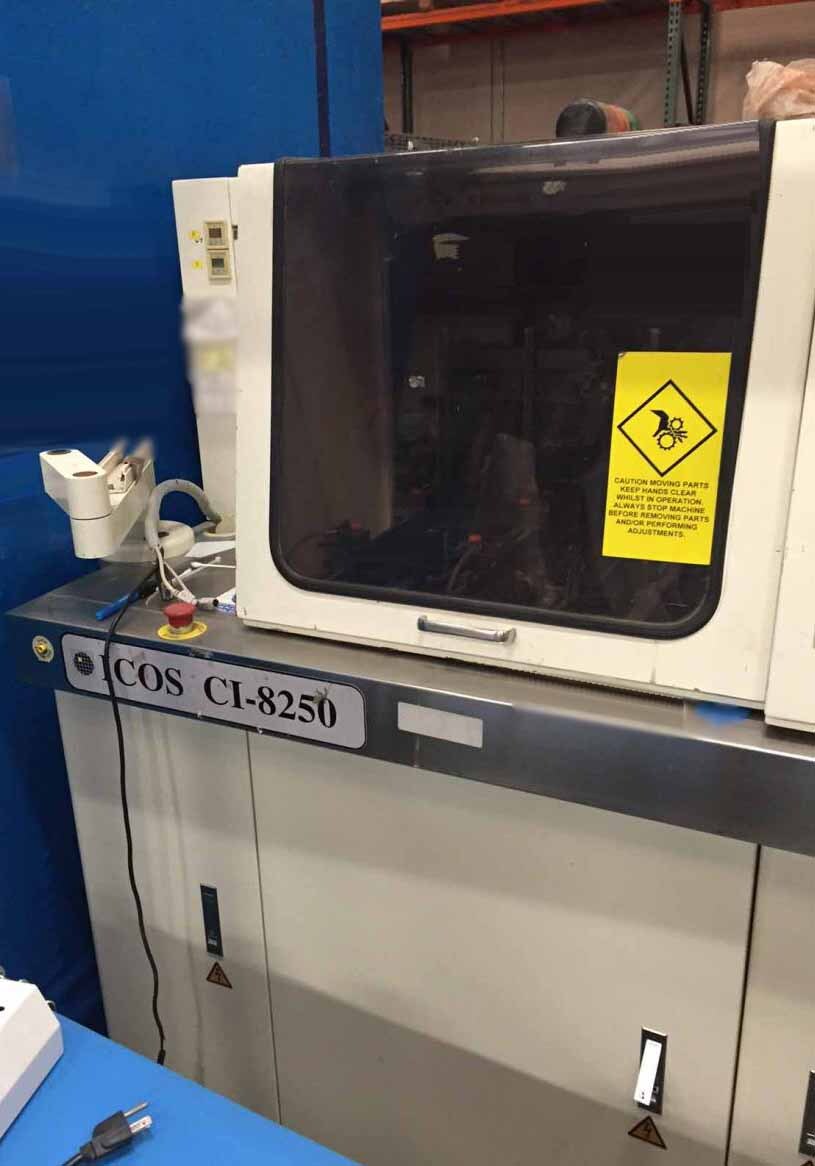

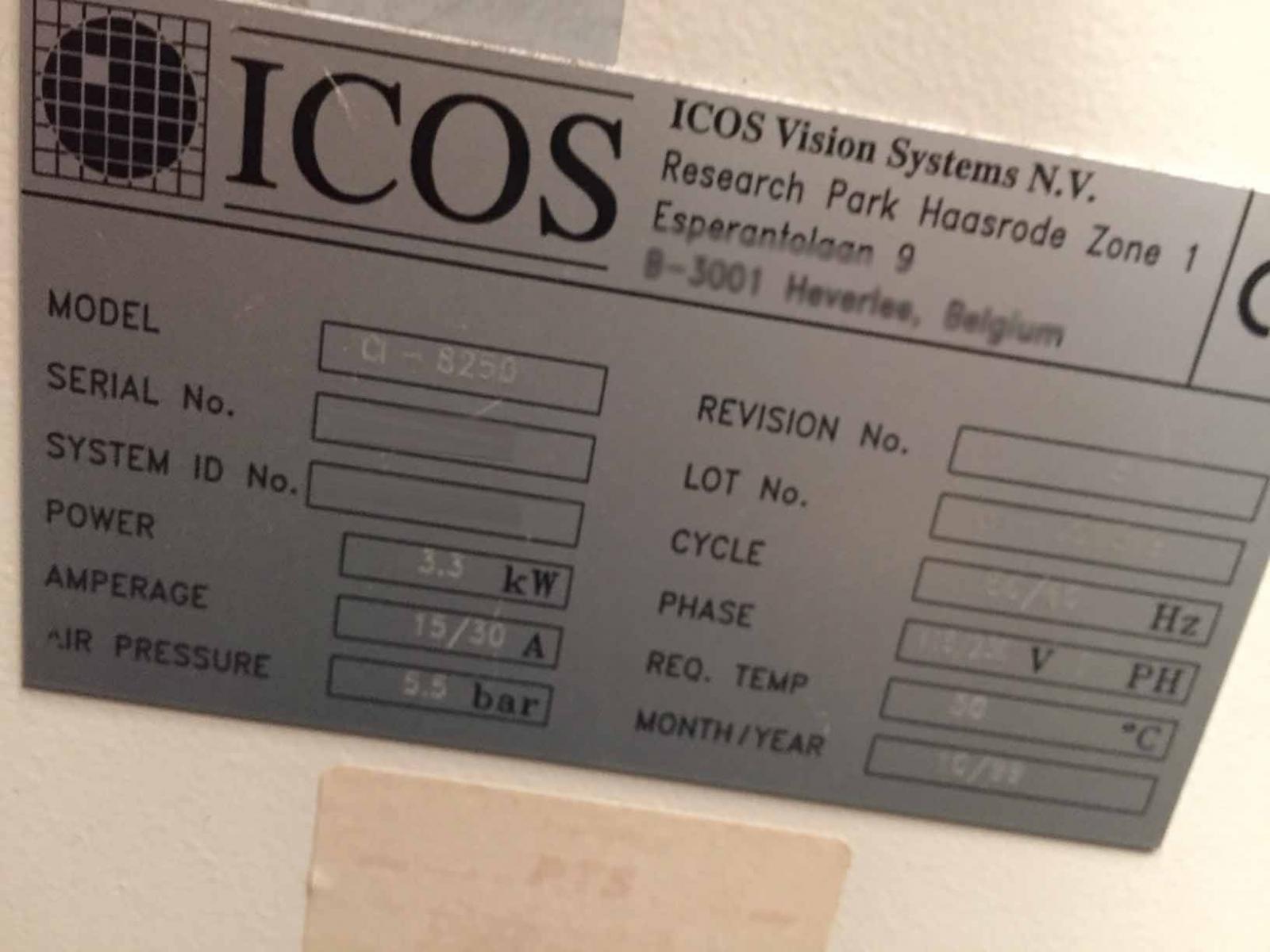

Used ICOS CI 8250 #9161520 for sale

URL successfully copied!

Tap to zoom

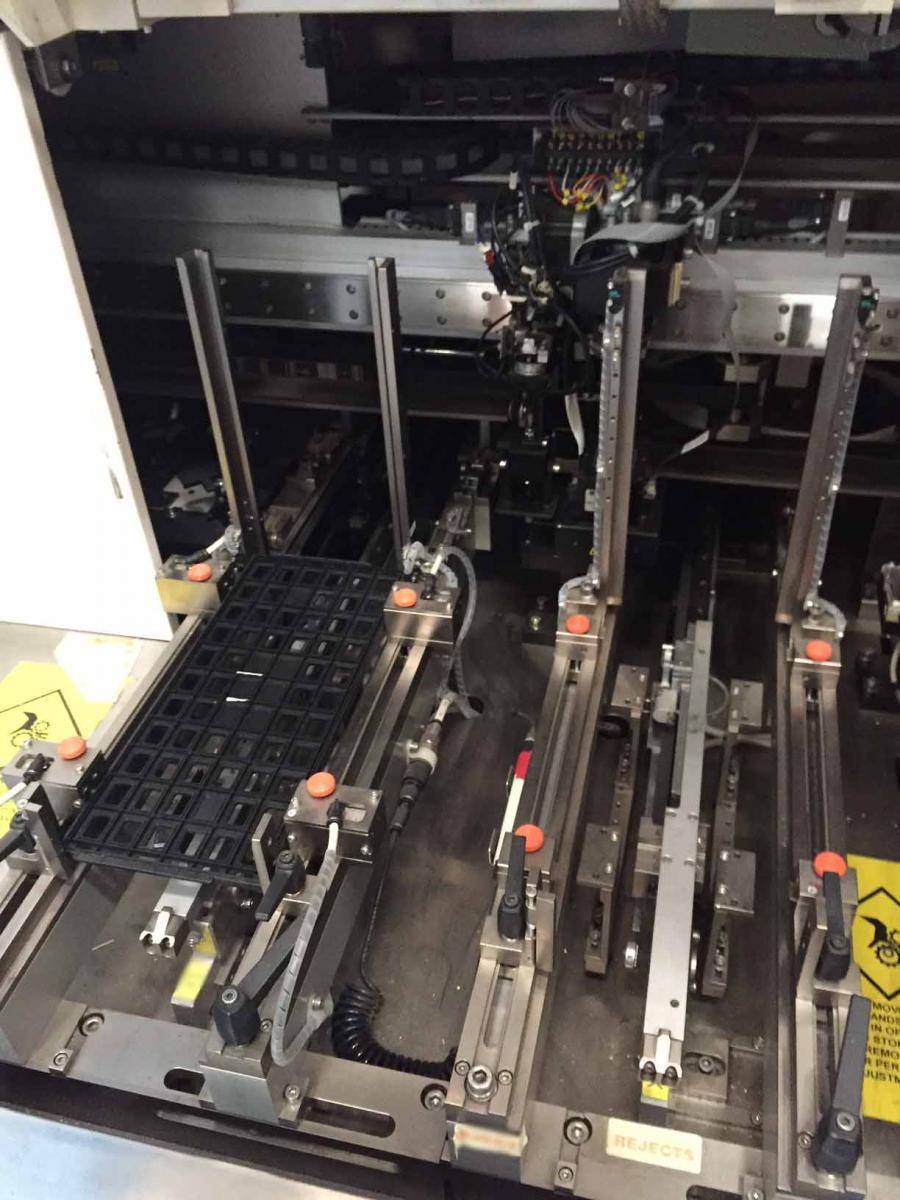

ICOS CI 8250 is a comprehensive mask and wafer inspection equipment that allows for quick and accurate identification of defects in masks and wafers. This system is designed to meet the demands of the most demanding semiconductor applications, as it is capable of pinpointing very small defects with precision. It provides improved image quality, a wide range of feature measurements, and improved image analysis capabilities while maintaining high production throughput. CI 8250 unit includes a wide variety of tools that will help in inspecting masks and wafers. It includes a comprehensive image storage machine for keeping track of inspection information, and a number of advanced systems for defect analysis. The tool is also capable of auto-focusing, providing inspectors with detailed images to enable them to accurately identify defects. ICOS CI 8250 asset also provides extensive support for redundancy and verification. It has features such as an Advanced Planning Model, which can help streamline the inspection process from start to finish and allow for quick decisions. There is also an exposure control equipment, which uses multiple sensors to ensure consistency and accuracy in exposures during the inspection process. CI 8250 system also uses advanced 3D processing algorithms to accurately identify defects in both planar and complex surface masks. This allows the unit to detect defects such as micro-mistakes, warping, pinholes, cracks, and other surface issues. It can also detect structural defects such as arc faults and dielectric failures. Finally, ICOS CI 8250 machine has an image processing tool that can detect dimensional defects in complex shapes. This feature allows for a high degree of accuracy in defect inspection. CI 8250 asset is a comprehensive and efficient inspection solution for masks and wafers. Its features and wide array of tools make it capable of identifying very small defects, providing improved image analysis capabilities, and improving throughput with high image quality and precision. These features, combined with its detailed support for redundancy and verification, make this model an ideal choice for high quality and accuracy in mask and wafer inspection.

There are no reviews yet