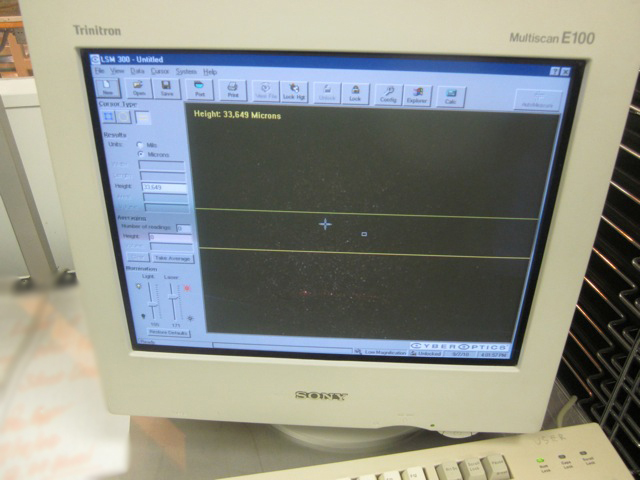

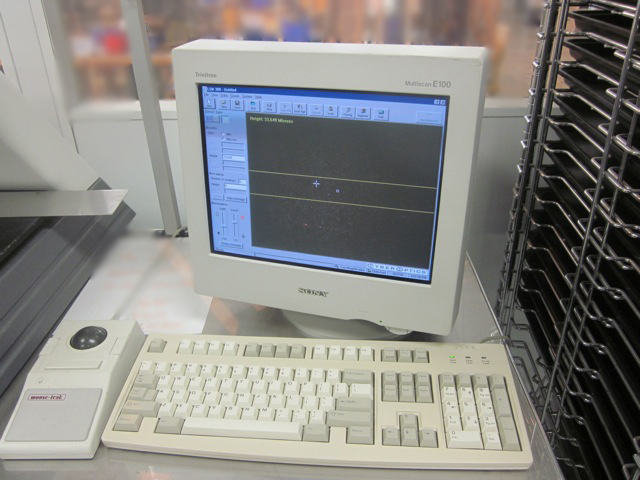

Used CYBEROPTICS LSM 300 #9008344 for sale

URL successfully copied!

Tap to zoom

CYBEROPTICS LSM 300 is an automated mask and wafer inspection equipment designed to help semiconductor manufacturers rapidly detect defects on their products. This system offers a complete solution to quickly and efficiently identify and analyze features on substrates, including masks, wafers, and lead frames. The unit allows for comprehensive automatic inspection using laser interferometric and optical metrology. In order to ensure the correct information is collected throughout the inspection process, LSM 300 utilizes unique, image processing algorithm. This algorithm recognizes regularly repeating structures in the mask and compensates for inaccuracies introduced by the substrate. The algorithm also effectively identifies low-profile features which would otherwise be undetectable. CYBEROPTICS LSM 300 offers a comprehensive examination of each mask and wafer. The machine is able to accommodate a vast range of substrates with dimensions of up to 450 mm in diameter. Additionally, ultraviolet and visible light sources are used to inspect both top and bottom surfaces of the substrates. In addition, the machine is compatible with a wide range of substrates, including quartz, silicon, and metallic ones. LSM 300 also features a reliable and efficient camera tool which offers high resolution imaging and precise measurements. This asset is able to capture and record images at speeds of up to 600 frames per second. The camera model is equipped with five different filters, enabling it to capture various colors and magnitudes of light. This enables accurate imaging of low-light features. Specifically built to meet the most demanding manufacturer requirements, CYBEROPTICS LSM 300 is capable of analyzing complex defects which would otherwise be overlooked. It can detect and distinguish surface and subsurface defects, as well as bevels, pits, and protrusion features. Furthermore, the equipment is also equipped with an autofocus capability, allowing the operator to focus at any point on the substrate. In summary, LSM 300 is an advanced mask and wafer inspection system designed to find and analyze defects on substrates. The unit boasts a robust camera machine which allows for high resolution imaging and precise measurements. It also uses a unique image-processing algorithm to identify regularly repeating structures in the mask and compensate for any inaccuracies. By utilizing CYBEROPTICS LSM 300, manufacturers can quickly detect defects and ensure quality products.

There are no reviews yet