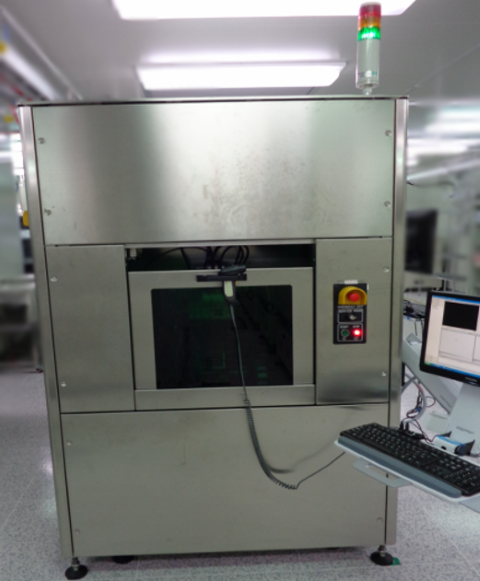

Used KLA / ICOS WI-1500 #9096185 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9096185

Inspection system

Power consumption:

1000W-HM only

2000W-HM + 1 WI

3000W-HM + 2 WI

Air: 3.0 to 6.0 (absolute) = 80 NI/min

Vacuum: 0.2 bar (absolute)i.e. -0.8 (relative)-90 NI/min

Connection type air: 1/4" male fitting (On machine)

Connection type vacuum: 1/8" male fitting (On machine)

Cable: Single Phase.

KLA / ICOS WI-1500 is a mask and wafer inspection equipment designed to provide accurate and reliable detection of defects on semiconductor devices. KLA WI-1500 system is versatile, capable of inspecting multiple wafer types, capacitors, resistors, films, and various other device types. ICOS WI-1500 unit is equipped with three refractive and reflective optical systems, along with an array of tandem imaging and spectral imaging sensors. The various optics provide a wide field of view to offer complete defect coverage across the wafer. A pair of illuminating sources are available, including a bright 300-Watt Xe/Ne source and a CoolLED near-infrared source. The imaging sensors scan the wafer at resolutions of up to 0.4 microns, including high-definition inspection modes with resolutions up to 0.15 microns. The machine is capable of detecting a variety of defects, including contaminants, scratches, short-circuit defects, and pin-holes. Additionally, WI-1500 supports automated defect signal enhancement, enabling it to detect and read out minute scratches and particles that can't be seen with the human eye. KLA / ICOS WI-1500 is fully automated, able to perform up to 500 wafer scans per hour depending on the type of defect being inspected. It also provides a quick throughput with minimal setup time. An integrated wafer tracking tool tracks wafer location and orientation, ensuring the accuracy and repeatability of defect measurement. The asset is equipped with a powerful suite of tools for rapid defect detection and classification. It features automated sorting capabilities, allowing experienced operators to quickly distinguish between false positives and true blind defects. Additionally, a multi-level defect classification model enables the equipment to quickly classify defects based on their size and shape. KLA WI-1500 also includes various data analysis functions designed to provide valuable insights into the performance of the device, including optical reflectivity, metal-line roughness, sidewall roughness, overlay accuracy, and 5D alignment. In addition to defect analysis, the system can generate automatic reports and complex graphs to provide detailed insight into the wafer's performance. Overall, ICOS WI-1500 provides a powerful solution for mask and wafer inspection, capable of accurately detecting and classifying defects at resolutions up to 0.4 microns. It offers powerful data analysis capabilities and can generate detailed reports and graphs, providing valuable insights into the device's performance.

There are no reviews yet