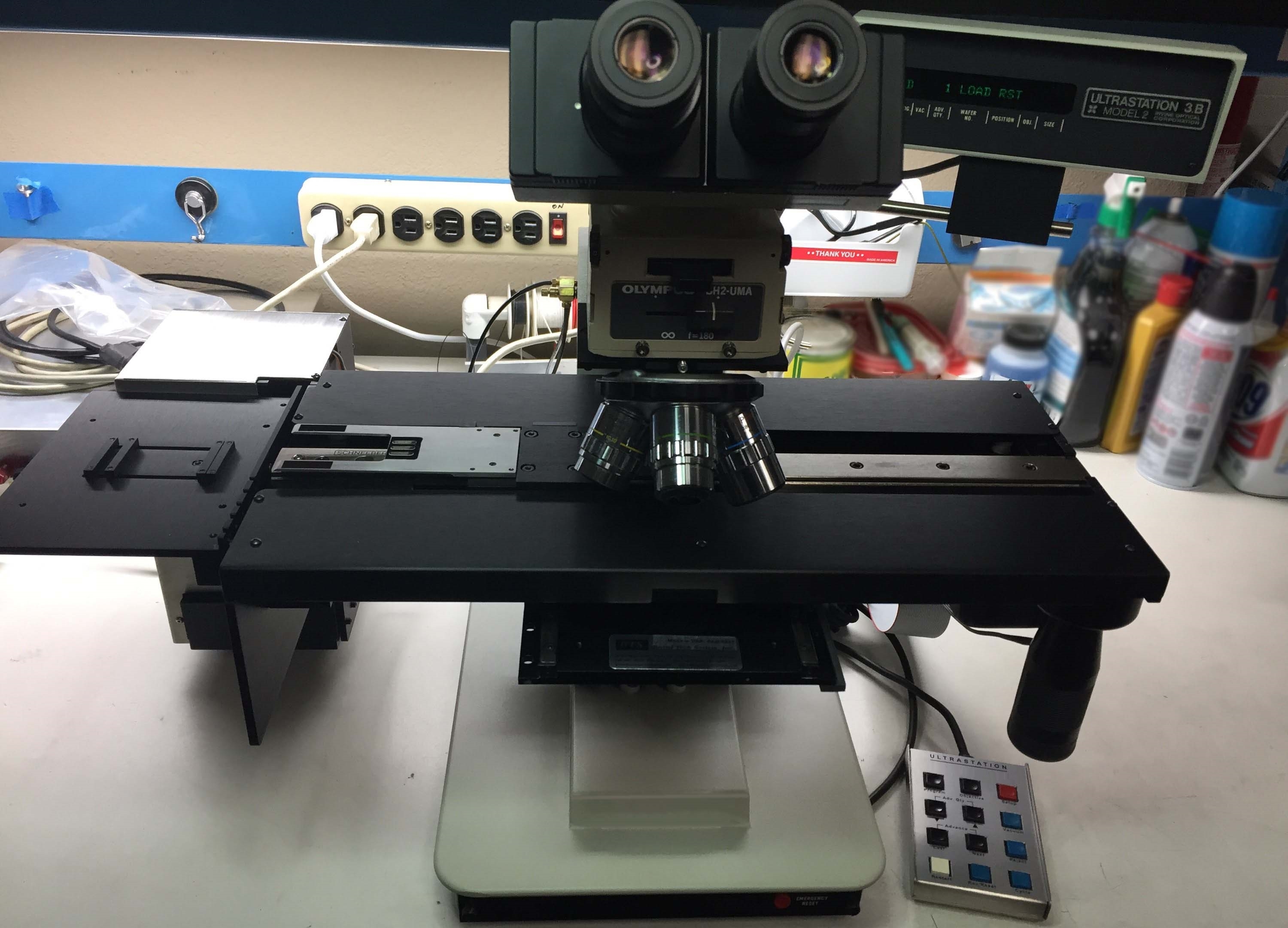

Used IRVINE OPTICAL Ultrastation 3B Model 2 #19179 for sale

URL successfully copied!

Tap to zoom

ID: 19179

Wafer Size: 2"-3"

Wafer inspection system, 2"-3"

Theta chuck wafer rotation

System options:

360° Theta wafer rotator

(2) Buttons pistol grip control

Motorized objective lens turret

Custom optical packages

Features:

High throughput: Up to 900 WPH

Handles: 2"-6" wafers

Auto-cassette elevator for wafer selection

Robotic trolley for auto-wafer pick up

Smooth-glide linear X and Y stage

Vacuum touch end effector with sensing

User defined inspection recipes

UltraStation 150 for 2"-6"

NIKON Optical package: 5x, 10x, 20x, 40x optics

Power: 120 VAC, 50/60 Hz, 800 Watts.

IRVINE OPTICAL Ultrastation 3B Model 2 is a mask and wafer inspection equipment designed for semiconductor fabrication. It is built for high-accuracy and high-throughput inspection processes, especially for the measurement and analysis of semiconductor substrates and devices. This system contains a sophisticated, multi-functional optical imaging unit that utilizes a variety of optical technologies such as still image and video imaging, Raman spectroscopy, laser scanning, and digital micrography. It also features multi-electrode line/dot pattern recognition and measurement, wafer and substrate mapping, overlay measurement, and various dielectric, metallic, and other material property analysis. At its core, IRVINE OPTICAL ULTRASTATION 3.B MODEL 2 includes a state-of-the-art digital imaging machine that consists of six digital camera systems, with up to 25 megapixel resolution for imaging. It also has a powerful software tool for image processing and analysis, as well as a high-resolution scanning asset for sub-micron level imaging. Ultrastation 3B Model 2 also contains a wafer-stage model, capable of handling substrates up to 200mm x 200mm in size. The stage is engineered for precise movement, allowing for rapid image acquisition, with a maximum speed of up to 400mm per second. It also is designed to have very low wavefront aberrations, reducing the impact of wavefront variations on the accuracy of the imaging equipment. For inspection, ULTRASTATION 3.B MODEL 2 is equipped with an advanced defect detection system, which utilizes an array of sensors to accurately distinguish between signals coming from wafer defects, highly reflective particles, and semiconductor devices. It also includes a fully automated defect review unit, which allows for quick and easy assessment of defects, and enables users to make well-informed decisions regarding corrective action. Finally, IRVINE OPTICAL Ultrastation 3B Model 2 includes an advanced analytics machine, providing users with comprehensive statistics on process performance, and allowing them to monitor their inspection and fabrication processes in real-time. By delivering real-time process control and monitoring, IRVINE OPTICAL ULTRASTATION 3.B MODEL 2 helps ensure quality and process stability, making it an invaluable tool for modern semiconductor fabrication.

There are no reviews yet