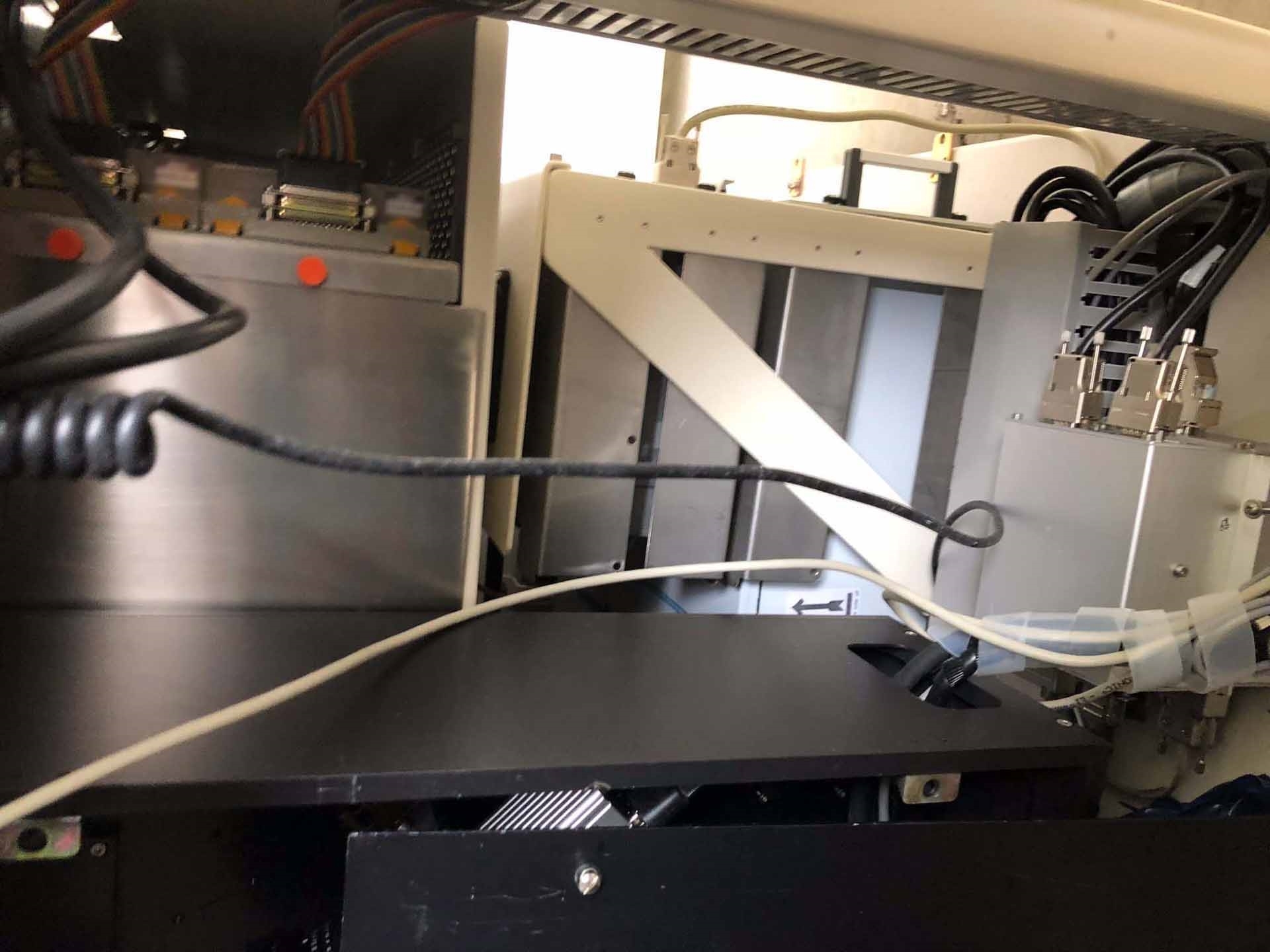

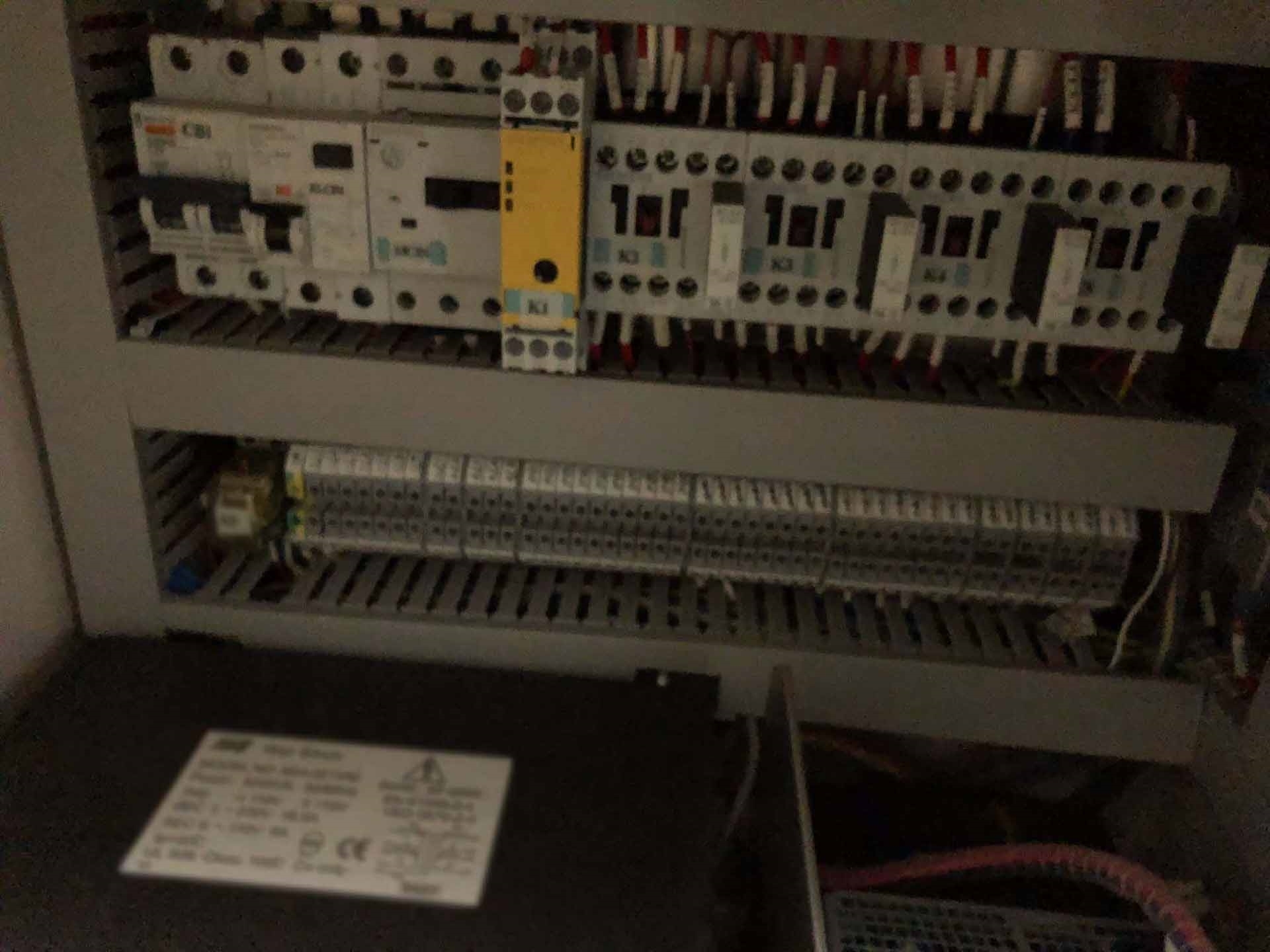

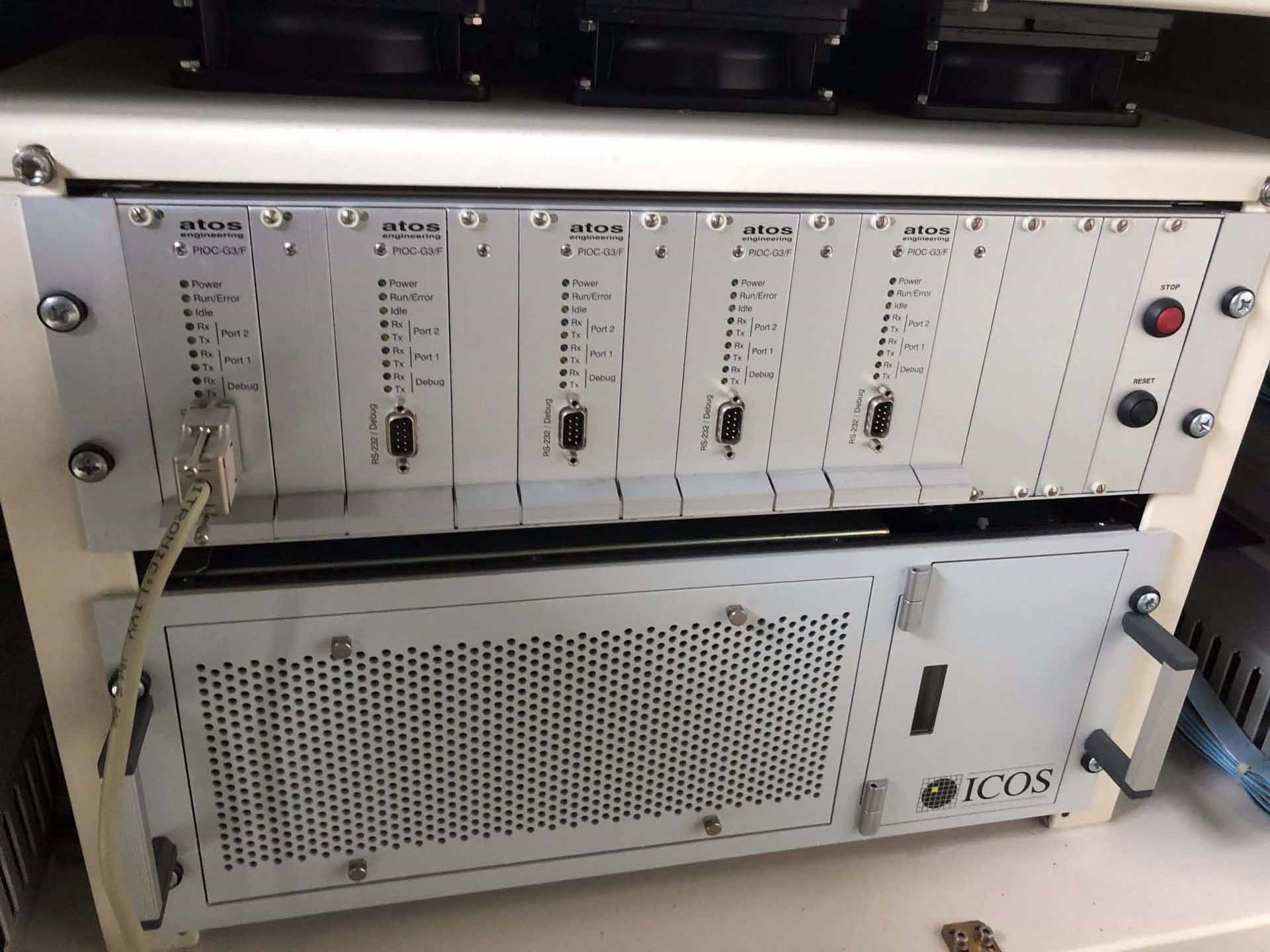

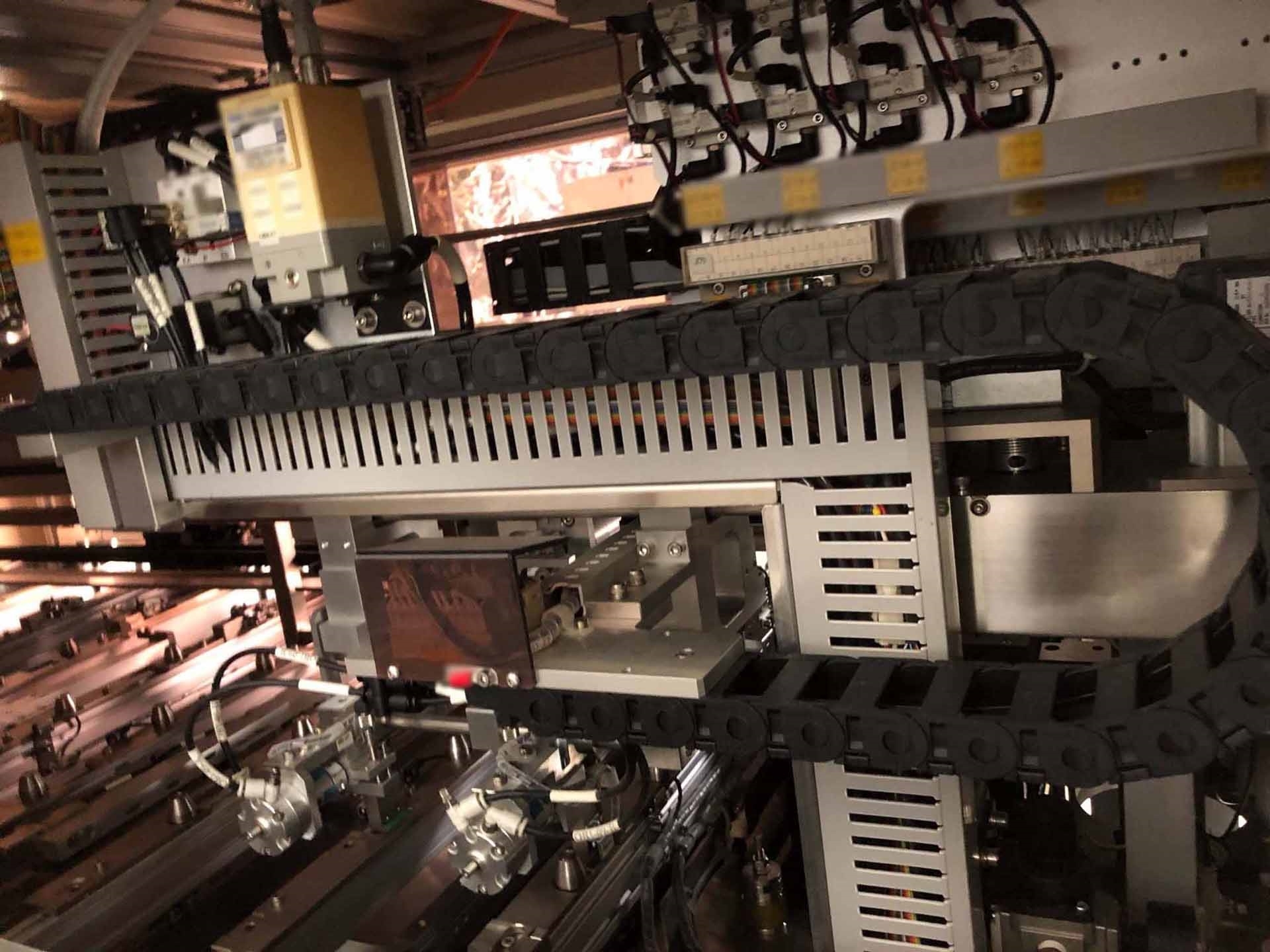

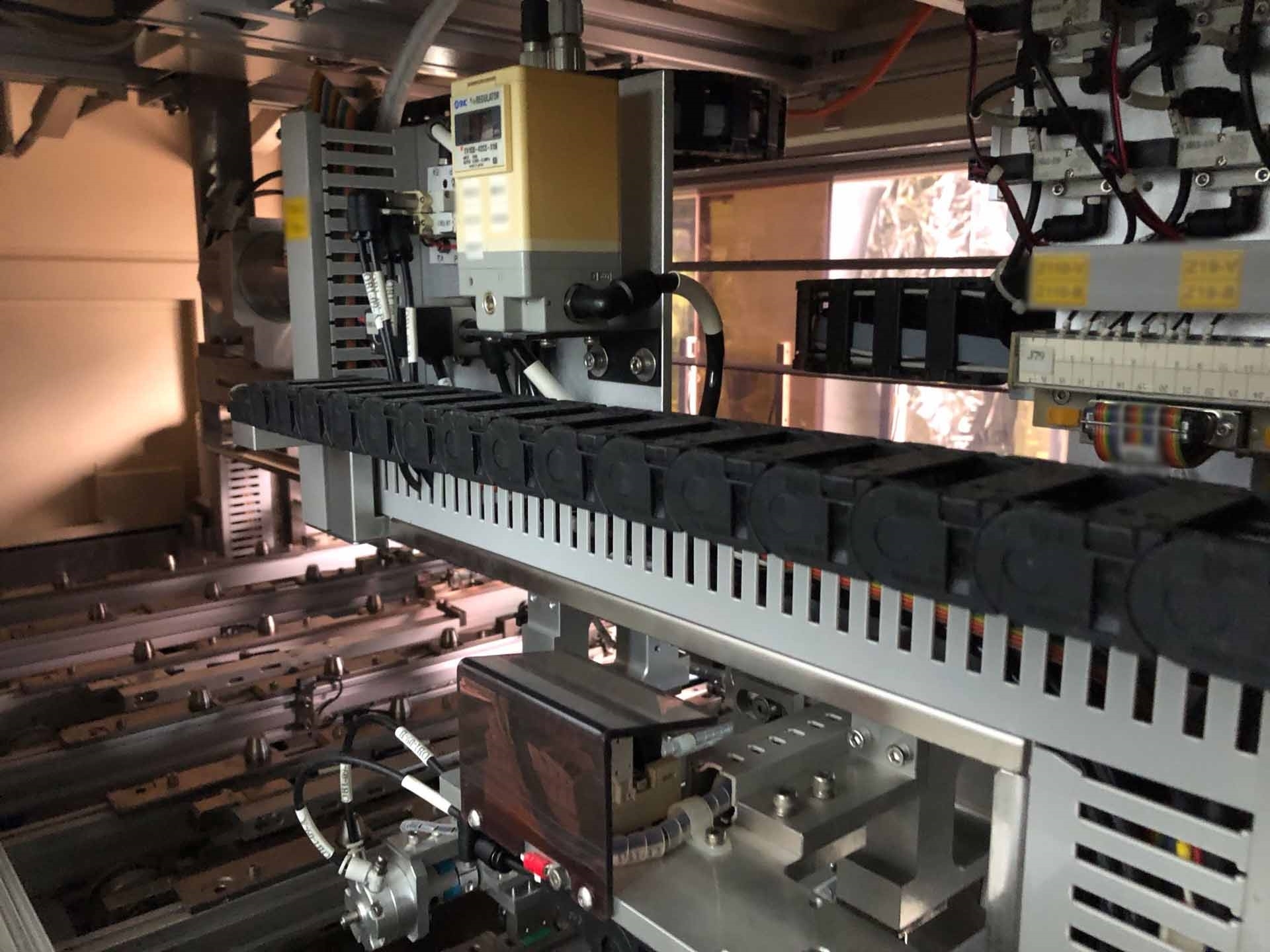

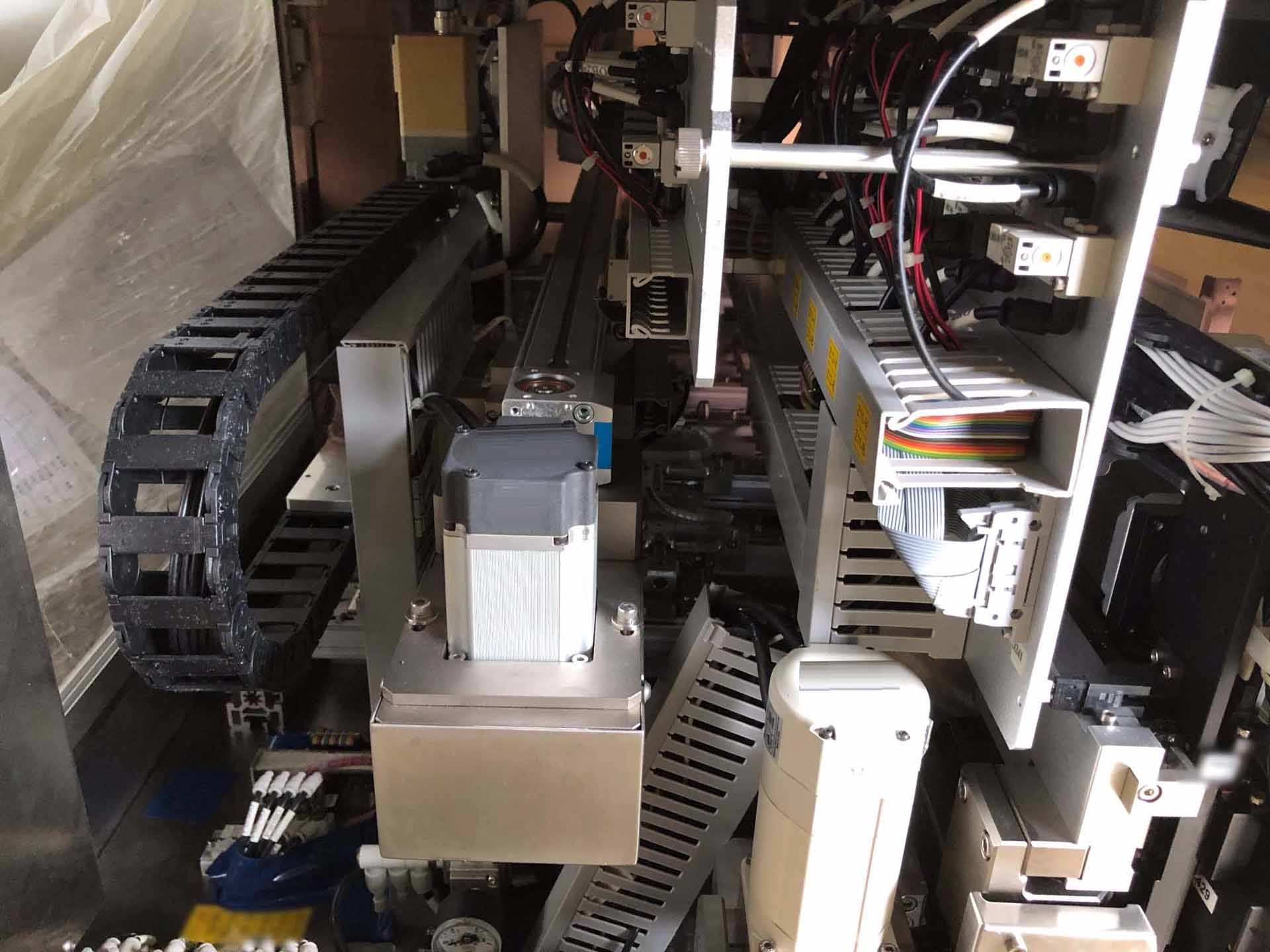

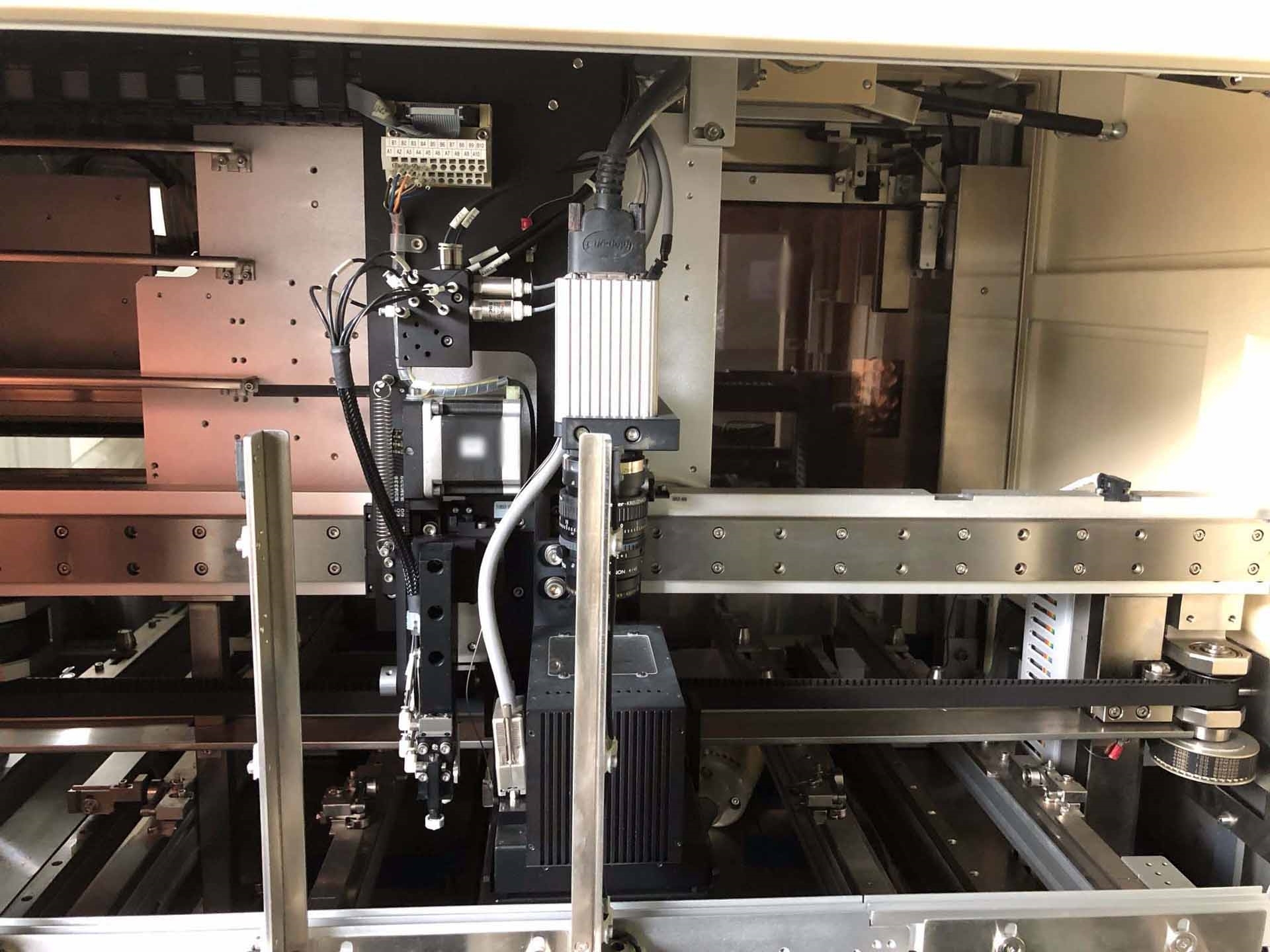

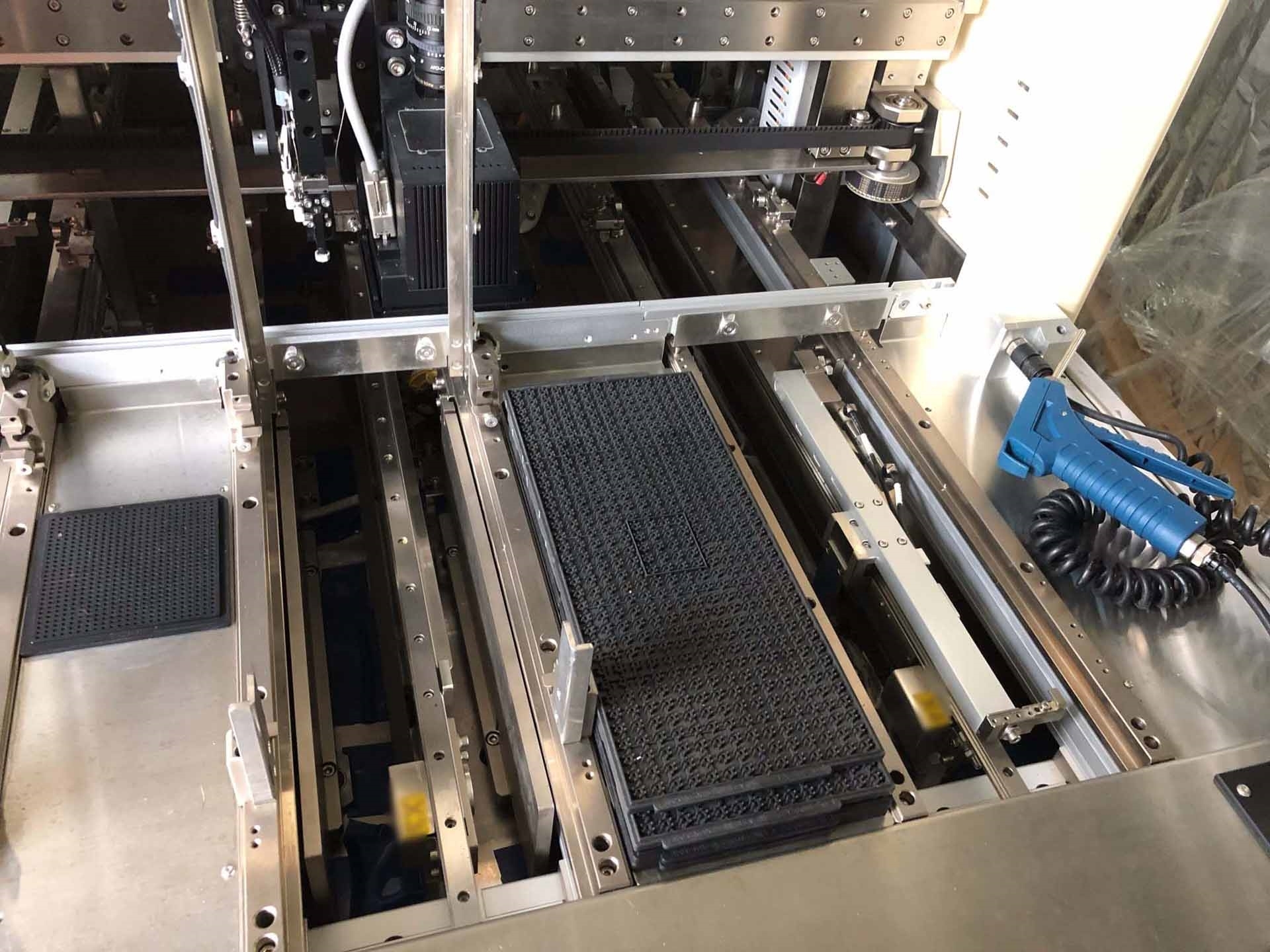

Used KLA / ICOS CI-T120 #9208705 for sale

URL successfully copied!

Tap to zoom

ID: 9208705

Vintage: 2008

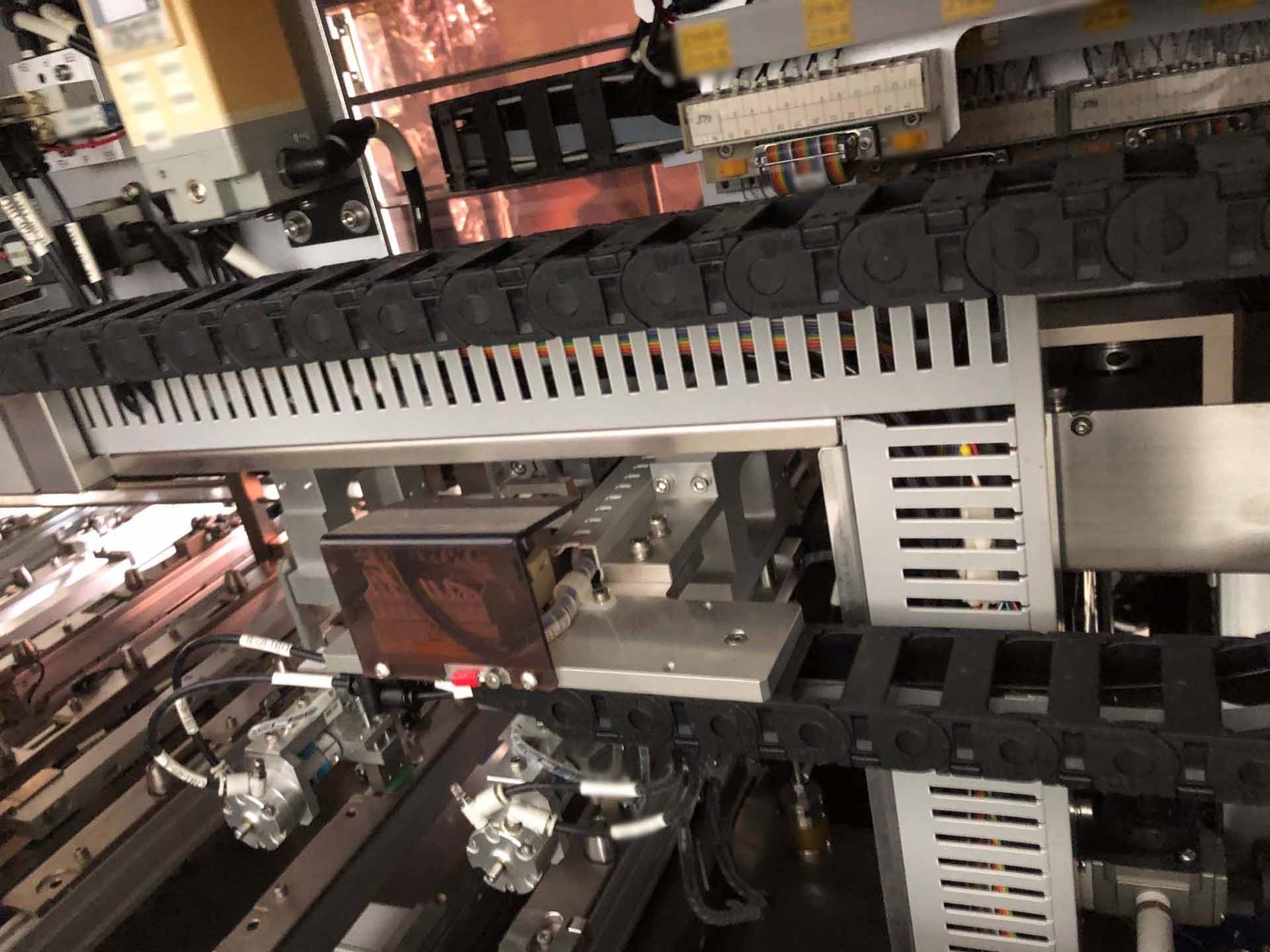

Inspection system

Modes:

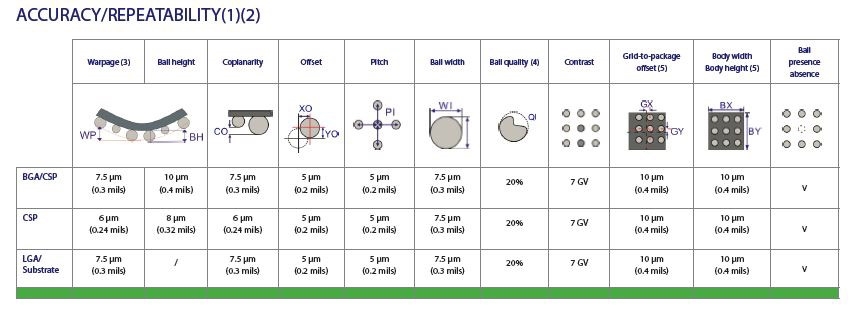

BGA/CSP

CSP

LGA/Substrate

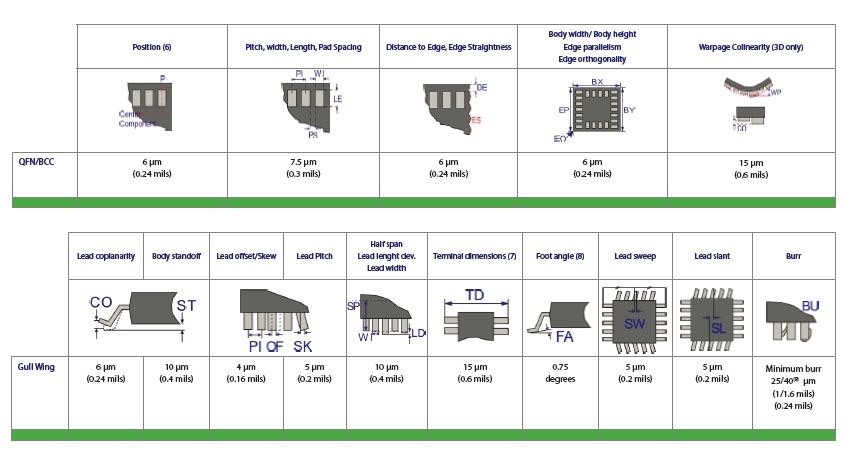

GW

QFN/BCC

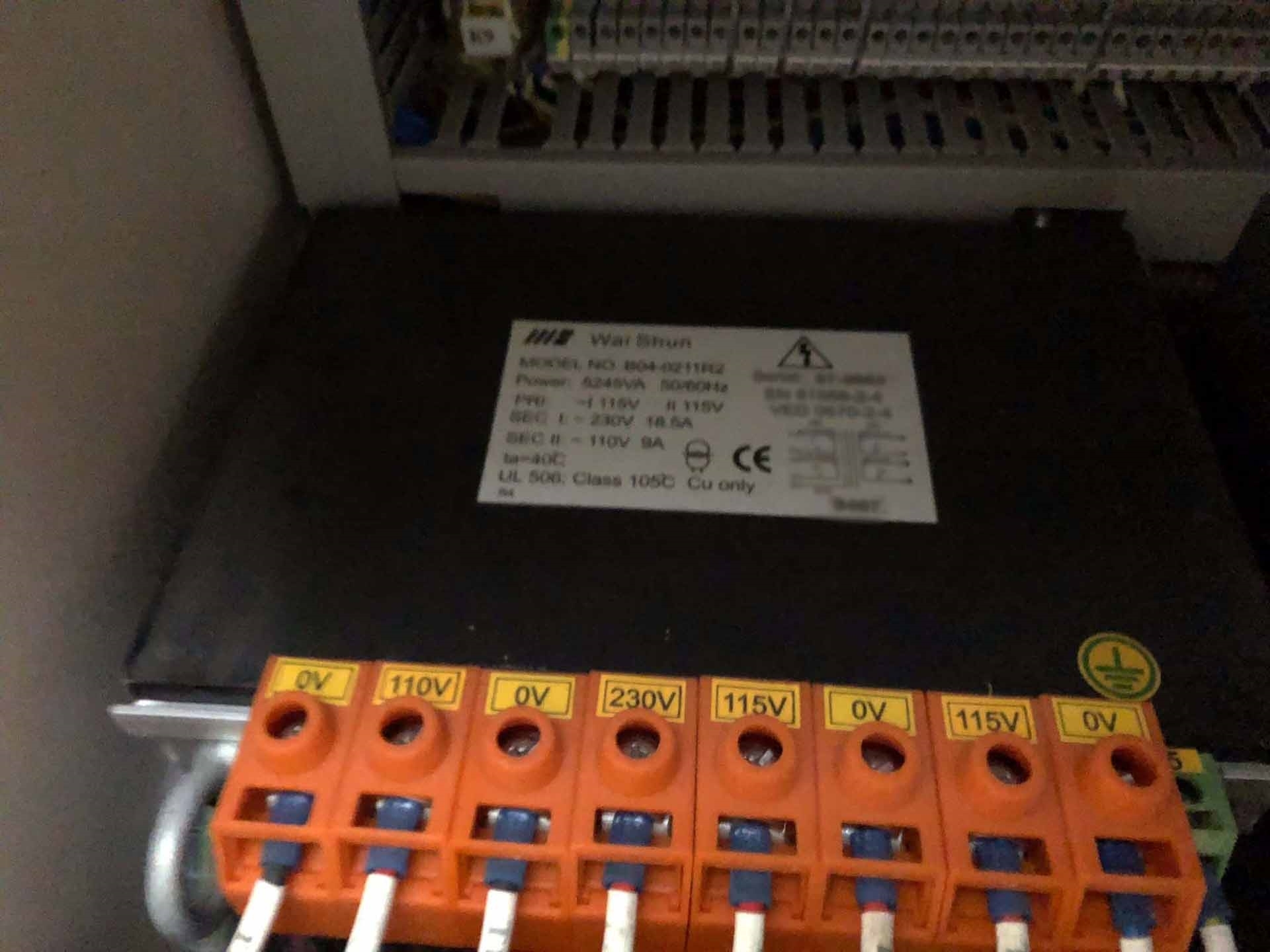

Power consumption: 3.3 kW

Air pressure: 5.5 bar ± 0.7 bar (80 psi ± 10 psi)

Power supply: 115/230 VAC (±10%), 50/60 Hz, Single phase

2008 vintage.

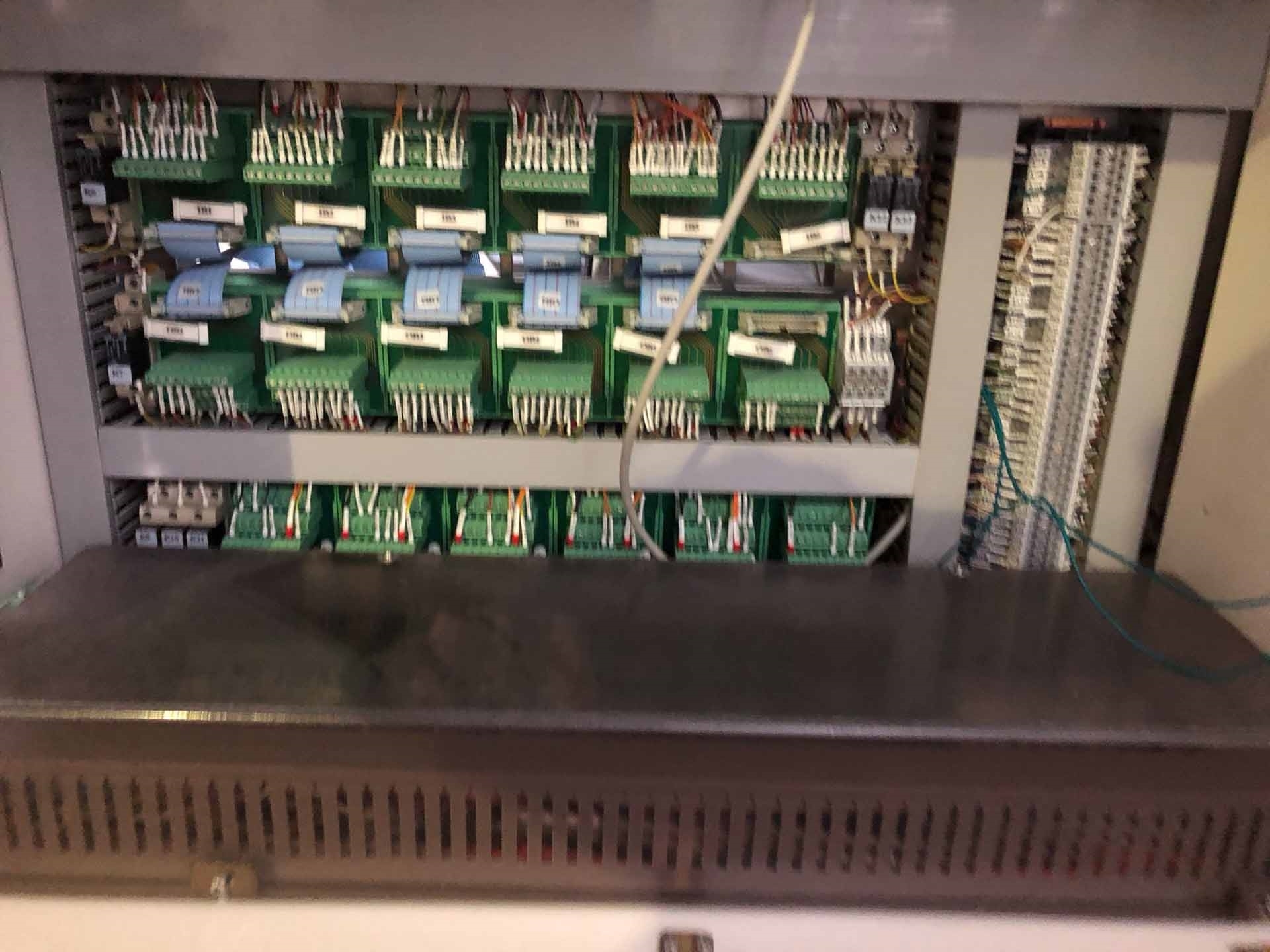

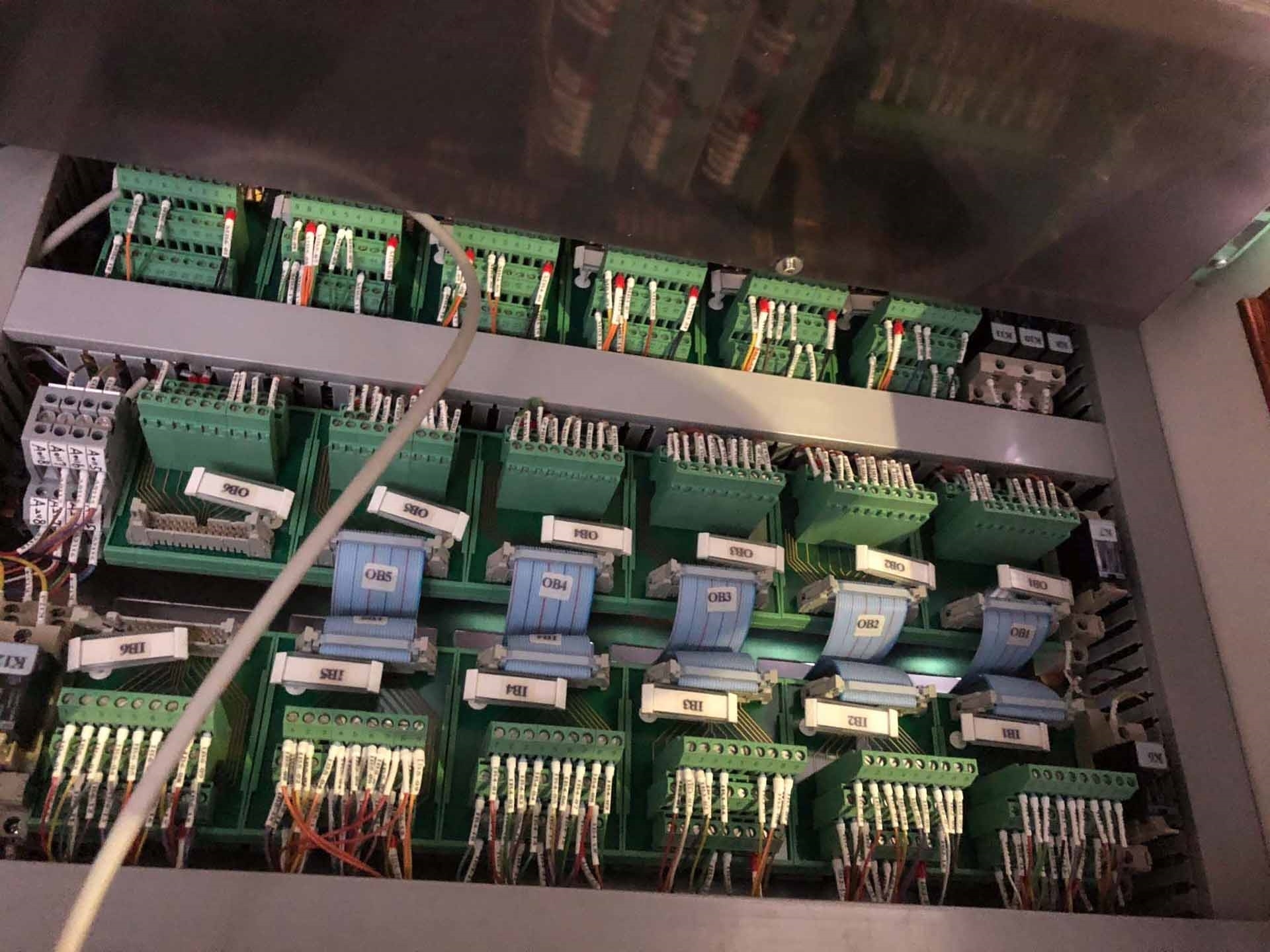

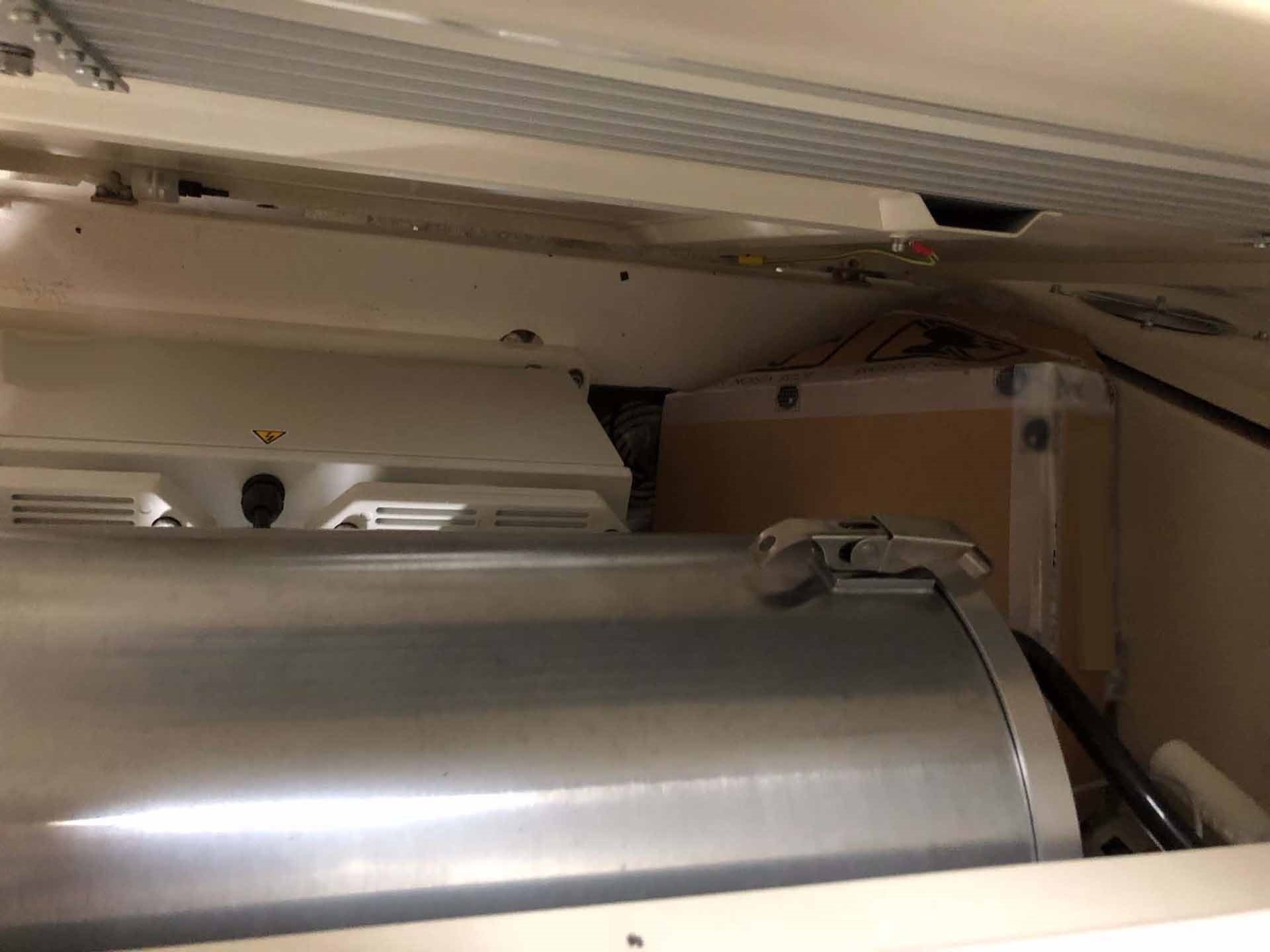

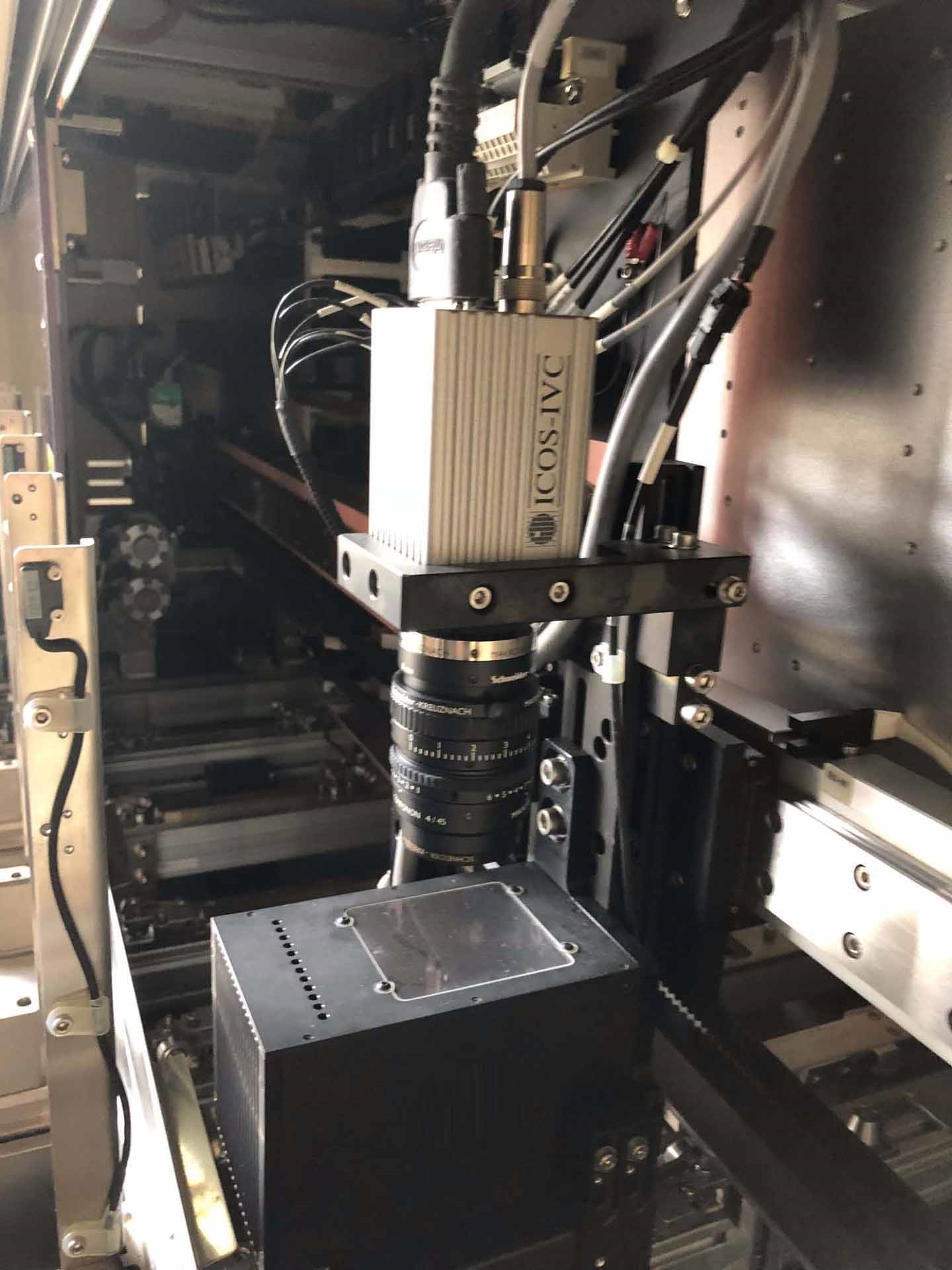

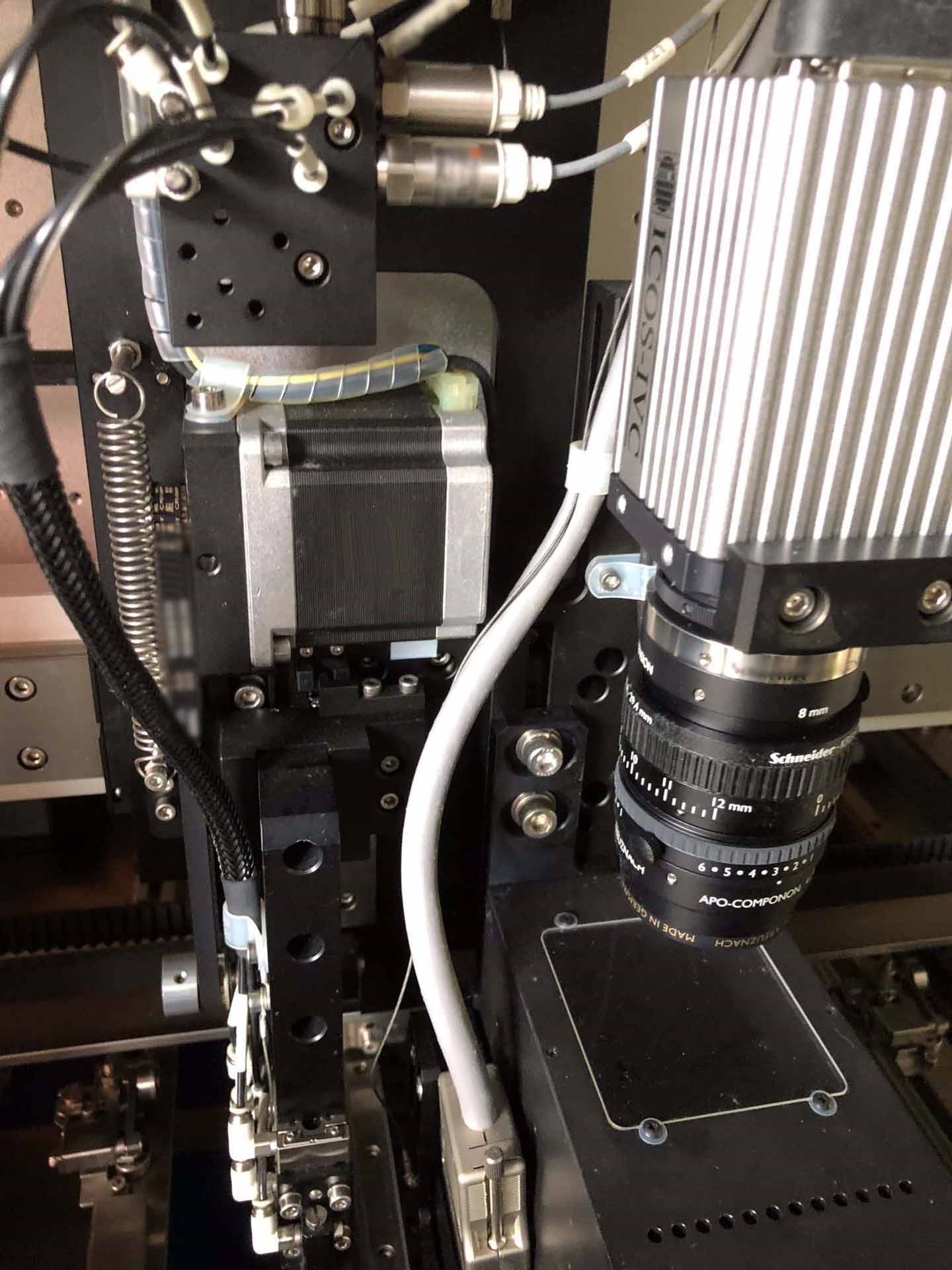

KLA / ICOS CI-T120 is a mask and wafer inspection equipment that is used to detect defects in semiconductor fabrication. The system is made up of three components: an image processing subsystem, a wafer inspection subsystem, and a control subsystem. The image processing subsystem uses an imaging spectrometer, an auto-focus unit, and an imaging optics machine to collect images from a variety of substrates including photomasks, wafers, dies, and other surfaces, and then converts them into image data points. This image data is then used to detect defects. The wafer inspection subsystem is made up of an array of advanced lithography systems and a multi-die alignment tool. The lithography systems are used to precisely pattern the wafer surface to create device features. The multi-die alignment asset is used to accurately locate, adjust, and align dies to ensure that they are all in the same orientation. The control subsystem is responsible for controlling the sequence of operations and ensuring that the inspection results are accurate. The subsystem also includes a central processor, a memory unit, an input/output control unit, and a communication link. The processor is responsible for controlling the model operations while the memory unit stores the data collected by the image processing subsystem and the lithography systems. The input/output unit is used to transfer data to and from the equipment while the communication link allows the system to be connected to other systems. KLA CI T120 mask and wafer inspection unit is a reliable and accurate machine for quickly locating and quantifying defects in semiconductor fabrication. It is an ideal tool for quality assurance in the manufacture of ICs and other semiconductor devices. The tool's image processing and lithography systems provide accurate results with excellent resolution while its control subsystem ensures that the asset operates in an efficient and reliable manner.

There are no reviews yet