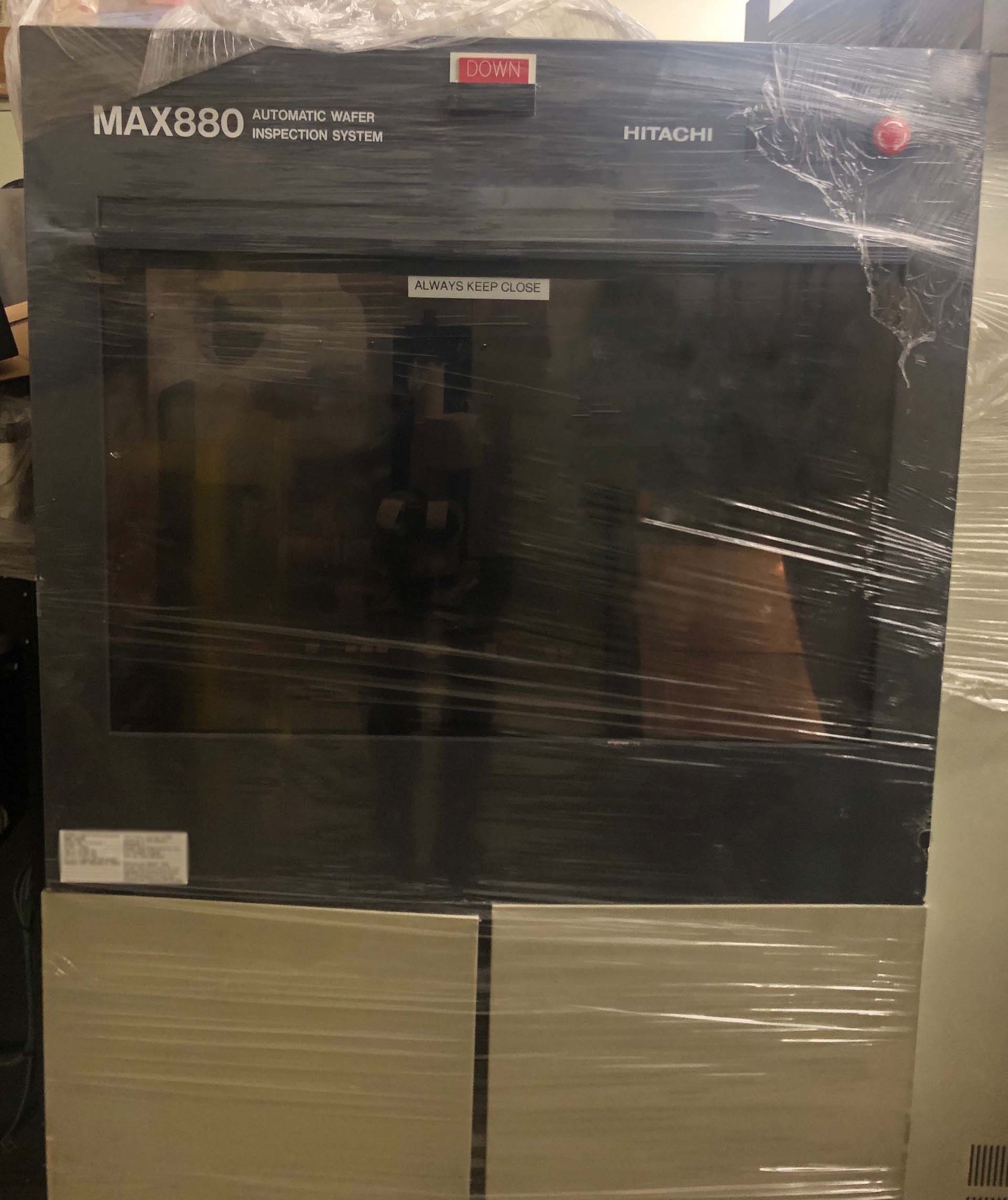

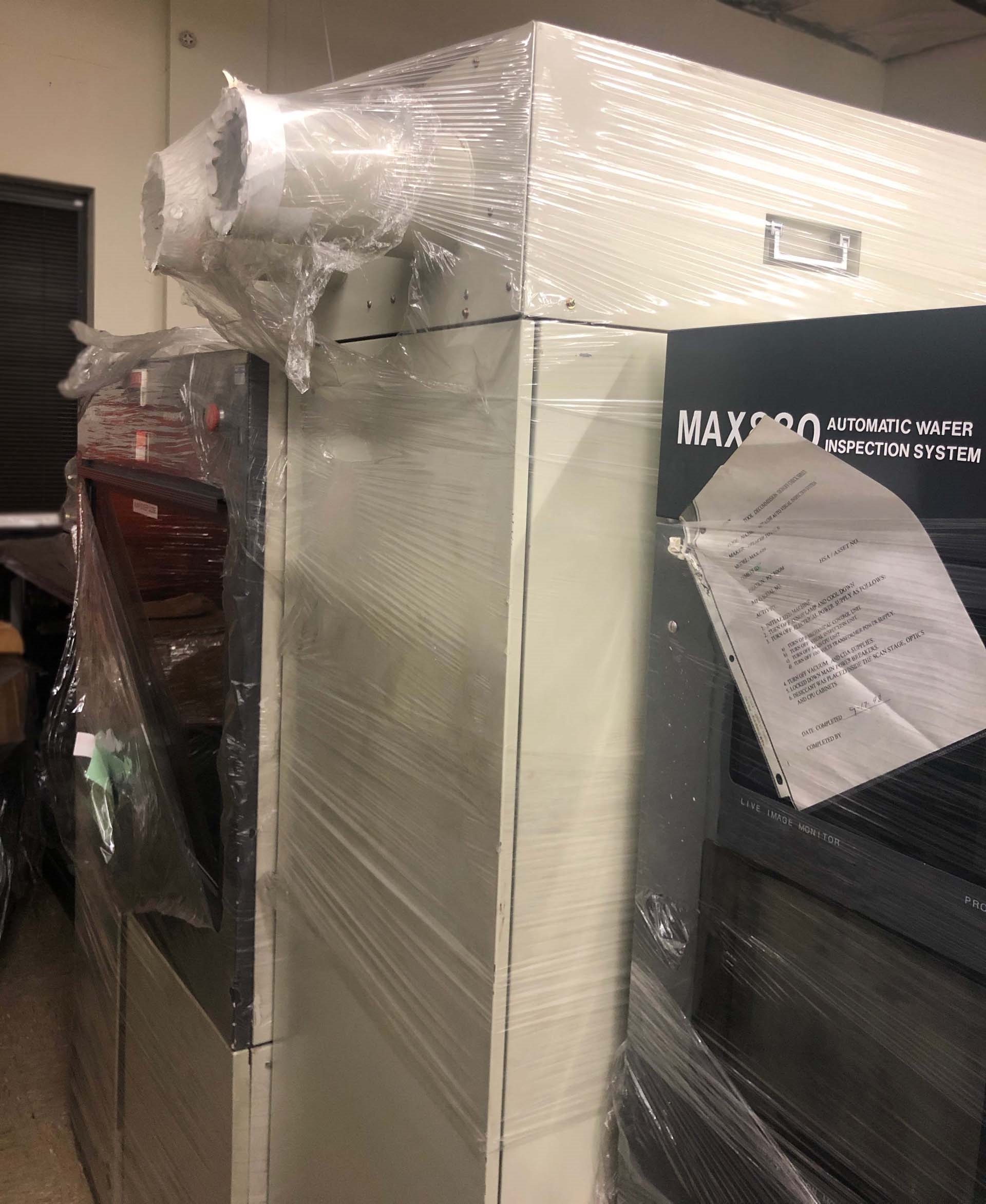

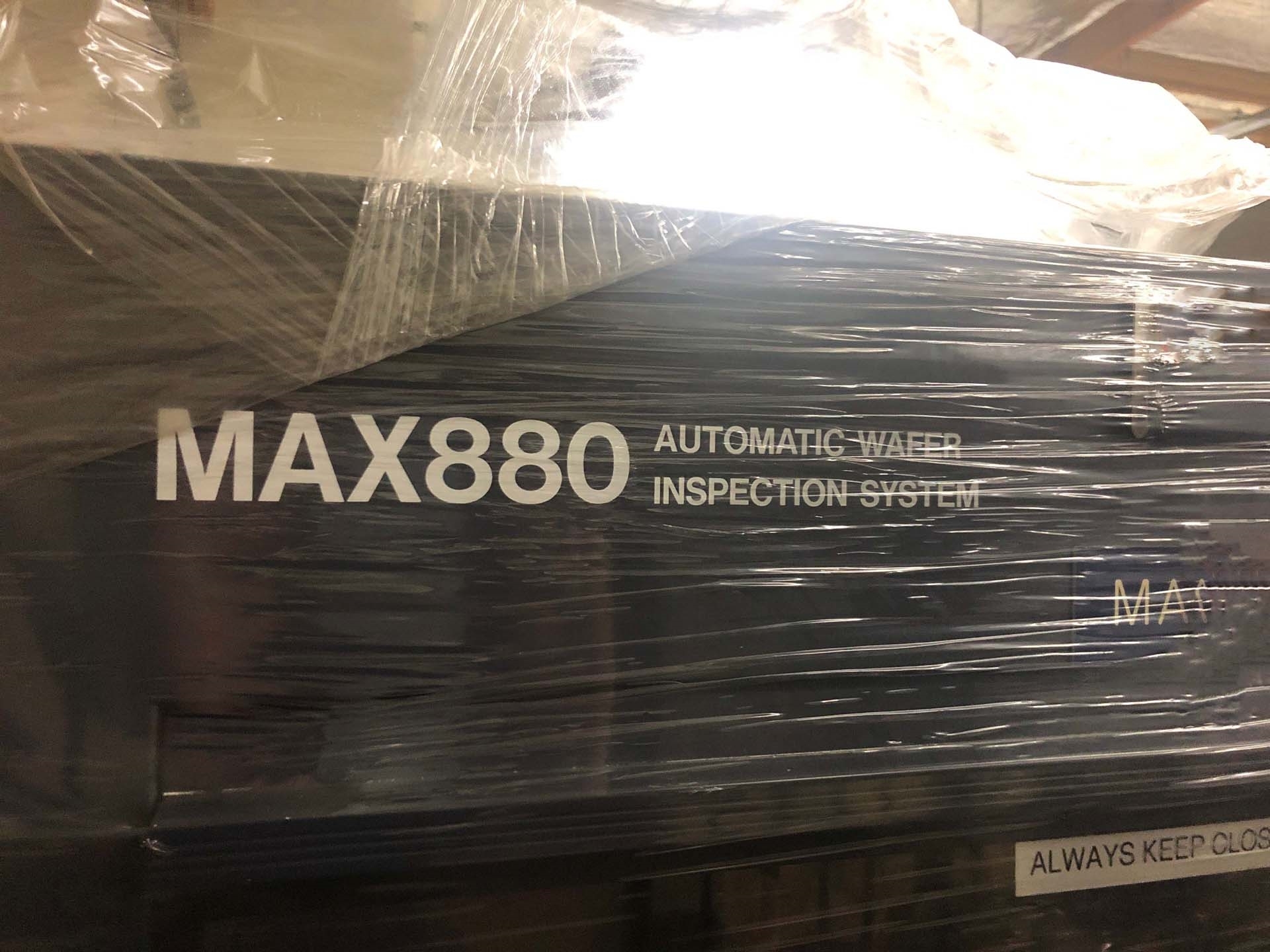

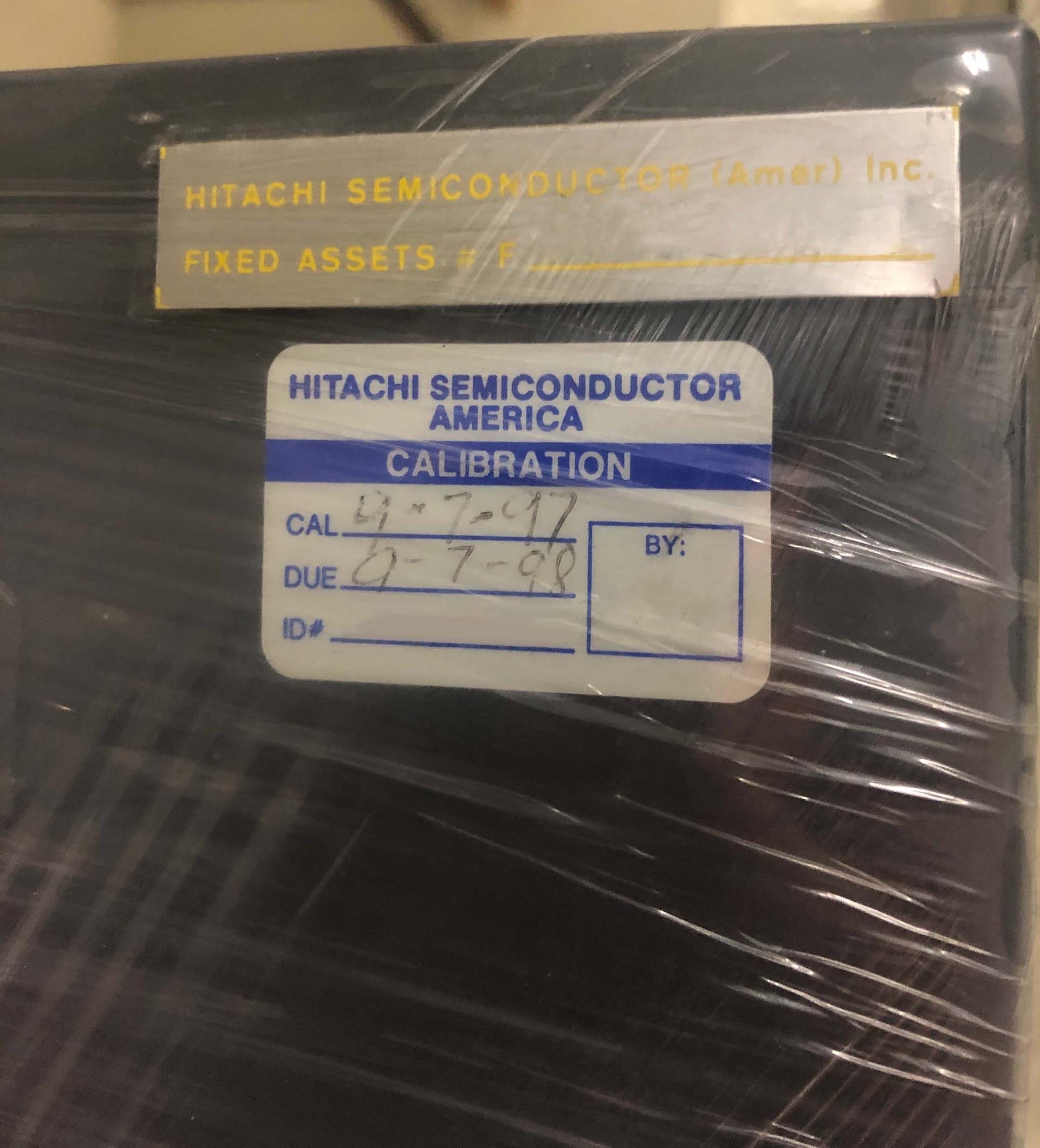

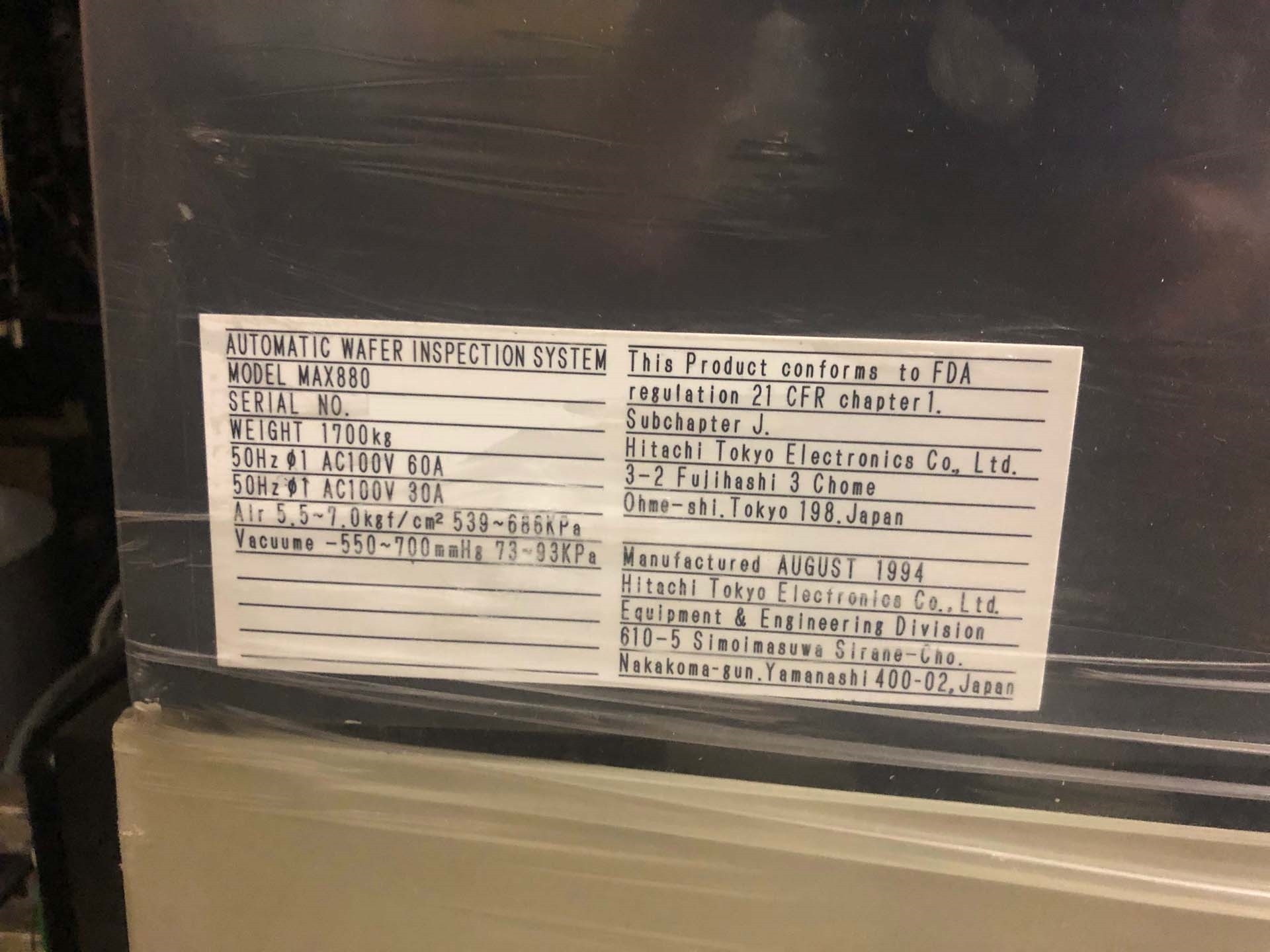

Used HITACHI MAX 880 #9244735 for sale

URL successfully copied!

Tap to zoom

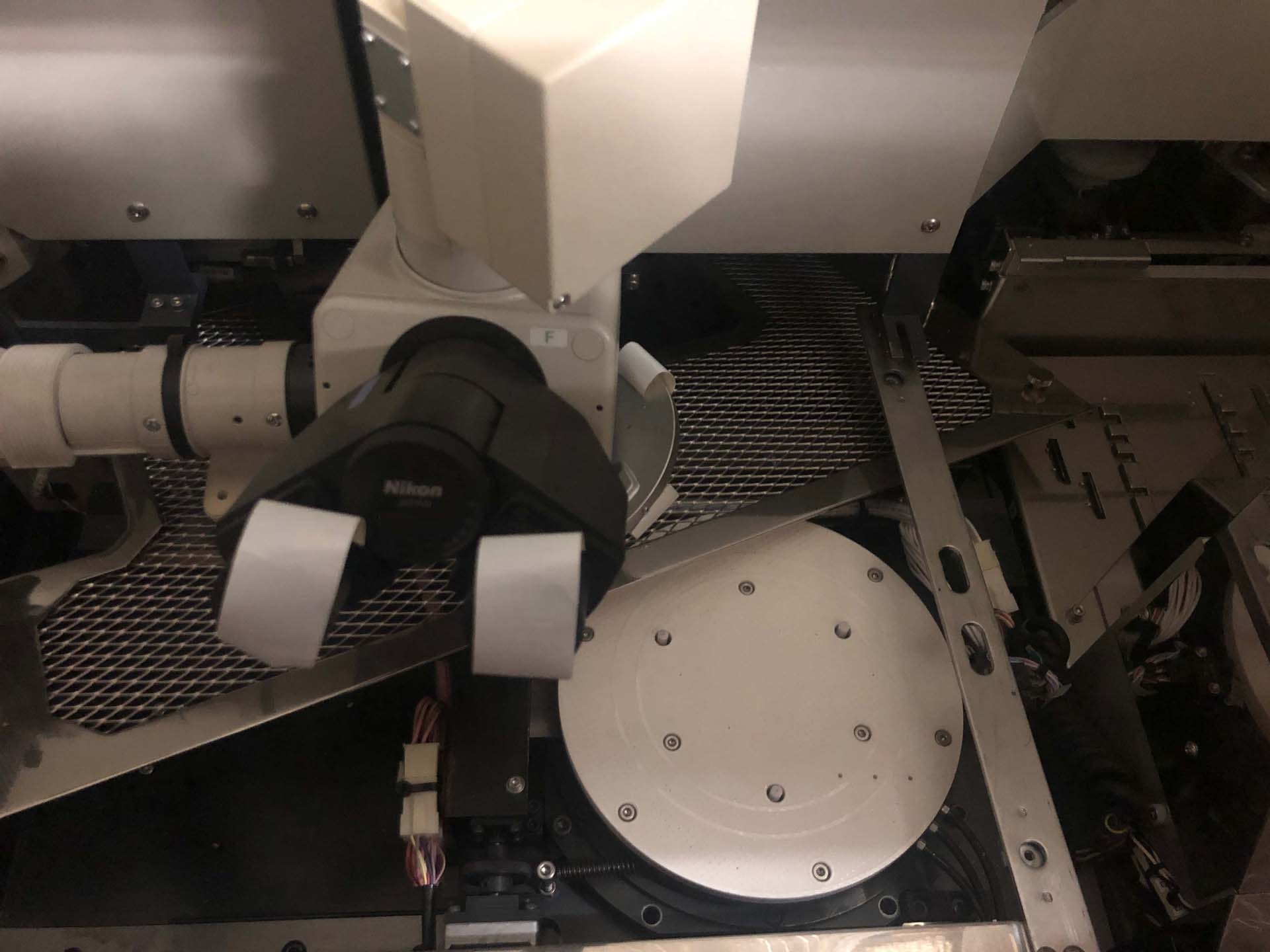

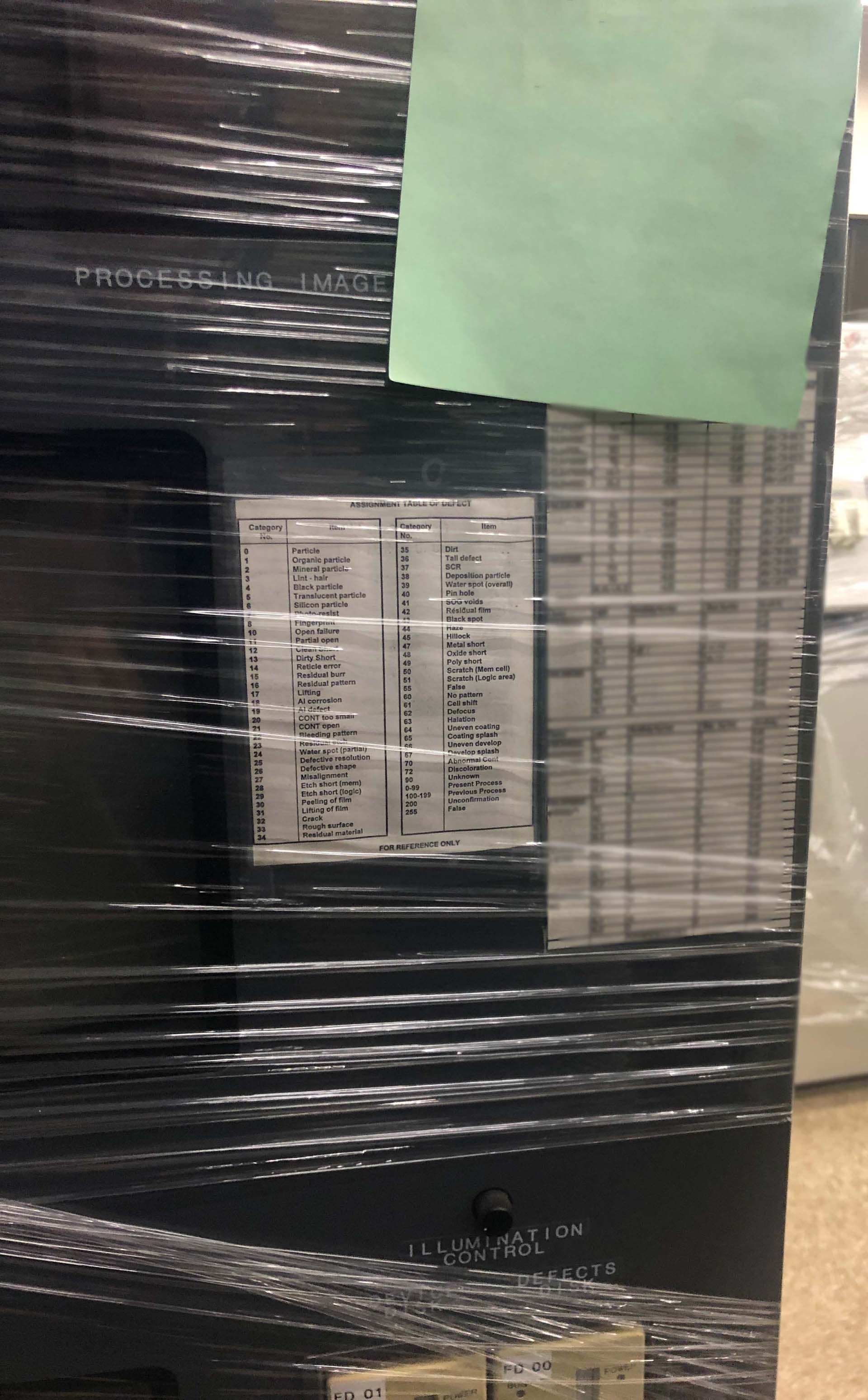

HITACHI MAX 880 is a mask and wafer inspection equipment designed to inspect pattern dimension and layer-to-layer alignment during semiconductor device fabrication. The system offers high performance and accuracy through the use of advanced imaging and pattern recognition technology. The unit is equipped with a global shutter camera for greater dynamic range and color fidelity. It utilizes Phase Shift Homography Metrology (PSHM) to achieve nanometer-level precision and sub-pixel accuracy for scan-through-field patterns for systems using laser and multiple line scanning. The machine is designed to expedite inspection processes by utilizing effective lighting and contrast enhancement, and performing inspections up to three times faster than comparable systems. The tool is equipped with a variety of tools such as defect inspection, 3D topography measurement, particle counting, die-to-die overlay, process monitoring, and resistivity measurement. These tools enable users to quickly identify discrepancies in process flow, yield marginality issues, and assess electrical performance. The asset features a user-friendly GUI that is simple to operate and intuitive enough to enable users to quickly adapt the model to their specific needs. It also allows for multiple layers of inspection to enable users to inspect more than one pattern simultaneously. Additionally, the equipment automatically stores and generates reports in a variety of formats, and it can be linked to a variety of external databases for easy sharing, export, and storage of results. The system has been designed for superior reliability and repeatability. It is certified to meet safety and ISOR standards, and it utilizes advanced image processing algorithms to continuously monitor and adjust to minimize errors and detect more defects in real time. The unit includes a comprehensive software library for image analysis, defect classification, color image correction, and edge detection. MAX 880 is a powerful and reliable mask and wafer inspection machine that is designed to deliver consistently high-quality results. It is cost-effective, easy-to-use, and offers a variety of tools to help users quickly and accurately identify defects and discrepancies. The tool is an ideal choice for semiconductor device fabrication processes.

There are no reviews yet