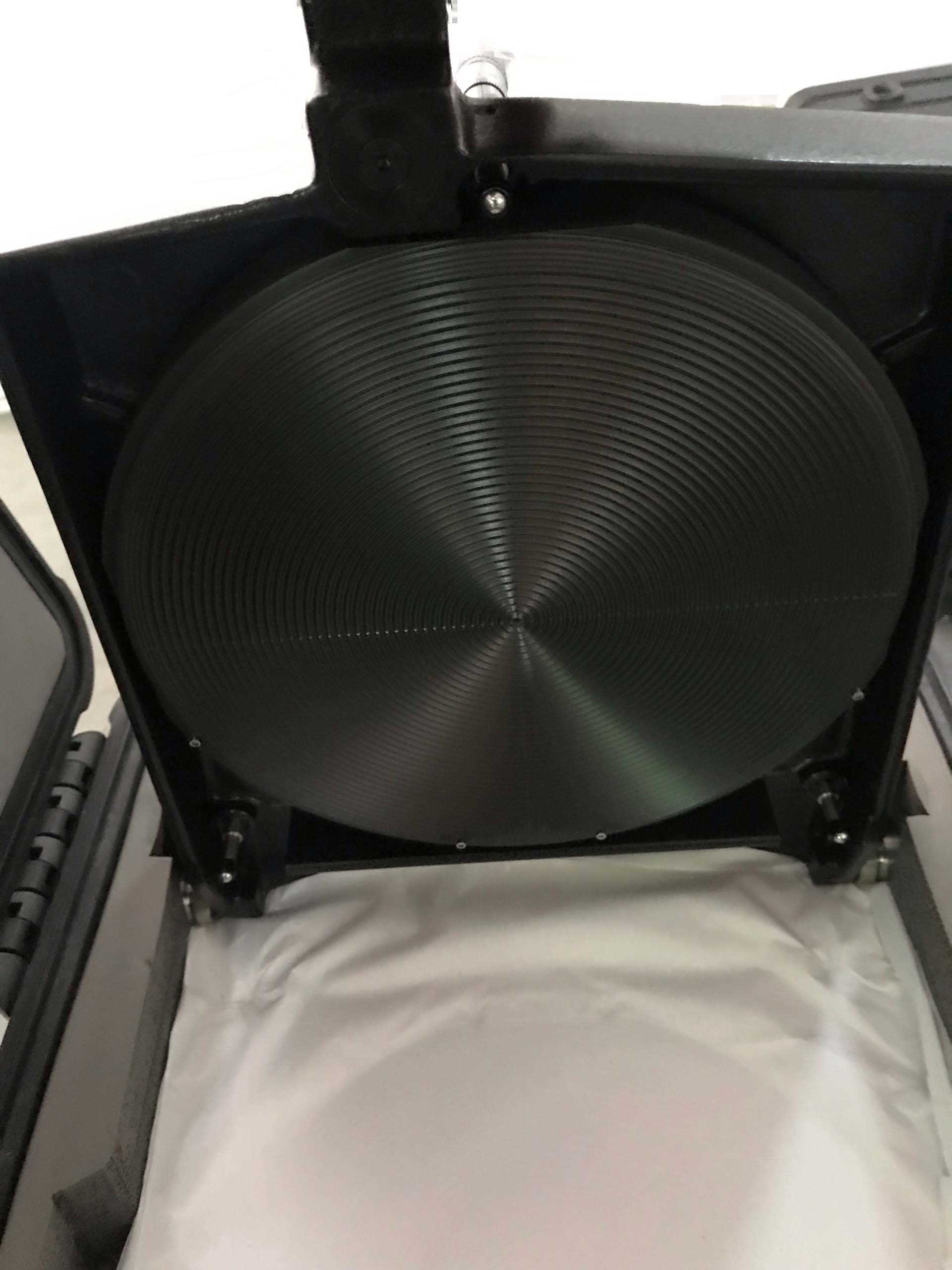

Wafer measurement system, 6"

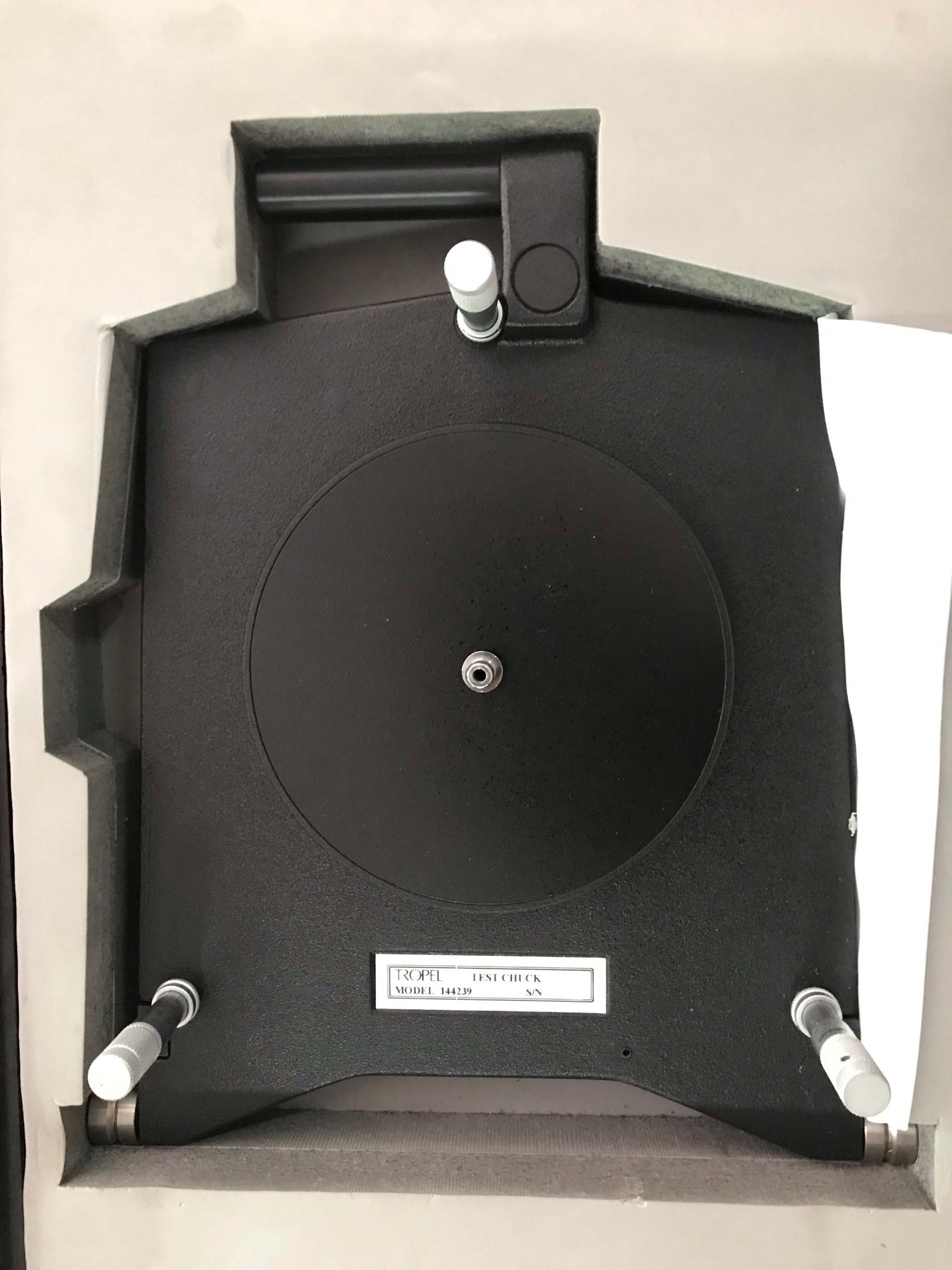

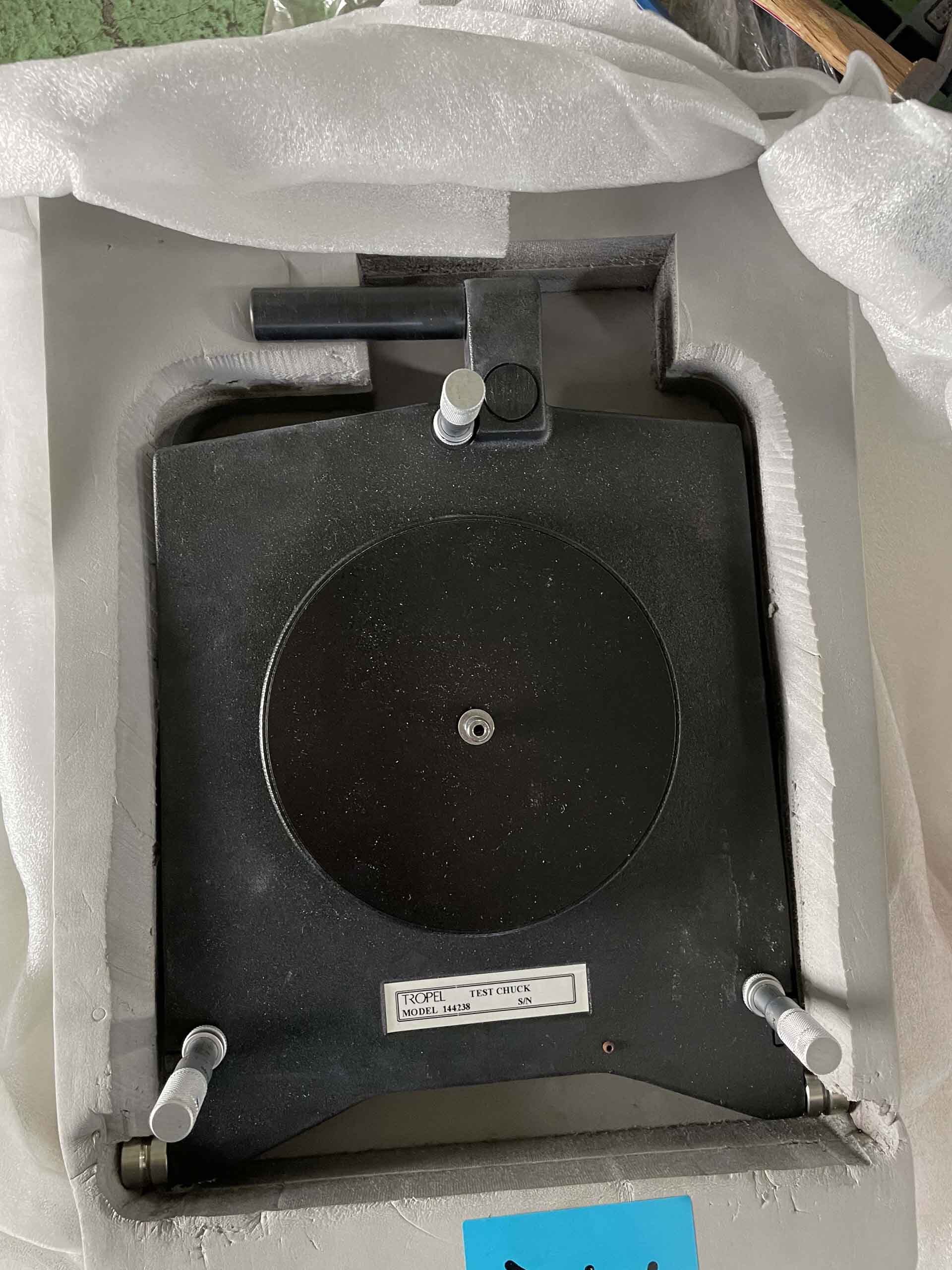

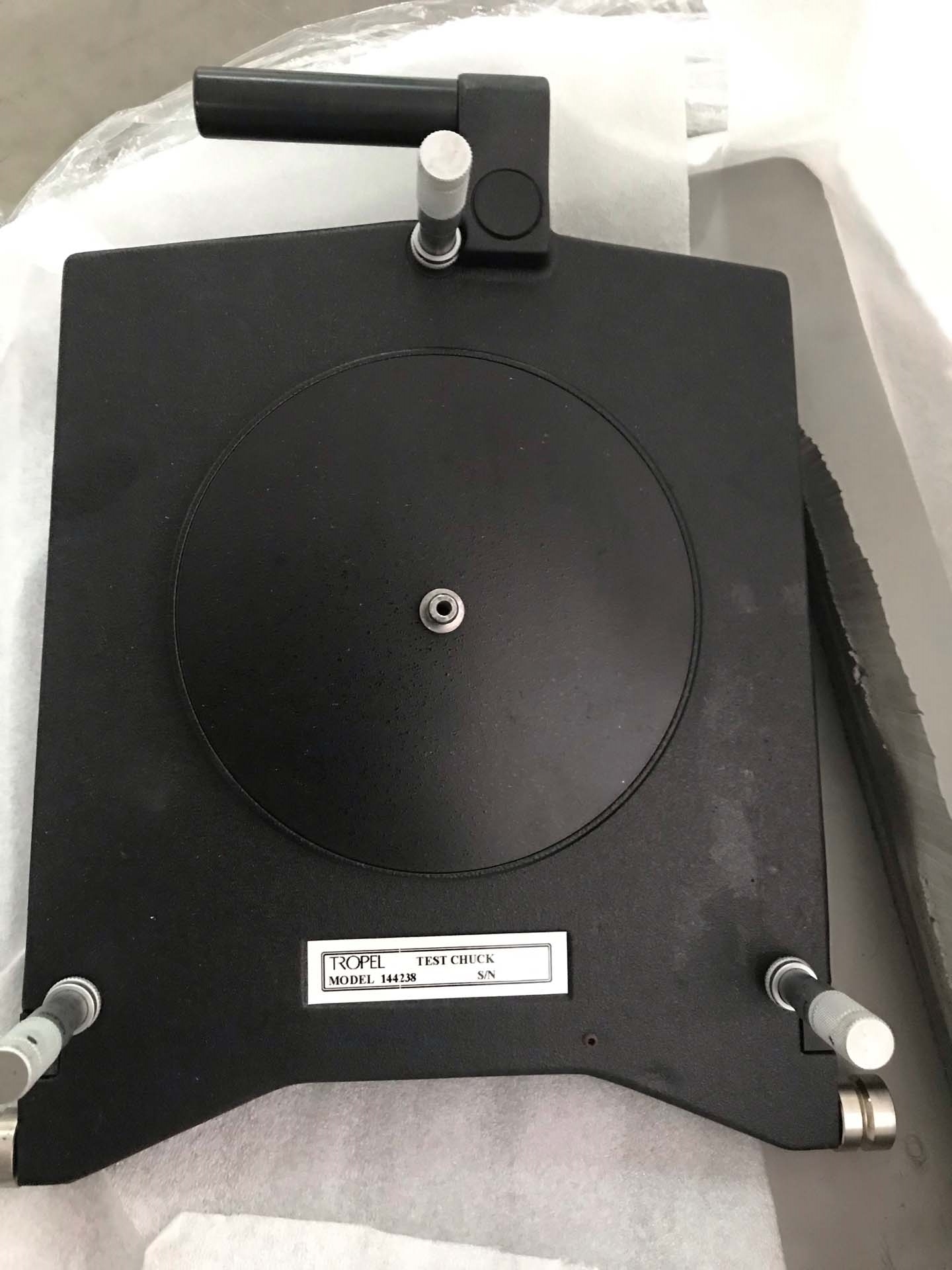

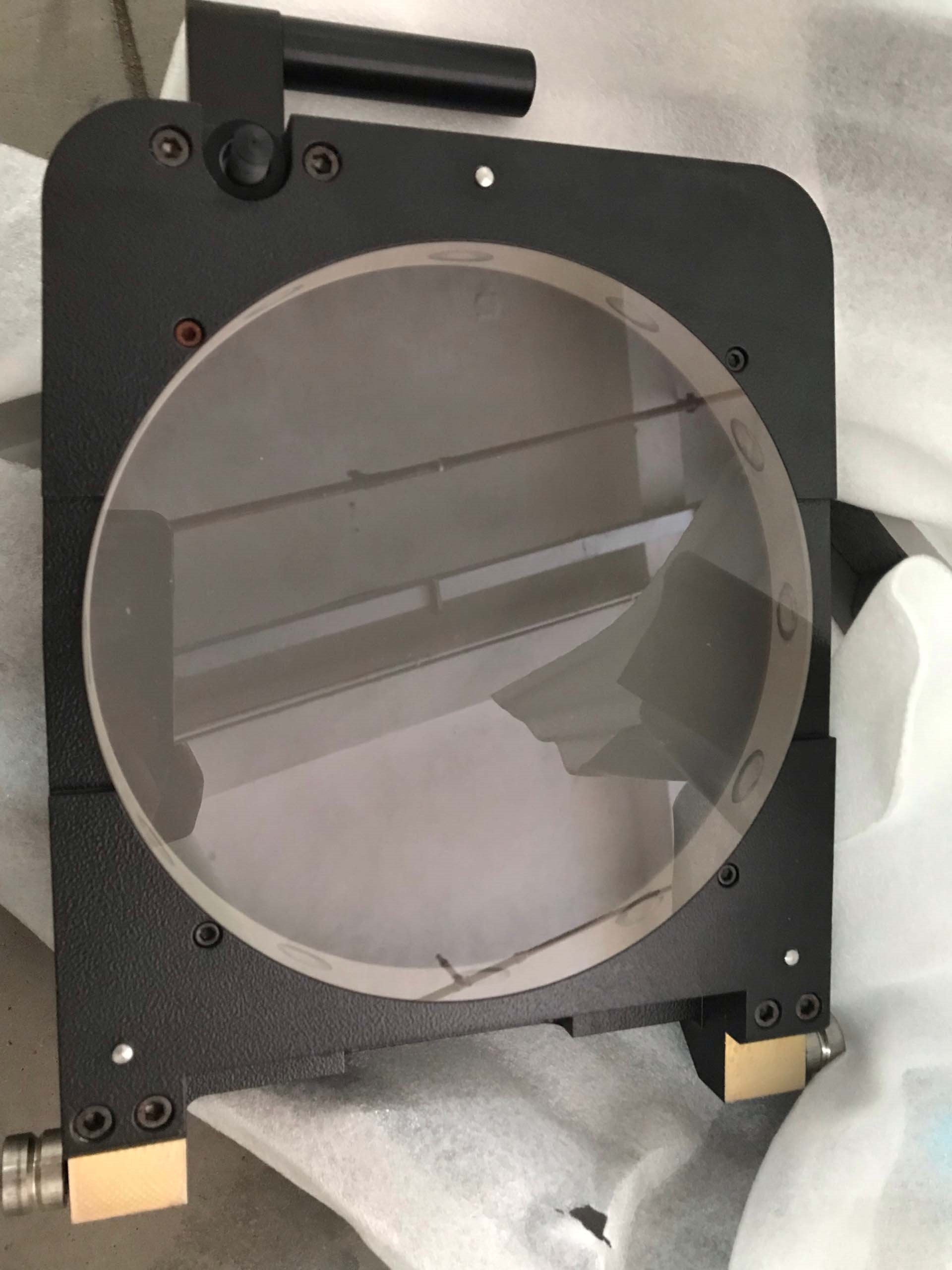

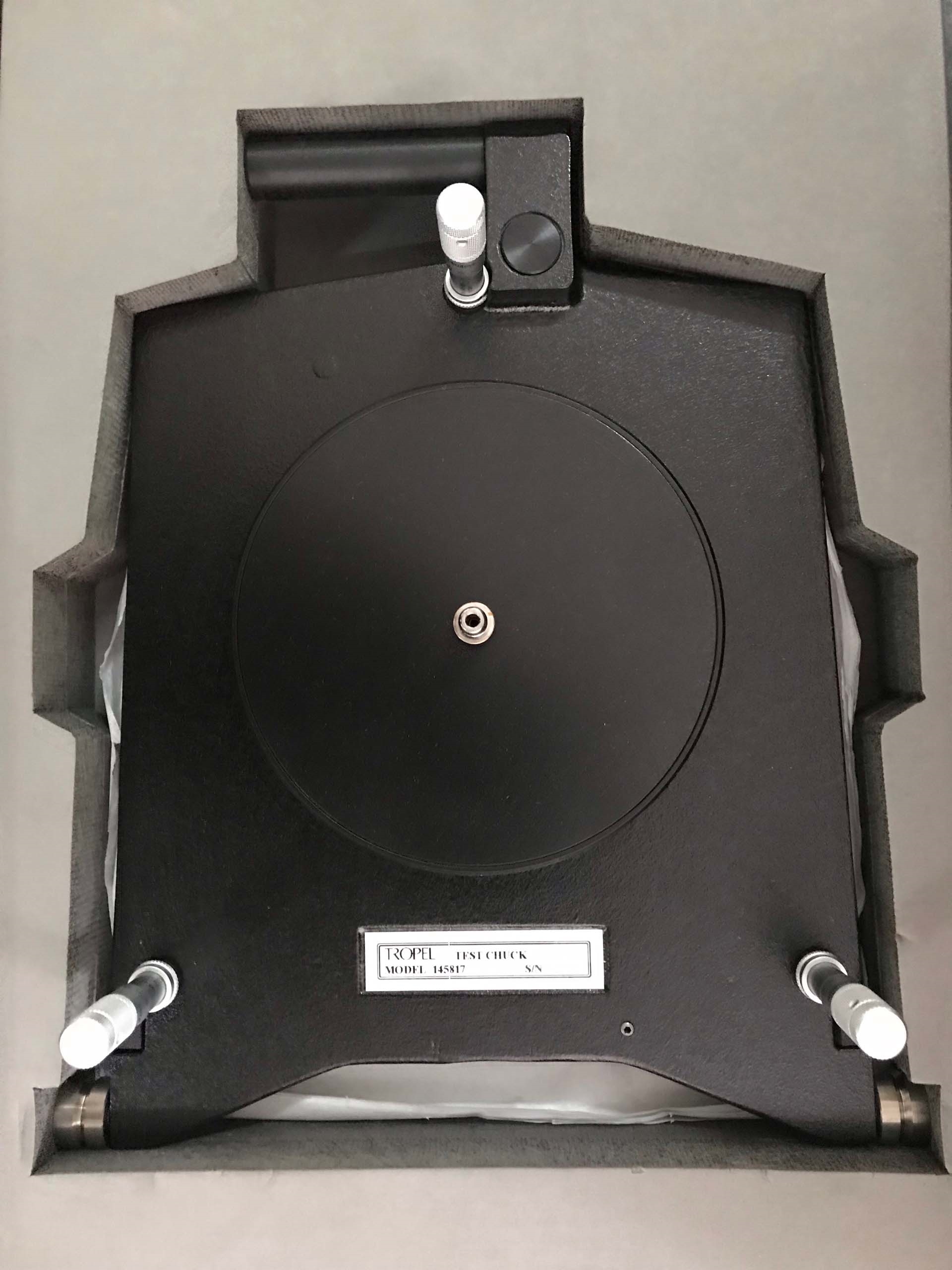

(5) Test trucks

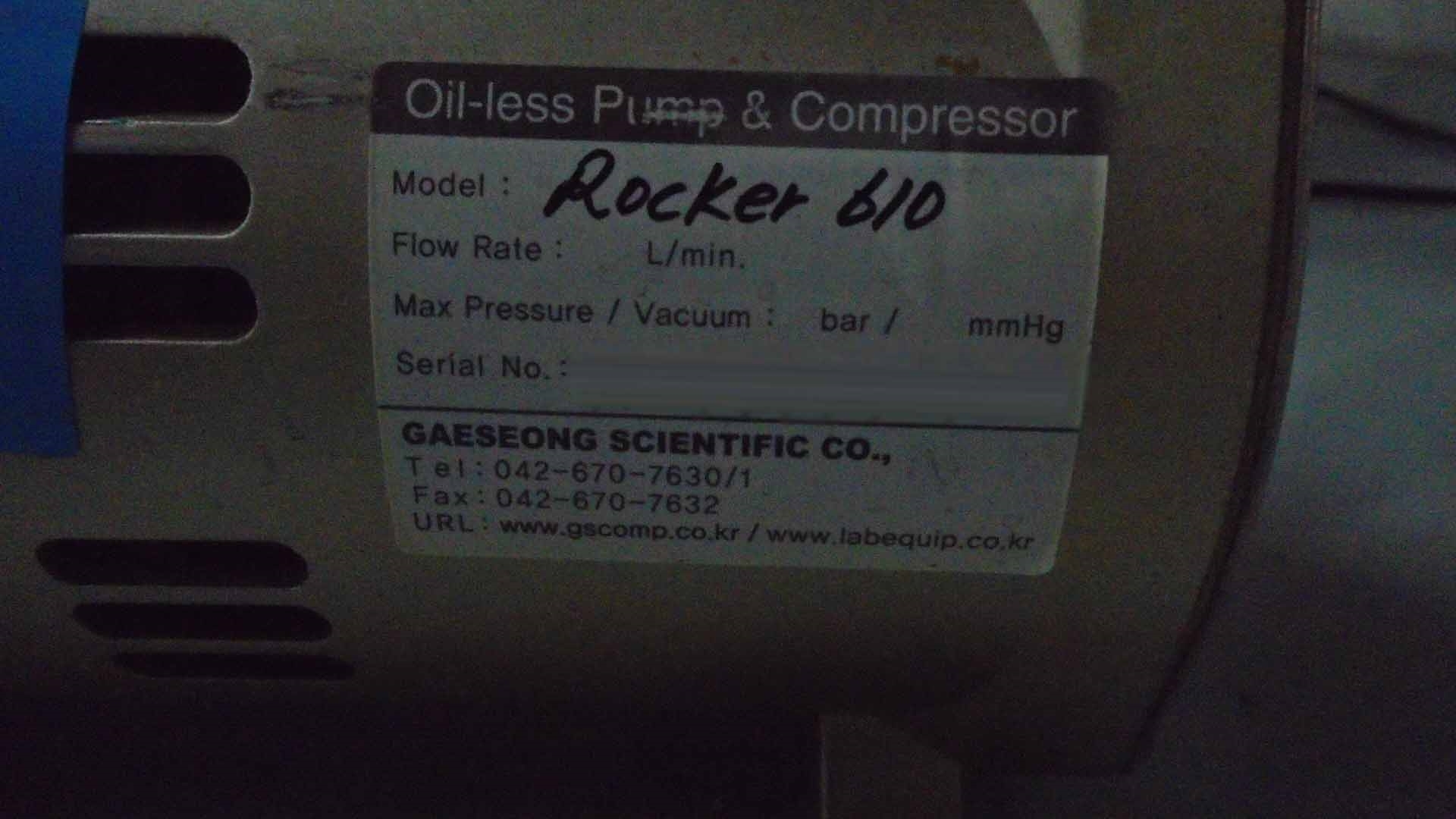

Pump

Computer

Manual

Oil free vacuum pump

Part size: 25 mm - 200 mm

Dynamic range: >100 µm

Accuracy: 50 nm

Repeatability: 15 nm, 1σ

Resolution: 5 nm

Measurement time: 5 s (Typical)

Measured data points: Up to 230,000

Measurement datum: Least squares, Minimum zone

Filtering: ISO standard

Materials: Metals, Glass, Polymers, Ceramics

Materials / Surfaces:

Reflectivity: 10% at 85° (Minimum)

Maximum roughness: 1µm, Ra (Typical at 4µm / fringe)

Temperature: 15°C-30°C

Rate of temperature change: 0.5°C-2°C

Humidity: 35-75% (Non-electrostatic / Non-condensing)

Power supply: 100-240 VAC, 50/60 Hz, 4 A

2007 vintage.

CORNING / TROPEL Flatmaster is an innovative mask and wafer inspection equipment that revolutionizes the inspection process for photolithography. This state-of-the-art system allows users to accurately inspect masks and wafers with extremely high uniformity, ultimately completing the photolithography process faster and more efficiently. TROPEL Flatmaster utilizes a unique dual image combination technique which combines both patterned and bare images to achieve the highest level of performance for mask and wafer images. This dual image combination provides an unprecedented level of clarity to users as the accuracy of the images are significantly improved. CORNING Flatmaster also utilizes advanced lighting techniques to minimize the effect of surface imperfections on the masked and wafer images. Flatmaster is controlled with a user-friendly, intuitive graphical user interface that allows users to quickly setup and initiate the inspection process. The user can interact with the unit to adjust sensitivity levels, exposure times, and image parameters. Additionally, the multi-layer configuration settings allow users to modify the machine to inspect multiple types of patterns and surfaces. CORNING / TROPEL Flatmaster is designed for full automation to maximize efficiency and minimize human intervention. It features a powerful image processing tool which is capable of identifying defects and generating reports based on user-defined criteria. This ensures that all inspections are carried out in a timely and cost effective manner. Additionally, TROPEL Flatmaster is compatible with a variety of existing inspection systems, eliminating the need for disruptive changes or unnecessary investments. CORNING Flatmaster has revolutionized the way photolithography is performed. This asset has been designed with speed, accuracy, and scalability in mind to deliver superior results. Flatmaster is a must-have for any organization looking to streamline their mask and wafer inspections.

There are no reviews yet