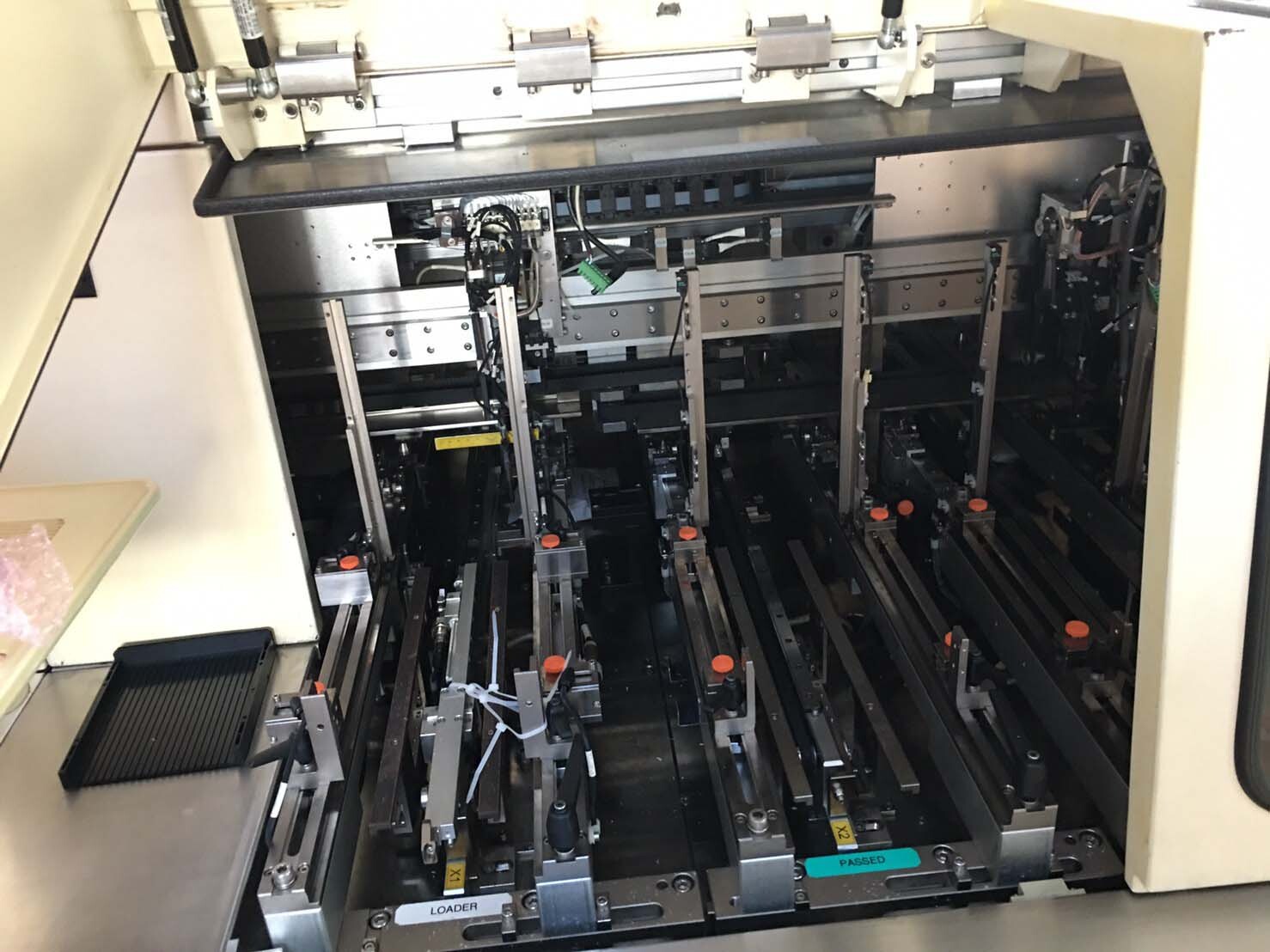

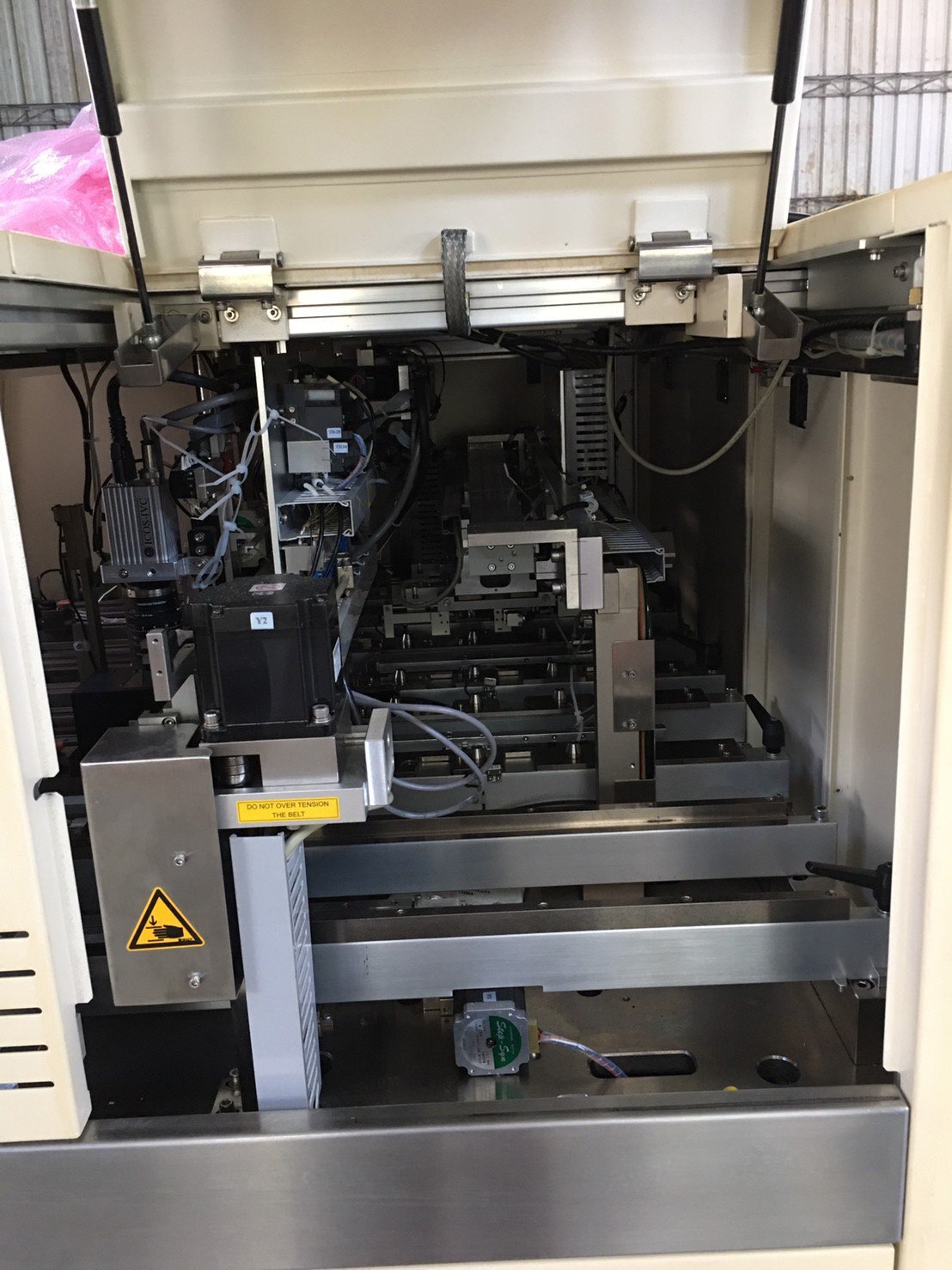

Used KLA / ICOS CI 9450 #9384067 for sale

URL successfully copied!

Tap to zoom

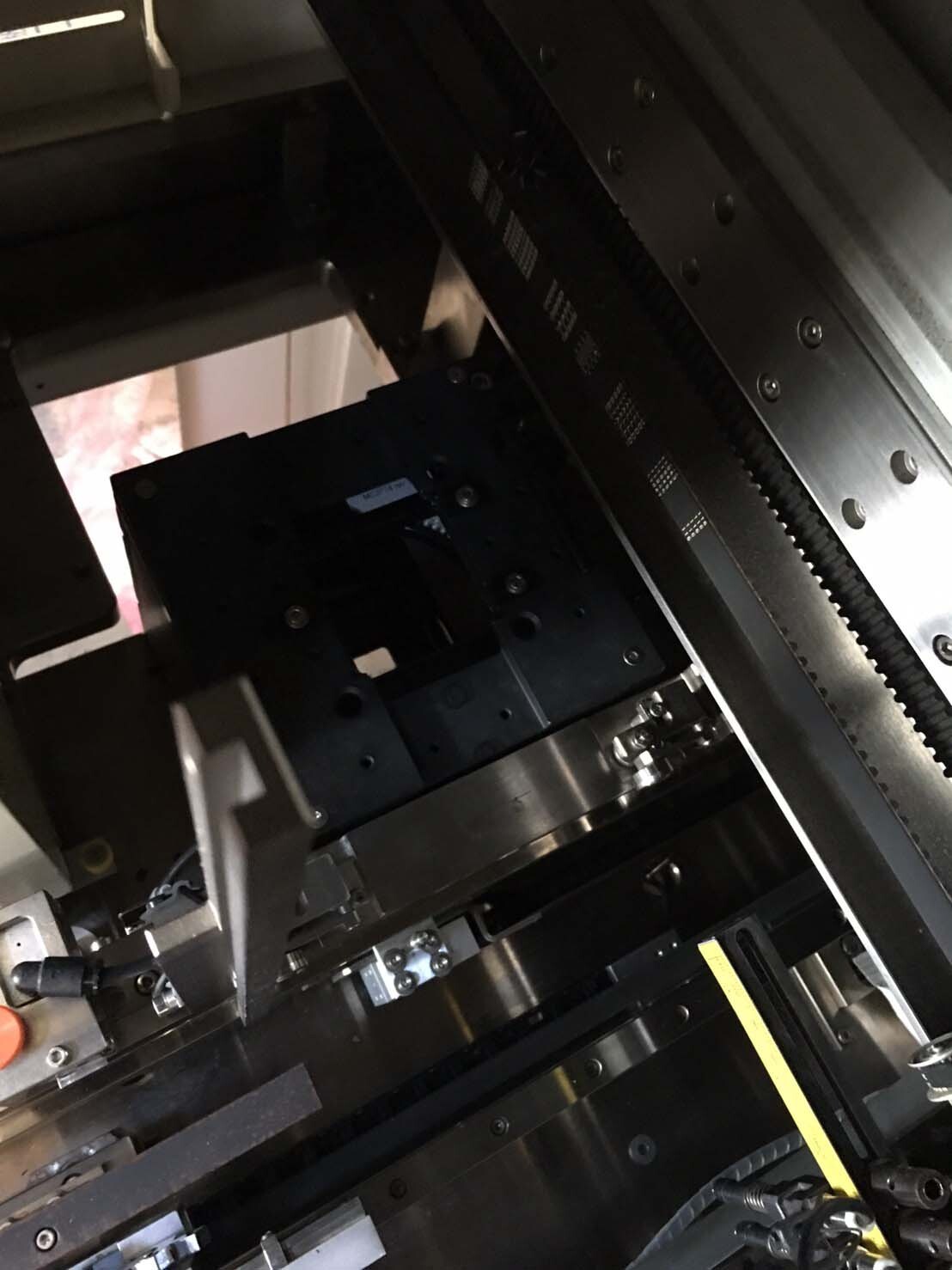

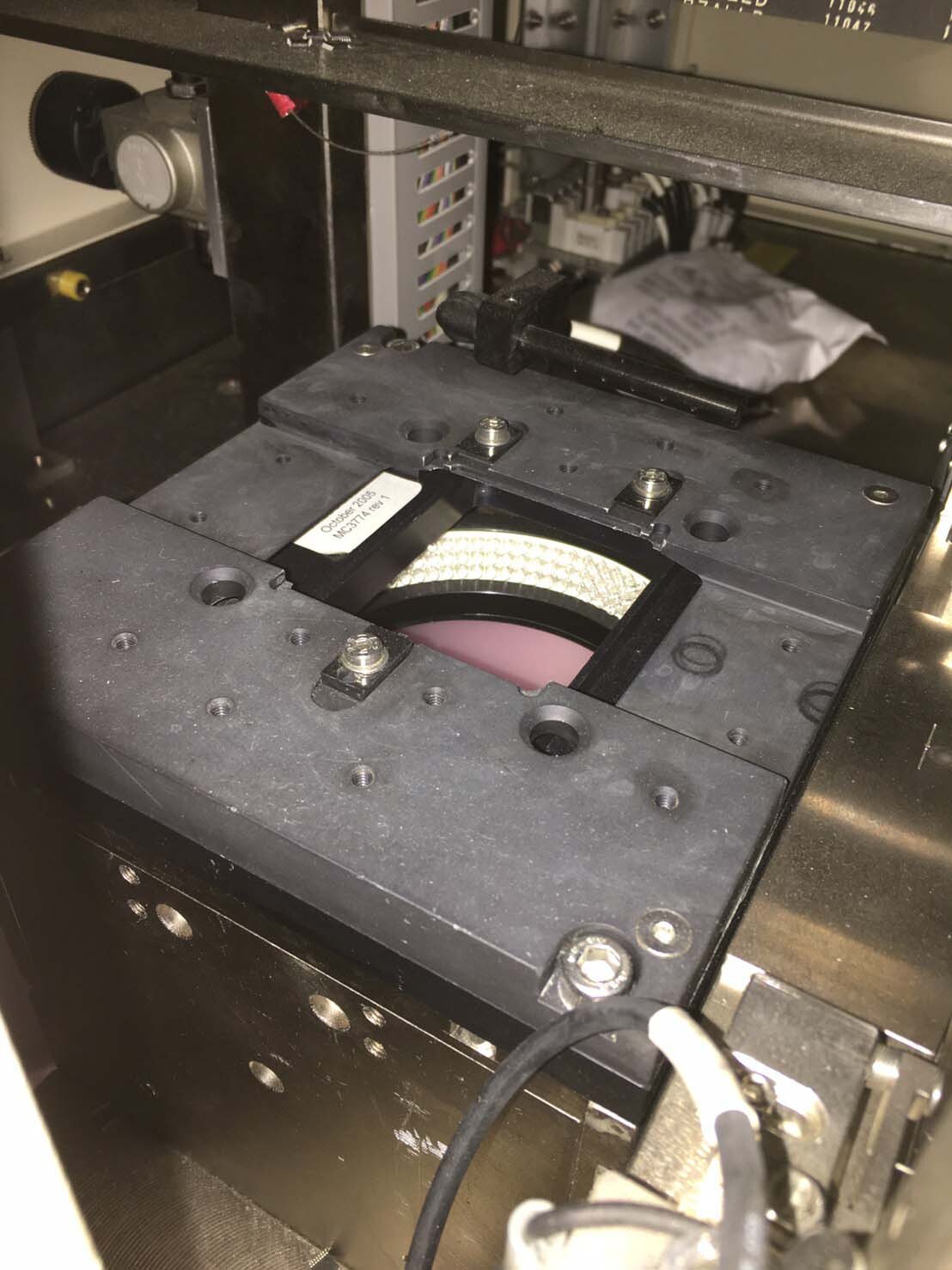

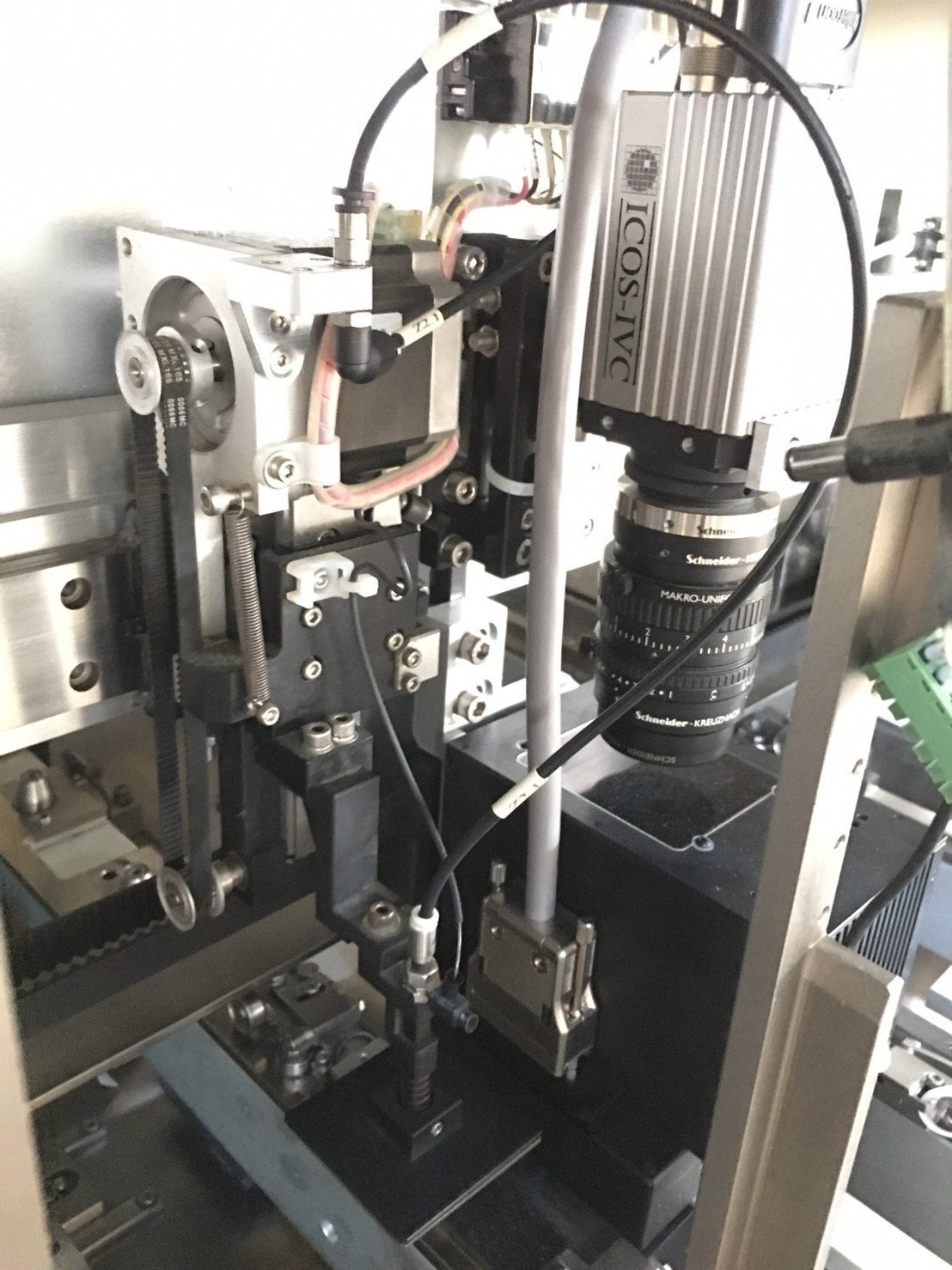

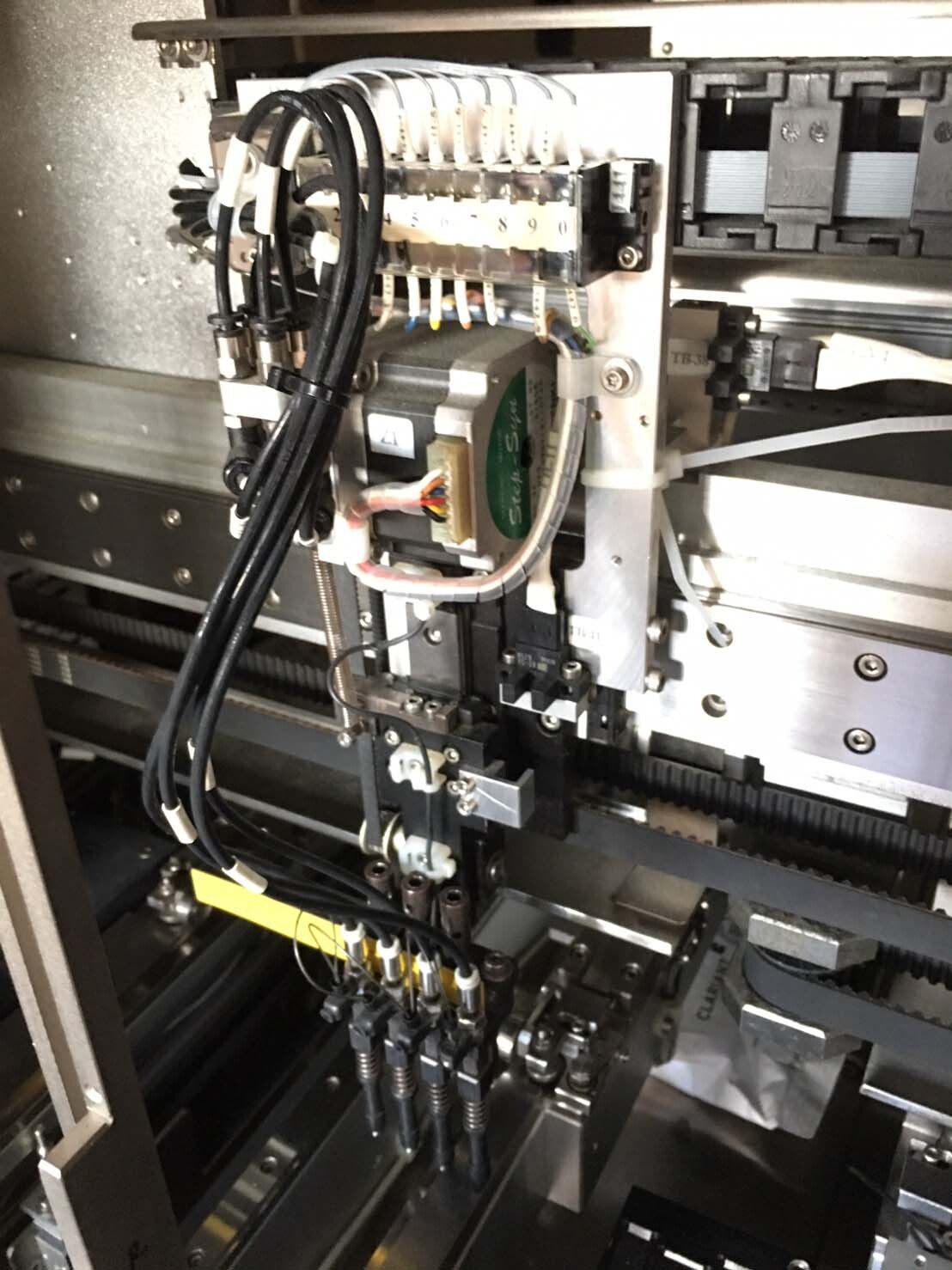

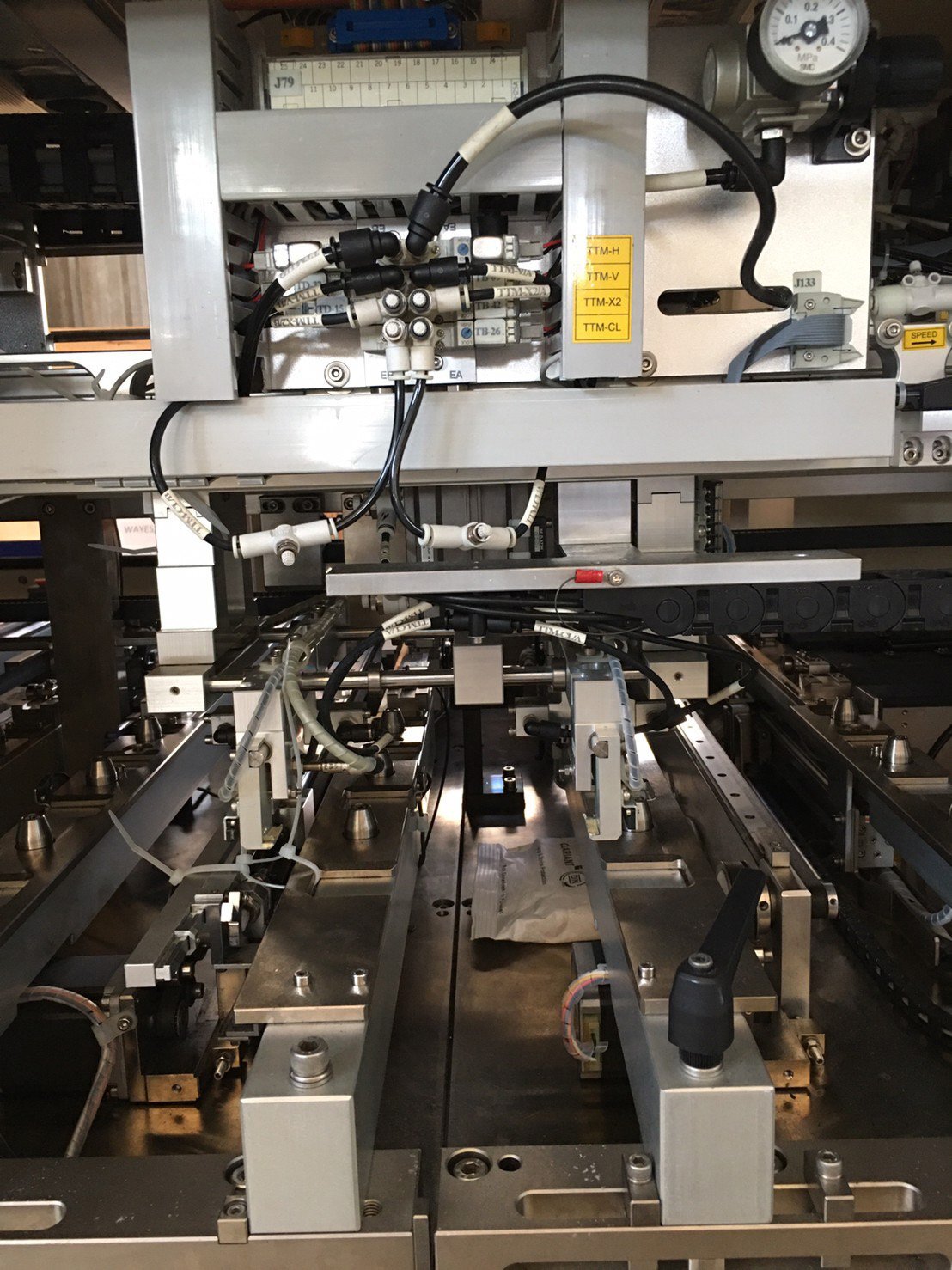

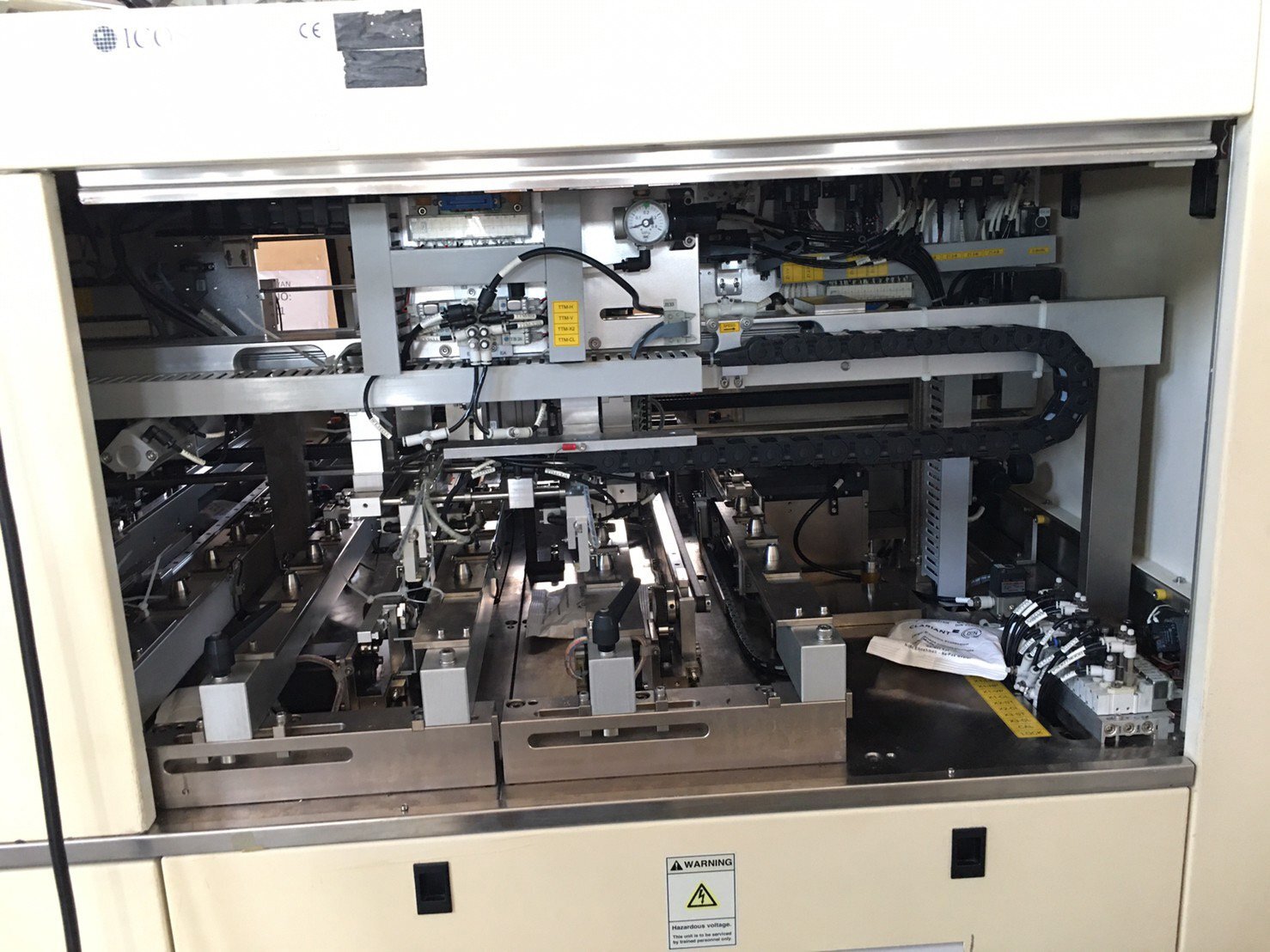

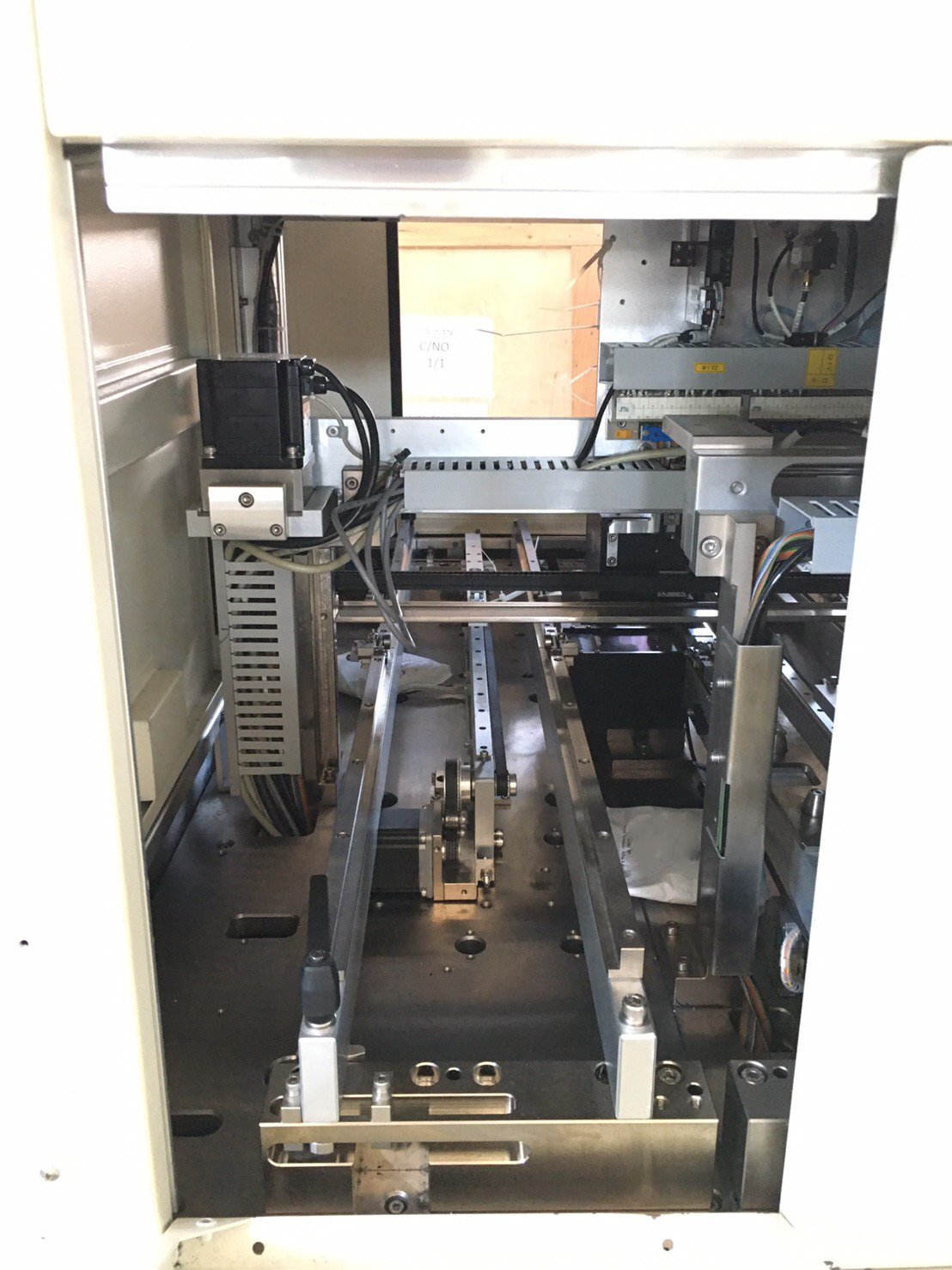

KLA / ICOS CI 9450 mask and wafer inspection equipment is an automated metrology system designed to inspect semiconductor masks and wafers. The unit is capable of measuring feature sizes and shapes, verifying good and bad dies, and providing comprehensive manual and automatic defect review across a wide range of wafers. KLA CI 9450 is equipped with a pair of rotating optical systems that allow users to capture a wide range of images and diagrams of a wafer. The first optical machine consists of multiple cameras that are capable of capturing single images for inspection. The second optical tool is an integrated wide angle camera that allows for high magnification images of feature sizes. ICOS CI-9450 is equipped with a powerful Digital Image Processor (DIP) that carries out a wide variety of probing, imaging and analysis tasks. The DIP is capable of capturing hundreds of images in a single cycle and utilizing a proprietary software algorithm to sort them into groups or ranges for further review. The asset has an intuitive graphical user interface that makes the process of manipulating the data easy and efficient. The model is capable of measuring sub-micron structures on the mask or wafer, such as metallic via holes, TSV's, sub-quarter micron lines, and motifs. It also has the ability to detect complex defects such as nanopatches, mask layer defects, edge defects, particles, scratches, and foreign materials. Additionally, KLA / ICOS CI-9450 can detect uniformity defects in masks and wafers, as well as detect and identify bad dies on wafers. KLA CI-9450 features a compact, robust housing with a number of ergonomic features, making the equipment a snap to set up and operate. A built-in fan keeps the optics cool and helps maintain the optical systems. Its high-resolution optical system can also be used to inspect samples that are mounted on non-flat surfaces, so users can inspect samples that are not perfectly flat. In conclusion, CI 9450 mask and wafer inspection unit is a reliable and robust machine that is ideally suited for rapid, accurate sub-micron metrology and defect analysis. Its integrated optical systems, DIP, and intuitive graphical user interface make it easy for users to inspect semiconductor masks and wafers with high accuracy and throughput.

There are no reviews yet