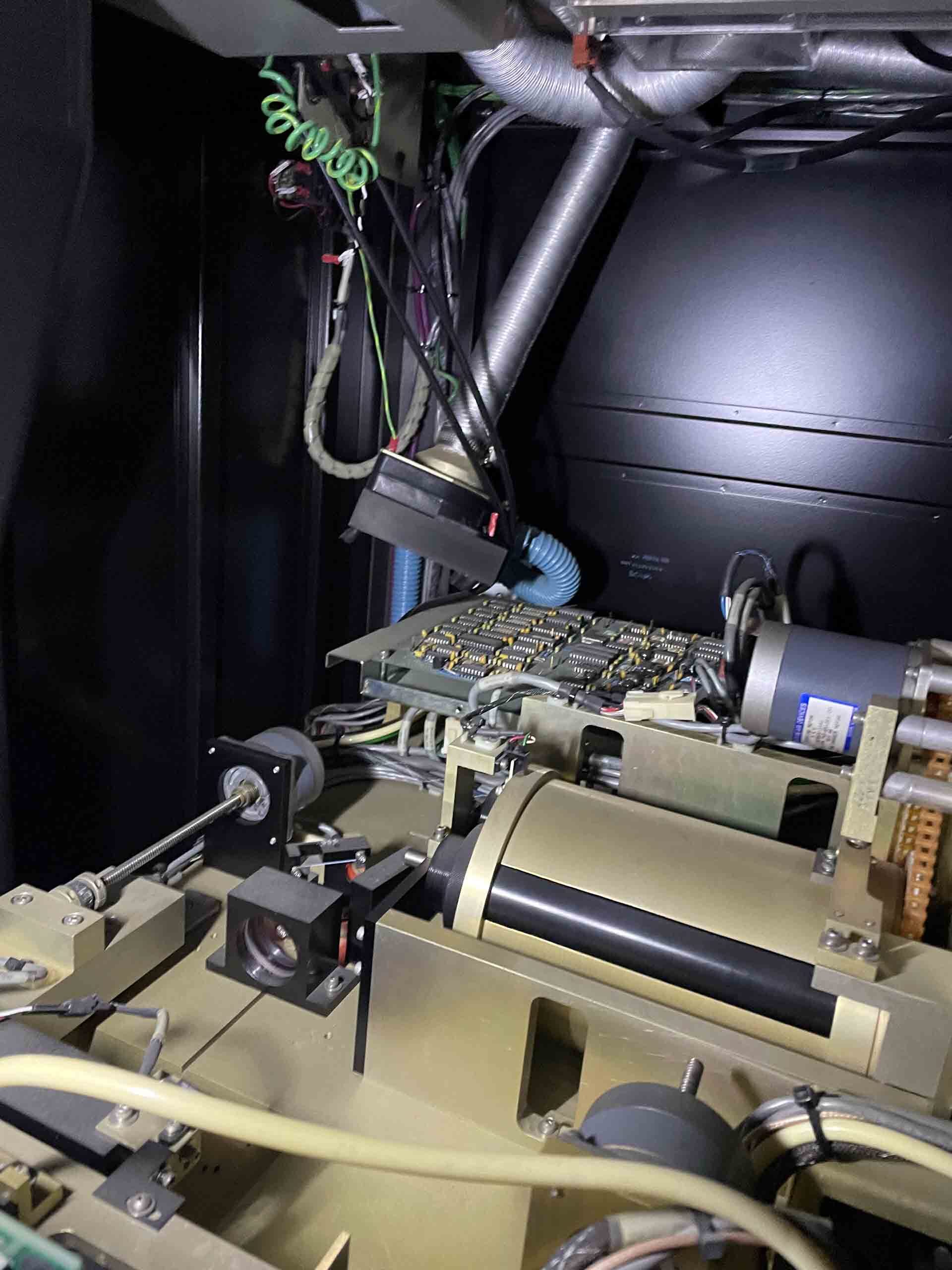

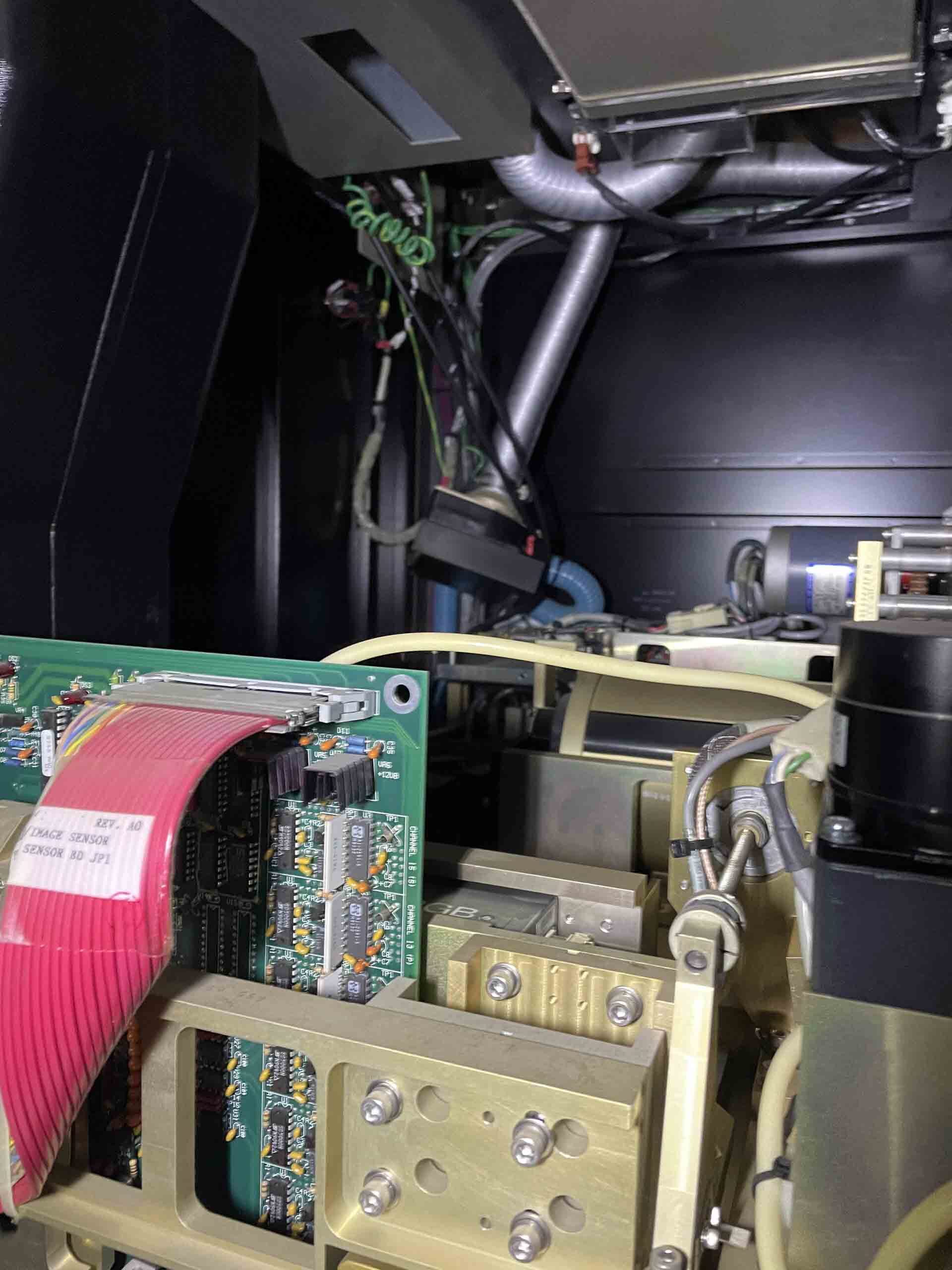

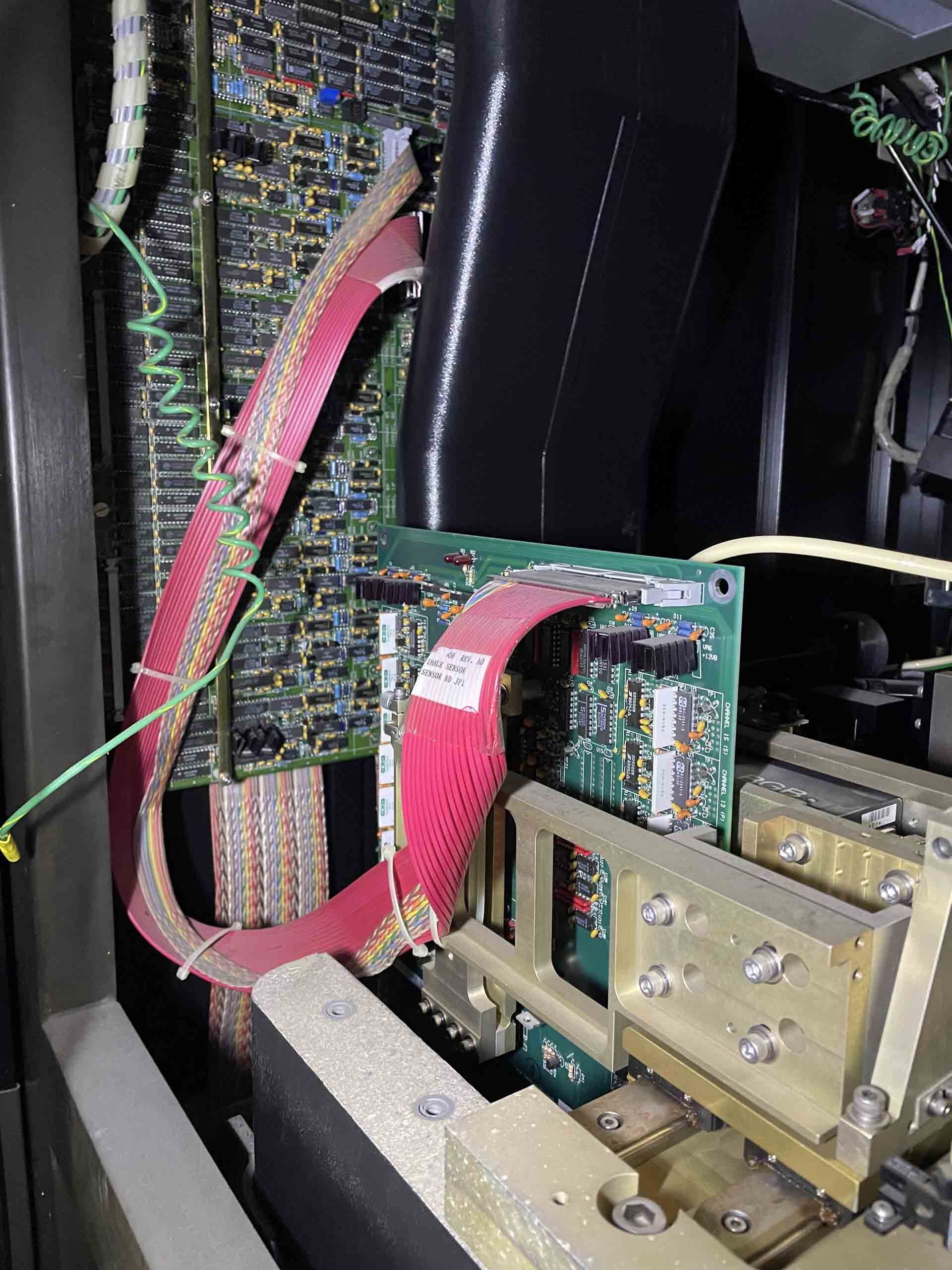

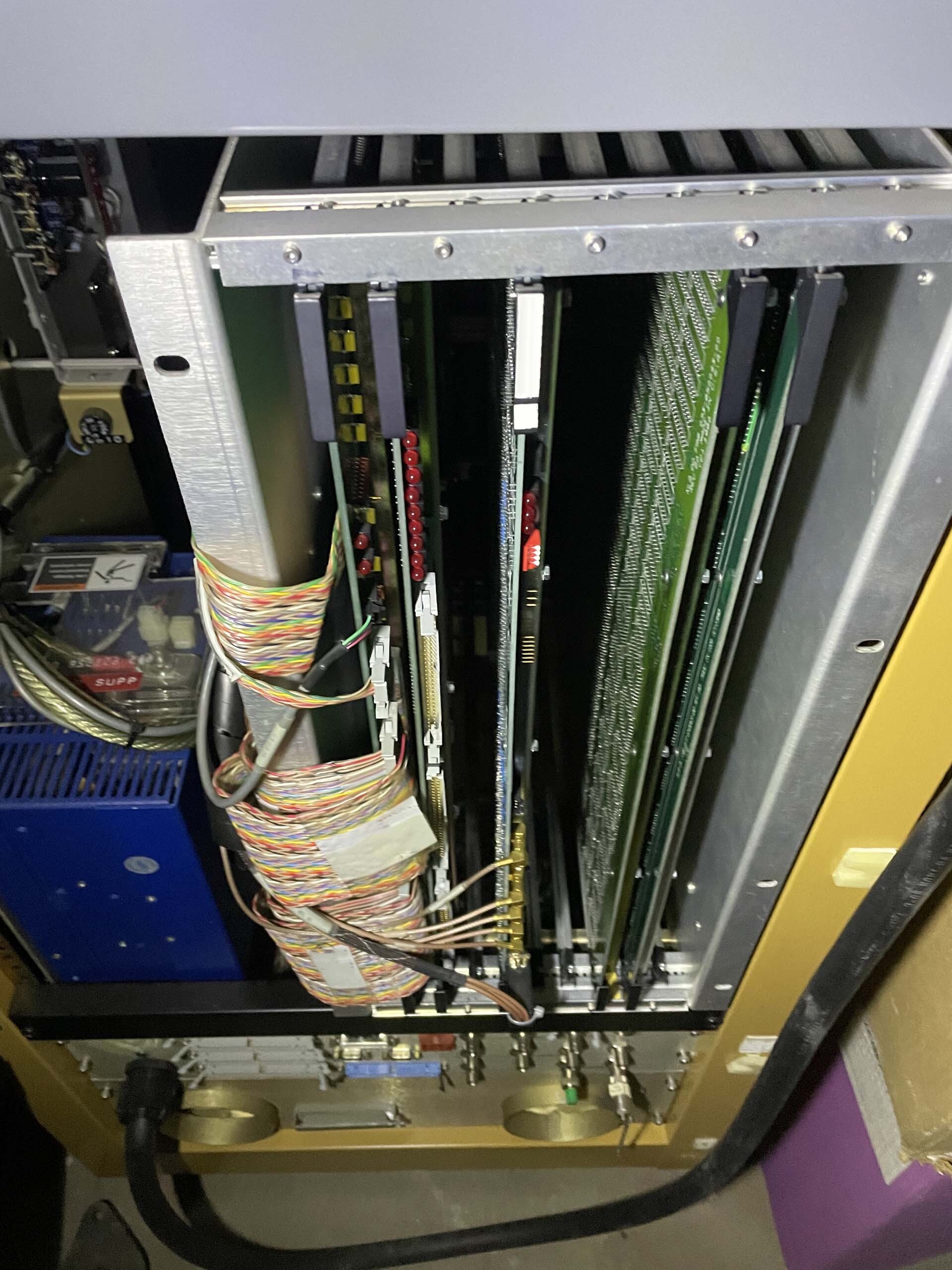

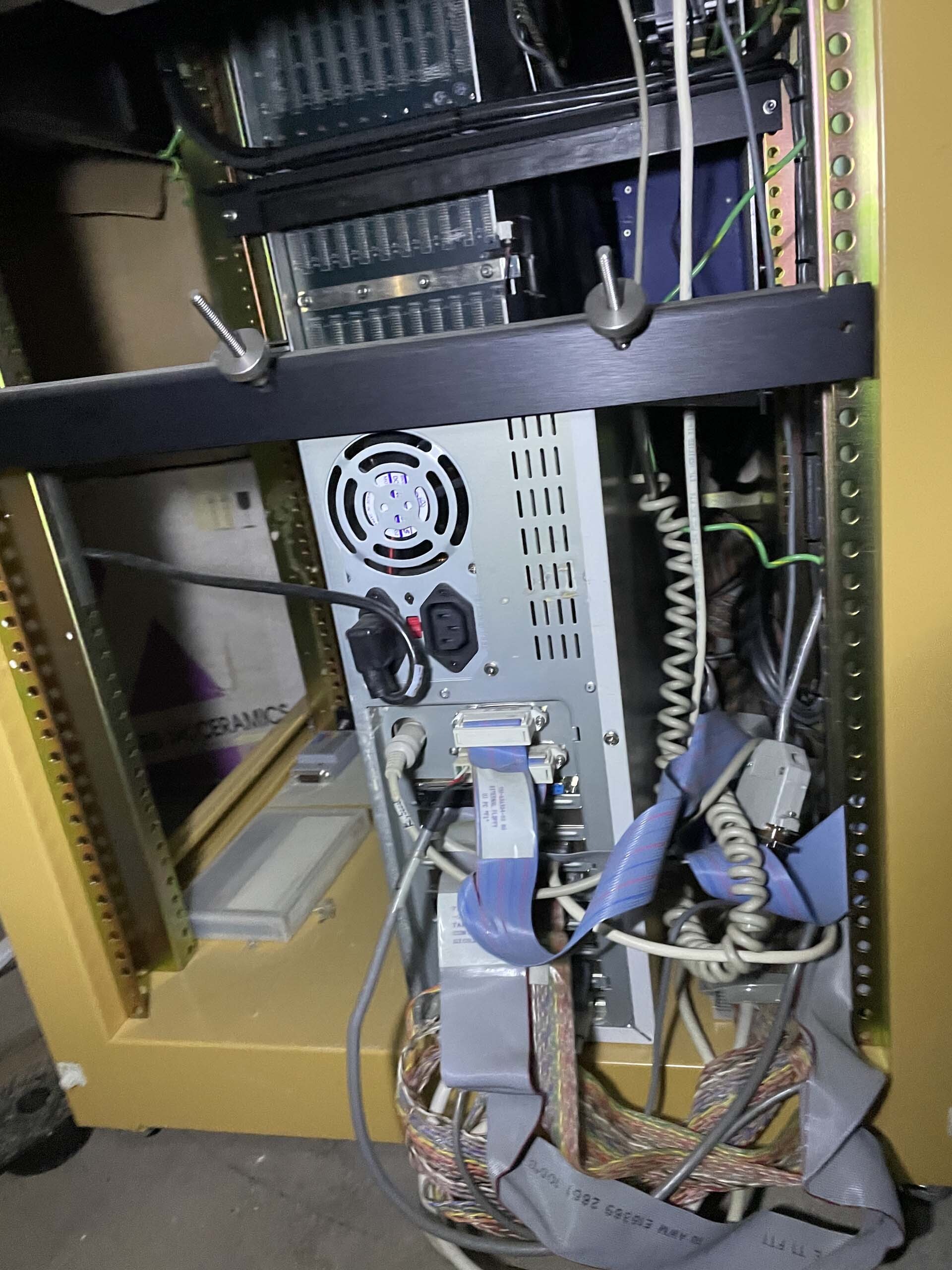

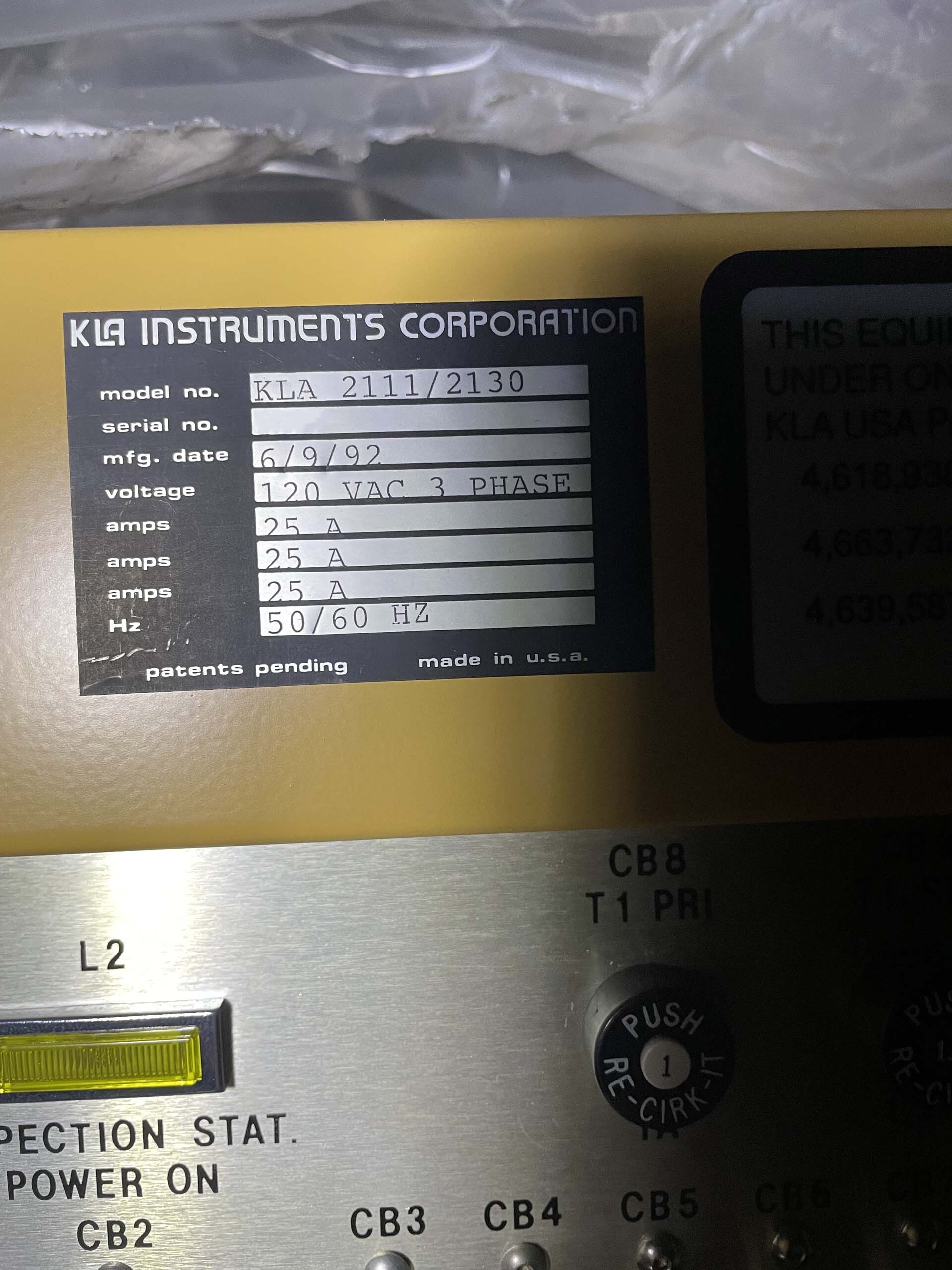

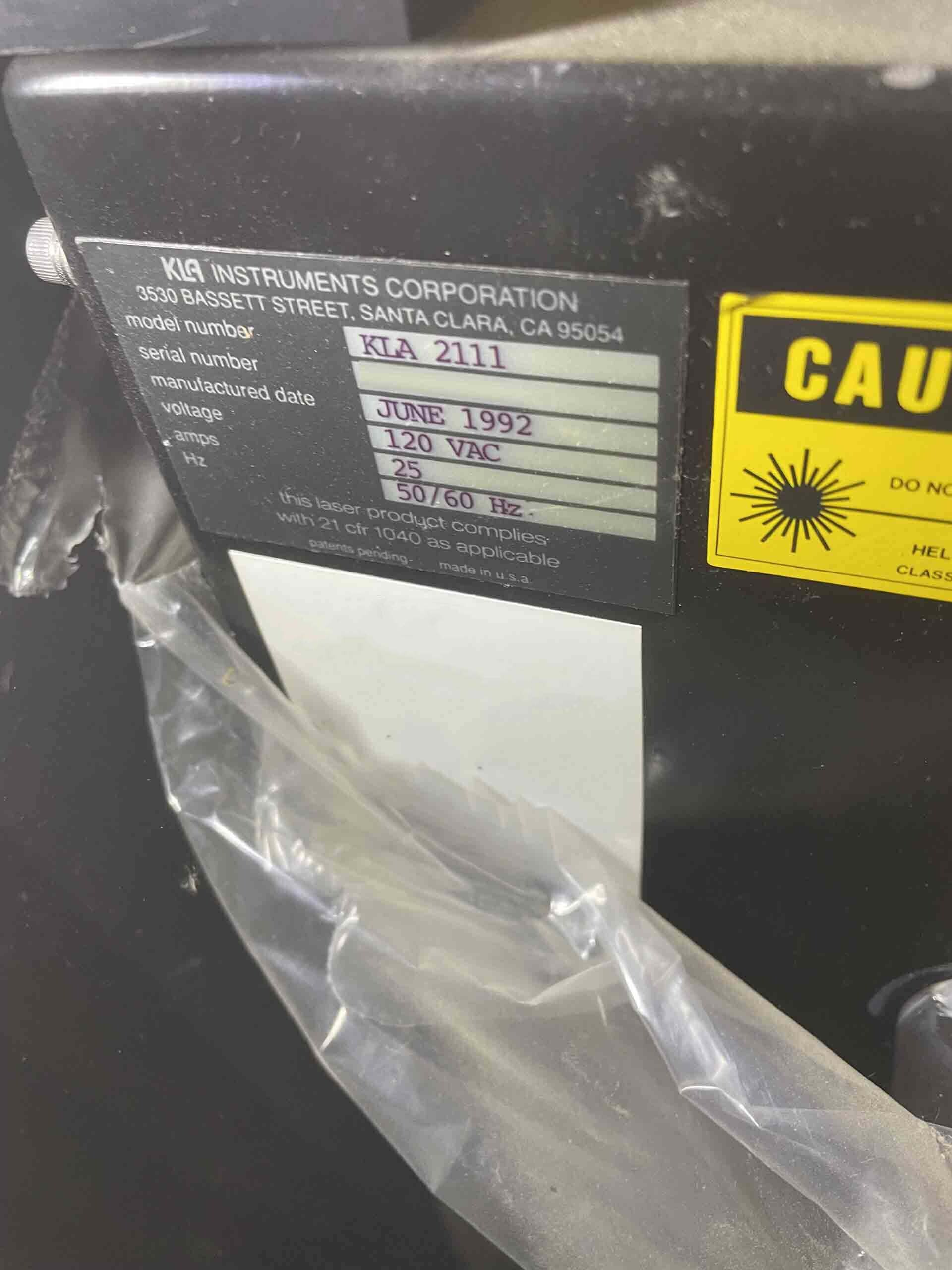

Used KLA / TENCOR 2111 #9410122 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR 2111 is a high-performance, high-resolution mask and wafer inspection equipment that can provide accurate, repeatable results at high speed. The system is designed to detect and analyze a variety of process-related defects, including line and space errors, particle concentrations, design geometry errors, and sub-micron pattern defects. KLA 2111 is equipped with an advanced dual-wavelength laser detection unit which allows for both high-resolution and high-speed defect detection. It also features a large field of view, enabling it to inspect up to 77mm of substrate area. The machine features a number of configurable processing parameters, allowing users to customize the mask and wafer inspection process to their specific needs. At the heart of the tool is the imaging and pattern recognition software. This software works in conjunction with the asset's dual-wavelength laser detection model to accurately detect and measure the size, shape, and contrast of different process-related defects. The software also has the option of being configured with a number of other parameters, including auto-population of false-alarm objects and statistical analysis of defect populations. The equipment is also equipped with an intuitive, user-friendly interface. It features a graphical user interface (GUI) that allows users to measure and monitor process-related defects quickly and easily. This makes it easy to monitor, report, and analyze process-related defects, as well as customize the inspection process to the user's exact needs. TENCOR 2111 is a high-performance, high-resolution mask and wafer inspection system designed for both industrial and research applications. It provides accurate and repeatable results at high speed, making it an ideal choice for applications in semiconductor production, microelectronics, and microelectromechanical systems (MEMS). Its advanced detection unit, intuitive GUI, and configurable processing parameters make it a powerful and reliable tool for those in the semiconductor industry.

There are no reviews yet