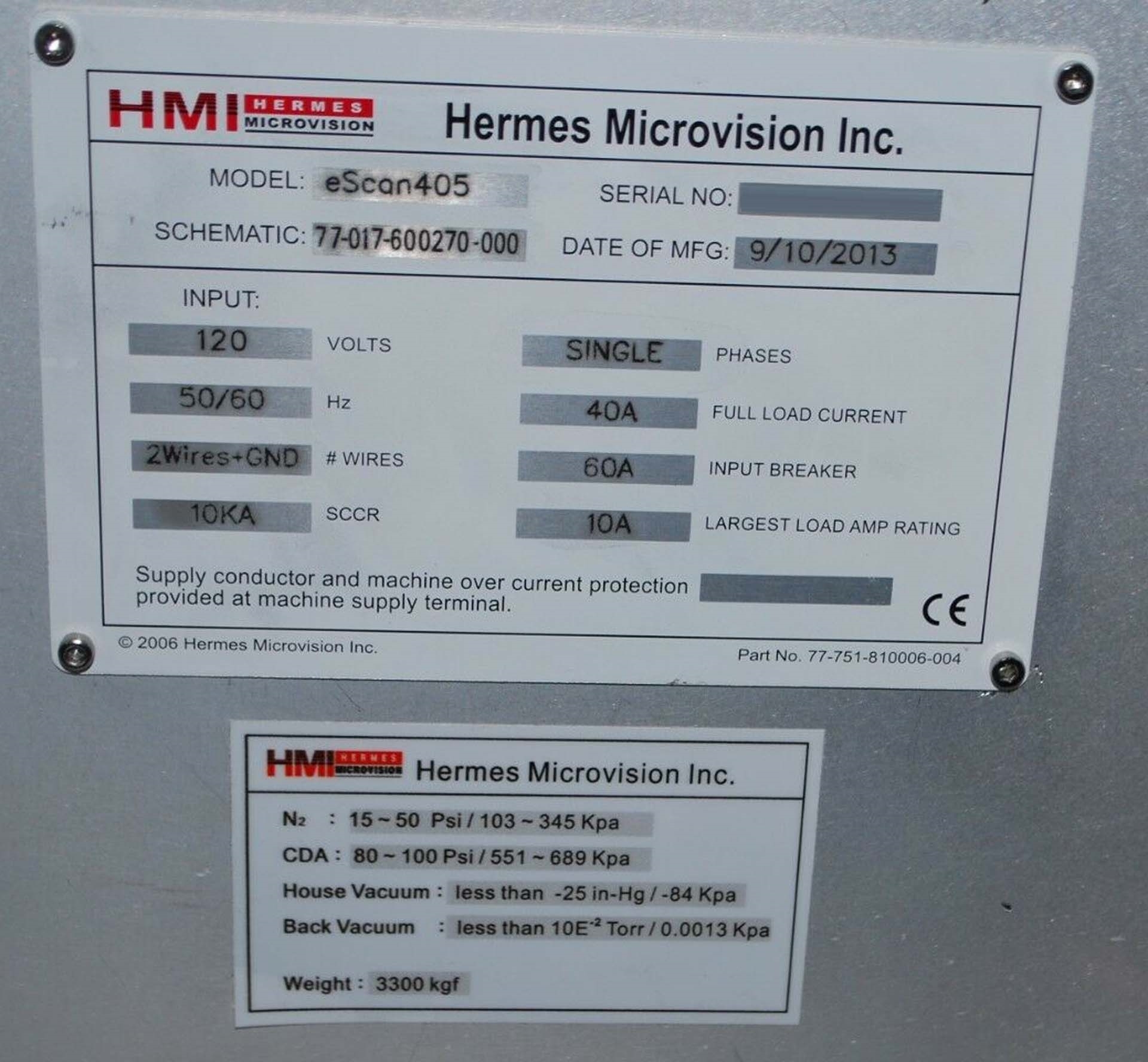

Used HERMES MICROVISION / HMI eScan 405 #9244052 for sale

URL successfully copied!

Tap to zoom

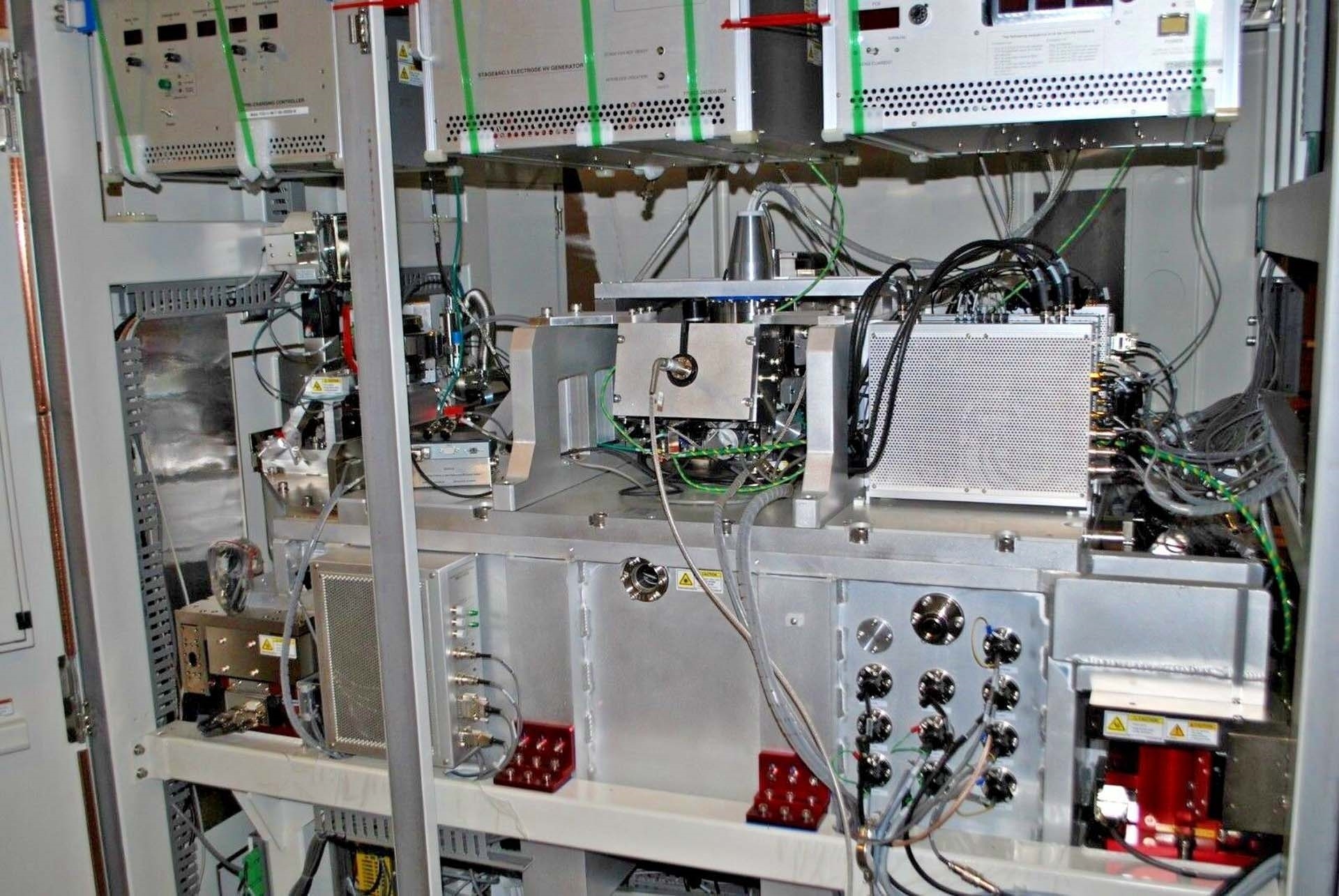

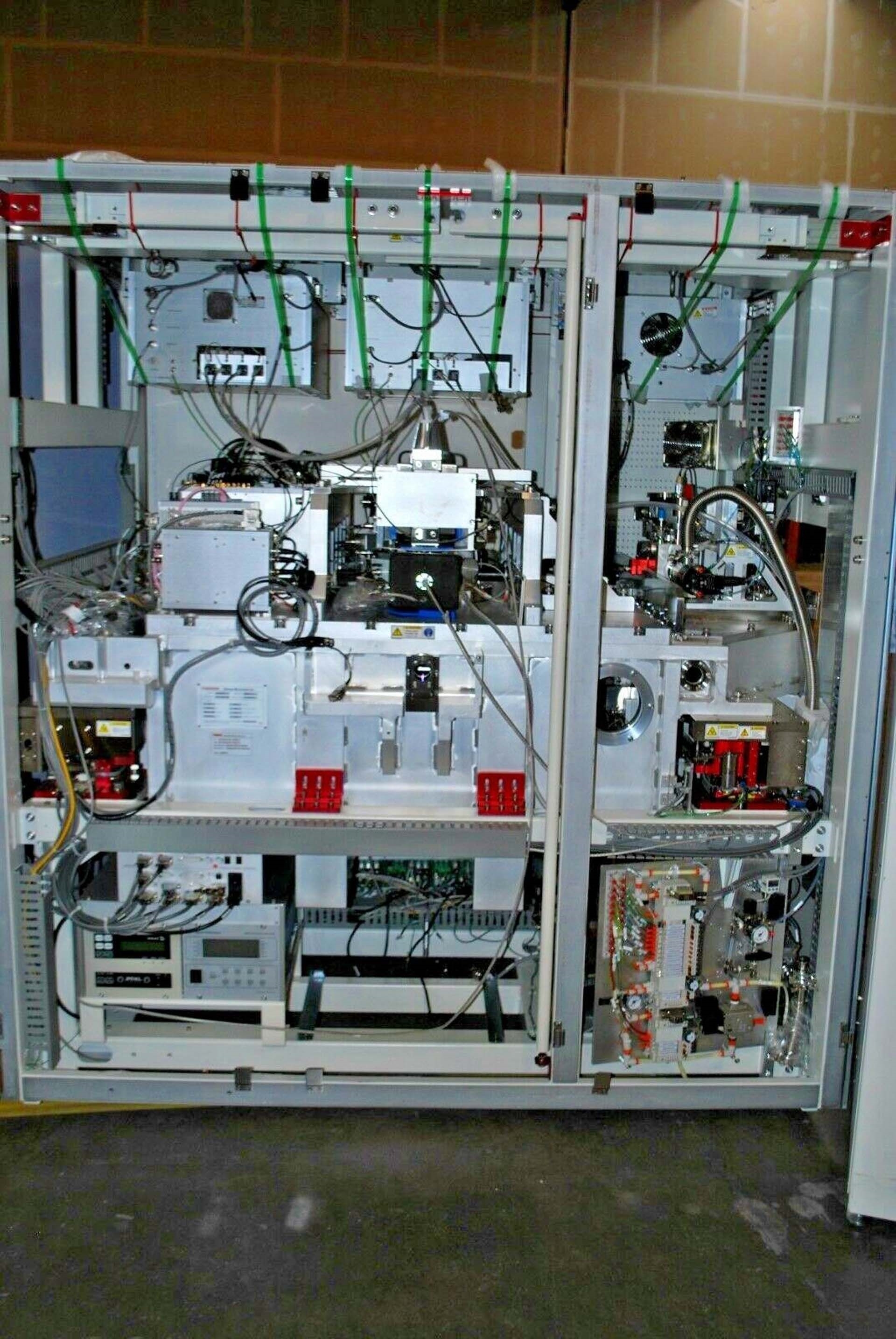

HERMES MICROVISION / HMI eScan 405 is a fully automated mask and wafer inspection equipment for the inspection of semiconductor masks used in lithography processes. The system facilitates inspection from four angles, including inspection of transmissivity, absorptivity, and reflection as well as automated defect localization. This unit can inspect 16M mask images within minutes, accelerating the whole process with high precision, and amazing speed. HMI eScan 405 comprises of a high-performance optics machine, including 10X and 20X objectives, an 8-inch monitor, and a vacuum mask chuck, allowing it to acquire UV light images from mask features with an excellent level of accuracy. By utilising an inbuilt calibration mechanism and an advanced auto-focus algorithm, the tool accurately captures high-resolution images with an effective pixel size of 340 x 510 nm. The inspection process of the mask/wafer in HERMES MICROVISION eScan 405 starts with mask alignment. The image of the mask is then acquired using a pair of LED illumination units. During this process, the edges of the mask are in-focus, and the original image is digitised and analysed using advanced image algorithms. All kinds of defect and mask aspect-ratio anomalies are rapidly detected in the image to rapidly conclude the inspection process with accurate results. For wafer inspections, the asset is equipped with a rotary stage to scan across multiple sites consecutively with high precision. Following the acquisition process, the integrated software packages help detect and map out defects. This approach is different from the typical manual process as this model can effectively analyse mask/wafer images in a fraction of time taken by manual operators. Furthermore, the equipment features an aggregated wafer image in the form of a bar-code, which can be used to track the process for related products and trace the validation history of wafers. EScan 405 system also features a high throughput program. The unit allows the user to pre-select the wafer/mask areas, which can be inspected faster, saving time that would be otherwise taken by traditional inspection methods like Sub-Field Verification (SFV). The machine also offers automated high resolution optical microscope observation for semiconductor devices. HERMES MICROVISION / HMI eScan 405 is an invaluable tool to inspect and detect various flaws in mask and wafer images. High speed, accuracy, and quality are guaranteed - making HMI eScan 405 an ideal choice for semiconductor applications.

There are no reviews yet