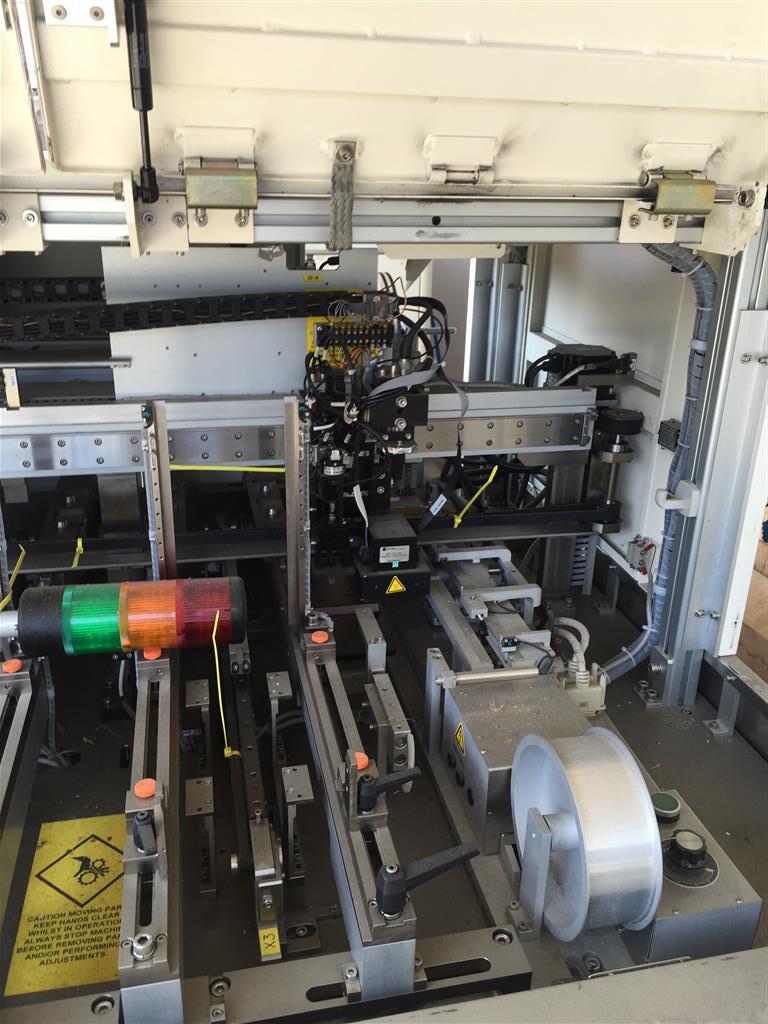

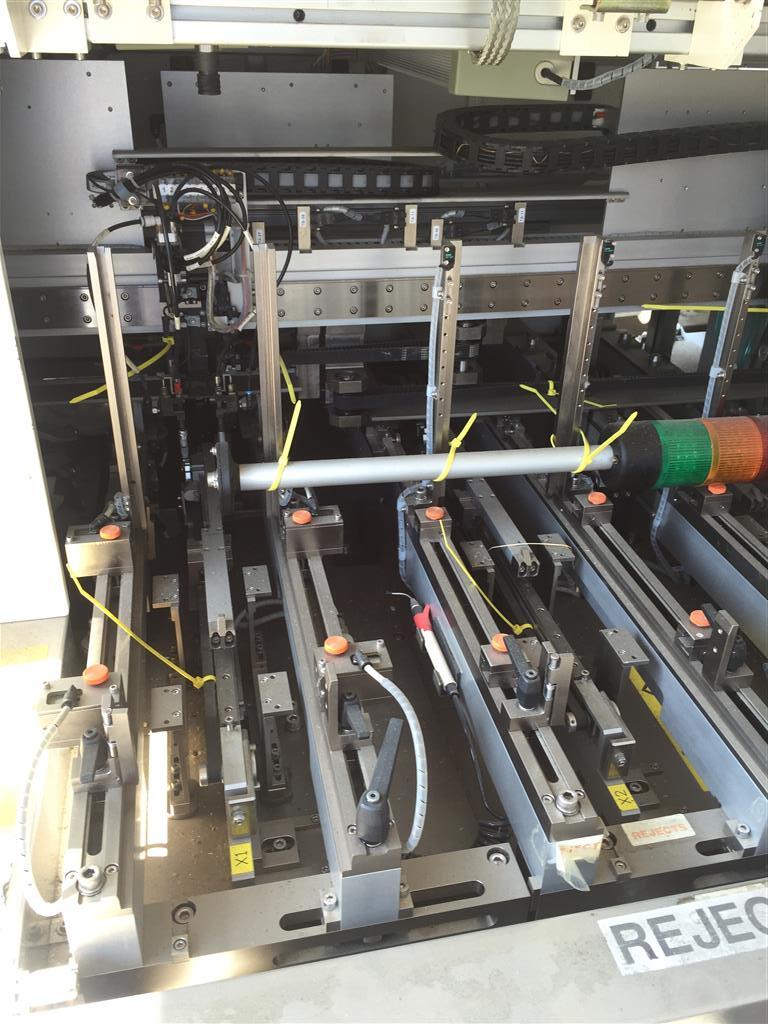

Used KLA / ICOS CI 8250 #9110005 for sale

URL successfully copied!

Tap to zoom

KLA / ICOS CI 8250 is an automated mask and wafer inspection equipment designed for high-volume, high-accuracy execution of critical semiconductor processing steps. KLA CI 8250 employs a cutting-edge combination of the latest in image processing and defect detection technology to enable the rapid and precise identification of defects on masks and wafers. By detecting and correcting errors early on in the manufacturing process, the system can help to reduce costs associated with delayed rework and yield losses. ICOS CI-8250 is equipped with an advanced optical unit featuring an advanced infinity corrected/apochromatic/plan-corrected objective lens for faithful sampling of high-resolution line-space pattern grids, which is essential for improved accuracy of defect detection. Its customizable illumination features a variable area illumination pattern, allowing mask and wafer defect inspection with great flexibility and optimal uniformity. CI-8250 is capable of performing high-precision defect measurements through the integration of a number of device-specific defect measurements. The built-in high accuracy 3D inspection technology can measure device features down to 70nm with unprecedented accuracy, enabling optimum identification and classification. The machine also supports flexible mask/wafer alignment for improved efficiency, with the ability to identify and align pattern types with 30nm overlay accuracy. The powerful analytics capabilities of ICOS CI 8250 can cut through the noise of complex proprietary data from a range of disparate sources. The tool enables predictive analytics by combining the powerful predictive algorithms with process data gathered from multiple sources across the manufacturing floor. This provides insights into future device performance, enabling proactive resolution strategies. Predictive analytics can also help identify, triage and classify device-level defects for optimized yield outcomes. The asset also supports standard web languages such as XML, JSON, and MQTT, allowing for seamless data exchange between it and external systems. It is also compatible with major software including JTAG, IEEE1532 standard Edition 2. It is also backed up by priority support and rigorous factory certification processes for the highest quality of service. All in all, the reliable and comprehensive CI 8250 is the ideal selection for high-volume, high-accuracy mask and wafer inspection. It measures and evaluates masks/wafers with great accuracy and enables predictive analytics for efficient and effective device inspection.

There are no reviews yet