Used HMI eScan 300 #9200269 for sale

URL successfully copied!

Tap to zoom

ID: 9200269

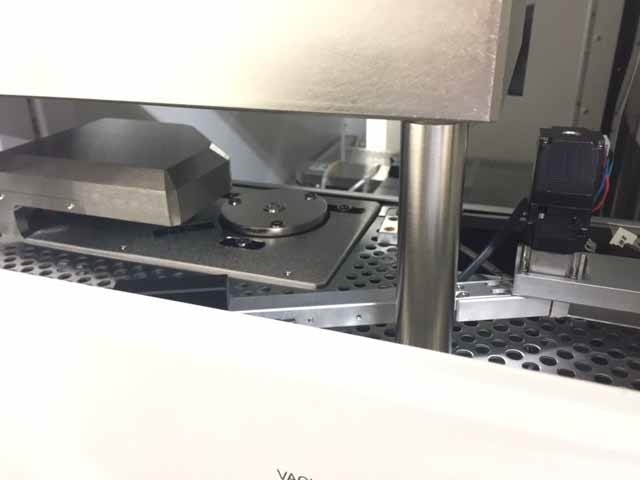

E-Beam inspection system

Front end:

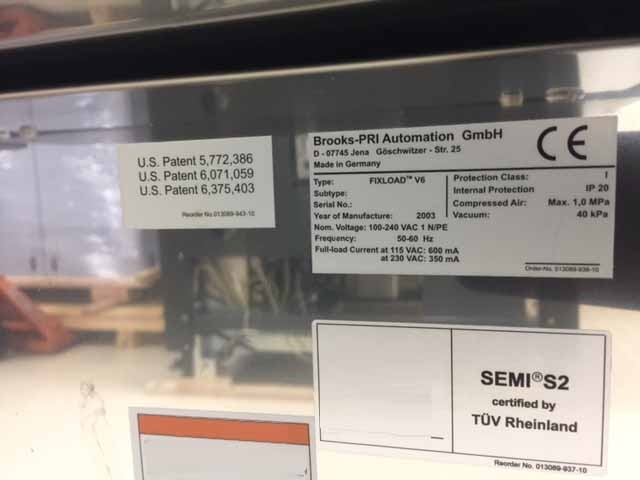

Brooks Automation:

Fixload V6, 12" Load port

ABM-407B-1-S-CE-S293 Robot

ESC Controller

Pre aligner

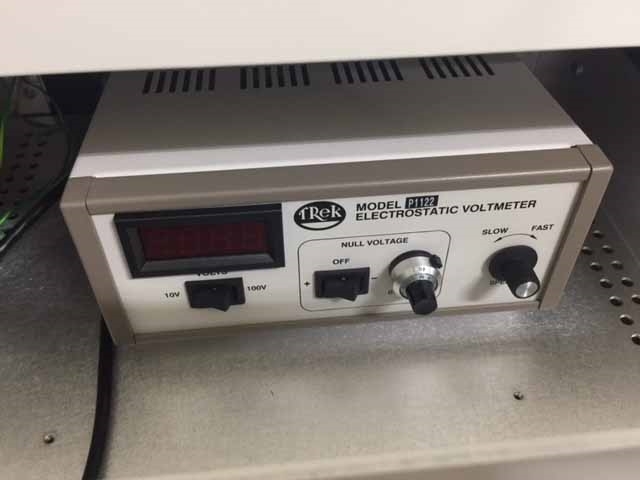

TREK Model P1122 electrostatic voltmeter

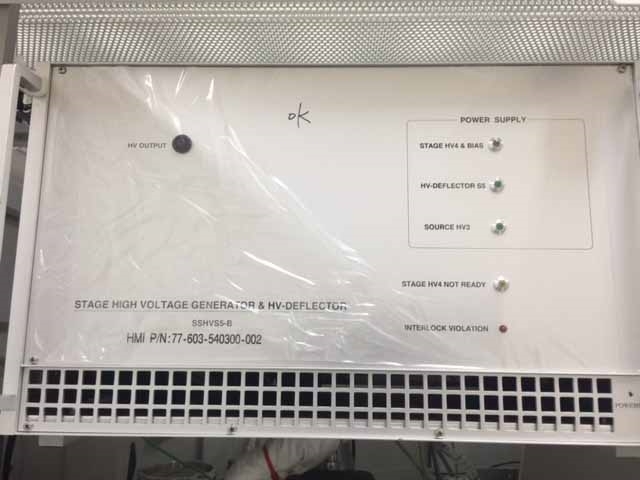

Main body

Power rack

VARIAN PTS06001UNIV Dry pump.

HMI eScan 300 is a mask and wafer inspection equipment used for measuring images of various sizes up to and including 300mm wafers. It offers superb contrast and acuity, combined with the ability to detect low contrast features on opaque and transparent mask images. The system utilizes an advanced laser-optical unit to acquire high-resolution images, with resolutions ranging from 50nm to 0.1mm. It is backed by a powerful computing platform and software that processes the data from the scans quickly and accurately. EScan 300 combines a 16bits optical image detector with a dual-band 256nm short and long wavelength laser illumination machine that have individually configurable power and signal intensity settings. This allows for an increase in scan speed and accuracy, while still producing high quality images. It offers a 9um laser spot size that is essential for detecting smaller defects and improving signal-to-noise ratios. In addition, an adjustable focal length and zoom capability can provide images as large as 40x the size of the native resolution. For measuring images, HMI eScan 300 uses a set of tools that are designed to facilitate the classification and validation of samples. These include: Edge Detection, Film Thickness Measurement, and Defect Detection. The Edge Detection tool identifies any areas that are not uniform, allowing for the accurate identification of active layer edges, welded feature boundaries, and scratches. The Film Thickness Measurement tool measures the thickness of acid masks, plating layers, and metal layers. Finally, the Defect Detection tool allows for the detection of voids, particle build-up, and pins. EScan 300 also provides an intuitive user interface, with features such as tooltips, color-coded markers, and region selection. This user interface helps to simplify and enhance the work experienced by the mask inspector. The tool also includes an industrial-grade environment where up to 4 mask and wafer images can be inspected simultaneously. This allows for efficient workflow and productivity. Finally, HMI eScan 300 is an innovative, cost-effective tool for mask and wafer inspection. It helps to improve accuracy and reduce costs associated with the production of modified integrated circuits and enhance the diagnosis and quality assurance processes. With its powerful hardware and software capabilities, eScan 300 is an ideal choice for any inspection needs in the semiconductor industry.

There are no reviews yet