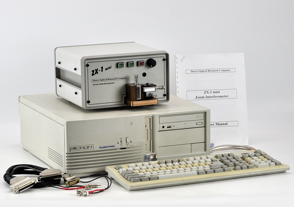

Used DIRECT OPTICAL ZX-1 Micro #127989 for sale

URL successfully copied!

Tap to zoom

ID: 127989

Mini Zoom Interferometer

Includes:

Computer DORC

Radius of Curvature:

Reproducibility - One Sigma: 0.25%

Repeatability - One Sigma: 0.10%

Apex Offset:

Reproducibility - One Sigma: 2.0µm

Repeatability - One Sigma: 0.5µm

Fiber Height:

Reproducibility - One Sigma: 1.5 nm

Repeatability - One Sigma: 1.0 nm

Radius of Curvature: 3mm Flat

Apex Offset:

0-500µm (value calculated if outside of captured frame)

Fiber Height: ± 6µm (with extended range option)

MICHELSON Interferometer (non-contact system)

Measurement Speed: Less than 1 second

Magnification:

X85 to X550 Using 12" monitor

X60 to X400 Using a 15" XGA monitor and the digital zoom turned off

Operating Wavelengths: 665 nm

Power Requirements: 100 to 120V AC, 50 / 60Hz.

DIRECT OPTICAL ZX-1 Micro is an advanced mask and wafer inspection equipment designed to provide high-precision 3D surface accuracy and rapid image analysis. The system uses a digital optics platform to detect microscopic defects and image processing algorithms to isolate and analyze them. At its core, ZX-1 Micro is driven by a fast-accelerated imaging unit. The technology utilizes advanced high-frequency parabolic optical lenses to capture and project images at higher speeds than traditional optics. As a result, the machine generates high resolution images with enhanced depth of field, allowing for a comprehensive understanding of the structure and surface of masks and wafers. DIRECT OPTICAL ZX-1 Micro also benefits from powerful image processing algorithms designed to accurately detect and isolate defects on the surface of masks and wafers. A mixture of various algorithms, such as particle analysis and process control methods, are employed to differentiate small defects on a full wafer or mask sample. In addition, the tool also supports real-time multiplexing, allowing it to rapidly process multiple structures simultaneously. ZX-1 Micro also features a practical and ergonomic design. User friendly controls, flexible mounting capabilities, and modular components make the asset simple and easy to use. Furthermore, the software package is optimized to be flexible and tailored to customer needs, enabling users to customize the model to their application or process. Altogether, DIRECT OPTICAL ZX-1 Micro is a sophisticated inspection equipment that offers precision, efficiency and flexibility. It provides an accurate, reliable and cost-effective way to detect microscopic defects on masks and wafers. From R&D centers to production lines, the system solves a variety of problems and provides valuable insight into the condition of masks and wafers.

There are no reviews yet