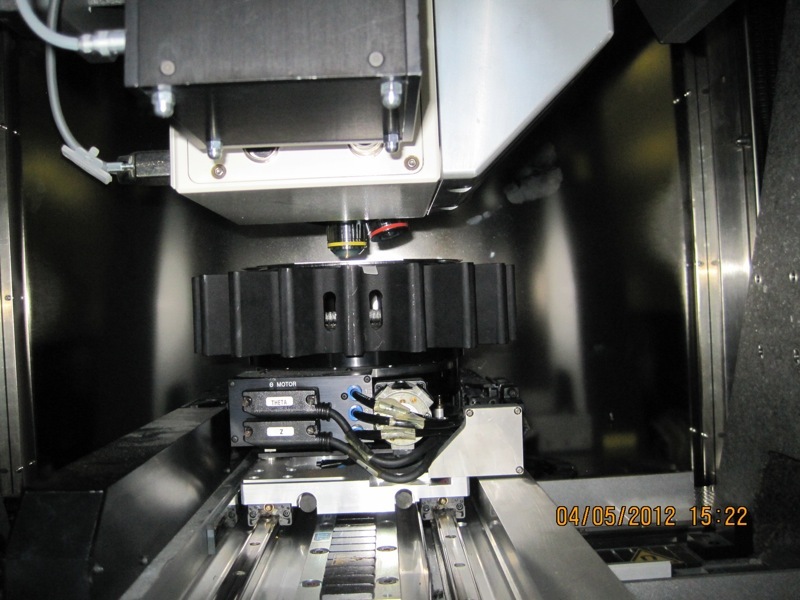

Used KLA / ICOS WI-2000 #188229 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 188229

Wafer Size: 4"

Vintage: 2005

Wafer surface inspection systems, 4"

2005 vintage.

KLA / ICOS WI-2000 is a highly advanced and versatile mask and wafer inspection equipment, providing fast imaging, reliable production, and comprehensive test coverage. In comparison to traditional mask and wafer inspection systems, KLA WI-2000 utilizes innovative technology that allows users to maximize their throughput and accuracy. ICOS WI-2000 utilizes the latest in mask and wafer imaging technology to provide maximum test resolution, thus ensuring its capability to accurately inspect individual features on masks and wafers, down to the sub-micron levels. In addition, WI-2000 is capable of inspecting extremely high-resolution mask and wafers with its sophisticated imaging system. Its multiple imaging channels and light sources enable it to accurately image multiple layers, ensuring seamless integration with existing mask layout and wafer test systems. The unit also features advanced real-time defect mask review, allowing users to quickly identify and prioritize any defects, allowing quick decisions to be made on any identified problems. To facilitate the review process, the inspection machine utilizes an intuitive user interface (UI) to ensure users can efficiently use the tool to detect and review defects without having to learn complex commands. KLA / ICOS WI-2000 further supports production process analysis, using its built-in process flow simulation and track map creation capacity to allow users to accurately identify problems before the product reaches the customers. Through the combination of advanced imaging technology and in-depth analysis capabilities, the asset allows for improved production efficiencies, thereby making it an invaluable asset to any fabrication facility. In addition, KLA WI-2000 features a separate, more sensitive imaging channel for inspecting critical and ultra-fine features, ensuring the utmost accuracy. With this feature, the model is able to detect and report on defects that might be overlooked by conventional imaging equipment. Further, its onboard software enables it to analyze and log defect characteristics including size, shape, density, and others for use in both process control and defect trending. All in all, ICOS WI-2000 is a state-of-the-art mask and wafer inspection equipment that is capable of accurately providing imaging and analysis capabilities at the highest industry standards. Its advanced imaging technology and ability to combine production process, analysis, and defect review makes it an extremely useful tool for any fabrication facility looking to maximize its production outputs.

There are no reviews yet