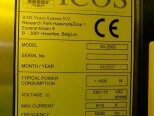

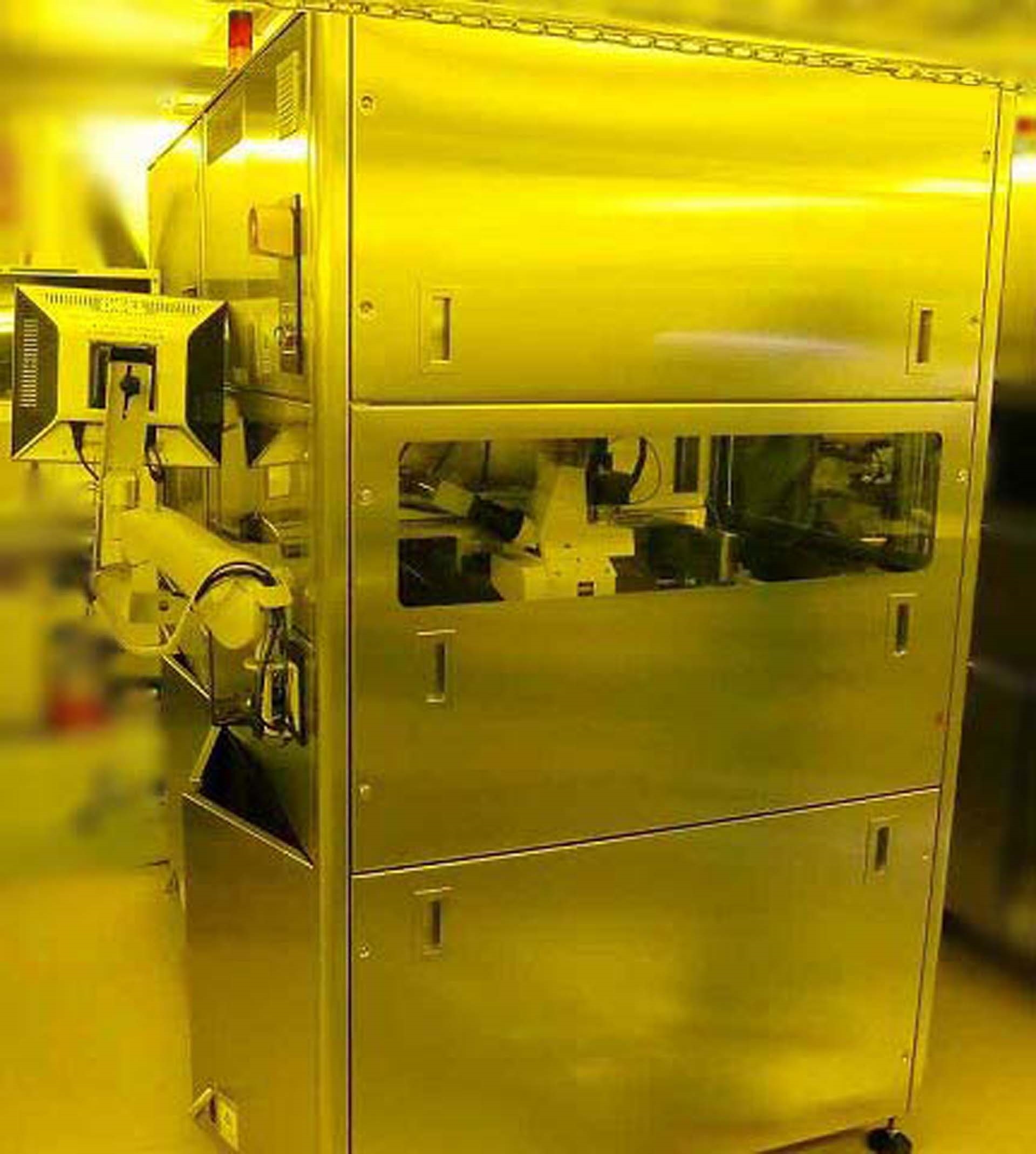

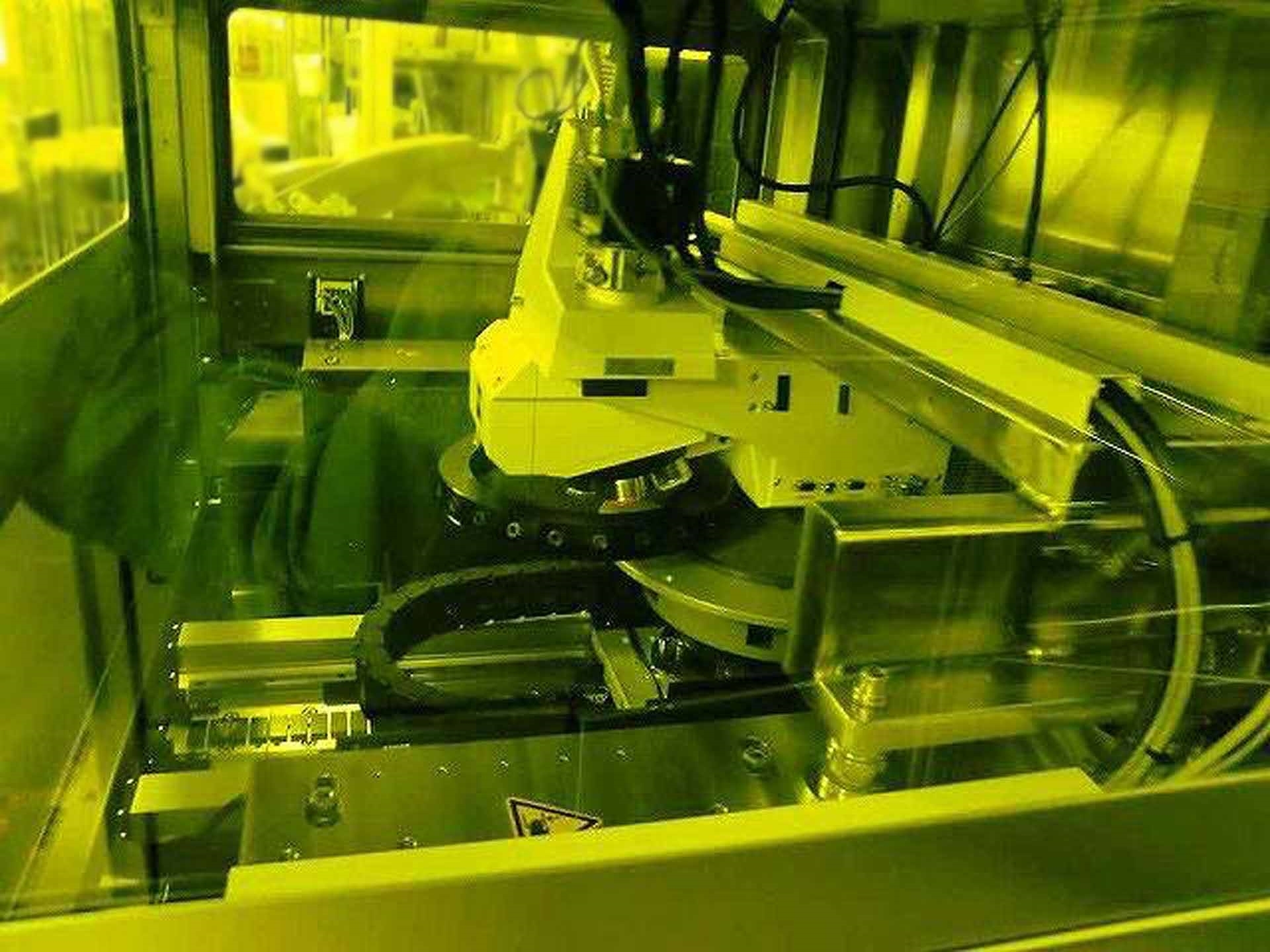

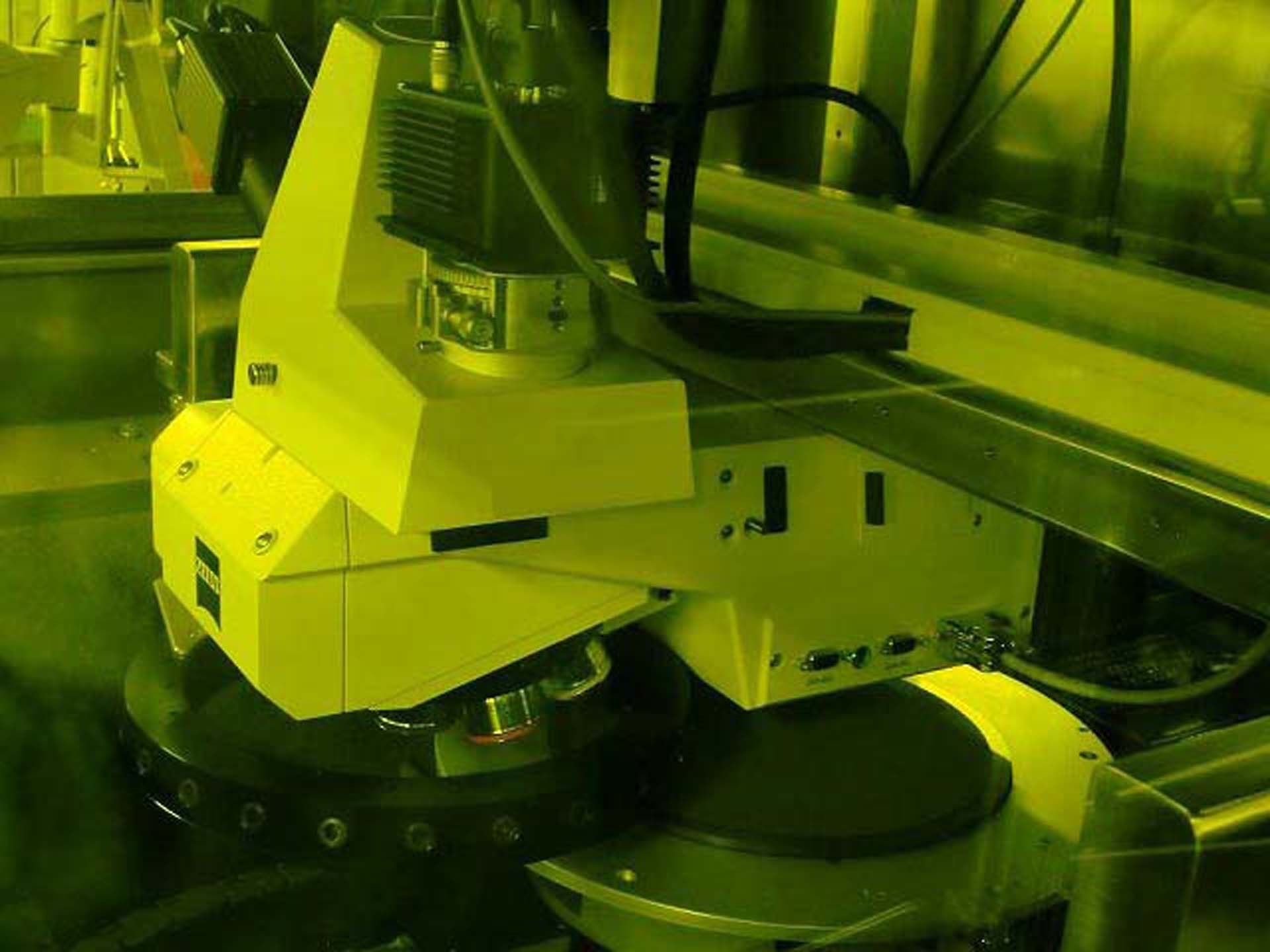

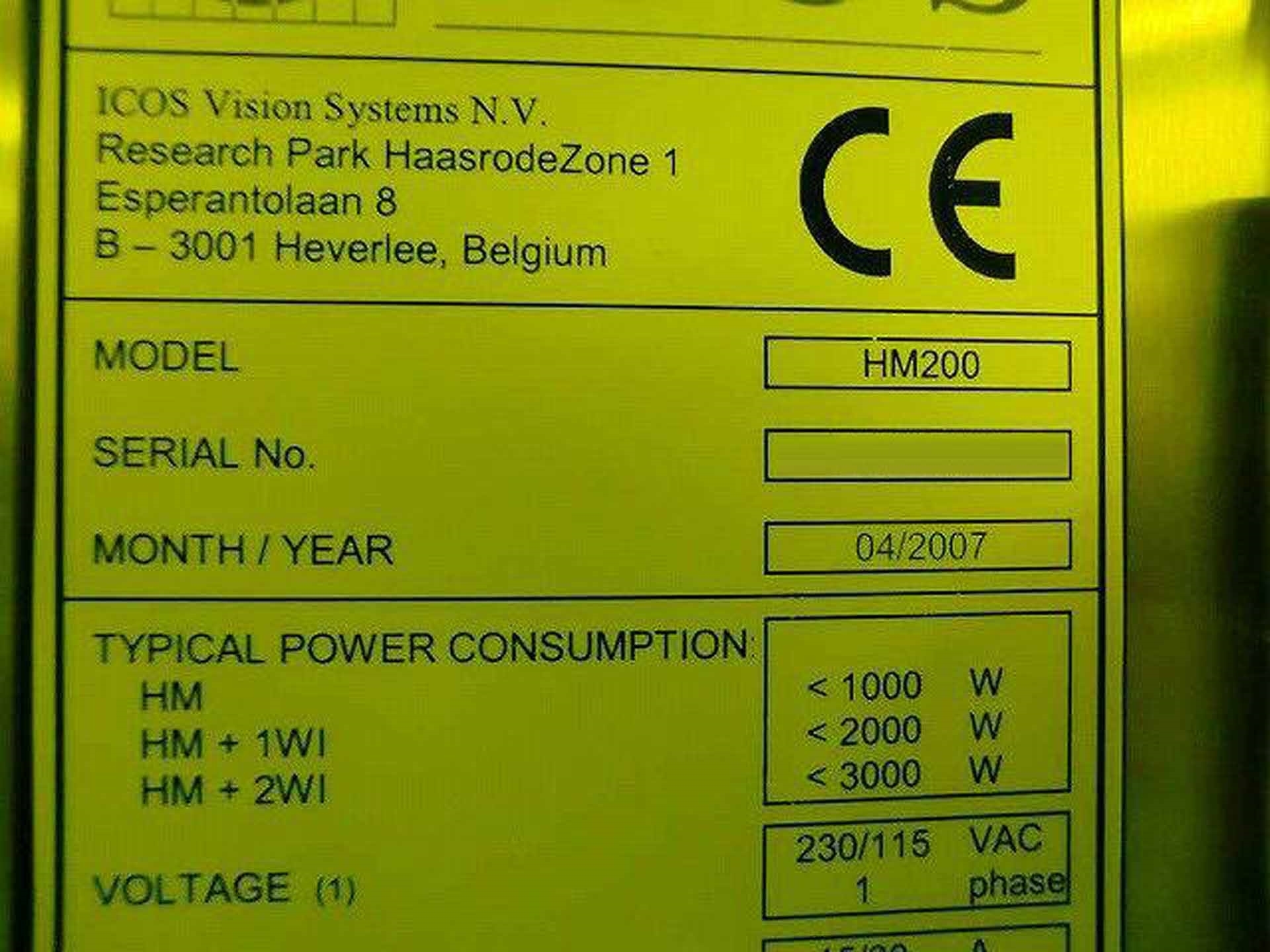

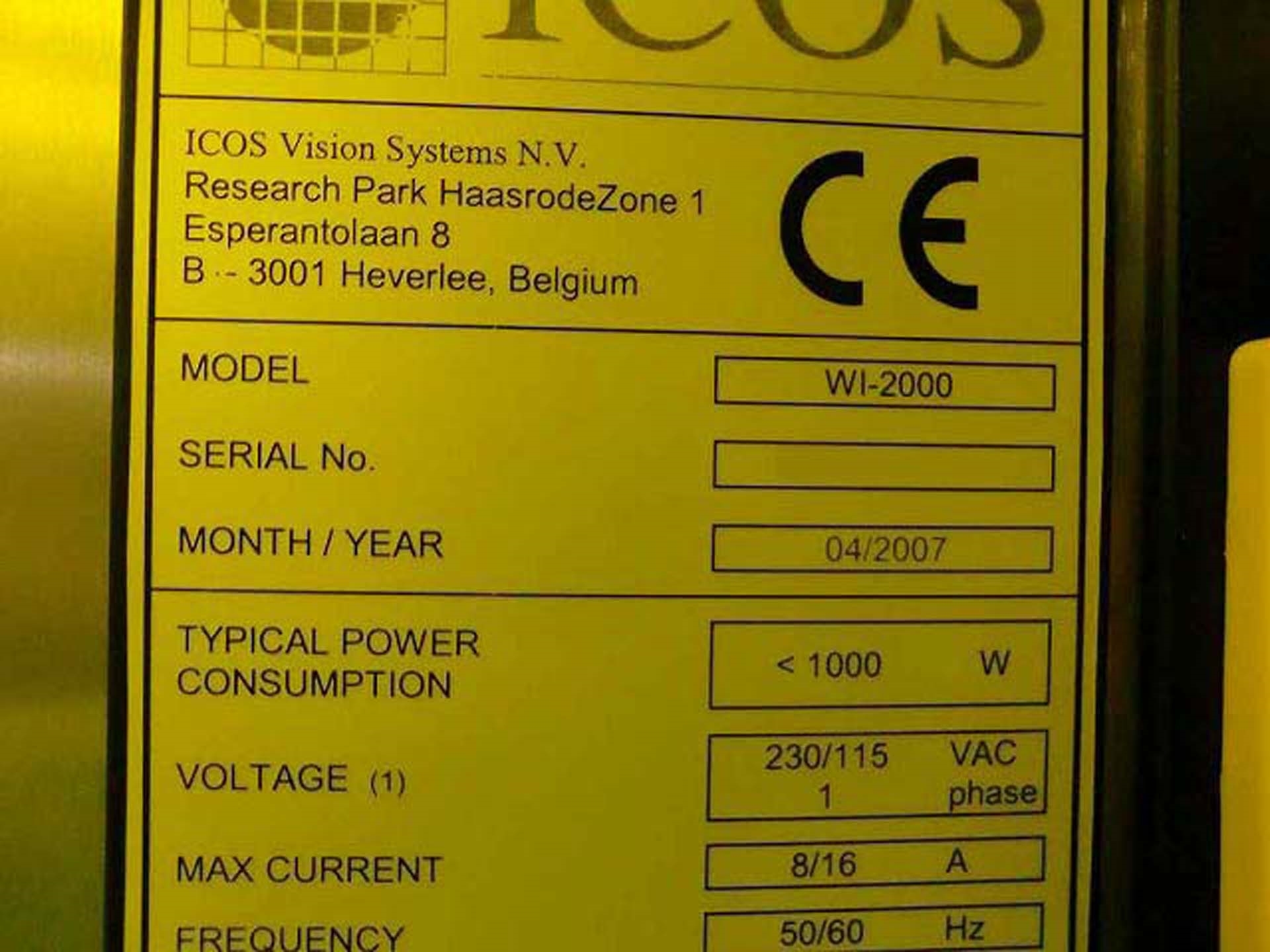

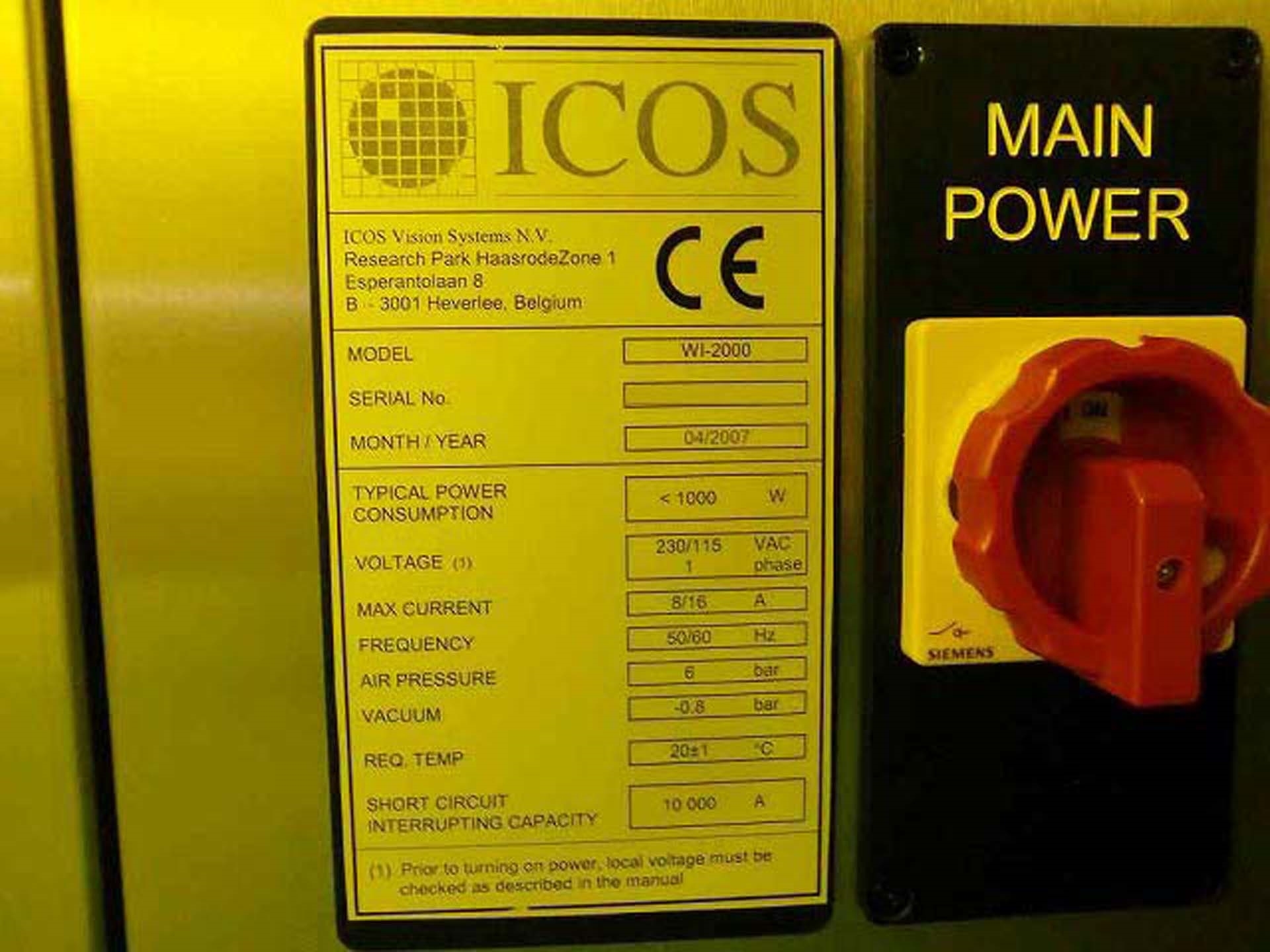

Used ICOS WI-2000 #9215635 for sale

URL successfully copied!

Tap to zoom

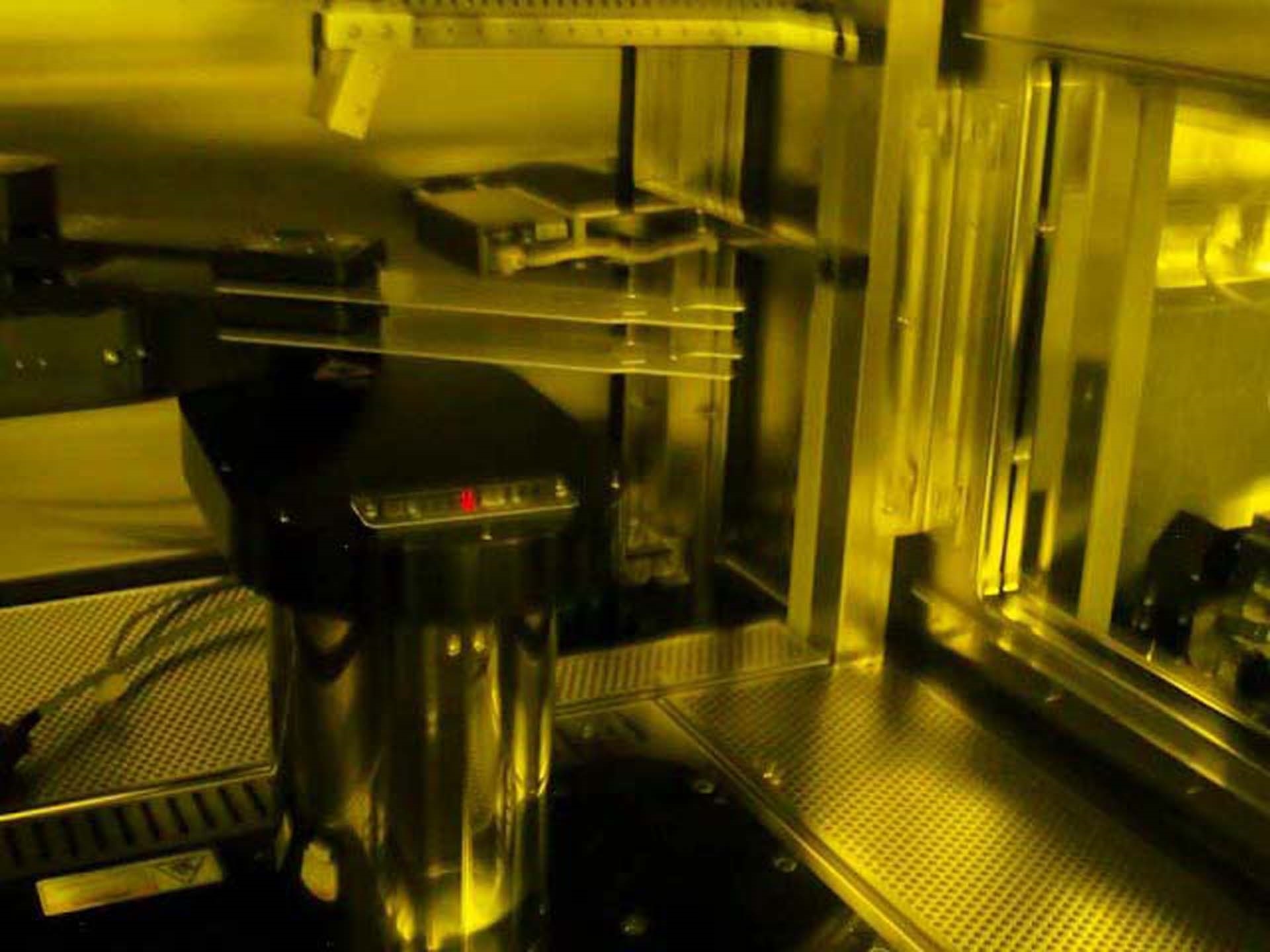

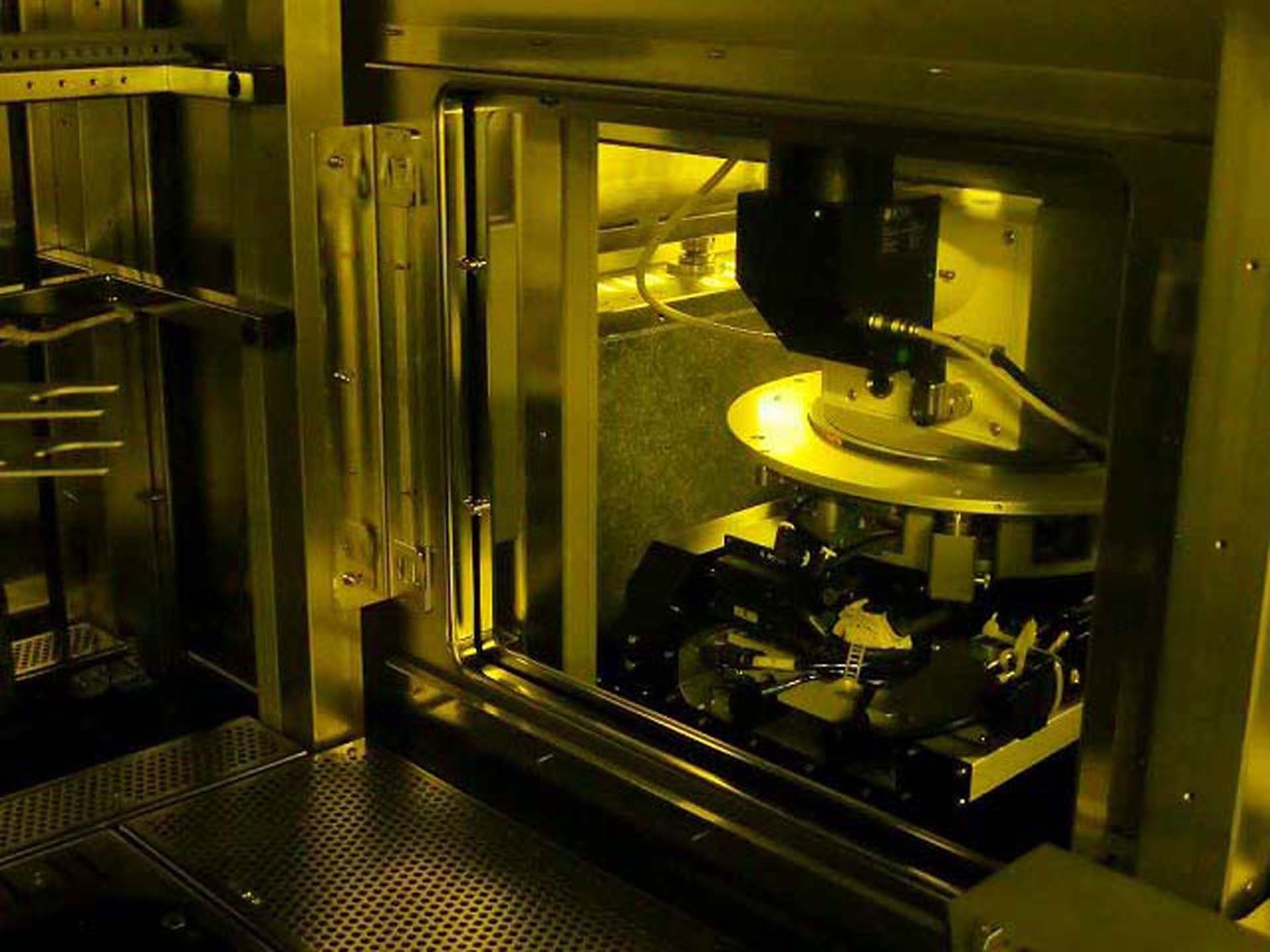

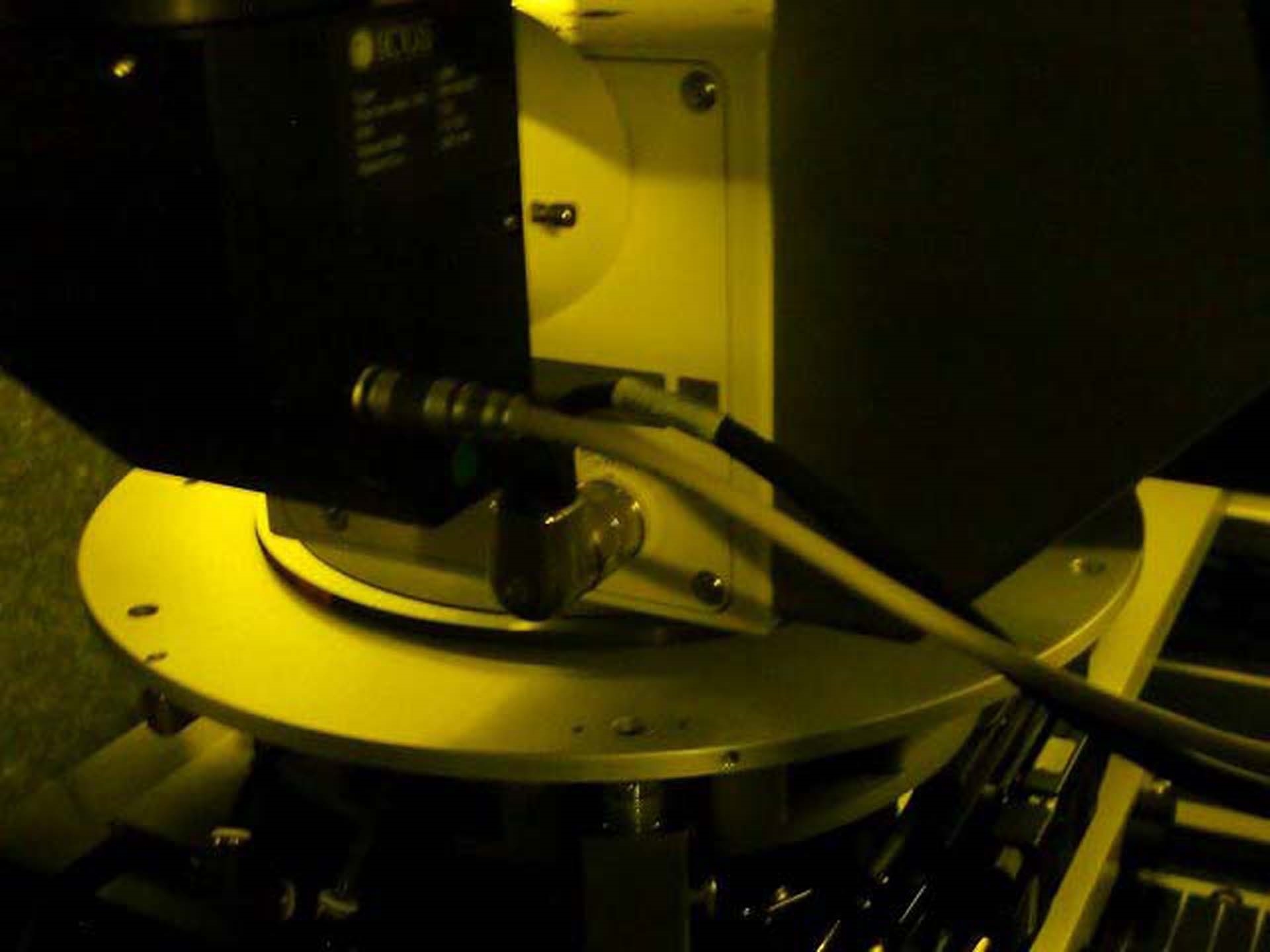

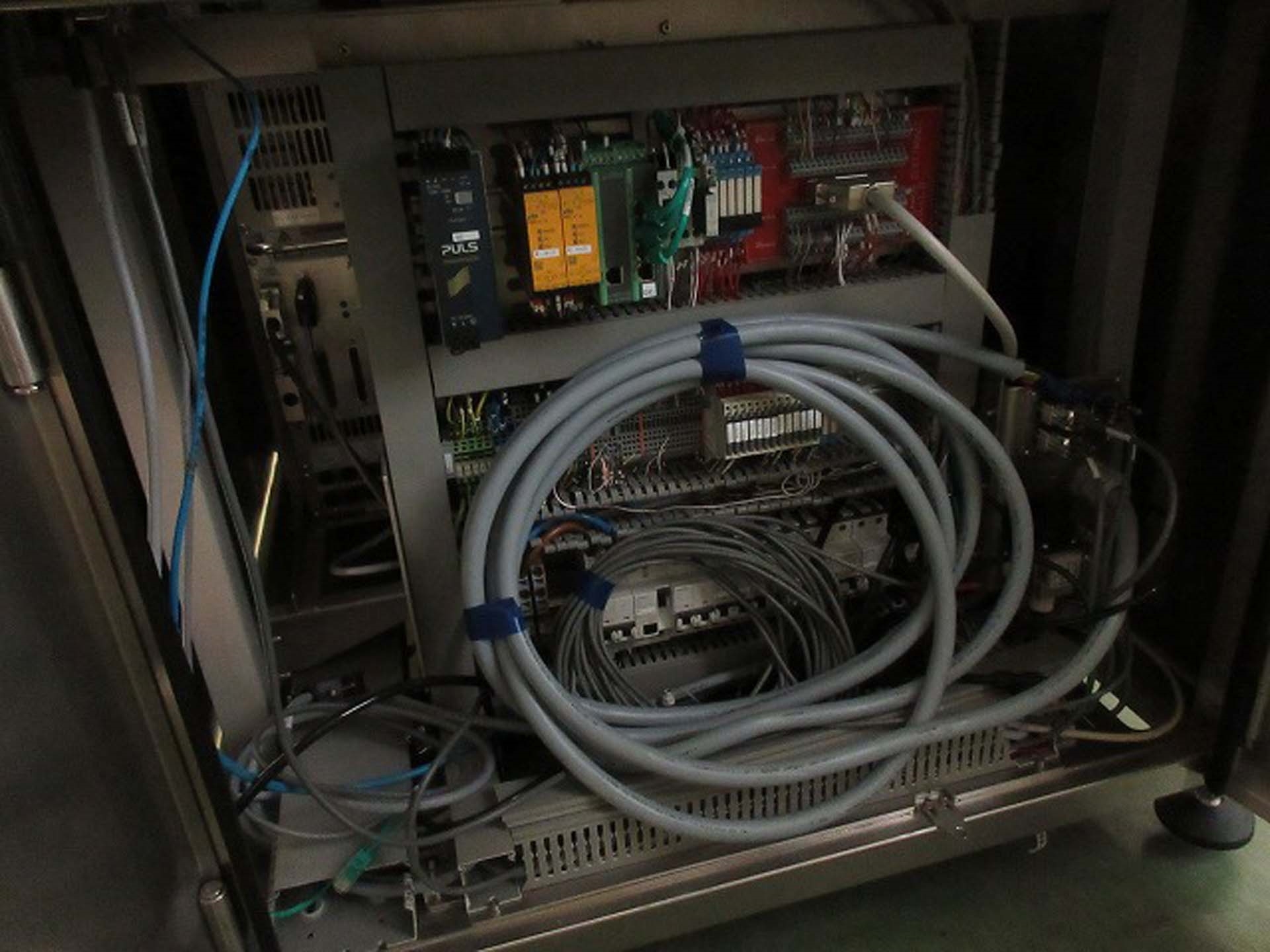

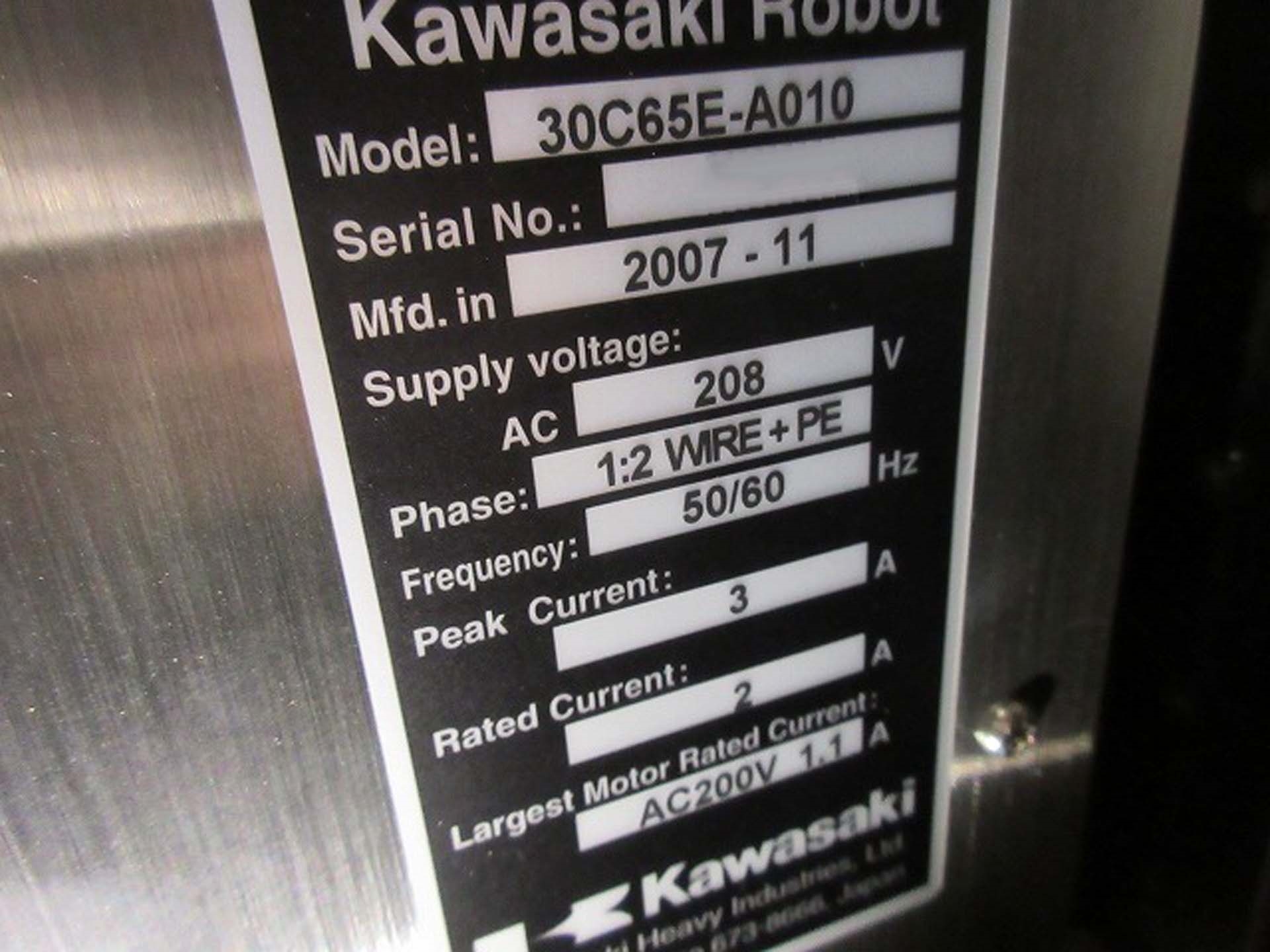

ICOS WI-2000 is an automated equipment for mask and wafer inspection. It uses advanced imaging optics, precise motion controls and advanced illumination techniques for optimum performance in the most demanding production environments. The system is configured with a unique 200mm active field alignment stage. This allows the user to quickly and accurately align any mask or wafer under inspection. The stage can also move up and down for high-speed inspections, allowing for optimal imaging conditions. WI-2000 is equipped with two types of illumination systems - UV and visible. Both lighting systems offer superior performance for inspecting a variety of wafer and mask surface structures. The UV light source provides high-contrast illumination for detecting any changes in patterning or layouts. The visible light source allows for greater detection sensitivity when inspecting opaque substrates. ICOS WI-2000's imaging optics and motion control technology provide nanometer resolution to examine mask features down to the nanometer level. The unit accurately captures surface patterns and defect information with non-contact, high-resolution (up to 2 μm pixel pitch) imaging. This advanced imaging technology also permits imaging of up to three wafers at once, and data acquisition is up to 20 times faster than conventional inspection systems. WI-2000 features a high-precision motorized Z-axis that is capable of a range of +/- 10mm to improve sample integrity and reduce sample abrasion during alignment. Users can choose from two imaging resolutions: high-resolution and low-resolution. With the low-resolution imaging mode, ICOS WI-2000 can inspect wafers and masks with complex layouts at high-speed without sacrificing accuracy. WI-2000 is an automated machine, powered by an intuitive graphical user interface, making it easy to operate and accommodate a variety of inspection goals. Additionally, the tool supports multiple interfaces and inspection modes, allowing users to tailor the asset to their specific inspection requirements. ICOS WI-2000 is an ideal model for the precise inspection of masks and wafers. It is able to quickly capture high-resolution images with two illumination systems, precise motorized Z-axis, and it is easy to use. With these capabilities, WI-2000 is customizable to meet the specific requirements of any inspection task and deliver optimum results.

There are no reviews yet