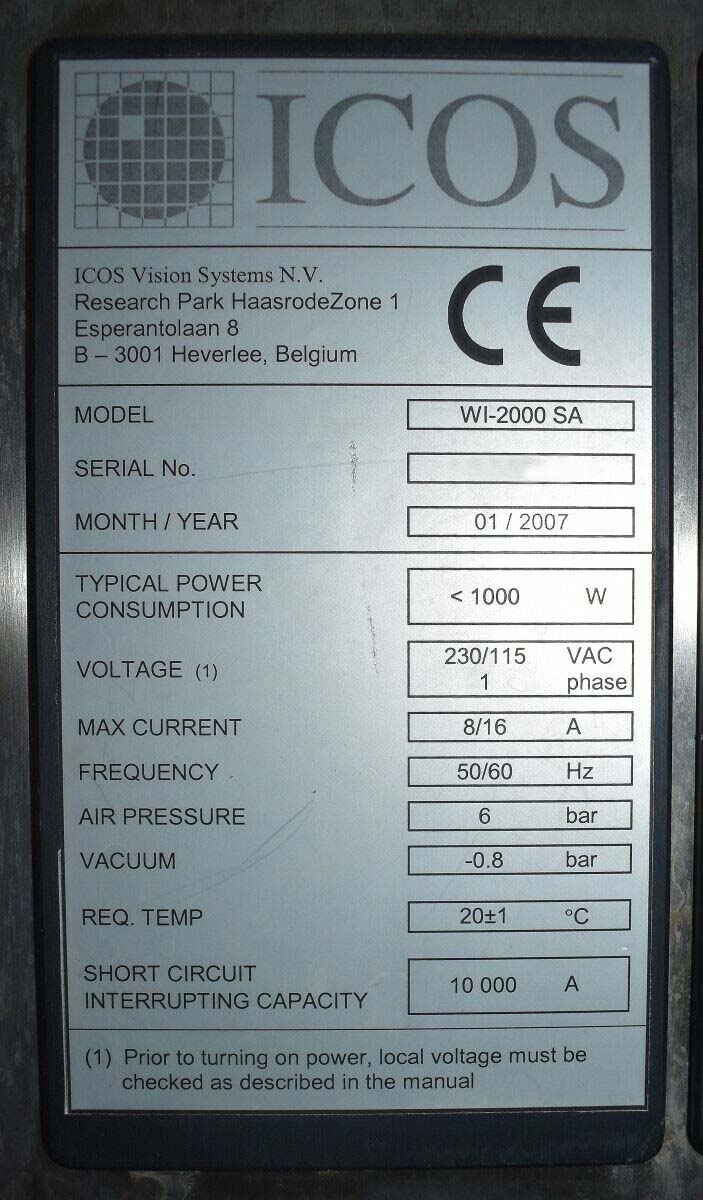

Used ICOS WI-2000 #9259988 for sale

URL successfully copied!

Tap to zoom

ID: 9259988

Vintage: 2007

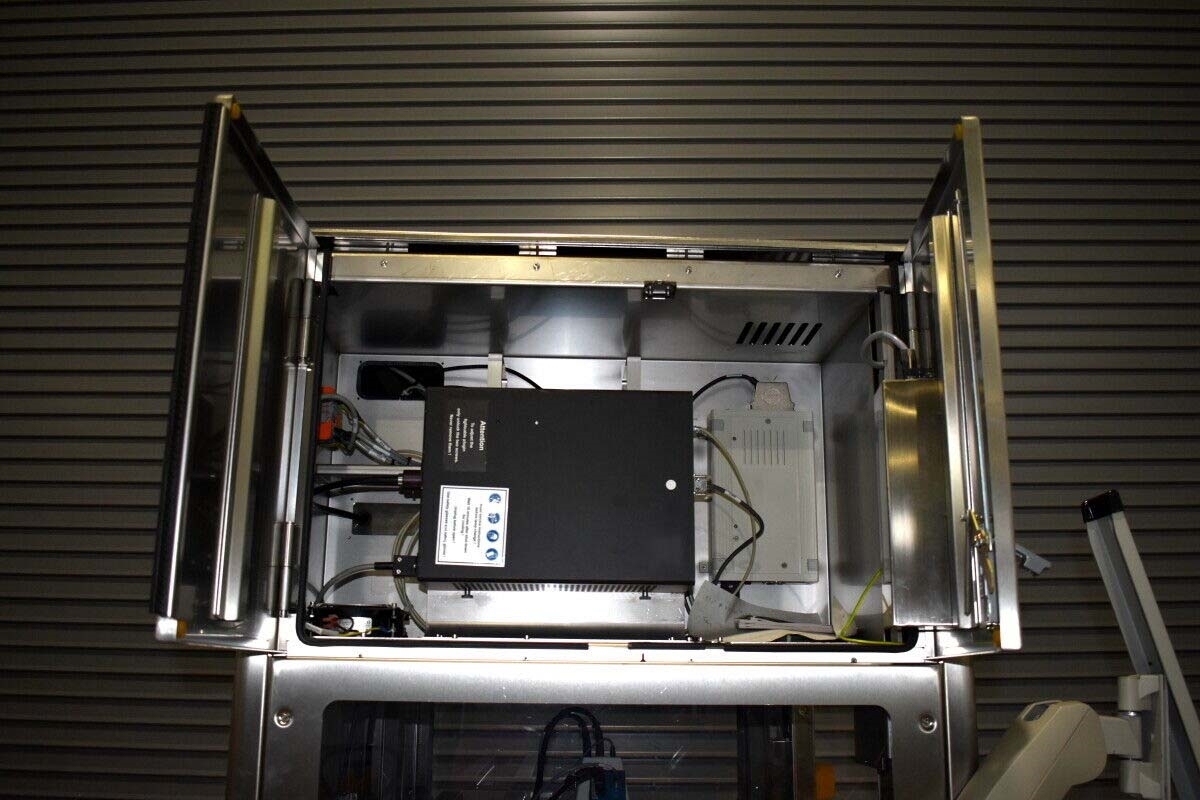

Wafer inspection system, parts machine

With CARL ZEISS microscope meg system

Magnification lenses: 2.5x, 5x and 10x

ADIMEC -1600c Color camera

DALSA PIRANHA HS-40-04K40 TDI line scan camera

NEWPORT MM4006 Motion controller

NEOFLUAR 422320-99630 Objective

Typical power consumption: <1000 W

Air pressure: 6 bar

Vacuum: -0.8 bar

Temperature range: 20°C to ±1°C

Short circuit interrupting capacity: 10,000 Amps

Includes:

Drive

Controls

Manuals

Computer missing

Power supply: 230/115 VAC, 8/16 Amps, 50/60 Hz, Single Phase

2007 vintage.

ICOS WI-2000 is a mask and wafer inspection equipment, engineered to inspect and analyze patterns on masks and wafers with high-resolution imaging. This system is equipped with advanced image analysis algorithms that provide superior accuracy, enabling highly accurate detection of defects and faults on the surface of the pattern. WI-2000 features a motorized, eight-powered optical lens that provides maximum resolution of 0.13μm/pixel (3000x magnification), enabling it to capture the finest masks and wafers details. For greater accuracy and flexibility, the unit includes two light sources - ultraviolet and visible - as well as an advanced auto-focus machine. With its fast data capture speed, ICOS WI-2000 can process large amount of data quickly and efficiently. It has a built-in image processing module that quickly sorts data and automatically detects patterns, while a statistically-based search algorithm enables easy identification of fault locations. The tool's software is designed to offer both manual and automated operations. WI-2000 is designed to provide safety and reliability. It is built with a speed booster mechanism that prevents accidental injuries from high-speed motors. It is also equipped with multiple sensors that detect motion and provide protective function against the asset moving suddenly. Its inspection model is designed with flexible transmission that can adjust to different wafer sizes. For more detailed information, ICOS WI-2000 provides traceability and enabling users to quickly and easily generate detailed reports of the inspection data. It can be easily connected to a wide range of external peripherals, as well as to other imaging systems. A powerful graphical user interface (GUI) allows operators to create customized inspection reports. Overall, WI-2000 is a reliable and accurate mask and wafer inspection equipment which is designed for high-end industrial applications. Its advanced imaging capabilities and flexible software make it an ideal choice for a wide-range of applications such as semiconductor manufacturing, electronics, and medical device inspection.

There are no reviews yet