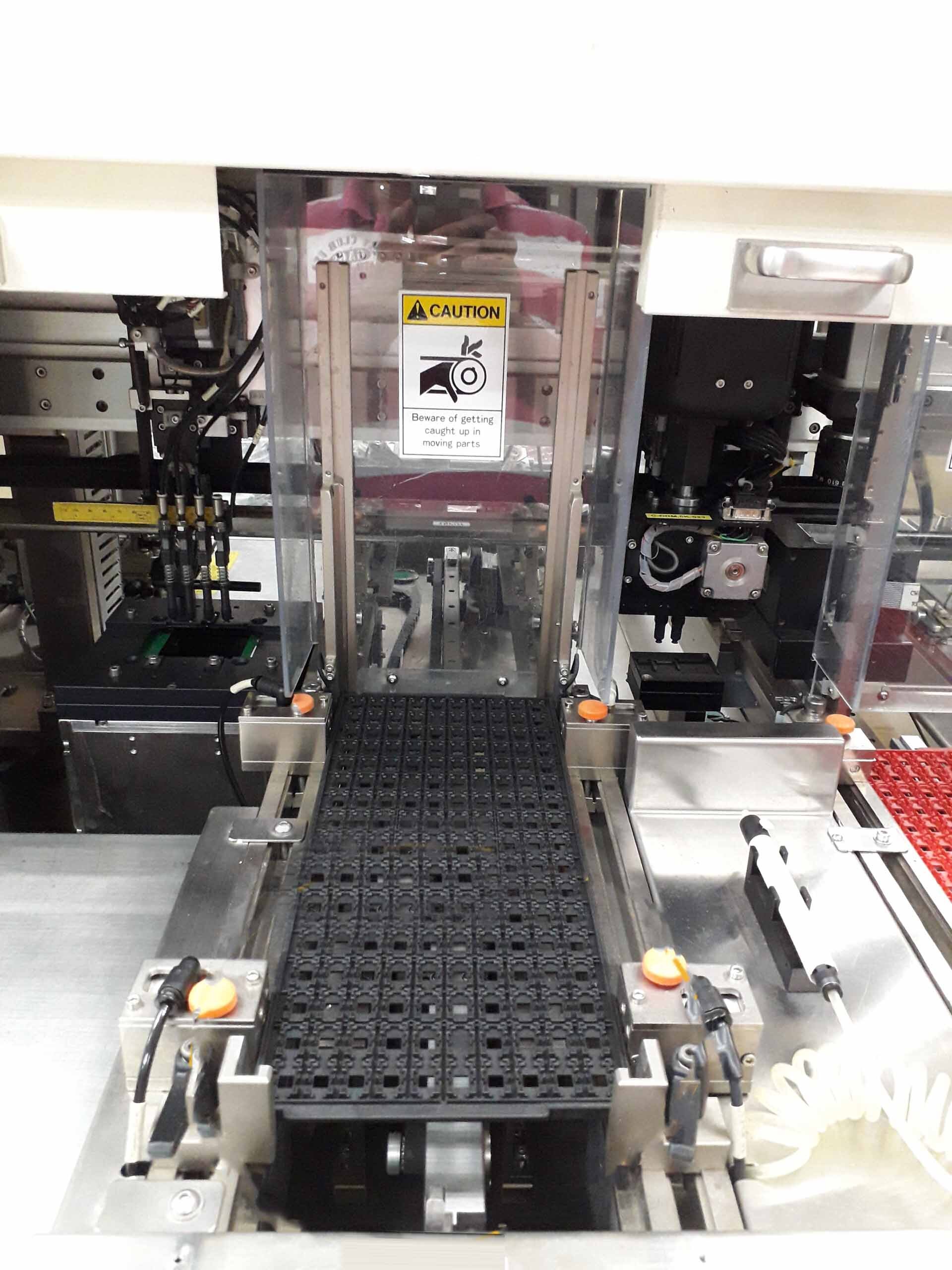

Used KLA / ICOS CI 9450 #9389733 for sale

URL successfully copied!

Tap to zoom

ID: 9389733

Lead scanner

With single taper

Auto tray loader

Unloader

(4) Pickup cups

(2) Rotate head sortings

Unit place:

Tape and reel pocket.

KLA / ICOS CI 9450 Mask & Wafer Inspection Equipment is a comprehensive solutions for automated mask and wafer inspection. It features a range of high performance image processing and analysis tools for fast and reliable defect detection, enabling the rapid recognition and display of problematics. The system is well suited for both front and backside wafer results, as well as lithography applications. It can provide high throughput and high accuracy inspection of lithographic masks and wafers in a wide range of industries, including computer and semiconductor manufacturing. KLA CI 9450 unit is based on a proprietary CMOS image sensor and algorithm package, developed from the ground-up to provide the highest performance for defect detection. Its advanced capabilities allow for a comprehensive optimization of the entire inspection process, from the completion of the basic inspection parameters to the efficient automatic recognition of different defect types and their respective areas of responsibility. The machine uses a series of different image sensors to capture images at different times and to reflect different levels of image resolution and dynamic range. This allows for quick assessment of defects and a decrease in false positives. It also makes it possible to accurately detect minor defects that may be misunderstood during manual inspection. ICOS CI-9450 tool has the ability to monitor micro-defects, feature and lithographic registration defects in different color modes. It has automated image stitching functionality to provide a higher level of precision in detecting defects and anomalies across a wider area, without the need of operator supervision. The asset also has a wide range of features for defect classification and analysis. It is capable of analyzing images pixel-by-pixel, helping to eliminate false positives and reduce the time needed to pinpoint the error. In addition, it has a CAD/Etch-Back analysis model to handle complex cases such as specific contact size, overhanging wires, or cross-sectional TEM features. CI-9450 equipment also makes use of advanced profile reporting, allowing for easy comparison between different sets of data points. This can be used to improve throughput and optimize inspection setup parameters. Additionally, its Level-Set and Structured-Light capabilities make it possible to inspect even the most complicated masks, wafers, and substrates, once again increasing the accuracy of defect detection. KLA / ICOS CI-9450 system is an excellent solution for mask and wafer inspection applications in the electronics industry. Its combination of advanced automation and imaging capabilities makes it capable of performing quick and reliable defect detection on a variety of tasks. With its flexibility and accuracy, the unit provide users with a complete and dependable mask and wafer inspection machine.

There are no reviews yet