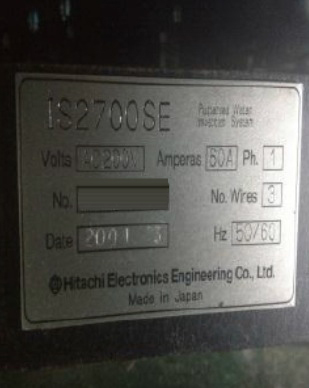

Used HITACHI IS 2700SE #9044470 for sale

URL successfully copied!

Tap to zoom

ID: 9044470

Defect inspection system

Power : 200VAC, 60A, 3phase, 50/60Hz

Operation unit:

Upper & Lower Monitor

Keyboard & Joystick

System Computer

CP750A Video Printer

Main AC Power Box

Coherent Laser Box

Missing:

Dalsa Header and controller

Stage X-Y controller

Stage Z controller

Robot Assembly in loader unit

TDK TAS300 Load port, L/R

2001 vintage.

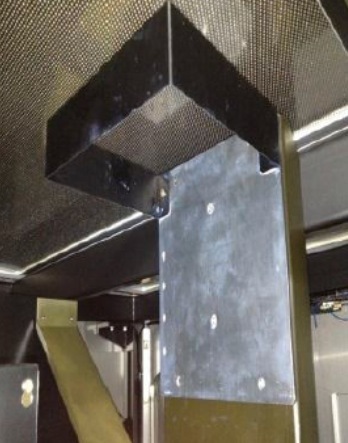

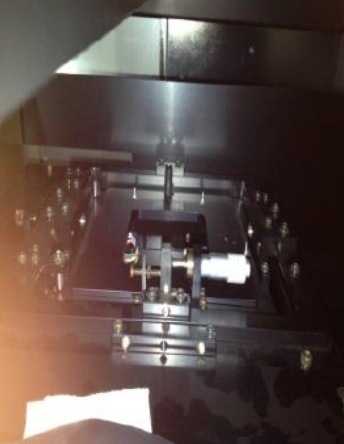

HITACHI IS 2700SE is a professional-grade mask & wafer inspection equipment that can be used for a variety of applications. The system is comprised of a control console, imaging station, and a wafer station. The console contains the central processing unit, the command processor, and ancillary support equipment. The imaging station contains a progressive scan CCD camera, deflection and astigmatism correction optics, and a mask station which is equipped with a fully automated wafer stage. The wafer station holds a wafer-holding chuck and an 8-inch open frame image sensor. The inspection process is designed to detect defects in wafer edge, membrane, and chip packing of sample masks. Features such as color inspection, image enhancement, measurement, and integrated defect analysis are included, allowing for faster and more accurate inspection of masks. The CCD camera has a 4K pixel resolution that provides high-resolution images of sample masks. The camera's dynamic range allows for a variety of masks to be viewed with various levels of brightness, contrast, color, pattern, and resolution. The inspection machine also includes a number of filter presets which allow the user to select inspection settings depending on the sample masks being inspected. Additionally, the tool includes a number of algorithms to facilitate fine defect detection and automated defect analysis. IS 2700SE asset is a highly efficient model for mask & wafer inspection. It has a software interface which allows easy control of the various equipment functions. The system is capable of executing various programs and greatly accelerates the process of mask inspection. Additionally, components such as the CCD camera, optics, filter presets, and automated defect analysis algorithms ensure that the user is able to achieve accurate and reliable inspection results.

There are no reviews yet