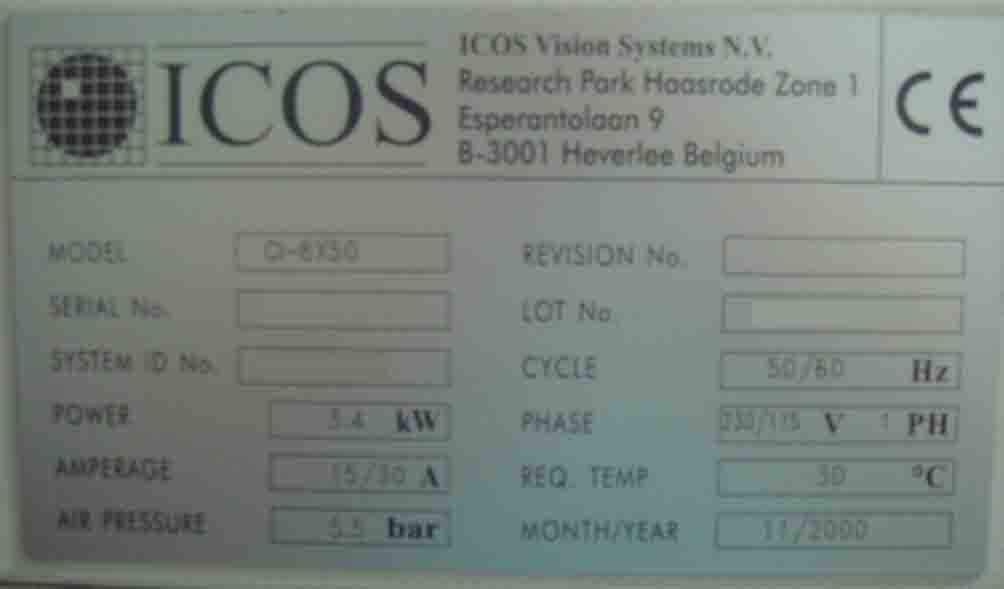

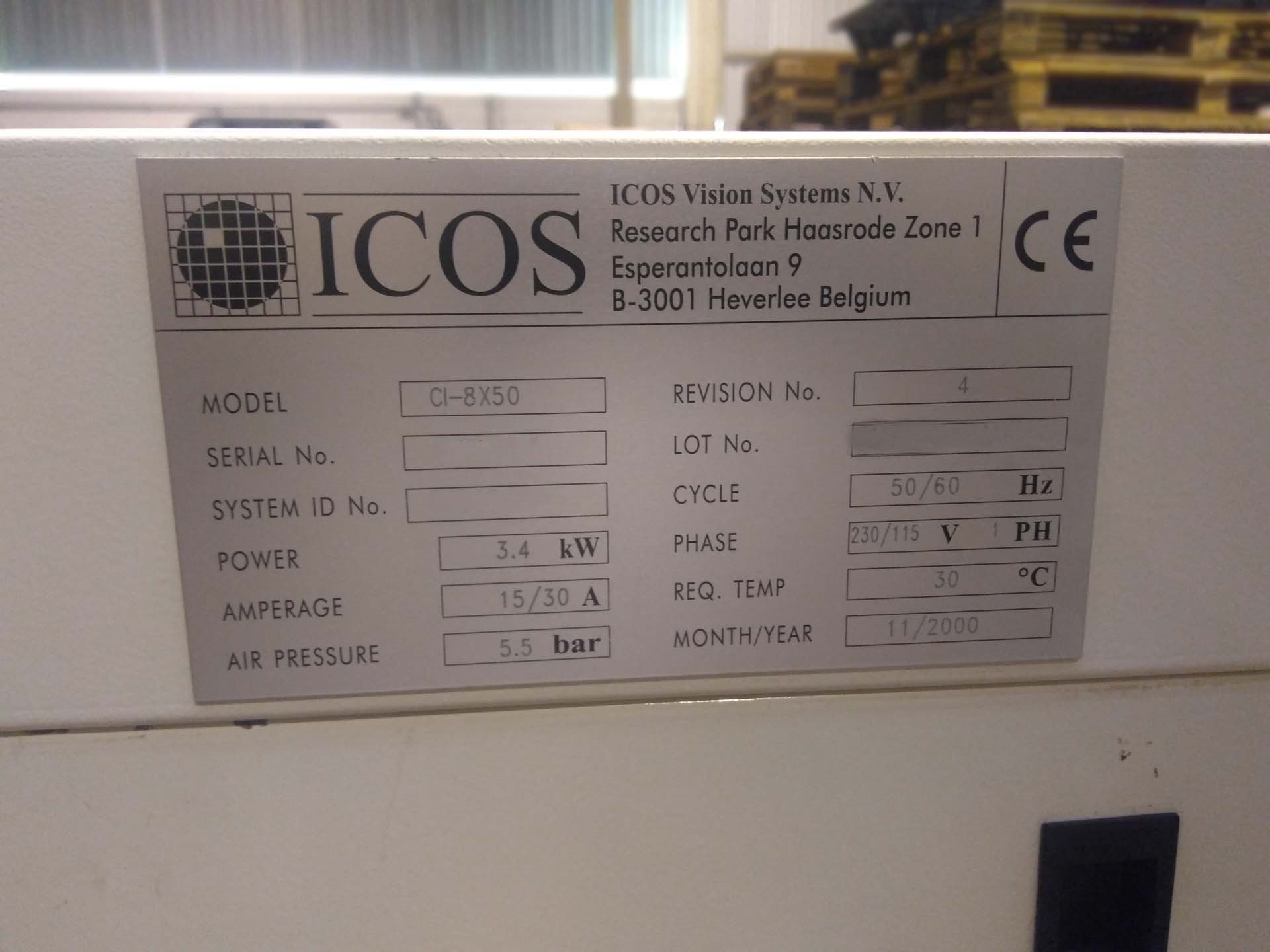

Used KLA / ICOS CI 8250 #9053897 for sale

URL successfully copied!

Tap to zoom

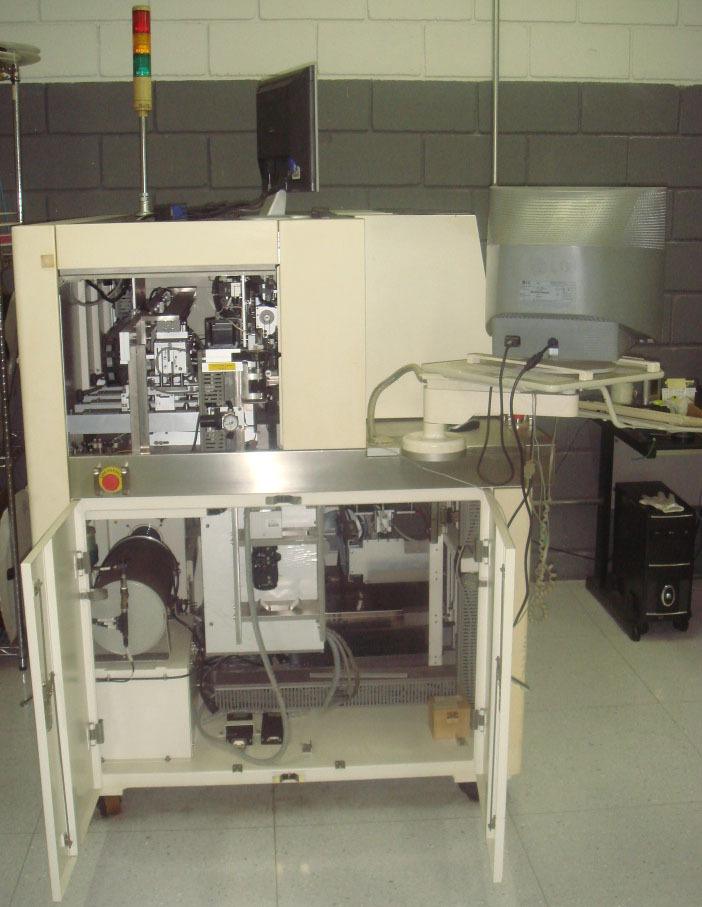

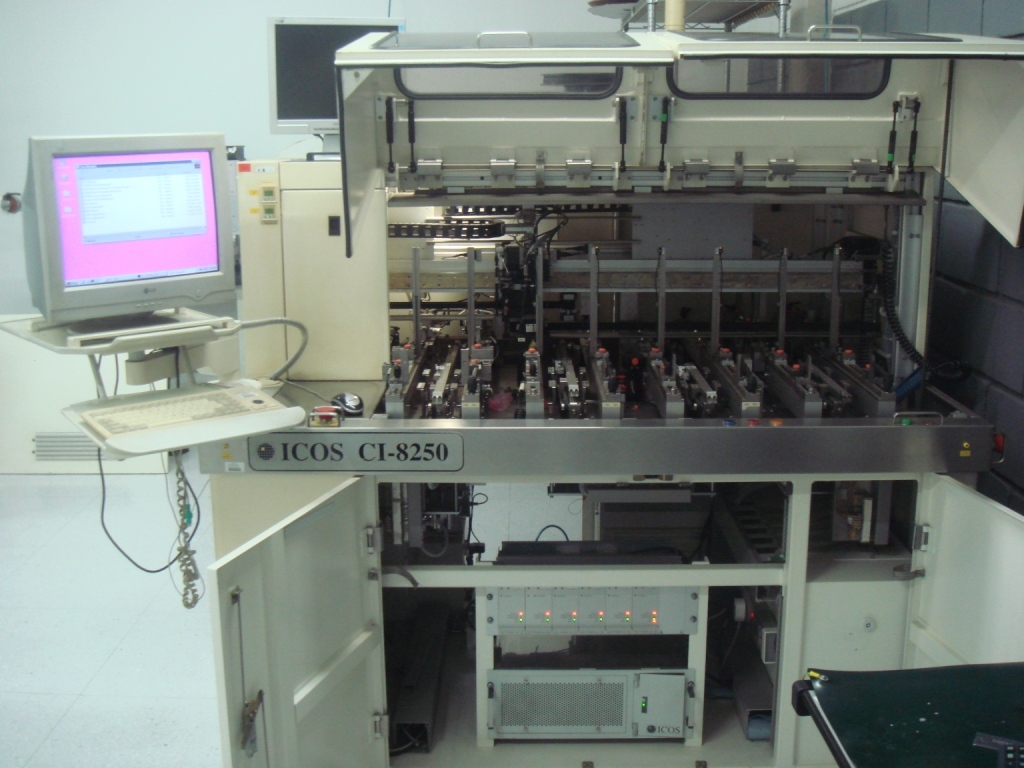

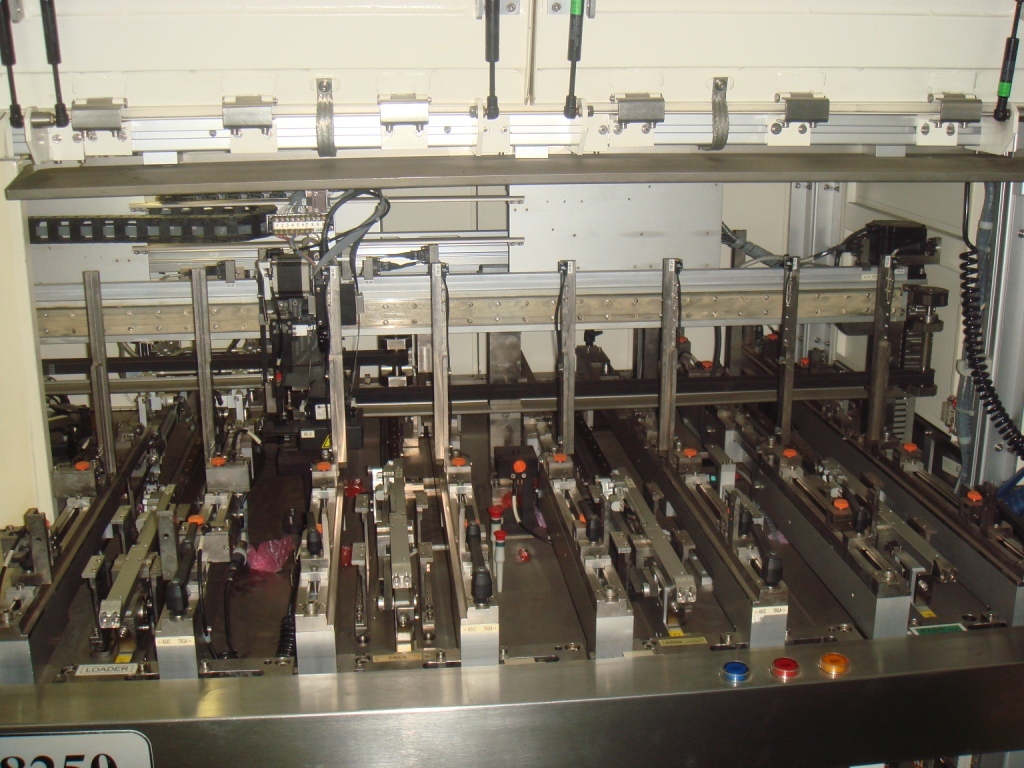

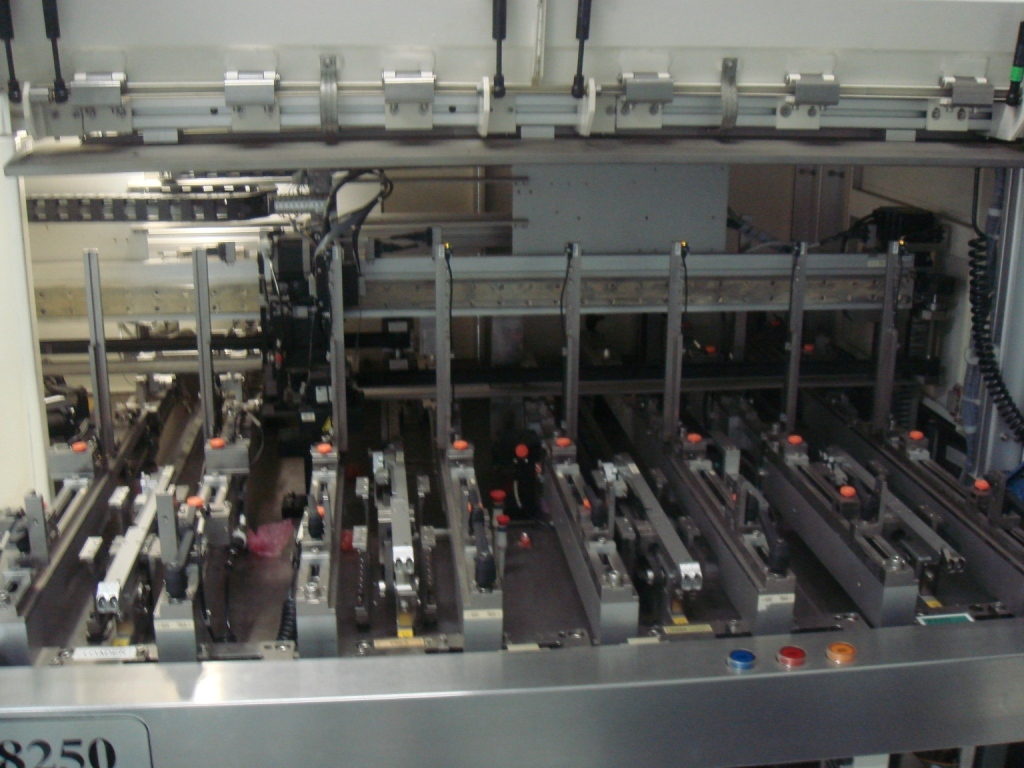

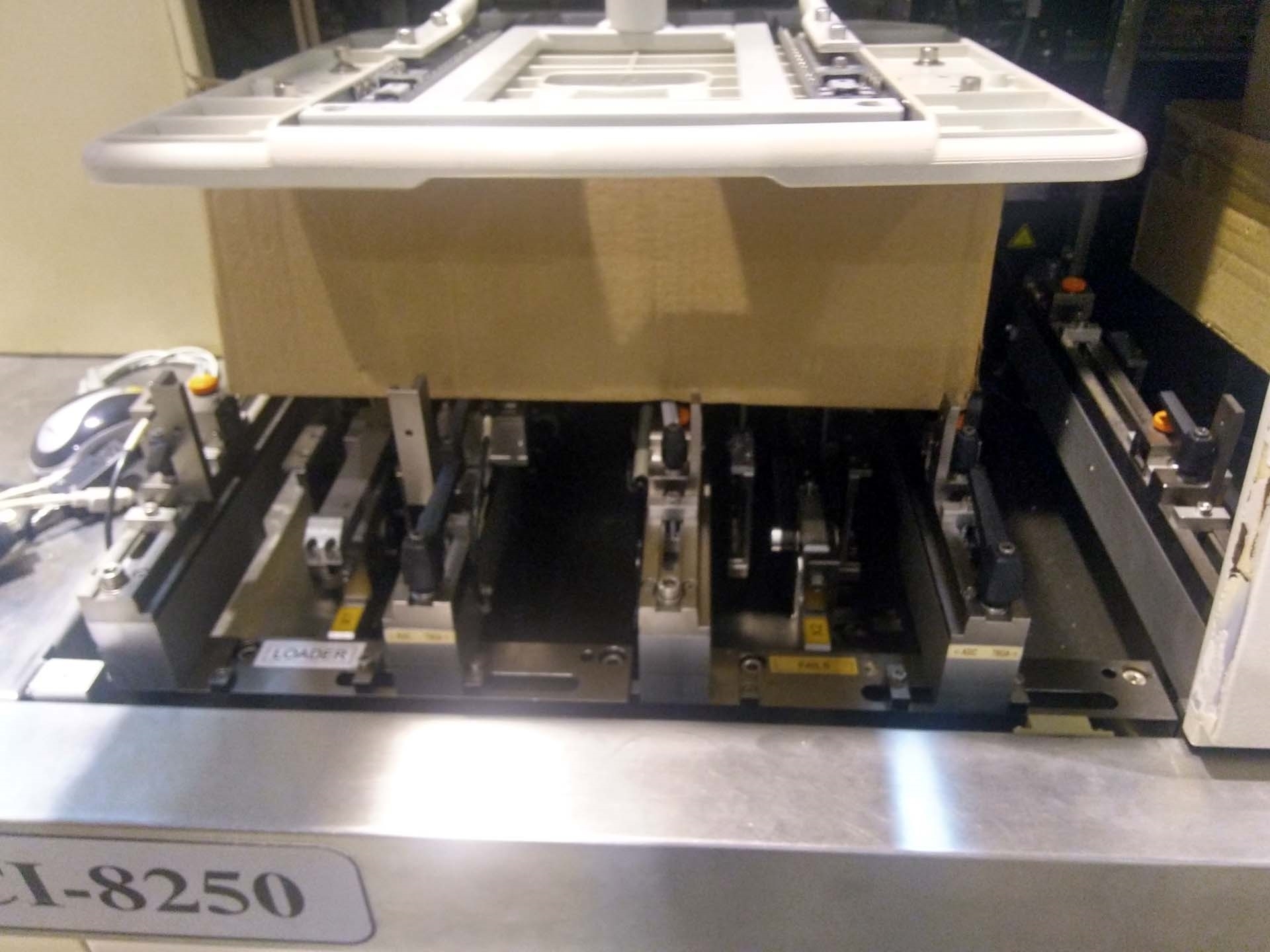

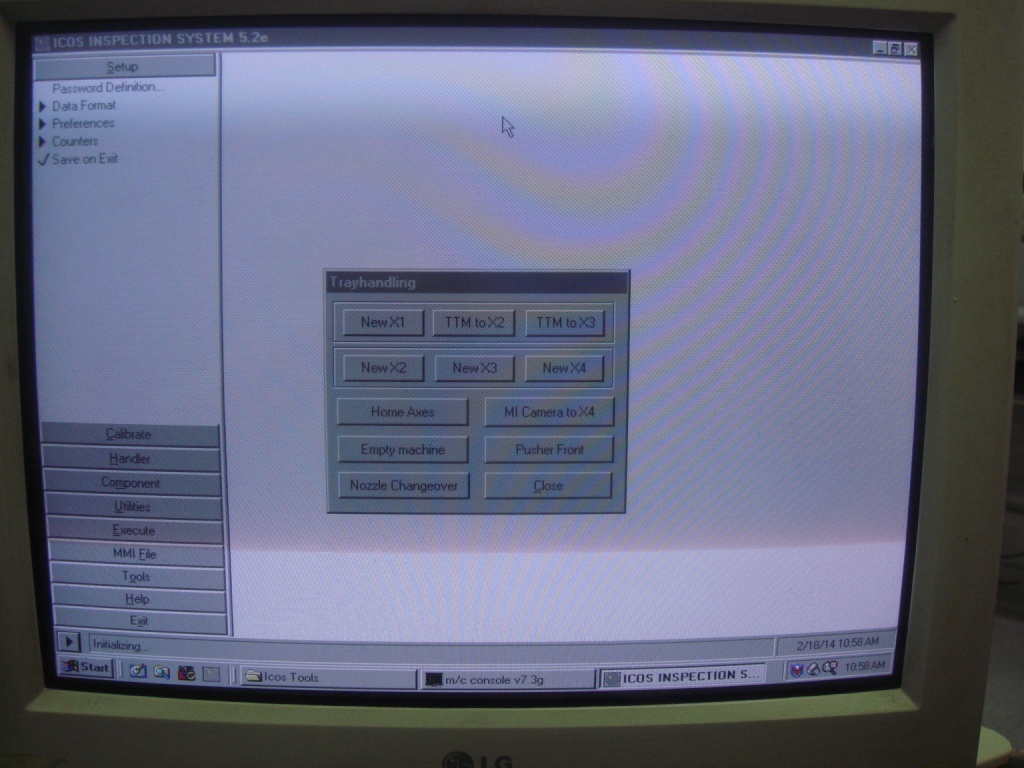

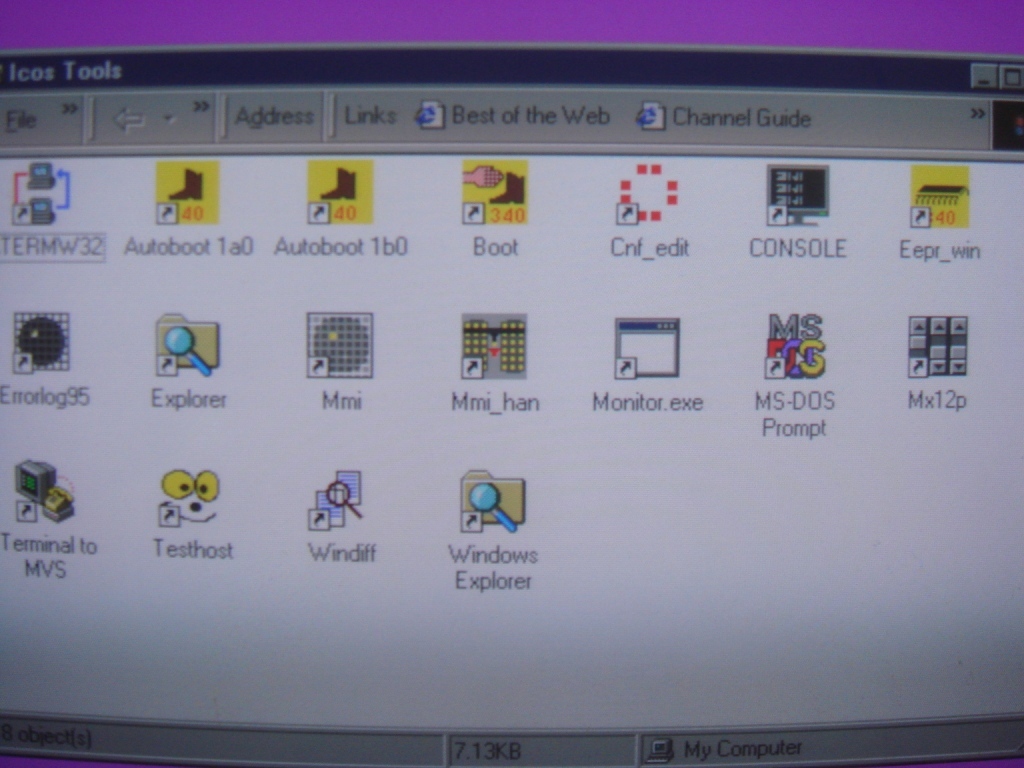

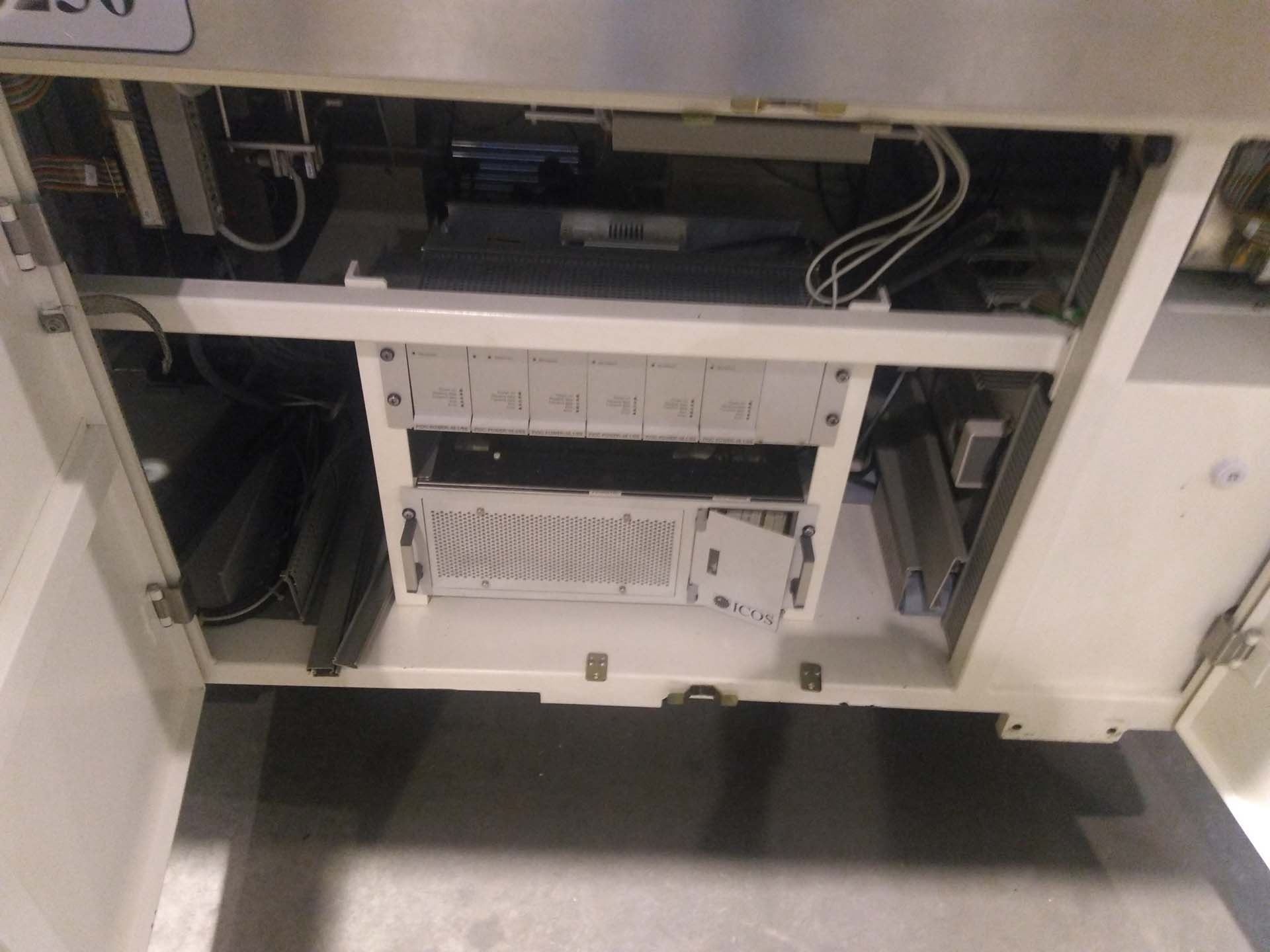

KLA / ICOS CI 8250 is a highly advanced mask and wafer inspection equipment. It is designed to detect, analyze, and classify various defects on both semiconductor photomasks and wafers during the manufacturing process. The system is comprised of an optical inspection unit, a wafer and mask cleaning machine, and a defect classification tool. The advanced optical inspection asset has three different optical heads that can each accommodate different mask and wafer sizes. Each head can detect a variety of different size and type of defects, such as line width or shape variations, foreign material inclusions, haze, voids, warpage, and other surface irregularities. The wafer and mask cleaning model is designed to thoroughly clean masks and wafers prior to inspection, providing maximum accuracy. This equipment utilizes proprietary technologies and processes that are capable of removing even the smallest of particles from the surface. Finally, the defect classification system which is comprised of powerful image processing algorithms that are designed to identify each type of defect. This enables the unit to not only detect the presence of a defect, but also accurately classify each type of defect for further analysis. The machine can even classify the severity of a particular defect, allowing for optimal corrective strategies during the manufacturing process. Overall, KLA CI 8250 is a powerful and sophisticated mask and wafer inspection tool that can ensure high quality and accuracy throughout the semiconductor manufacturing process. Its ability to detect and accurately classify various types of defects enables manufacturers to identify and address potential issues quickly and effectively. The asset is capable of reducing time, materials, and labor costs associated with correcting defects in the manufacturing process, making it an invaluable tool for any semiconductor manufacturer.

There are no reviews yet